What is Asset Tracking?

Asset tracking refers to monitoring physical assets’ location, status, and usage in real time or over time. This process ensures that organizations maintain visibility over their equipment, machinery, tools, vehicles, or other valuable resources, helping optimize their utilization and management. Asset tracking typically involves using technologies such as barcodes, QR codes, RFID tags, GPS, and IoT sensors to automatically gather data about assets and update it within a management system.

The primary objective of asset tracking is to ensure that assets are available, accounted for, and in optimal condition when needed. It helps organizations prevent the loss or misplacement of assets, monitor their movement, and identify their exact location.

Asset tracking is essential for operational efficiency in logistics, manufacturing, healthcare, and construction industries, where assets are frequently transported or shared between departments or locations.

Many organizations use Computerized Maintenance Management Systems (CMMS) or Enterprise Asset Management (EAM) software to centralize asset tracking information. These systems store data like asset ownership, movement history, current location, and condition, allowing real-time updates and easy reporting. GPS-based tracking is often used for vehicles and mobile equipment, while RFID or barcode systems are more common for tracking tools, machinery, and inventory.

Asset tracking is important for preventive maintenance. It ensures maintenance teams know where each asset is located and can schedule service without delays. It also provides insights into asset utilization, helping organizations make data-driven decisions about equipment allocation, replacements, or disposals.

Organizations can improve productivity, lower operational costs, and extend asset lifespans by using modern tracking technologies.

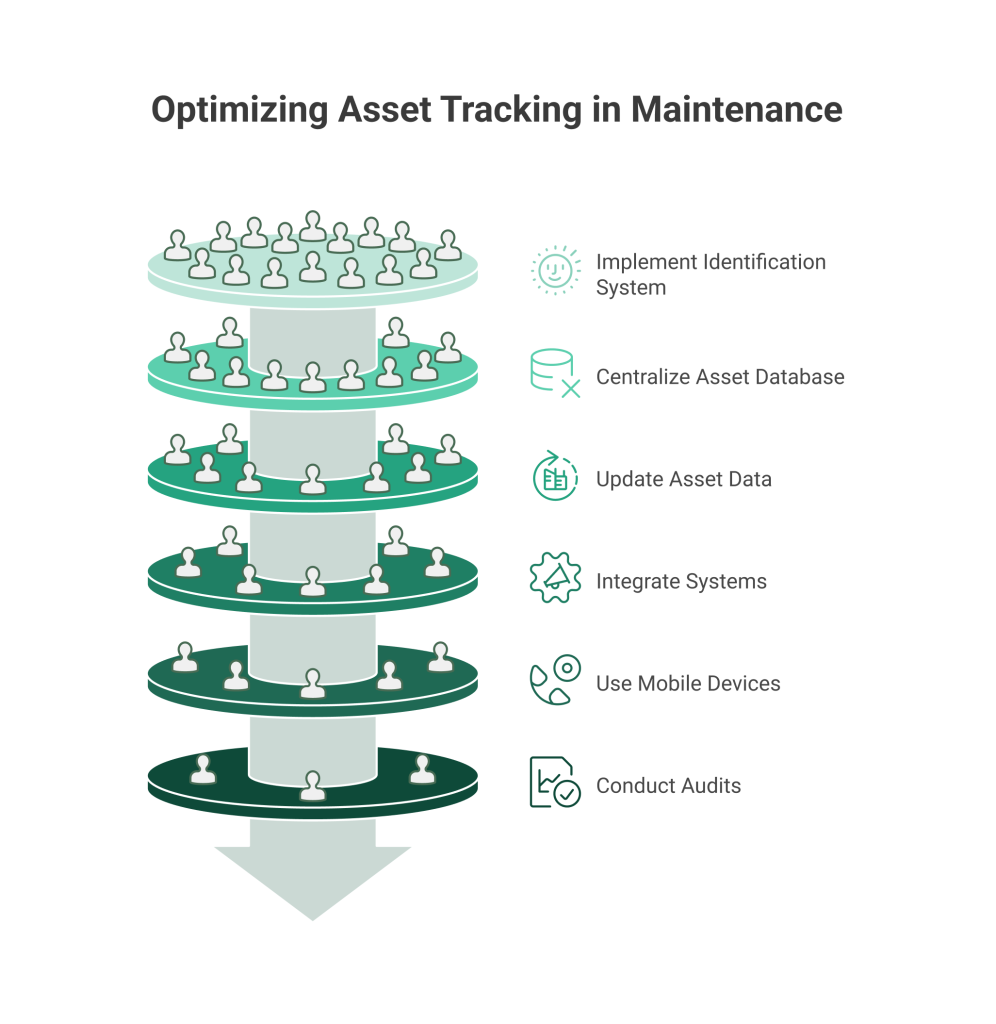

Best Practices for Asset Tracking

Here are some best practices for asset tracking in a maintenance organization:

- Implement a unique identification system: Assign each asset a unique identifier, such as a barcode or RFID tag, to ensure accurate tracking and avoid confusion.

- Maintain a centralized asset database: Use a centralized database, such as a CMMS or EAM system, to store and manage all asset data, including location, maintenance history, and other relevant information.

- Keep asset data up-to-date: Regularly update asset information, such as location changes, maintenance activities, and condition assessments, to ensure the accuracy and reliability of the asset database.

- Integrate with other systems: Integrate your asset tracking system with other relevant systems, such as ERP, financial, and procurement systems, to enable seamless data sharing and streamlined workflows.

- Use mobile devices for data collection: Equip maintenance technicians with mobile devices, such as smartphones or tablets, to enable real-time data collection and updates from the field.

- Implement asset audits: Conduct regular physical audits of assets to verify the accuracy of the asset database and identify any discrepancies or missing assets.

- Track asset movement: Use location tracking technologies, such as GPS or indoor positioning systems, to monitor the movement of mobile assets and ensure they can be easily located when needed.

- Monitor asset condition: Regularly assess and record the condition of assets to enable condition-based maintenance and proactively address potential issues.

- Establish asset tracking policies and procedures: Develop and enforce clear policies and procedures for asset tracking, including data entry standards, audit frequencies, and roles and responsibilities.

- Train staff on asset tracking: Regularly training maintenance staff on the importance of accurate asset tracking and effectively using the relevant systems and tools.

- Use data analytics: Leverage data analytics tools to gain insights from asset tracking data, such as identifying trends, optimizing maintenance strategies, and predicting future asset requirements.

- Continuously improve: Review and refine your asset-tracking processes and technologies regularly to identify opportunities for improvement and ensure ongoing effectiveness.

By implementing these best practices, maintenance organizations can improve the accuracy and reliability of their asset tracking, enabling better decision-making, increased efficiency, and reduced costs.

Types of Asset Tracking

Here are the main types of asset tracking:

- Barcode Asset Tracking:

- It uses barcodes attached to assets, which handheld or fixed readers scan to record asset information.

- It provides a simple, low-cost way to track asset location, identity, and movement.

- Suitable for inventory management, check-in/check-out, and auditing applications.

- RFID Asset Tracking:

- Uses radio-frequency identification (RFID) tags attached to assets, which communicate wirelessly with RFID readers.

- Enables automatic, real-time asset location, movement, and status tracking without line-of-sight requirements.

- Offers longer read ranges and higher data storage capacity compared to barcodes.

- Suitable for tracking high-value, mobile, or frequently moving assets in manufacturing, logistics, and healthcare.

- GPS Asset Tracking:

- Uses global positioning system (GPS) devices attached to assets, communicating location data via cellular or satellite networks.

- Provides real-time, outdoor tracking of asset location, movement, and routes.

- Suitable for tracking vehicles, equipment, and shipments across wide geographic areas.

- BLE Asset Tracking:

- Uses Bluetooth Low Energy (BLE) beacons attached to assets, which communicate with nearby smartphones or receivers.

- Enables indoor tracking of asset location and proximity within a limited range.

- Suitable for tracking assets within a facility, such as equipment, tools, or personnel.

- Wi-Fi Asset Tracking:

- Uses Wi-Fi-enabled tags or devices attached to assets, which communicate with Wi-Fi access points to determine location.

- Provides indoor tracking of asset location and movement within a Wi-Fi network coverage area.

- Suitable for tracking assets in office buildings, hospitals, or campuses.

- Ultra-Wideband (UWB) Asset Tracking:

- Uses UWB tags and anchors to provide precise, real-time indoor positioning and tracking.

- Offers high accuracy (within centimeters) and resistance to interference.

- Suitable for tracking critical assets in complex environments, such as manufacturing plants or construction sites.

- Infrared Asset Tracking:

- Uses infrared (IR) tags and sensors to detect the presence and movement of assets within a limited range.

- Provides directional and line-of-sight tracking within a room or defined area.

- Suitable for tracking assets in small, controlled environments, such as laboratories or server rooms.

- Computer Vision Asset Tracking:

- Uses cameras and image recognition software to identify and track assets visually.

- Enables non-intrusive tracking of assets without the need for physical tags or devices.

- Suitable for monitoring stationary assets or detecting anomalies in asset appearance or position.

- IoT Asset Tracking:

- Uses various Internet of Things (IoT) sensors and devices to collect data on asset condition, usage, and performance.

- Provides real-time monitoring of asset parameters such as temperature, humidity, vibration, or energy consumption.

- Enables predictive maintenance and optimization of asset utilization.

- Manual Asset Tracking:

- Uses human observation and record-keeping to track asset location, status, and movement.

- Relies on physical inventories, check-in/check-out logs, or visual inspections.

- Suitable for low-volume, infrequently moving, or non-critical assets.

The choice of asset tracking type depends on factors such as the nature of the assets, the required level of accuracy and real-time visibility, the tracking environment, the available infrastructure, and the budget. Organizations often combine multiple types of asset tracking to create a comprehensive solution that meets their specific needs. Integration with asset management software enables centralized data storage, analysis, and reporting for informed decision-making and optimization.

Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for free