Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeIn inventory management, choosing between just-in-time and just-in-case can be challenging. Just-in-time aims to reduce waste by aligning orders with demand, while Just-in-Case keeps extra stock to handle uncertainties.

This article is an ultimate guide in understanding the Just-in-Time & Just-In-Case Inventory and provides sample use cases for each method.

Source: WorkTrek

Source: WorkTrek

This article will explore their benefits, challenges, and costs to help you decide which is best for your business.

Listen to a Podcast on JIT and JIC Inventory Management

Just-In-Time Inventory Management

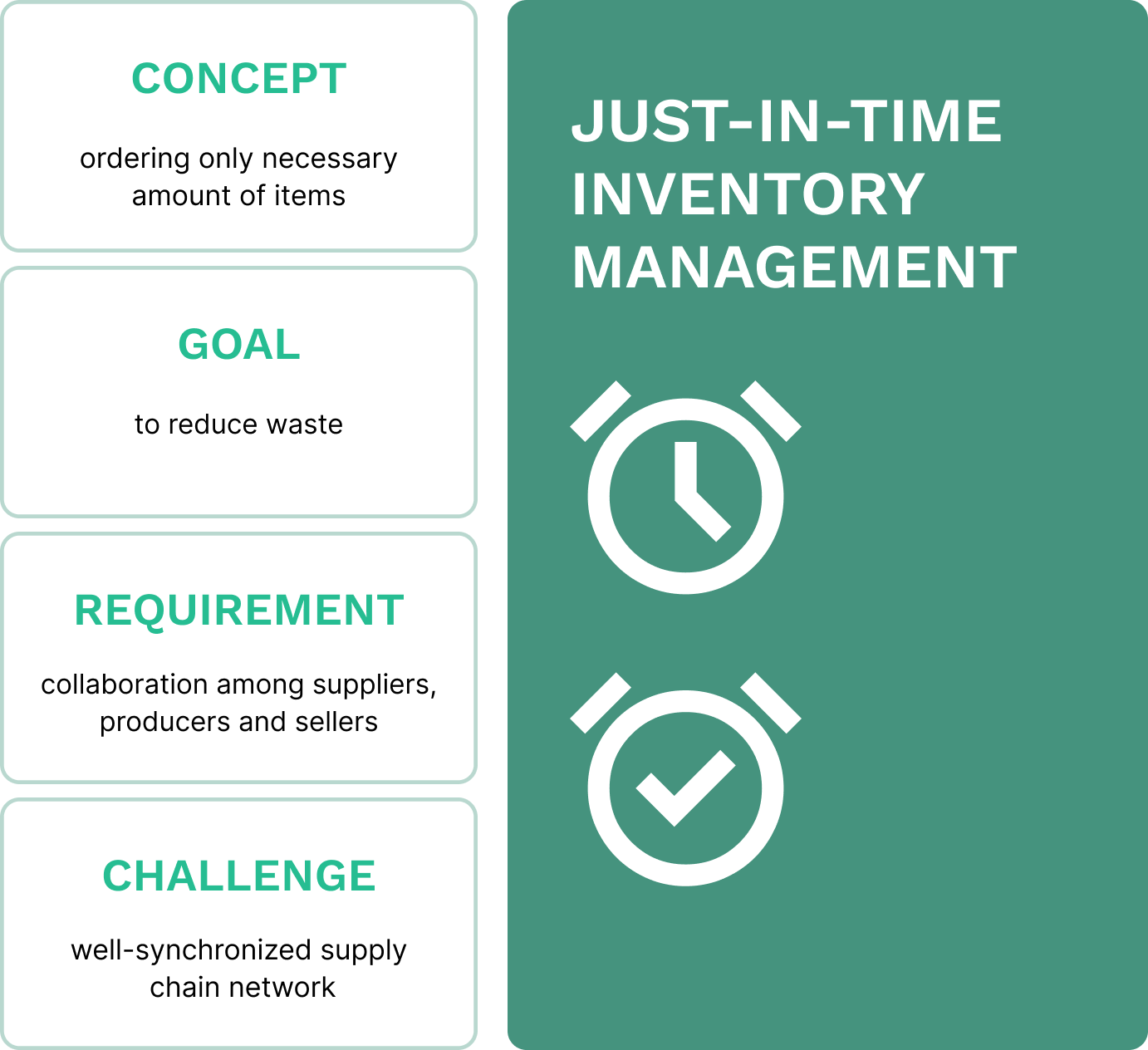

Inventory management using the Just-In-Time (JIT) methodology focuses on streamlining and enhancing efficiency by aligning inventory levels closely with customer demand.

The fundamental concept of JIT is to have goods delivered precisely when they’re required, thereby reducing unnecessary stockpiles and cutting down on associated carrying costs.

Source: WorkTrek

Successful implementation depends upon seamless collaboration among suppliers, producers, and sellers to ensure prompt fulfillment. Within this system, as consumer orders are placed, only the necessary amount of items are ordered through JIT to fulfill that demand without overstocking.

One of the challenges with JIT is that it requires a well-synchronized supply chain network. This requires maintaining reliable partnerships with suppliers and operating a practical logistical framework.

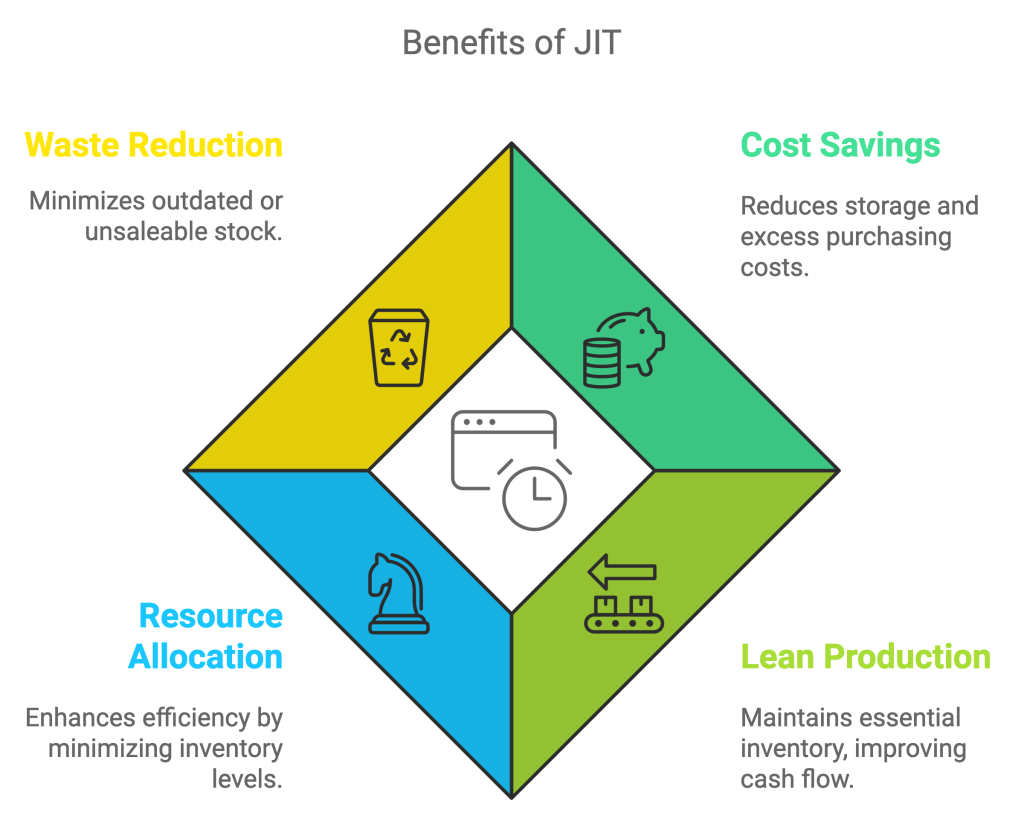

Benefits of Just-In-Time Inventory

There are several benefits to JIT. They include:

- Cost Savings: By eliminating surplus stock, organizations diminish both storage costs and the expense of purchasing more goods than necessary.

- Lean Production Process: The just-in-time approach maintains only essential inventory on hand, which improves cash flow.

- Effective Resource Allocation: Businesses can use their resources more efficiently when they minimize inventory levels, thus enhancing working capital.

- Waste Reduction: Since JIT delivers parts when they are needed, it can greatly reduce having outdated or unsaleable items in stock.

Source: WorkTrek

Challenges of Just-In-Time Inventory

Managing inventory with the Just-In-Time (JIT) strategy brings several advantages but is not without its difficulties.

A key issue it faces pertains to disturbances within the supply chain, which can be particularly problematic due to JIT’s dependency on exact timing and smooth coordination. Everything from bad weather to road conditions can result in delivery delays.

Unexpected surges in customer demand make these disruptions more impactful, as they may result in severe delays or a lack of sufficient stock to satisfy increased needs.

Just-In-Case Inventory

Just-in-case (JIC) inventory management is a strategy in which companies maintain large inventories of raw materials, components, or finished goods to mitigate the risk of stockouts caused by unexpected disruptions, such as supply chain delays, increased demand, or production problems. The goal of JIC is to ensure that the business can continue operations without interruption, even if issues arise.

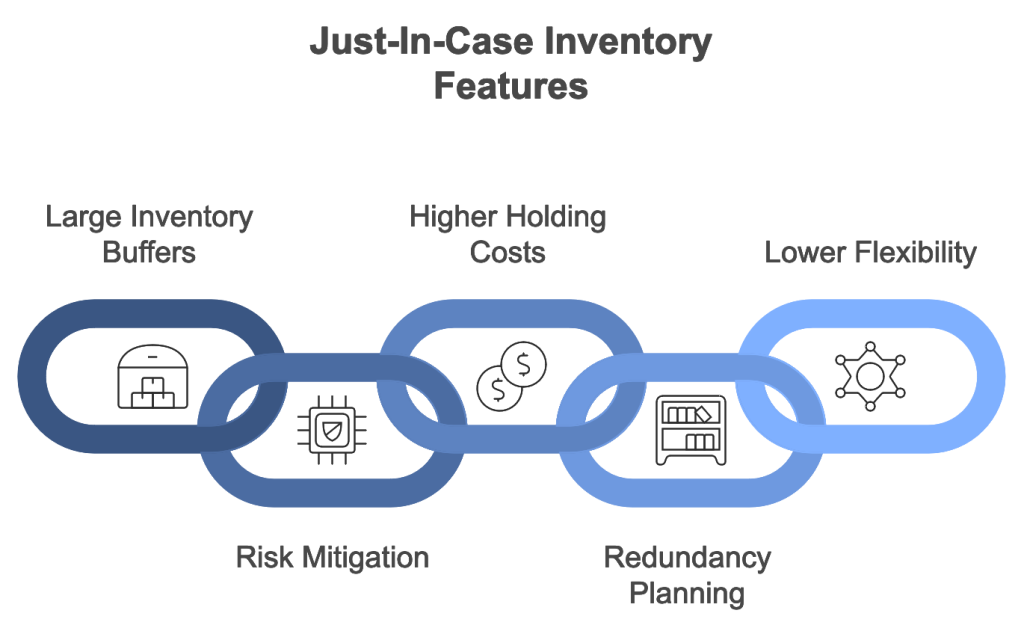

Some of the key features of JIC inventory management include:

- Large Inventory Buffers: Businesses store more stock than immediately needed to cover unforeseen changes in demand or supply.

- Risk Mitigation: Helps avoid delays in production and customer service issues due to stock shortages.

- Higher Holding Costs: Maintaining large inventories requires more storage space and capital, increasing costs.

- Redundancy Planning: Reduces dependency on suppliers by keeping extra inventory on hand.

- Lower Flexibility: Changes in demand patterns can lead to excess stock, resulting in wastage or obsolescence.

Source: WorkTrek

During the Covid-19 pandemic, and as a direct result of supply chain problems, several enterprises started adopting JIC. This strategic pivot proves advantageous for sectors plagued by erratic demand cycles or dependent on fickle sources of supply.

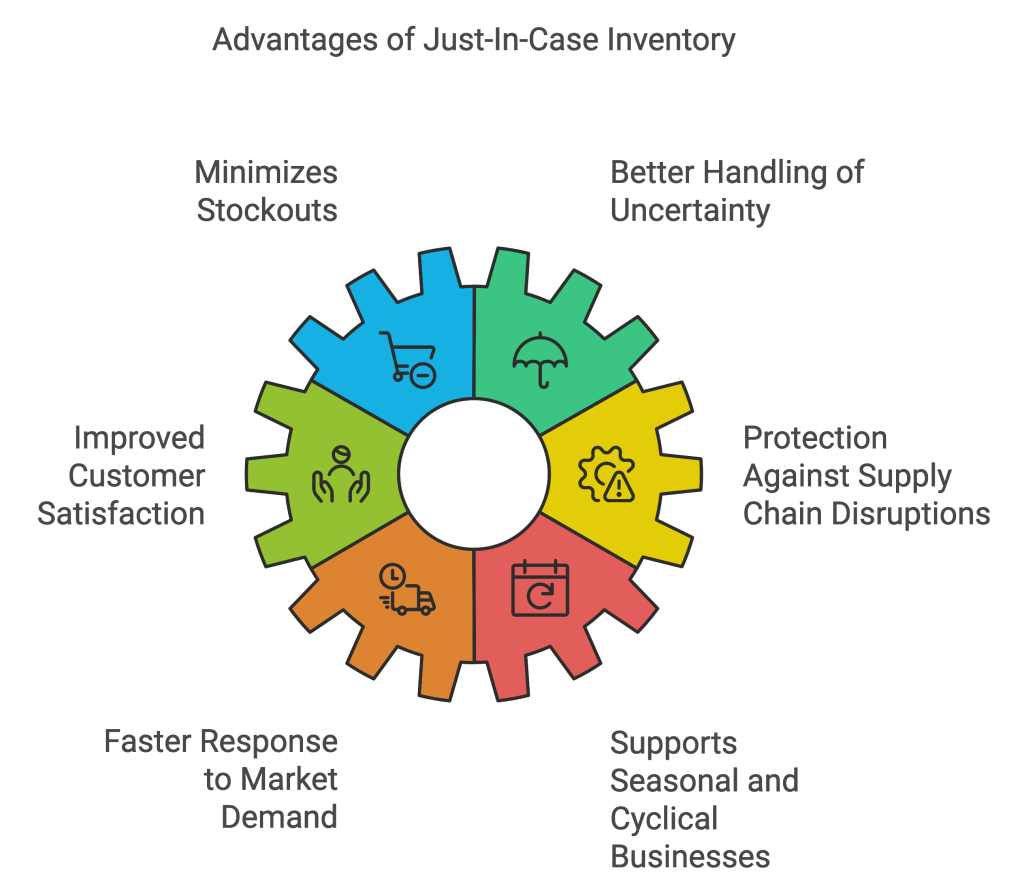

Advantages of Just-In-Case Inventory

Inventory management that employs the Just-In-Case (JIC) approach confers various benefits that can help a business outshine its competitors. Key advantages of this strategy include:

- Minimizes stockouts: Ensures goods are always available to meet customer demand.

- Better handling of uncertainty: Useful when unstable supply chains or high demand fluctuations exist.

- Improved Customer Satisfaction and Retention: Keeps service levels high by ensuring products are always in stock.

- Protection Against Supply Chain Disruptions: It reduces the reliance on “perfect” supply chain logistics, offering resilience when suppliers or transportation networks underperform.

- Faster Response to Market Demand: Companies can quickly respond to fluctuating market trends and sudden demand increases since they already have the goods in stock.

- Supports Seasonal and Cyclical Businesses: Some businesses experience seasonal demand fluctuations. JIC allows them to prepare for busy periods by building up inventory beforehand.

Source: WorkTrek

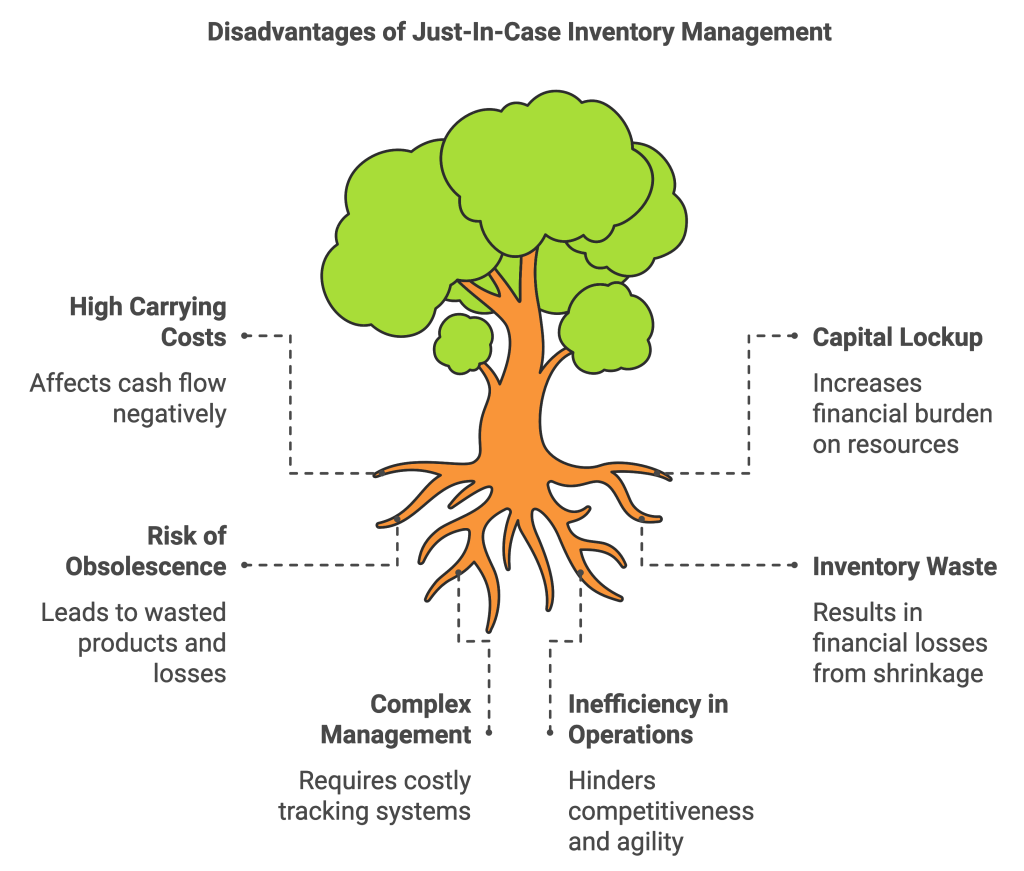

Drawbacks of Just-In-Case Inventory

Like any process, there are some disadvantages to using JIC inventory management model. Holding excess inventory can lead to storage costs equivalent to 20% to 30% of its value. Below are a few more drawbacks to JIC inventory management;

- High Carrying and Storage Costs: Companies using JIC store spare parts and goods in bulk, which can affect cash flow.

- Capital Tied Up in Inventory: Your carrying costs are much higher since you hold excess inventory.

- Risk of Obsolescence or Expiry: Products with short life cycles or perishable goods (like food, electronics, or fashion items) can become obsolete or spoiled if held too long in inventory.

- Inventory Waste and Shrinkage: Shrinkage (loss of inventory) can occur due to theft, errors, or damage during storage and handling.

- Complex Inventory Management: Managing large inventories requires sophisticated tracking systems and experienced personnel to avoid errors and inefficiencies.

- Inefficiency in Lean Operations: In highly competitive industries that rely on lean practices to reduce costs, JIC can appear wasteful and inefficient.

Source: WorkTrek

Choosing the Right Strategy for Your Business

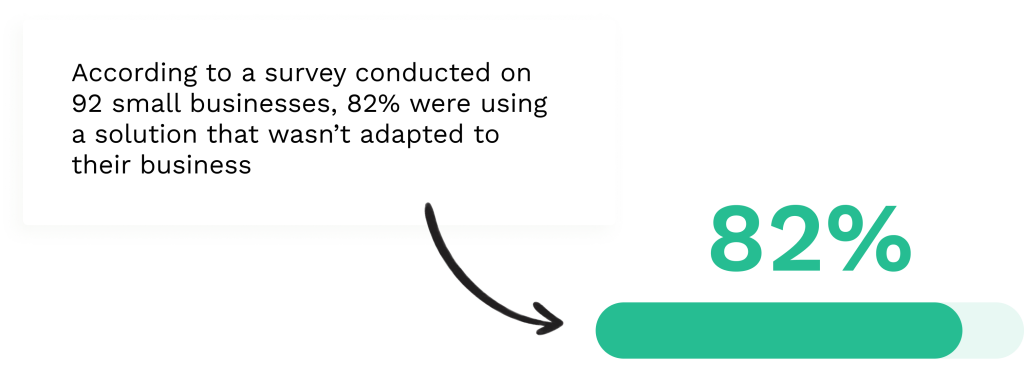

Illustration: WorkTrek / Data: bci

Choosing the right inventory strategy can keep your business profitable and your customers happy. A poor plan can lead to high storage costs, fulfillment delays, and lost sales.

The kind of business you have, changes in customer demand, and what’s going on in the market all play a role in figuring out which strategy will work best for you.

Start by reviewing your inventory. This will help you determine essential items and how to manage them effectively.

For example, a Just-In-Time (JIT) system might be perfect for items that aren’t very popular or are only needed once in a while. On the other hand, a Just-In-Case (JIC) approach could be ideal for products in high demand or where customer needs can change quickly.

Things to Consider

Things to Think About When deciding on the best inventory strategy, several important factors must be considered.

- Market predictability

- Dependentibility and relationship with suppliers

- Size of business

- Team experience and training

All of these things can affect whether you should use a JIT or JIC system. Your decision about your inventory approach can greatly impact your company’s profits by helping you manage the risks of having too much or too little stock. These impacts can be different depending on the size of your business.

In addition, current market conditions can significantly influence your chosen inventory management strategy.

When markets are unstable, it’s even more important to choose between JIT and JIC carefully because they both rely on smooth operations to manage risk effectively. For businesses that choose Just-In-Time (JIT) strategies, it’s essential to have strong relationships with suppliers to help reduce the risks of supply chain disruptions.

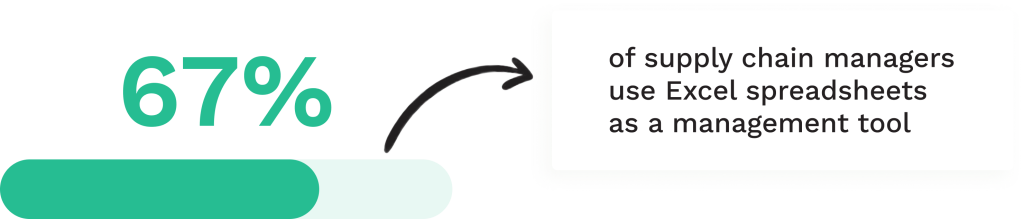

Hybrid Inventory Management Model

Illustration: WorkTrek / Data: Erplain

Another option is using a hybrid approach, which combines parts of both Just-In-Time and Just-In-Case models to keep the right amount of stock on hand. The main goal of a hybrid strategy is to keep inventory levels low enough to be cost-effective but high enough to meet demand.

This approach lets businesses take advantage of the strengths of both JIT and JIC, adjusting inventory management based on the specific characteristics of each product and the market conditions.

A hybrid model can be customized to use JIT for items with predictable demand and JIC for those with uncertain demand. This flexibility allows businesses to adapt more effectively to changing market conditions and customer demands.

Inventory management software can improve this approach by automating inventory tracking, reducing manual errors, and streamlining effective inventory management processes.

Role of CMMS in Inventory Management

Illustration: WorkTrek / Data: zhenhub

Computerized Maintenance Management Systems (CMMS) like WorkTrek are game-changers for inventory management. They help organizations easily track their inventory.

CMMS provides a clear overview of stock levels, ensuring that businesses know exactly what they have on hand. This system helps to prevent both shortages and overstock situations, which can save money and reduce waste. By setting low inventory alerts, CMMS ensures managers can reorder supplies promptly.

CMMS also enhances accuracy and efficiency in managing inventory. It automates the tracking process, reducing the chances of human error. With real-time data, organizations can make informed decisions quickly.

This is particularly useful for forecasting demand and planning future orders. The system’s analytical tools provide insights into inventory trends, helping businesses optimize their stock levels. This means less time spent on manual checks and more time focusing on core business activities.

Moreover, CMMS fosters better communication between departments. It connects maintenance teams with procurement and finance, creating a seamless flow of information. This collaboration ensures everyone is aligned, which is crucial for smooth operations. With CMMS, organizations can respond swiftly to changes in demand or supply chain disruptions. In essence, CMMS streamlines inventory management and strengthens overall operational efficiency.

Summary

Managing inventory well is super important for a business to be successful.

When choosing between just-in-time and Just-In-Case strategies, many factors must be considered, such as the market’s performance, the reliability of your suppliers, and the size of your company.

Just-in-time is all about cutting down on waste and making manufacturing more efficient. It works best for businesses with a good idea of the demand. On the other hand, Just-In-Case gives you a safety net against surprises in supply and demand, so you always have enough products to keep your customers happy.

You can get the best of both worlds by using a mix of both strategies. Just-In-Time helps you save money and streamline operations, while Just-In-Case lets you be flexible and prepared for the unexpected.

Tools like inventory management or CMMS software can improve these strategies by helping you stay competitive when the market changes.