What is Asset Management?

Asset Management is a systematic approach to governing physical assets’ acquisition, operation, maintenance, upgrade, and disposal to optimize their performance, risks, and costs over their entire lifecycle. It aims to enable an organization to maximize the value of its assets while minimizing related costs and risks.

A physical asset is any tangible thing with potential or actual value to an organization. Assets include equipment, machinery, vehicles, tools, spare parts, materials, buildings, infrastructure, land, and natural resources.

The scope of asset management encompasses all activities involved in identifying asset needs, acquiring assets, maintaining and repairing assets, upgrading or replacing assets, and retiring and disposing of assets.

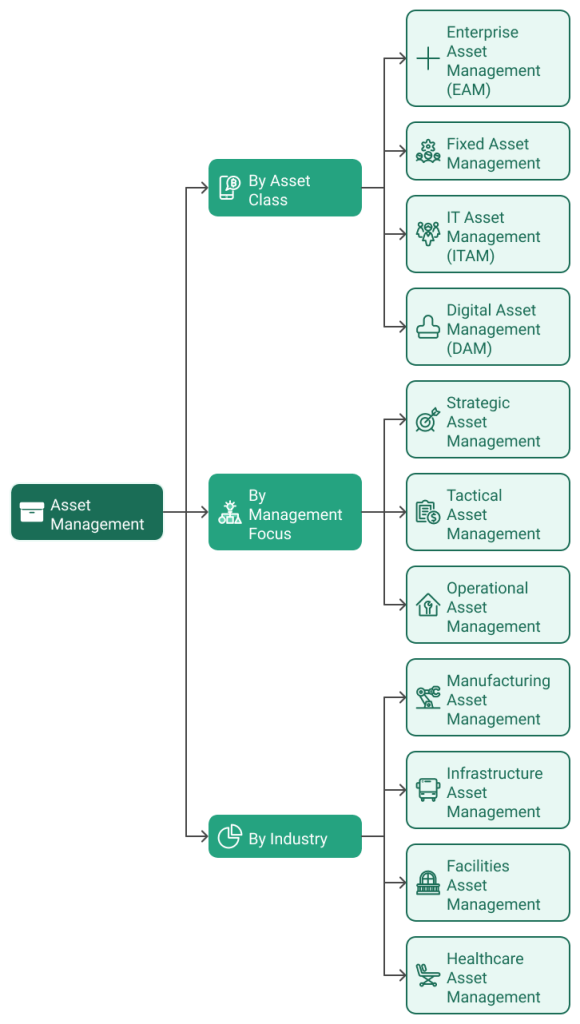

What are the different types of asset management?

Types of Asset Management Asset management can be categorized in several ways:

- By Asset Class:

- Enterprise Asset Management (EAM): Managing all assets across an entire organization, often with the help of an EAM software system.

- Fixed Asset Management: Focused on managing long-term tangible assets that are not easily converted to cash, such as buildings, land, equipment, and vehicles. Includes financial reporting of asset depreciation and valuation.

- IT Asset Management (ITAM): Overseeing the purchase, deployment, maintenance, utilization, and disposal of an organization’s IT assets, including hardware, software, and cloud services.

- Digital Asset Management (DAM): Managing digital assets such as documents, images, multimedia, and content throughout their lifecycle.

- By Management Focus:

- Strategic Asset Management: Making high-level decisions about which assets to invest in, how to configure them, and when to upgrade or replace them based on long-term organizational goals.

- Tactical Asset Management: Determining the best ways to operate and care for assets daily to maximize their performance and minimize disruptions and downtime.

- Operational Asset Management: Executing the practical, hands-on activities required to keep assets functioning, including inspections, servicing, calibrations, and repairs.

- By Industry or Sector:

- Manufacturing Asset Management: Managing production equipment and machinery in factories and plants.

- Infrastructure Asset Management: Overseeing transport, utility, communication, and public works assets in rail, road, power, water, telecom, and related sectors.

- Facilities Asset Management: Maintaining and optimizing buildings, structures, and installed equipment used for commercial, institutional, or residential purposes.

- Healthcare Asset Management: Managing medical equipment, devices, and facilities in hospitals, clinics, and health systems.

While the specific assets and priorities may differ, the core principles of lifecycle optimization, risk management, and data-driven decision-making are common across all types of asset management.

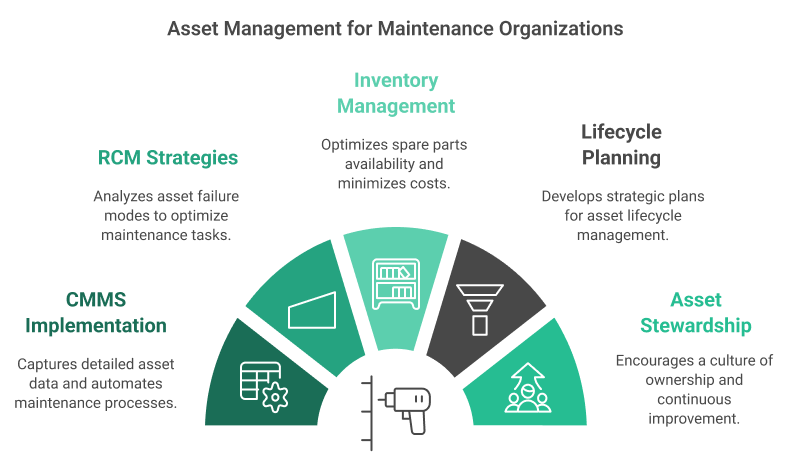

Top Ways to Manage Assets for Maintenance Organizations

For organizations focused on maintenance, some key ways to effectively manage assets include:

With a CMMS system, you can capture detailed asset attributes, hierarchies, condition assessment findings, meter readings, maintenance history, spare parts inventory, and related costs. You can also automate work order generation, planning, scheduling, and completion tracking. Additionally, CMMS can help you analyze asset and work order data to identify performance trends, improvement opportunities, and investment needs.

2. Implement Reliability-Centered Maintenance (RCM) Strategies:

You can use RCM methodology to analyze asset failure modes, effects, and criticality thoroughly. This can help you develop optimal preventive maintenance and condition monitoring tasks to mitigate the risks and consequences of potential failures cost-effectively. Additionally, you can implement condition-based and predictive maintenance techniques such as vibration analysis, oil analysis, and thermography to detect and correct root causes of failure. Don’t forget to continuously review asset performance and failure data to refine maintenance strategies.

3. Establish a Spare Parts Inventory Management Program:

You can use RCM methodology to analyze asset failure modes, effects, and criticality thoroughly. With a good spare parts management program, you can easily optimize spare parts stocking levels and reordering points to minimize costs while maximizing availability. Consider implementing robust storeroom procedures for parts procurement, receiving, issuing, and cycle counting. More importantly, implement a CMMS system to help manage your spare parts inventory.

4. Develop a Strategic Asset Lifecycle Plan:

Start by creating a long-term plan for acquiring, deploying, operating, maintaining, renewing, and disposing of significant assets. Base the plan on thoroughly understanding asset condition, performance, risks, and lifecycle costs. Use the plan to optimize the timing and scope of asset investments, upgrades, and replacements. Don’t forget to align the plan with organizational objectives, budgets, and risk tolerance.

5. Foster a Culture of Asset Stewardship and Continous Improvement:

Start by clearly defining roles and responsibilities for asset management across the organization. Train and empower employees to take ownership of asset care and performance optimization. Focus on collaboration between maintenance, operations, engineering, and finance. Always celebrate successes and share best practices in asset management.

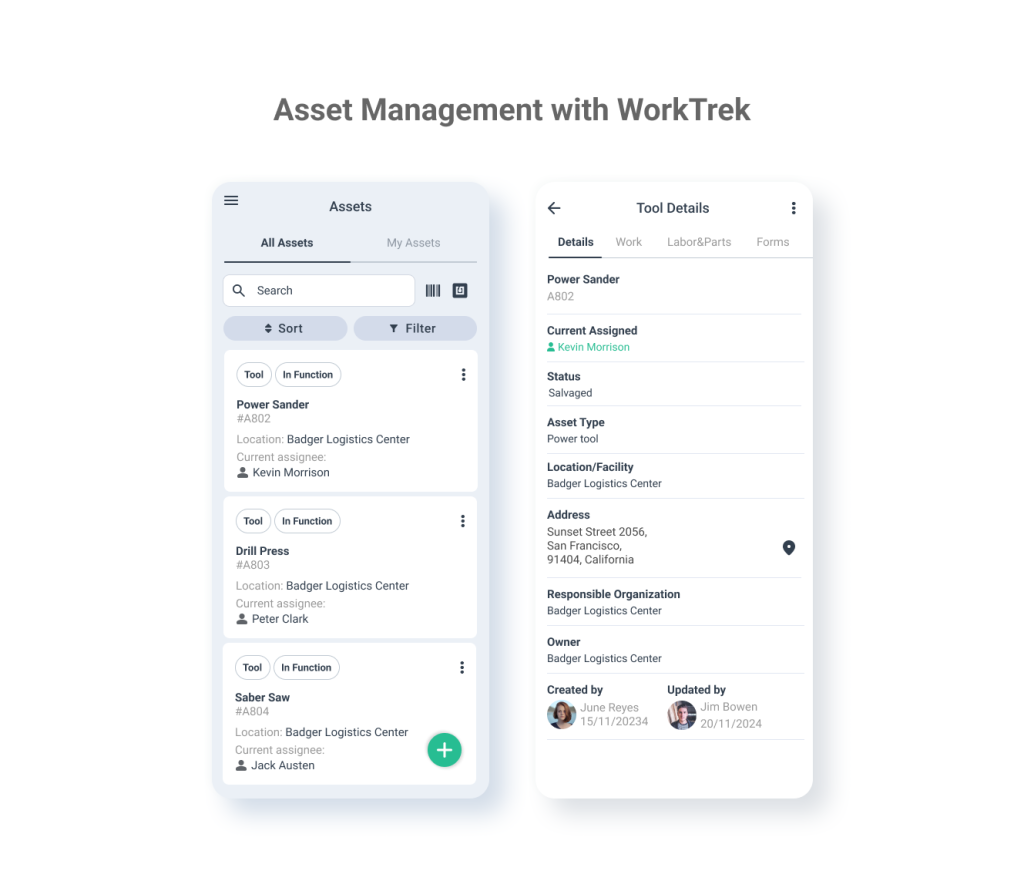

Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for free