Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeStandard Operating Procedures (SOPs) are key tools for businesses. They help teams work better and make fewer mistakes. A good SOP breaks down tasks into simple steps that anyone can follow.

Writing an SOP might seem difficult, but it’s not. The key is to be clear and thorough. This article will guide you through the steps to write a SOP.

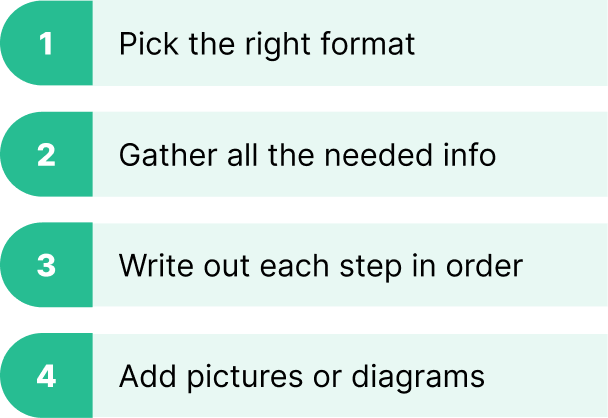

Start by picking the right format. There are several SOP formats, such as simple steps or flowcharts.

Source: WorkTrek

Next, gather all the needed info. Talk to the people who do the job every day. They know the task best. Then, write out each step in order. Use plain language that’s easy to understand.

Add pictures or diagrams if they help explain things better. Remember to test the SOP to ensure it works well in real life.

Listen to this Article

Planning Your SOP

Good SOP planning involves three key steps. These steps help create a clear, useful document for everyone involved.

Identifying Stakeholders

Stakeholders play a big role in SOP creation. They include staff using the SOP and managers overseeing the process.

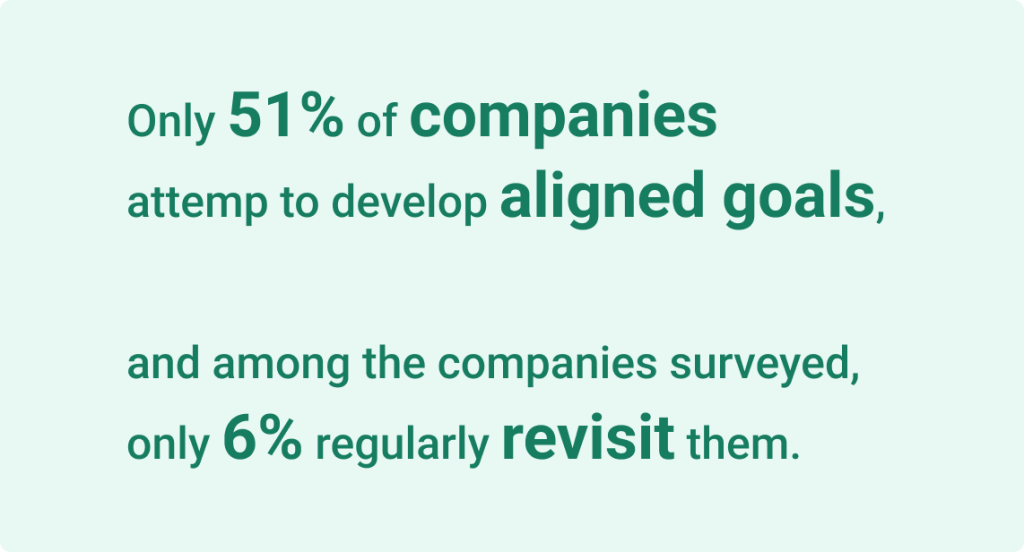

Illustration: WorkTrek / Quote: Linkedin

To find stakeholders:

- List all departments affected by the SOP

- Note key people in each department

- Include customers if the SOP impacts them

Talk to these stakeholders. Get their input on the current process and ask about their problems. This will help create a better SOP.

Defining Scope and Objectives

The scope sets the SOP’s limits. It says what the SOP covers and what it doesn’t. A clear scope prevents the SOP from getting too big.

Objectives are the goals of the SOP. They explain why it’s needed. Good objectives are:

- Specific

- Measurable

- Achievable

Illustration: WorkTrek / Data: Collato

Write down the scope and objectives. Share them with stakeholders.

Make sure everyone agrees before moving on.

Determining the Format and Content

The SOP format depends on the process’s complexity. Simple tasks need simple formats, while complex tasks need more detail.

Common SOP formats include:

- Step-by-step lists

- Flowcharts

- Checklists

For content, think about the SOP’s audience. New hires need more detail. Experts need less. Include these parts:

- Purpose

- Needed materials

- Safety info

- Step-by-step instructions

- Troubleshooting tips

Use clear, simple language. Add visuals like diagrams if they help explain the steps.

SOP Structure

A well-organized Standard Operating Procedure (SOP) helps readers quickly find and understand important information. The structure typically includes a title page, a table of contents, and clearly defined sections with hierarchical steps.

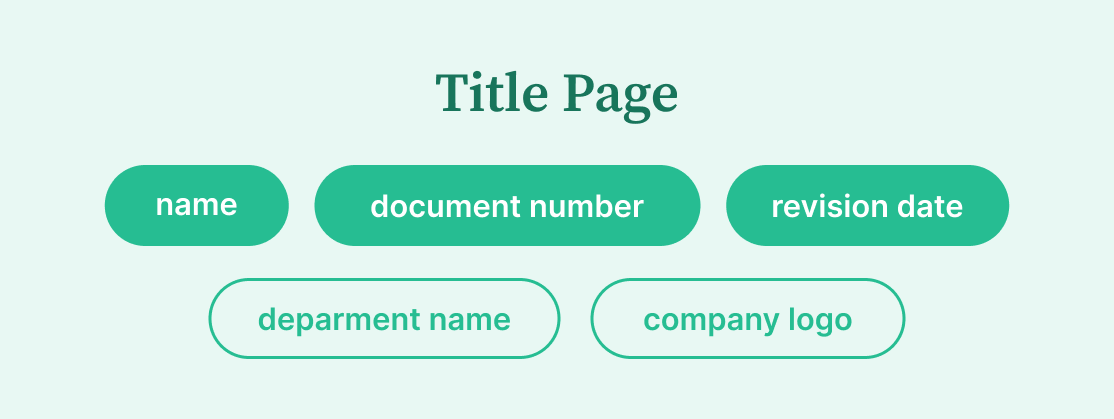

Title Page and Table of Contents

The title page is the first thing readers see. It should include the SOP name, document number, and revision date. The company logo and department name are also often included.

Source: WorkTrek

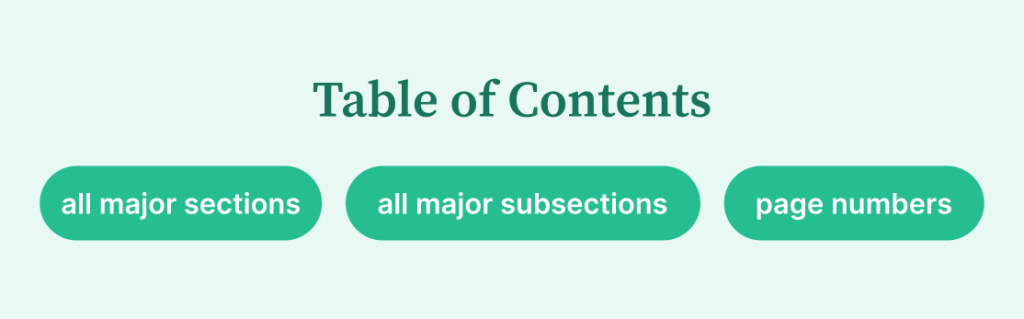

The table of contents lists all major sections and subsections with page numbers, helping readers navigate the document easily.

Source: WorkTrek

A good table of contents is detailed but not overly long. It should cover the main topics and essential subtopics.

Sections and Hierarchical Steps

SOPs are divided into logical sections. Each section focuses on a specific part of the process.

Steps within sections use a hierarchical format:

- Main step 1.1 Sub-step 1.2 Sub-step

- Next main step 2.1 Sub-step 2.2 Sub-step

This format makes complex procedures easier to follow. It breaks tasks into manageable chunks.

Use clear, action-oriented language for each step. Start with verbs like “Click,” “Enter,” or “Select.”

Roles and Responsibilities

This section outlines who does what in the procedure. It clarifies team member duties within the process.

Illustration: WorkTrek / Quote: Peter Simoons

A table can effectively show roles and tasks:

Role Responsibilities Manager Approve final document Technician Perform steps 1-5 Quality Control Check output in step 6

Include any special qualifications or training needed for each role. This ensures the right people handle each task.

Writing the SOP

Creating a clear and effective Standard Operating Procedure requires careful planning and attention to detail. The following steps will guide you through writing an SOP that is easy to understand and follow.

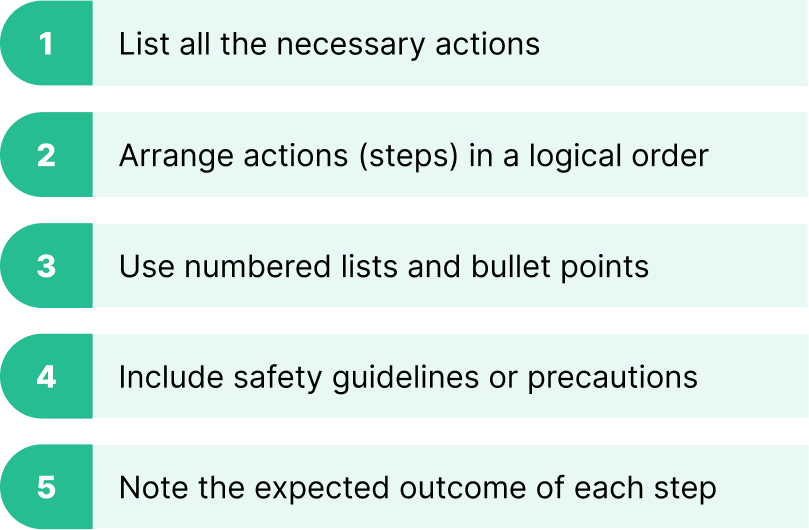

Creating Clear, Step-by-Step Procedures

Source: WorkTrek

When writing an SOP, it’s crucial to break down complex tasks into simple, manageable steps. Start by listing all the actions needed to complete the process. Then, arrange these steps in a logical order.

Use numbered lists for sequential tasks. Use bullet points for tasks that can be done in any order. Each step should be concise and action-oriented.

Include any necessary safety guidelines or precautions at the beginning of the procedure. This ensures that workers are aware of potential hazards before starting the task.

It’s also helpful to note the expected outcome of each step. This allows workers to check their progress and ensure they’re on the right track.

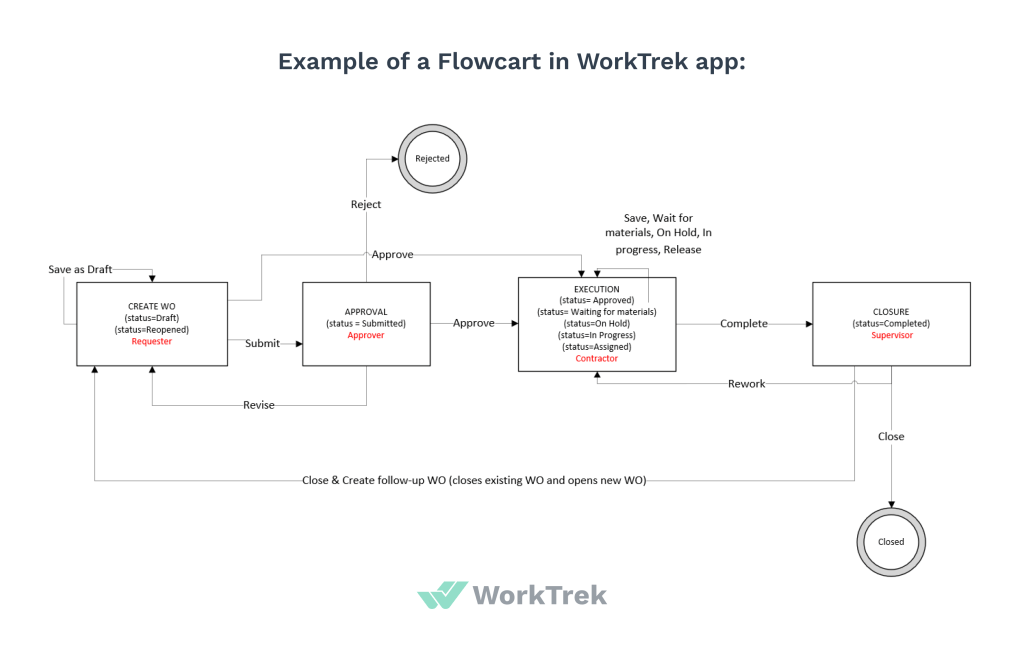

Incorporating Visuals: Flowcharts and Diagrams

Visual aids like flowcharts and diagrams can significantly enhance the clarity of an SOP. They provide a quick overview of the process and help workers understand the relationship between different steps.

Flowcharts are handy for processes with decision points. They show the different paths a procedure can take based on specific conditions.

Source: WorkTrek

Source: WorkTrek

Diagrams can illustrate equipment setups, parts of a machine, or the layout of a workspace. These visuals can help prevent confusion and reduce errors.

When creating visuals, keep them simple and easy to read. Use clear labels and consistent symbols. Color coding can be helpful, but ensure the SOP is still understandable in black and white.

Using Clear and Simple Language

The language used in an SOP should be straightforward to understand. Avoid technical jargon unless it’s necessary for the job. If industry-specific terms must be used, provide clear definitions.

Write in short, direct sentences. Use active voice to make instructions clear. For example, write “Turn off the machine” instead of “The machine should be turned off.”

When writing, consider the audience’s language abilities. If the SOP will be used by non-native English speakers, use simple vocabulary and avoid idioms or colloquialisms.

Be consistent with terminology throughout the document. If a piece of equipment is called a “conveyor belt” in one section, don’t refer to it as a “transport system” in another.

Ensuring Compliance and Quality

Standard Operating Procedures play a key role in maintaining compliance and quality standards. They help organizations meet regulatory requirements, implement quality control measures, and ensure workplace safety.

Meeting Regulatory Standards

SOPs are essential for meeting regulatory standards in various industries. They outline specific steps to comply with regulations from agencies like the EPA and DOT.Organizations should:

- Research relevant regulations for their industry

- Include compliance steps in SOPs

- Update SOPs when regulations change

- Train employees on compliance procedures

SOPs help track and document compliance activities. This is crucial for audits and inspections. Companies can use SOPs to show they follow required practices and standards.

Quality Control and Assurance

Quality control and assurance are vital for consistent products and services. SOPs support these efforts by:

- Defining quality standards

- Outlining inspection processes

- Specifying testing procedures

- Establishing documentation practices

SOPs help maintain ISO 9001 certification. They provide a framework for continuous improvement, and when included in SOPs, quality checks become routine.

Employees can refer to SOPs for correct quality procedures. This reduces errors and improves product consistency. SOPs also help identify and address quality issues quickly.

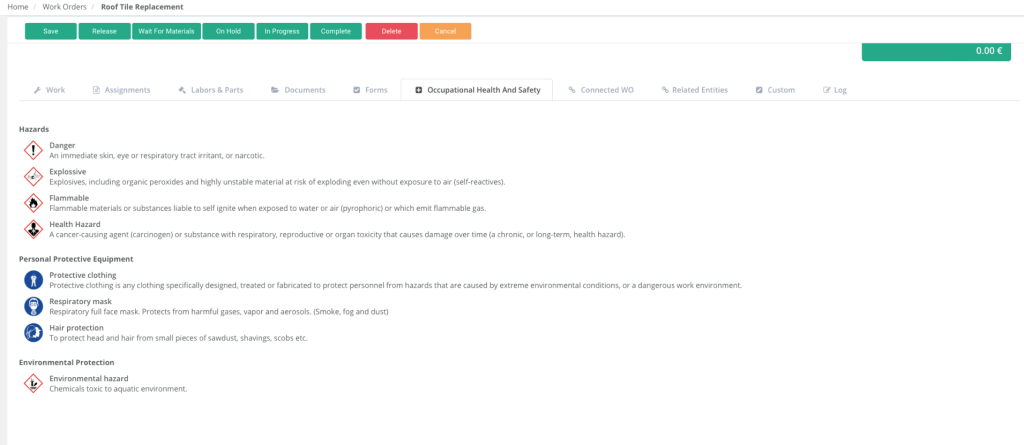

Health and Safety Warnings

SOPs are crucial for workplace safety. They should include clear health and safety warnings. This helps prevent accidents and protects employees.

Illustration: WorkTrek

Key elements to include:

- Hazard identification

- Required safety equipment

- Emergency procedures

- First aid instructions

SOPs should highlight potential risks in each step. They can specify how to handle dangerous materials safely. Clear safety instructions reduce workplace injuries.

Regular safety training based on SOPs is important. This ensures all employees understand and follow safety protocols. SOPs should be updated when new safety risks are identified.

Testing and Validation

Testing and validation are key steps to ensure a Standard Operating Procedure (SOP) works well. These steps help find and fix any issues before the SOP is used.

Conducting Internal Reviews

Internal reviews check whether the SOP meets all rules and standards. A team of experts examines each part of the SOP to ensure it is clear, correct, and follows company policies.

The review team uses a checklist to test the SOP. They check things like

- Is the language easy to understand?

- Are the steps in the correct order?

- Does it cover safety rules?

They also trial-run the SOP. This helps them identify any steps that are difficult to follow or don’t work well.

Gathering Feedback from End-Users

End-users are the people who will use the SOP every day. Their input is very important. Here’s how to get their feedback:

- Give them the draft SOP to try out.

- Ask them to note any confusing parts.

- Have them fill out a survey about the SOP.

- Watch them use the SOP and see where they struggle.

Illustration: WorkTrek / Quote: Muuk Test

This feedback helps make the SOP more user-friendly. It also finds problems that experts might miss.

Making Necessary Revisions

After reviews and feedback, it’s time to make changes. This step is crucial for quality control.

The SOP writer looks at all the comments and suggestions. They decide which changes to make. Some standard revisions are:

- Adding missing steps

- Making instructions clearer

- Fixing errors in the process

After changes are made, the SOP goes through testing again. This cycle may repeat until the SOP works well for everyone.

Implementing the SOP

Implementing a Standard Operating Procedure requires careful planning and execution. Effective implementation ensures that the SOP becomes an integral part of organizational operations.

Training and Communication

Training employees is crucial for successful SOP implementation. Develop a comprehensive training program that covers all aspects of the procedure.

Use a variety of training methods:

- Classroom sessions

- Hands-on practice

- E-learning modules

Communicate the SOP’s importance to all staff members. Explain how it contributes to organizational goals and improves efficiency.

Create a feedback loop to address questions and concerns. This will help refine the SOP and ensure everyone understands their role.

Regular refresher courses keep employees up-to-date with any changes or updates to the procedure.

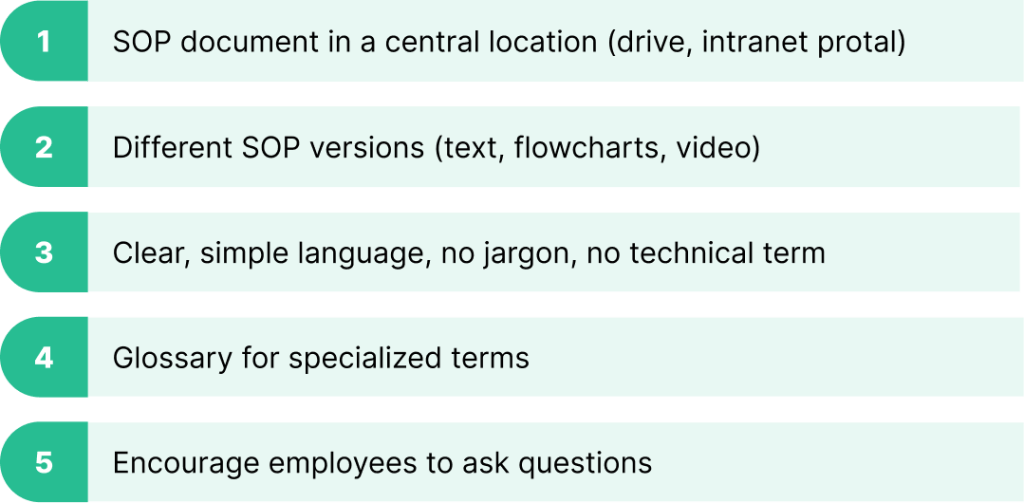

Ensuring Accessibility and Understanding

Source: WorkTrek

Make the SOP easily accessible to all relevant personnel. Store it in a central location, such as a shared drive or intranet portal.

Create different versions of the SOP to cater to various learning styles:

- Text-based documents

- Flowcharts

- Video tutorials

Use clear, simple language to enhance comprehension. Avoid jargon and technical terms unless necessary.

Provide a glossary for any specialized terms used in the SOP. This helps ensure consistent understanding across the organization.

Encourage employees to ask questions if anything is unclear. Foster an environment where seeking clarification is welcomed and encouraged.

Monitoring and Management

Review the SOP regularly to ensure it remains current and effective. Set up a schedule for periodic evaluations, such as quarterly or annually.

Monitor adherence to the SOP through:

- Direct observation

- Performance metrics

- Quality control checks

Collect feedback from employees who use the SOP daily. Their insights can reveal areas for improvement or potential issues.

Track key performance indicators (KPIs) related to the SOP. This helps measure its impact on organizational efficiency and productivity.

Be prepared to make adjustments based on monitoring results. An SOP should be a living document that evolves with the organization’s needs.

Designate a person or team responsible for managing and updating the SOP. This ensures consistent oversight and timely revisions when needed.

Reviewing and Maintaining SOPs

Standard operating procedures need continuous improvement to remain useful. Regular reviews, timely updates, and proper storage keep SOPs accurate and accessible.

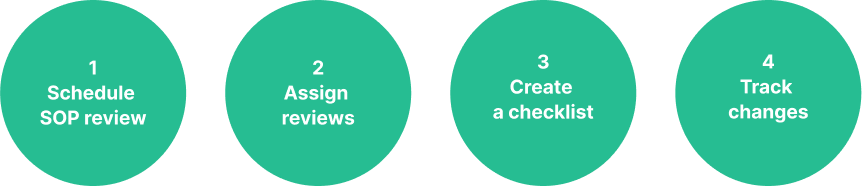

Scheduling Regular Reviews

Source: WorkTrek

Set up a review schedule for SOPs. Decide how often each procedure needs to be checked. This could be yearly, quarterly, or monthly.

Assign reviewers who know the processes well. They should look for outdated steps, new rules, or better ways of doing things.

Use a checklist to guide the review:

- Are all steps still correct?

- Do safety measures need updates?

- Have any laws or rules changed?

- Can anything be made clearer?

Keep a log of when reviews happen and what changes were made. This helps track the SOP’s history.

Updating SOPs in Real-Time

Don’t wait for scheduled reviews to fix SOPs. Update them as soon as changes happen.

Set up a system for workers to suggest improvements. This could be a form or a regular meeting.

When updating:

- Mark the new version clearly

- Note what changed and why

- Get approval from the right people

Tell everyone about updates right away. Use emails, meetings, or training sessions to spread the word.

Document Control and Storage

Use a clear naming system for SOPs. Include the date and version number in file names.

Store SOPs where everyone can find them easily. This might be a shared drive or a special software.

Source: WorkTrek

Control who can change SOPs. Only let authorized people make edits.

Keep old versions for records, but ensure everyone uses the latest one.

Back up SOPs regularly to prevent loss. Consider both digital and physical copies for important procedures.

Use clear file organization to group related SOPs together. This makes it easier to find and update connected procedures.