Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeWithout clear guidelines, maintenance tasks are often inconsistent and inefficient. This leads to equipment failures, unexpected downtime, and costly repairs, which can seriously impact your organization’s performance.

Without a clear Standard Operating Procedure (SOP), teams can approach maintenance tasks differently, resulting in miscommunication, missed steps, and even safety hazards. This lack of consistency creates uncertainty, increases the risk of errors, and fosters a reactive “firefighting” mentality, where problems are only addressed after they’ve caused significant damage.

Illustration: WorkTrek / Quote: ClickUp

Implementing Standard Operating Procedures (SOPs) for maintenance helps your organization stay proactive, ensuring tasks are performed consistently, efficiently, and safely.

SOPs provide clear, step-by-step instructions for maintenance processes, helping to reduce downtime, prevent costly mistakes, and extend equipment lifespan. With SOPs in place, you empower your team to perform maintenance correctly—every time.

What is a Standard Operating Procedure?

Standard operating procedures (SOPs) are step-by-step instructions that help workers execute routine tasks consistently and effectively.

These SOPs are detailed guides that foster consistency within workflows. This reduces variability and minimizes the risk of errors.

An effective standard operating procedure clearly outlines best practices and methods, enabling organizations to maintain high-quality standards while complying with relevant industry regulations.

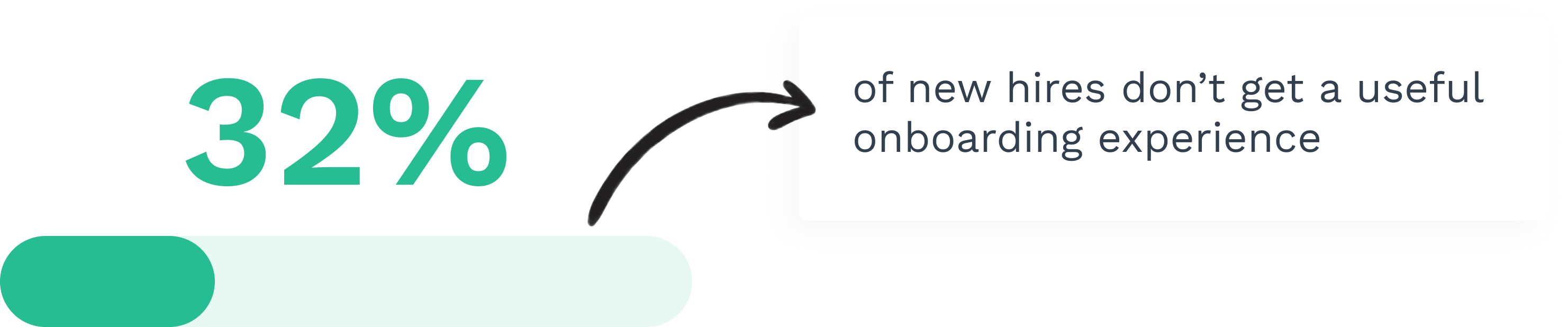

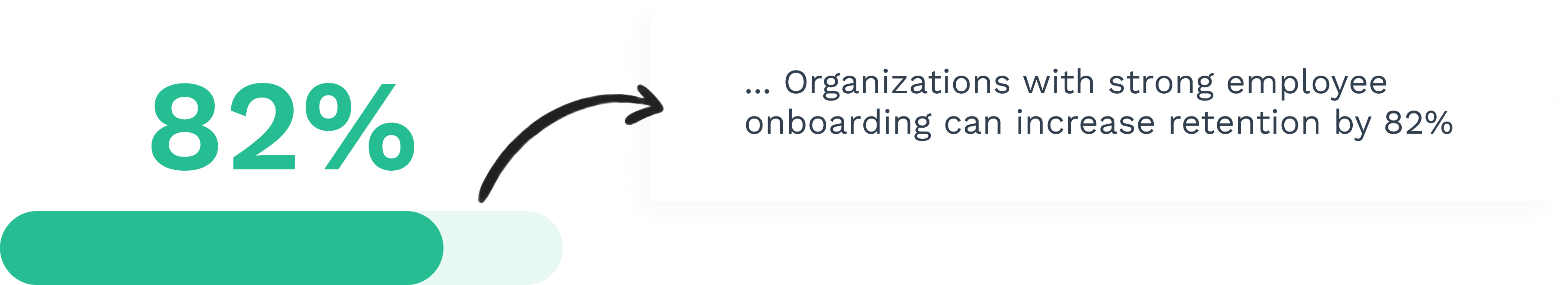

Illustration: WorkTrek / Data: LinkedIn

HR organizations can implement SOPs to streamline employee training. SOPs can also enhance workplace safety measures and improve employee retention of critical knowledge.

One huge benefit of SOPs is onboarding new maintenance team members. If you can provide new hires with detailed SOPs, it reduces onboarding time and makes team members productive faster.

Life without SOP

Without SOPSs, organizations are vulnerable to interruptions in their operations, a slide in productivity levels, and a spike in mistakes due to inconsistent duty execution.

When employees lack clear guidance on procedures, they can perform actions variably, which may lead to errors. Implementing standardized operating procedures (SOPs) safeguards against this variability by ensuring all tasks are conducted uniformly, reducing blunders, and sustaining high-quality outcomes.

Purpose of SOP Document

Standard Operating Procedures (SOPs) ensure operational activities are executed precisely and uniformly, leading to high-quality results across various sectors and all the stakeholders.

These documents provide an organized approach for upholding quality and efficacy throughout operations beyond completing tasks. SOPs guide resolving issues, preserving safety, sustaining top-notch performance levels, and adhering to regulatory mandates.

Industry Specific SOP

For several industries, such as healthcare, creating and following SOPs is standard practice and, in many cases, required.

Without SOPs, organizations can experience significant disruptions and diminished efficiency due to confusion and unclear directives.

As the foundational framework for operational efficiency and quality assurance, SOPs guarantee that employee actions consistently meet high standards. It can also assure compliance with regular requirements.

Fundamental Objective of SOPs

Illustration: WorkTrek / Quote: Montrium

The fundamental objectives of Standard Operating Procedures (SOPs) include:

- Guaranteeing that operations are executed with precision and uniformity

- Attaining desired quality results

- Synchronizing the efforts of various team members

- Elevating the efficiency of operational processes as a whole

- Streamlining the management of employees by setting clear guidelines for expected performance

- Outlining compliance requirements

- Provide detailed steps to employees

- Ensure consistency

- Outlines all steps involved in the process

SOPs improve time management and reduce costs by eliminating redundant steps in performing tasks. They can also lead and promote an organization-wide culture focused on control, safety, and adhering to industry regulatory requirements.

Ensuring Consistency in Processes

SOP documentation can streamline and coordinate team activities by setting clear process execution guidelines. It eliminates ambiguity within organizations, promoting smooth operational continuity.

By outlining specific procedures, SOPs eliminate misunderstandings and ensure best practices. This consistency can improve quality outcomes while reducing errors attributed to human factors.

Implementing SOP documentation reinforces procedural consistency and addresses essential interdependencies, ensuring each team member knows their responsibilities and accountabilities.

Organizations that lack established procedures should begin by implementing a few SOPs in each department to standardize their operations.

Utilizing SOP templates can assist in harmonizing procedures throughout the organization.

Enhancing Efficiency and Productivity

SOPs can significantly improve a maintenance organization’s efficiency and productivity. They turn best practices into specific procedures and standards.

SOPs can help maintenance staff reduce mistakes and increase efficiency and output.

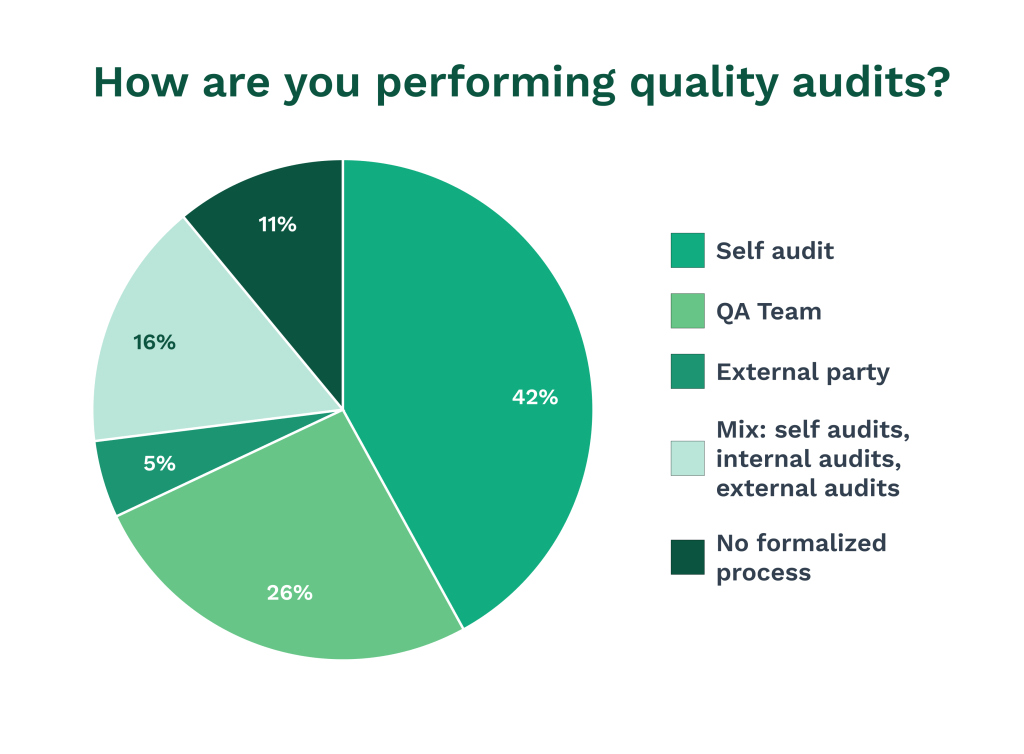

Illustration: WorkTrek / Data: Touchpoint

Defining and refining SOPs is key for organizations that want to grow. Without them, companies will struggle with operational hiccups and a dip in productivity caused by uncertainty and lack of direction.

These guidelines help streamline by including hierarchical levels in SOPs and flowcharts with flexible steps for different outcomes at decision points.

Quality Standards

Standard Operating Procedures (SOPs) provide a framework for maintaining quality and regulatory compliance across industries. By ensuring consistency in task execution, SOPs ensure work is done to a high standard.

Each industry has protocols for operating equipment, quality checks, and safety measures to produce consistent products.

Illustration: WorkTrek / Data: peeriosity-100

In quality assurance, SOP documentation requires team members to follow established procedures.

Team members should review individually and during regular reviews. Any deviations from the SOP must be addressed immediately, and changes must be made.

Meeting Regulatory Compliance

In sectors such as healthcare, keeping Standard Operating Procedure (SOP) documentation up-to-date is a legal requirement.

SOPs establish the best practices necessary for meeting cybersecurity, patient care, hospital maintenance, and other regulatory standards.

In healthcare, SOPs typically detail procedures critical for correctly identifying patients and reducing medical mistakes. They provide explicit instructions on processes, including patient registration and securing medications to maintain precision and fulfill regulatory obligations.

Benefits of Implementing SOPs

SOPs have many benefits, such as better training protocols, safer workplaces, and better knowledge retention.

They standardize procedures, bring consistency across operations, and ensure regulatory compliance, which increases an organization’s productivity and overall efficiency.

Sections will go into more detail.

Better Training and Onboarding

Illustration: WorkTrek / Data: Exploding Topics

Defined procedures in SOPs make newbie onboarding easier. These key documents give them a clear understanding of job roles and help them get up and running faster in the organization.

The step-by-step guidance in SOPs is especially useful during onboarding as it provides explicit instructions.

Standardizing orientation and training methods through SOPs means consistency in hiring and training practices for all recruits. When existing staff follow revised SOPs, uniformity across staff is achieved by following established procedures.

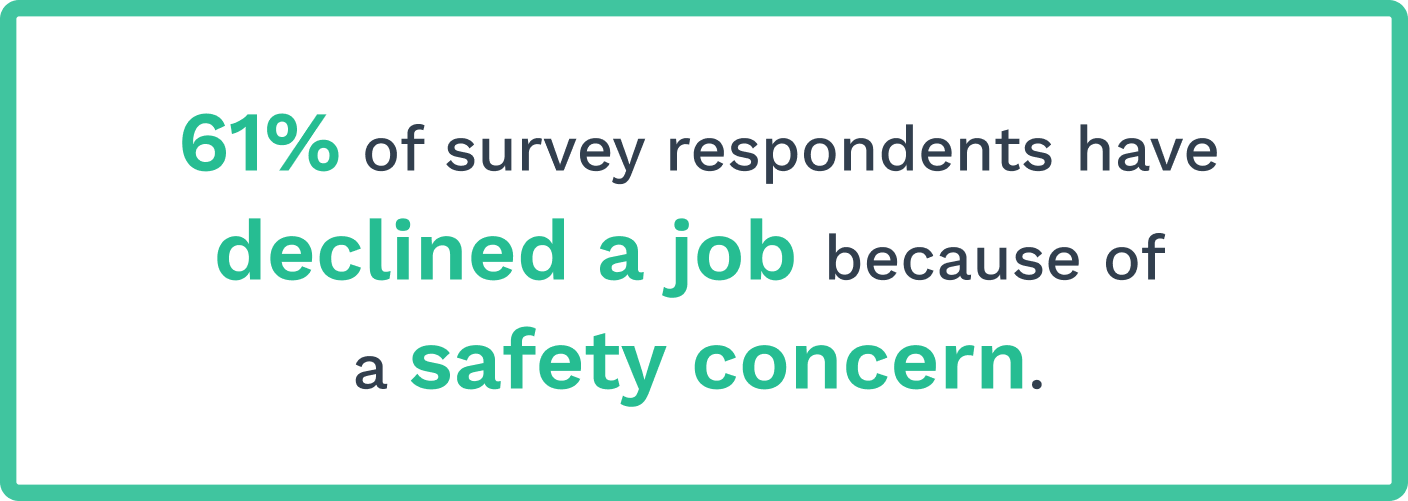

Safer Workplaces

Illustration: WorkTrek / Data: DuraPlas

Clear guidelines in SOPs greatly reduce the risk of accidents in the workplace. These safety-focused SOPs are important as they outline procedures to address hazardous situations, equipping every employee with the knowledge to manage risks better.

Organizations that follow standardized safety protocols can create an environment where safety is for every team member.

Better Knowledge Retention

Documented SOPs protect institutional knowledge, capturing information that could be lost during staff turnover. They are important because they can retain organizational knowledge and mitigate the risk of employee turnover.

Digital SOPs enhance this protection by securely storing critical data and making it easily accessible, which means better retention of key information.

By codifying tasks in SOPs, organizations prevent the loss of critical information and make it easier for new staff to quickly get up to speed with their roles. This ensures continuity and uniformity even with personnel changes.

SOP Formats

Try to tailor SOP formats to specific requirements and situations they are designed to cover. Common ways of writing SOPs are step-by-step instructions, hierarchical structure, and flowcharts.

Other ways of writing SOP documents are checklists, slide presentations, handouts, and infographics, each chosen based on the purpose and target audience.

Organizations often get inspiration from existing examples to develop SOP examples customized to their needs. The following sections will go into more detail.

Step by Step Instructions

The SOP is written as a sequence of steps. Each task has detailed instructions to guide the user through the process. This format is good for simple procedures. It provides clear and easy-to-follow instructions to minimize errors and achieve the desired outcome.

These step-by-step guides are important when inducting new staff or when tasks require strict protocol adherence. Such detailed instructions are crucial for consistency across operations and getting the same results from those performing these tasks.

Hierarchical Format

The hierarchical SOP format uses a descending approach to break down complex tasks into main steps and sub-steps. This format is often used for complex tasks that can’t be explained in a simple step-by-step list.

This format organizes information, making it more accessible and understandable for employees who need to understand and execute the process.

Flowchart Format

A flowchart for an SOP shows the sequence to complete a task or procedure. It simplifies process documentation, making it more accessible and executable.

These flowcharts can be shared among team members, promoting teamwork and communication.

Adding levels to an SOP flowchart handles the details while keeping the visual layout clear. This graphical representation of the steps allows users to understand the process better and navigate through it.

You can use tools like Canva or Lucid to create flowcharts for SOP.

Key Bits of an SOP Document

Illustration: WorkTrek / Quote: ATR

Start with a short title that sums up what they are and what they cover. Then a summary section that covers the purpose, scope and objectives.

An SOP must name who is responsible for what for all parties involved. Don’t skip this.

These should be laid out in a step-by-step format with safety and compliance guidelines to follow.

Make it easy for the team to read and follow.

We’ll get into these in more detail later.

Title Page

You need to include key information on the title page. This includes the document title, which must sum up what it’s about and who it’s for, and the SOP version number and revision date.

This information on the title page helps hold people accountable, as it shows that team members know and understand this procedure.

As a reference, the title page is key to what document this is and what it’s for.

Table of Contents

In SOPs include a table of contents over a few pages. This makes it easy to navigate and find specific bits of the document. It lists all main sections and sub-sections, so it’s a map of the SOP.

It is more useful when dealing with complex procedures in long SOPs, as it helps the user find what they need quickly.

Procedures

The first part of the procedures section should state the purpose of the SOP. This section must break down each step into each sequence and include sub-steps, diagrams, or decision trees to help clarify.

Clarity is key to avoid confusion.

When someone refers to an SOP document, they need to know what’s in it. Following these guidelines allows organizations to create detailed and simple SOPS for employees to follow – that’s how tasks get done consistently and correctly.

Best Practices for Writing SOPs

When creating an SOP, adopt best practices such as utilizing straightforward and understandable language, engaging stakeholders in the development process, and ensuring a system for routine reviews and updates. These strategies guarantee that your SOPs are user-friendly and tailored to suit your organization’s requirements.

Subsequent segments will explore these recommended approaches more thoroughly, offering practical guidance on crafting effective SOPs to boost operational effectiveness and uniformity.

Use Clear and Simple Language

Utilizing straight forward language in Standard Operating Procedures (SOPs) mitigates the potential for confusion and fosters improved compliance with procedures. Rather than complex terminology, active voice improves user understanding, rendering SOPs more approachable and simpler to execute.

This transparency contributes to uniformity in following processes and diminishes mistakes that result from communication breakdown.

Concentrating on lucid instructions allows entities to guarantee the efficacy and ease of use of their SOPs.

Involve Stakeholders in SOP Creation

Illustration: WorkTrek / Quote: ATR

The involvement of all stakeholders in the SOP creation process is crucial for crafting effective SOPs. By incorporating feedback from those who will be directly impacted, resistance to new procedures can be minimized, and their practicality and relevance are ensured.

Soliciting engagement from everyone with a stake in the procedure fosters more efficient SOPs and strengthens organizational commitment and adherence to these standard operating procedures.

Regularly Review and Update SOPs

Conducting periodic evaluations of SOPs is crucial for maintaining their relevance and efficacy. Establishing scheduled intervals, such as every 3 or 6 months, to scrutinize an SOP ensures it reflects the latest procedural modifications or regulatory updates.

By seeking input from staff members and performing routine inspections, opportunities for enhancement can be pinpointed, thus simplifying the complexities inherent in SOPs.

Once approved and examined, the SOP should transition to active use within the organization—this confirms that it continues as a dynamic record that adapts alongside organizational progression.

Challenges in SOP Implementation

Although SOPs offer advantages, their adoption may encounter hurdles. This could be internal to the complexities of creating SOPs and matching them to current procedures.

Challenges such as lack of employee participation and organizational cultural shifts also play a significant role in integrating SOPs.

As processes or technologies change, continue to review and update existing SOPs.

Resistance to Change

Involved maintenance managers and other employees in the process of creating SOPs. This approach will reduce their resistance to the established processes and make them stakeholders.

Some steps to reduce resistance include:

- Employees should be included in the development of SOPs.

- The designed SOPs must be pragmatic and directly applicable to their routine work activities.

- To lessen resistance, providing training and transparent communication about the advantages of following SOPs.

Complexity of SOPs

Resist adding unnecessary complexity to your SOPs. Complex task. The more complex the SOP, the less likely it will be for employees to use it.

Here are a few tips to reduce the complexity of SOP Documents:

- Employ straightforward and succinct language.

- Utilize visual tools like flowcharts to improve understanding.

- Facilitate ongoing instructional programs for staff concerning new updates on SOPs.

- Engage pertinent stakeholders to ensure reliable upkeep and compliance with these procedures.

These strategies can improve comprehension and utilization of SOPs for the entire team.

Summary

Illustration: WorkTrek / Data: Steelwedge

As this article outlines, SOPs are important instruments to optimize operations and promote uniformity.

They serve as an integral guide for sustaining quality and efficiency during operations, aiding in the effective resolution of issues while securing safety standards and superior performance levels.

They are critical in helping organizations meet regulatory demands to prevent operational disruptions and decrease productivity.