Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- Preventive maintenance delivers a 545% ROI, with every dollar spent saving an average of $5 in future repair costs

- Organizations achieve 25-40% reduction in overall maintenance costs through optimized PM programs

- Predictive maintenance strategies can reduce costs by an additional 8-12% beyond standard preventive maintenance

- 70-75% of equipment failures are eliminated through comprehensive preventive maintenance optimization

Your maintenance costs are bleeding your budget dry, and you know it.

While reactive maintenance might seem cheaper in the moment, the reality is stark: companies lose billions annually to emergency repairs, unplanned downtime, and premature equipment replacements.

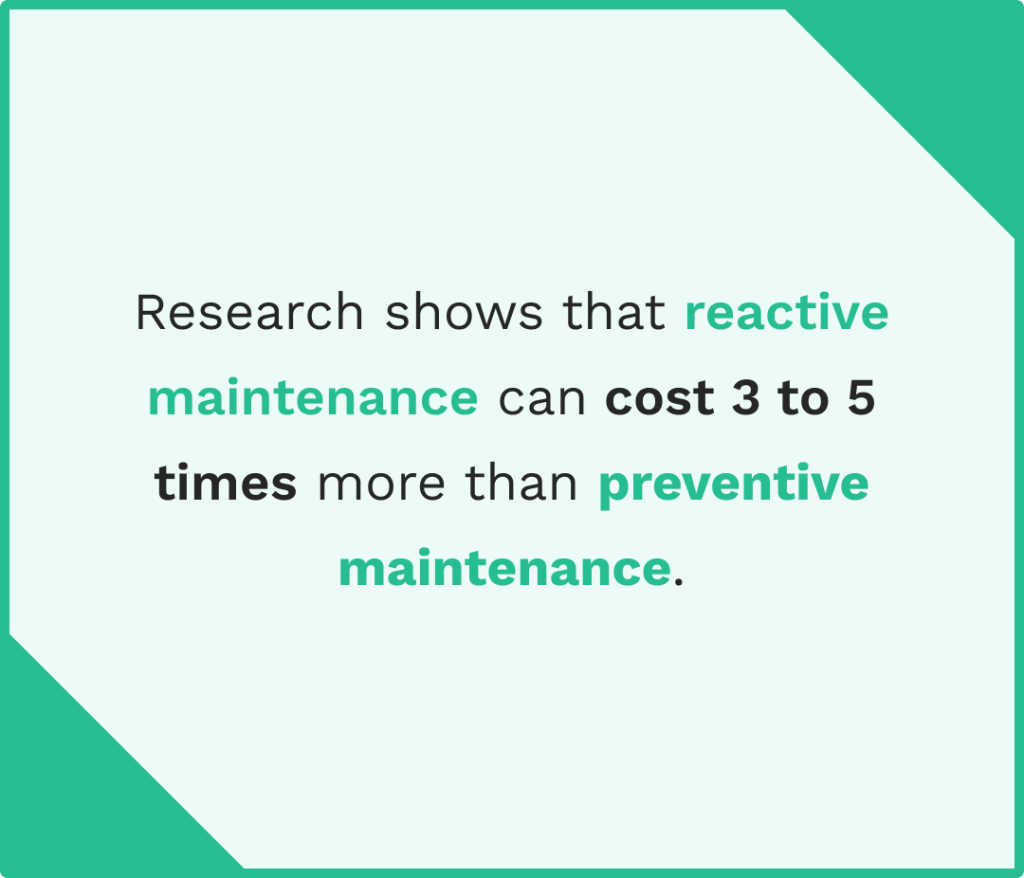

According to the U.S. Department of Energy, reactive maintenance costs 3-5 times as much as preventive maintenance when indirect costs are factored in.

Yet despite these numbers, many organizations continue operating in crisis mode, treating maintenance as an unavoidable expense rather than a strategic investment.

That’s where preventive maintenance optimization changes everything. By strategically refining your maintenance processes, you don’t just reduce costs—you transform maintenance from a financial burden into a profit center.

The True Cost of Poor Maintenance Practices

Before exploring how preventive maintenance optimization reduces maintenance costs, let’s confront the harsh reality of what inadequate maintenance actually costs your organization.

The Hidden Financial Drain

Most maintenance managers focus on obvious costs like parts and labor. But the true financial impact runs much deeper.

Research from Siemens reveals that unplanned downtime at a large automotive plant costs up to $2.3 million per hour. This is amazingly a twofold increase since 2019.

In heavy industry, these costs have quadrupled over the past five years.

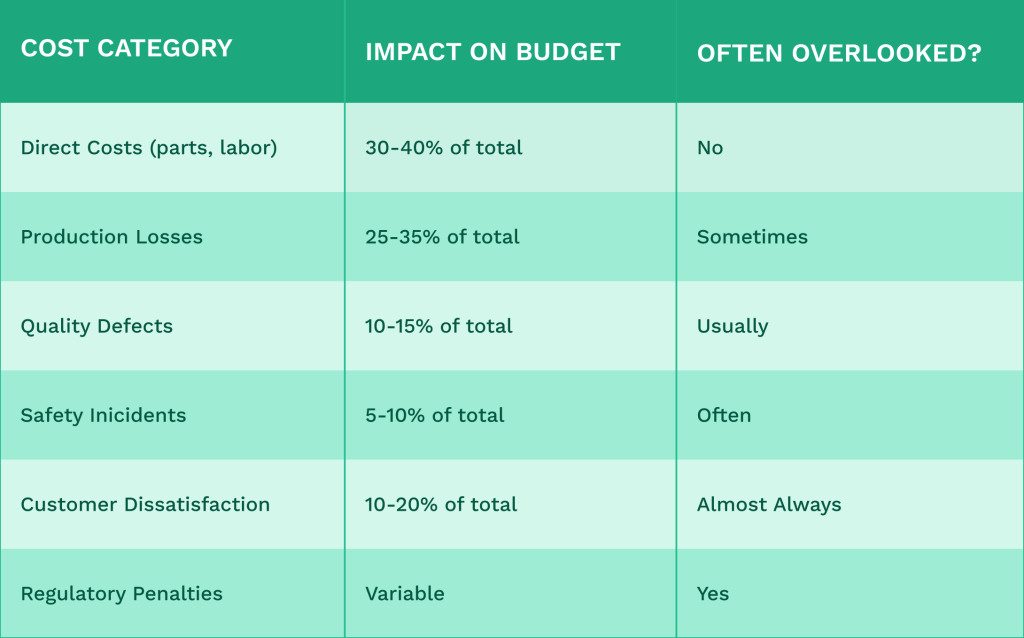

The breakdown of maintenance costs reveals multiple layers:

These indirect costs often exceed direct maintenance expenditures by 2-3 times, yet they rarely appear in maintenance budgets.

The Reactive Maintenance Trap

Data shows that 21% of facilities still rely primarily on reactive, run-to-failure maintenance strategies.

This approach can create a vicious cycle:

- Equipment runs until failure

- Emergency repairs cost 3-5x more than planned maintenance

- Rushed repairs increase the likelihood of future failures

- The cycle repeats, draining resources and slowing down production

Breaking this cycle requires a fundamental shift in how organizations approach maintenance—from reactive firefighting to proactive optimization.

How Preventive Maintenance Optimization Drives Cost Savings

Preventive maintenance optimization isn’t just about doing maintenance. It’s about doing the right maintenance at the right time for the right reasons.

Direct Cost Reduction Through Strategic Planning

With an optimized preventive maintenance program, you can experience immediate cost savings. Some of those savings include:

Labor Efficiency:

Planned maintenance requires 50% less labor time than emergency repairs. Technicians work more efficiently when they have adequate preparation time, the proper tools, and clear procedures.

Parts and Materials:

Boston Consulting Group research shows that robust inventory management through PM optimization leads to a 15% improvement in spare parts efficiency. Optimizing parts management can help you avoid both emergency procurement costs and excess inventory carrying costs.

Contractor Expenses:

Emergency repairs often require the services of expensive outside contractors, which can become costly. A solid preventive maintenance program reduces contractor dependency by up to 60%.

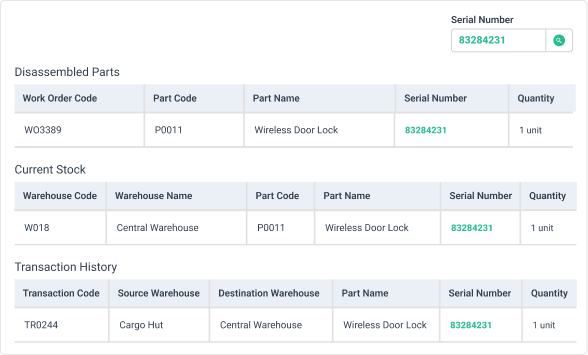

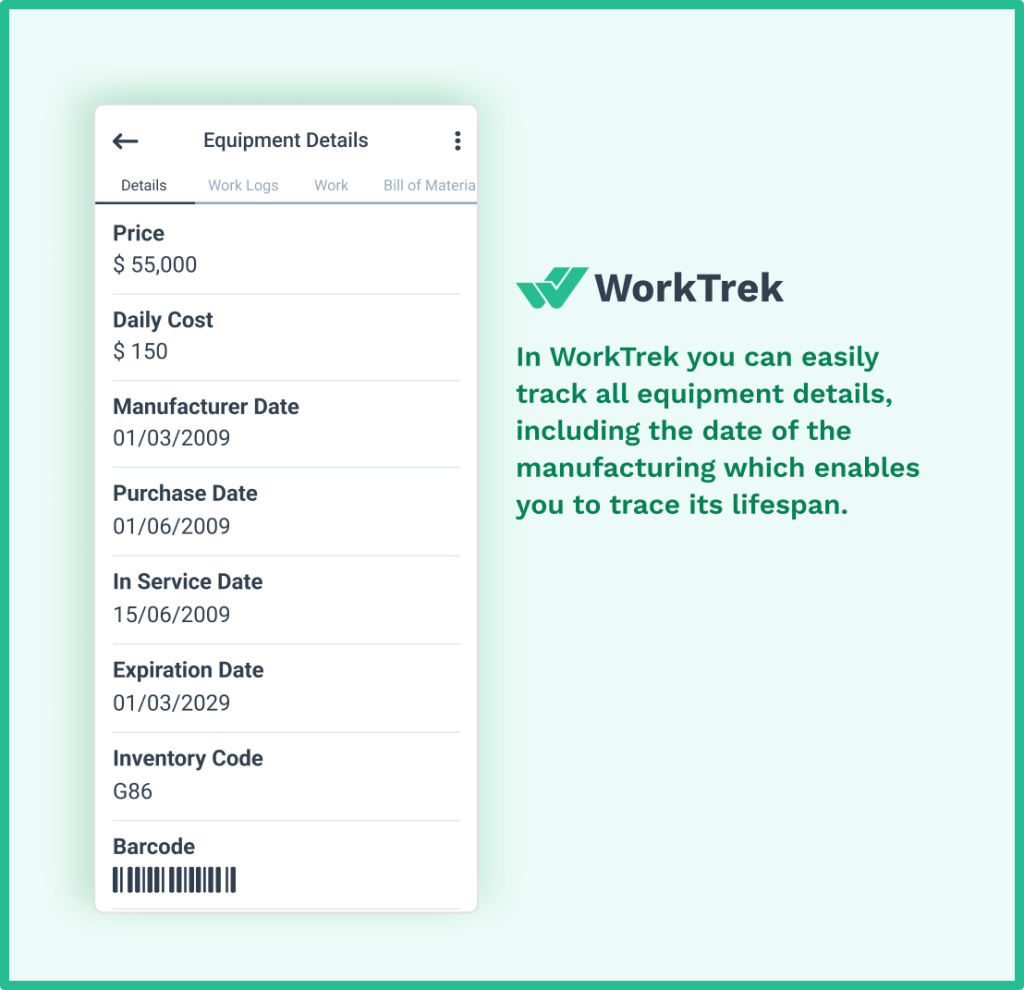

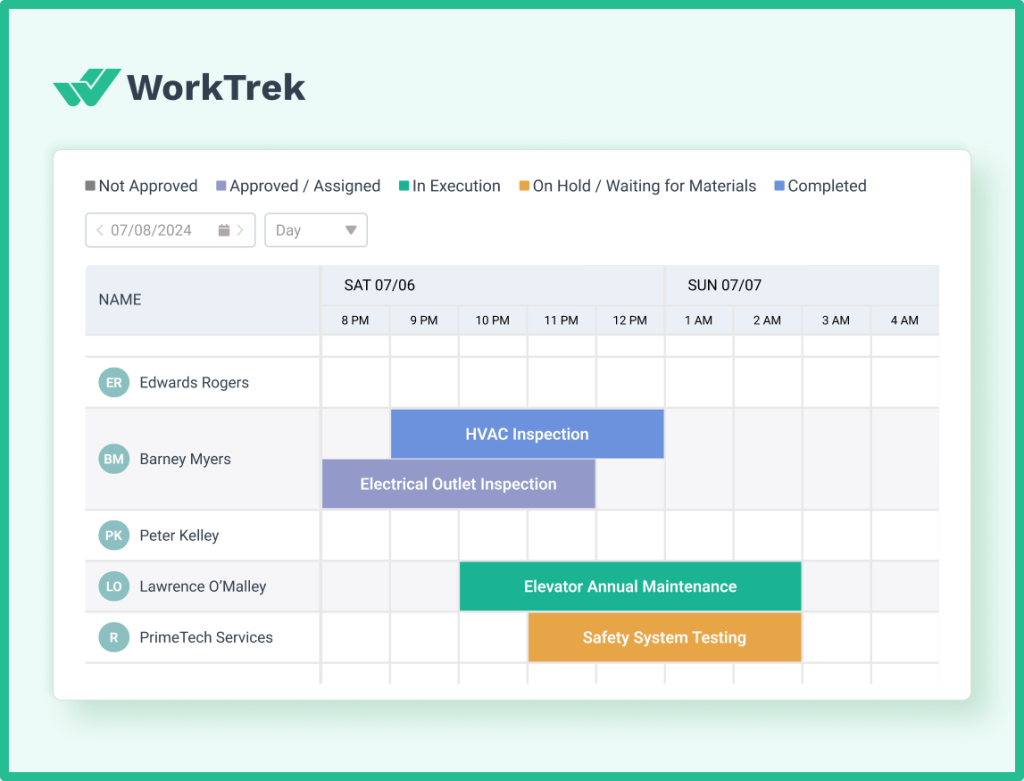

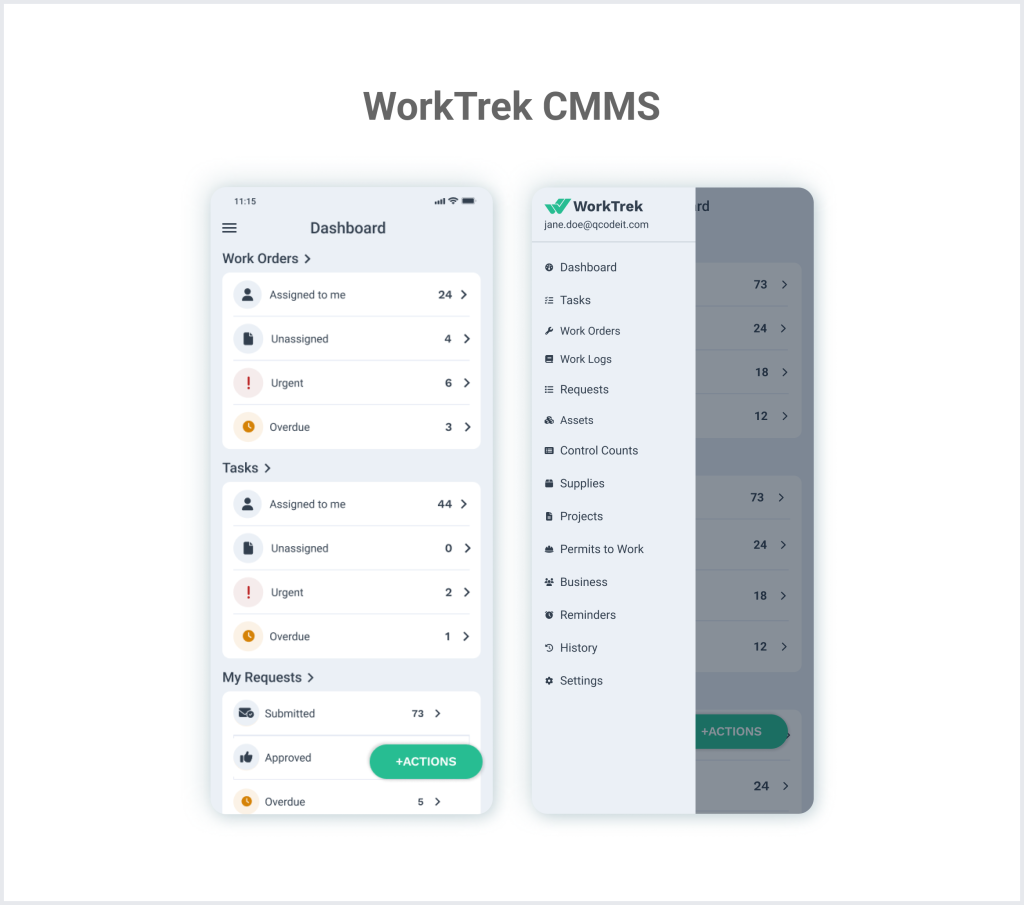

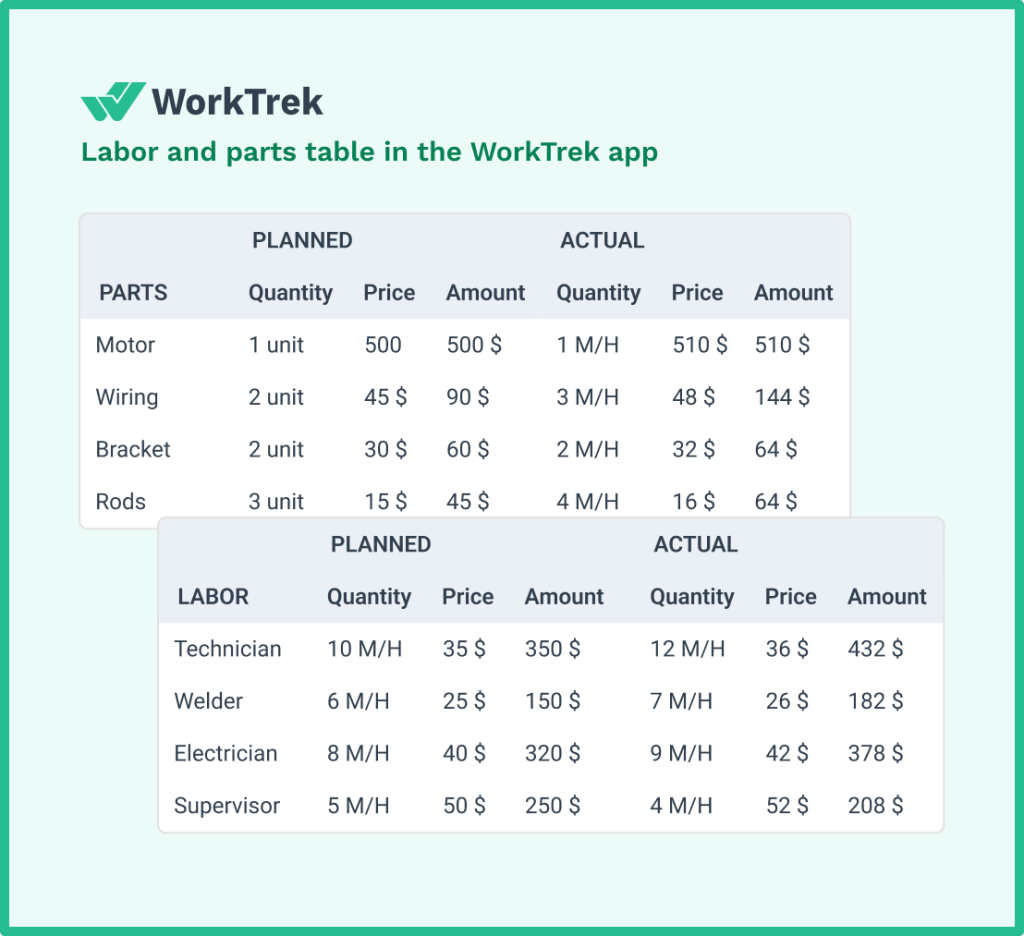

WorkTrek’s maintenance management platform streamlines these processes, ensuring maintenance tasks are planned, scheduled, and executed efficiently.

Extending Equipment Life for Long-Term Savings

Equipment replacement can be one of the largest capital expenses for most organizations. Preventive maintenance cost optimization dramatically extends equipment lifespan, delaying these costly replacements. Like a car, you don’t want to have to replace it every few years if you fail to do basic oil changes.

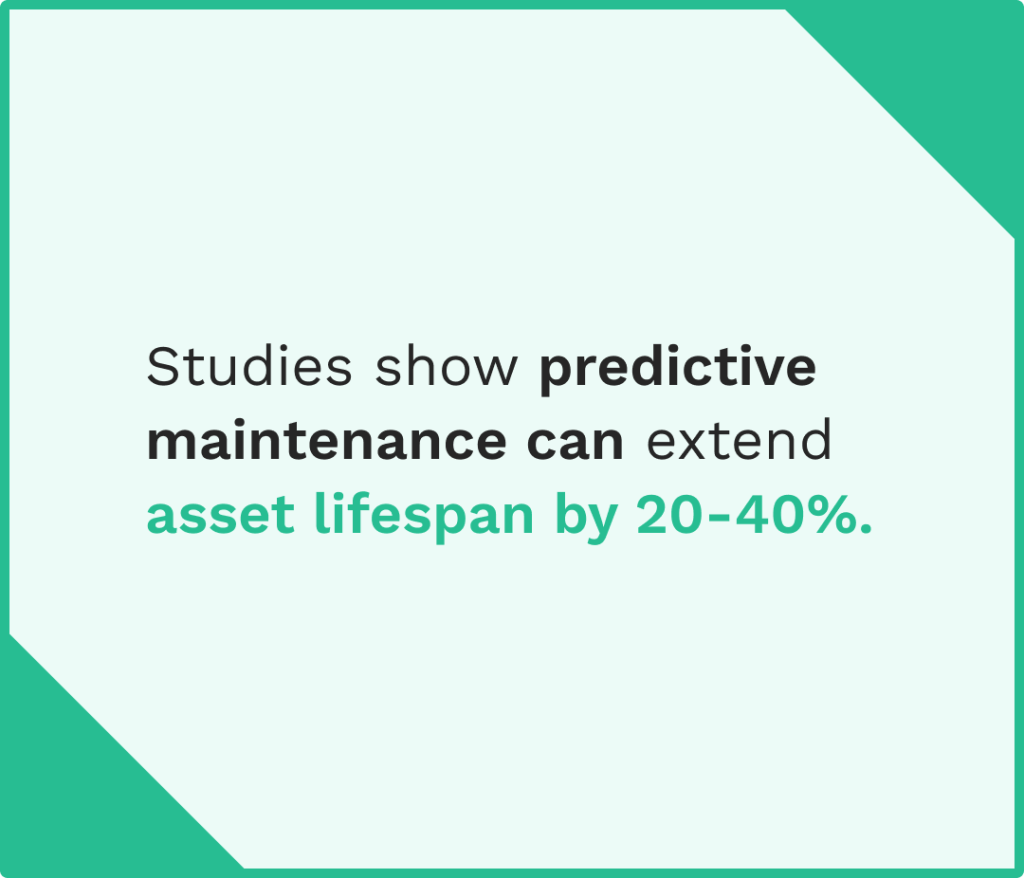

McKinsey research found that optimized maintenance programs increase machine life by 20-40%. For a $350,000 chiller with proper maintenance costing $5,500 annually, extending its life by just 5 years saves $70,000 in avoided replacement costs.

This life extension applies across all assets. Below are a few examples:

- HVAC systems: 40% longer operational life

- Production equipment: 30-50% extended lifespan

- Fleet vehicles: 25-35% more operational years

- Facility infrastructure: 20-30% delayed replacement

Reduced Downtime: The Biggest Financial Win

Unplanned downtime devastates budgets.

Fortune Global 500 companies lose 11% of their yearly turnover to unexpected equipment failures.

Preventive maintenance optimization attacks this problem head-on:

Fewer Failures:

Organizations implementing comprehensive PM optimization achieve 70-75% reductions in breakdowns.

Shorter Repairs:

When issues do occur, they’re typically minor and quickly resolved. Repair times decrease by 35-50% compared to emergency breakdowns.

Better Scheduling:

Planned downtime occurs during off-peak hours, minimizing production impact. This alone can reduce downtime costs by 60%.

Core Elements of Cost-Effective Preventive Maintenance

Building a maintenance program that consistently reduces costs requires multiple elements to work in harmony.

Data-Driven Task Optimization

Not all maintenance tasks deliver equal value. Maintenance expert John Schultz notes that analysis often reveals 30% of PM activities add little or no value and can be eliminated or replaced.

Optimize your preventive maintenance tasks by:

- Analyzing historical data to identify which tasks actually prevent failures

- Eliminating redundant or unnecessary inspections

- Adjusting frequencies based on actual wear patterns

- Focusing resources on critical assets with the highest failure costs

WorkTrek’s analytics tools provide the data visibility needed to make these optimization decisions confidently.

Reliability-Centered Maintenance Integration

Reliability-centered maintenance (RCM) ensures every maintenance dollar targets specific failure modes. This systematic approach evaluates:

- Failure consequences and their financial impact

- Probability of different failure modes

- Cost-effectiveness of prevention strategies

- Optimal maintenance intervals

By applying RCM principles, organizations typically reduce maintenance costs by 25-30% while improving equipment reliability.

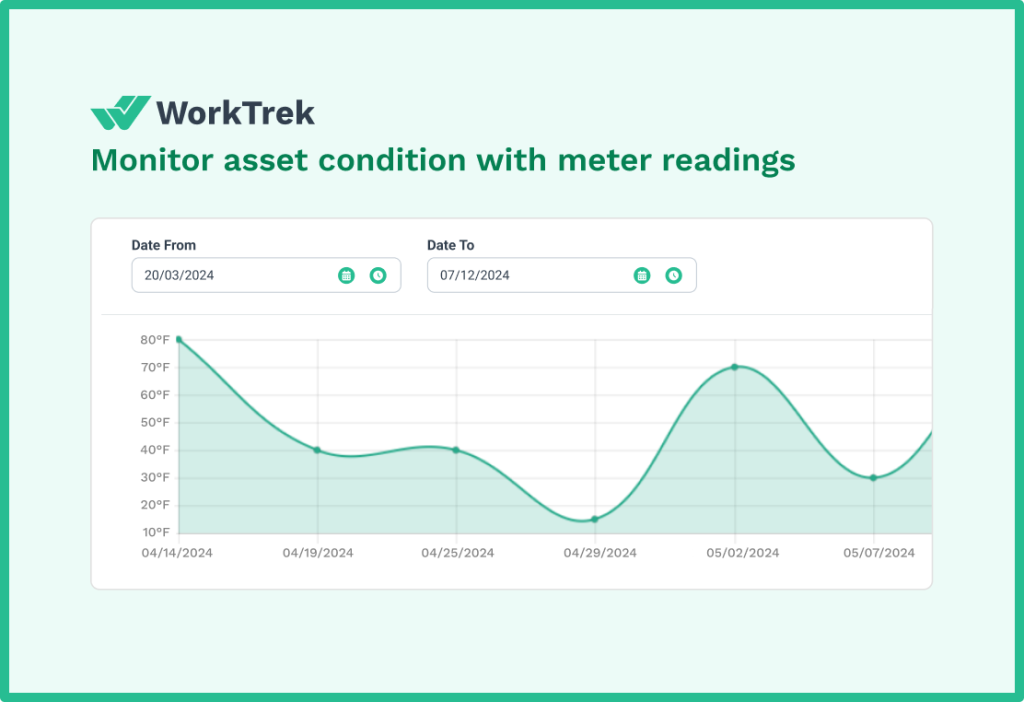

Condition Monitoring Technologies

Modern condition-monitoring technologies enable precise maintenance scheduling. This approach can eliminate both under-maintenance and over-maintenance.

Key technologies driving cost reduction include:

Detects bearing wear, misalignment, and imbalance before catastrophic failure. ROI typically exceeds 10:1.

Oil Analysis:

Identifies contamination and wear particles, preventing major mechanical failures. Extends equipment life by 20-30%.

Thermography:

Finds electrical and mechanical hot spots before failure. Prevents 70% of electrical fires.

Ultrasonic Testing:

Detects leaks and mechanical issues that other methods miss. Reduces energy costs by 10-15%.

These predictive maintenance strategies add 8-12% cost savings beyond traditional preventive maintenance alone.

How to Implement a Cost-Optimized Preventive Maintenance Strategy

The steps listed below will help you create a cost-optimized preventive maintenance program.

Step 1: Assess Current Maintenance Expenditures

You can’t optimize costs you don’t understand. The key to success is to start with a comprehensive audit:

- Calculate total maintenance costs, including all indirect expenses

- Identify your costliest equipment failures from the past year

- Determine your current reactive vs. preventive maintenance ratio

- Benchmark against industry standards for your sector

Industry data shows leading facilities allocate 40-60% of their maintenance budget to preventive activities, achieving optimal cost efficiency.

Step 2: Prioritize Critical Assets for Maximum Impact

Focus initial optimization efforts where they’ll deliver the greatest financial benefits:

- High-failure-cost equipment: Assets where downtime costs can exceed $10,000/hour

- Bottleneck equipment: Single points of failure in production

- Safety-critical assets: Equipment whose failure risks injury or regulatory penalties

- Customer-facing equipment: Assets directly impacting service delivery

This targeted approach ensures rapid ROI while building momentum for broader implementation.

Step 3: Develop Optimized PM Schedules

Generic maintenance schedules waste money. Your preventive maintenance schedule should reflect:

Usage-Based Intervals:

Equipment operating 24/7 needs different maintenance than assets used sporadically. Adjust schedules based on actual operating hours.

Environmental Factors:

Harsh conditions accelerate wear. Increase equipment frequency in demanding environments.

Criticality Adjustments:

Critical assets may justify more frequent preventive maintenance to ensure reliability.

WorkTrek’s preventive maintenance software enables dynamic scheduling that automatically adjusts based on multiple factors, ensuring optimal performance at minimum cost.

Step 4: Leverage Technology for Efficiency

Manual maintenance processes drain resources and increase costs. Technology solutions deliver immediate efficiency gains:

CMMS Implementation:

By implementing a CMMS like WorkTrek, you can reduce administrative time by 30-40% while improving data accuracy.

Mobile Access:

Technicians complete work 25% faster with mobile tools providing instant access to procedures and history.

Automated Scheduling:

Eliminates missed PM tasks that lead to costly failures.

Inventory Integration:

Can reduce parts costs by 15-20% through better procurement and stocking decisions.

Step 5: Measure and Refine Continuously

Cost optimization in not a one time task, and requires ongoing refinement based on performance data:

Monitor these key performance indicators:

- Maintenance cost per unit produced

- PM compliance rates

- Emergency maintenance percentage

- Mean time between failures

- Inventory turnover rates

Regular analysis identifies opportunities for further cost reduction while maintaining reliability.

Advanced Cost Optimization Techniques

Once you’ve created the foundational elements, advanced strategies can drive even deeper cost savings.

Predictive Maintenance Integration

While preventive maintenance forms the foundation of your program, adding predictive maintenance capabilities delivers substantial additional savings.

Machine learning algorithms analyze equipment data to:

- Predict failures days or weeks in advance

- Optimize maintenance intervals dynamically

- Identify degradation patterns invisible to human analysis

- Reduce unnecessary maintenance by 30-40%

Start with pilot programs on critical equipment, then expand based on proven ROI.

Total Productive Maintenance (TPM)

TPM engages operators in basic maintenance, multiplying your maintenance capacity without adding labor costs:

- Operators perform daily inspections and minor maintenance

- Early problem detection through constant equipment contact

- Reduced burden on skilled technicians

- 15-20% reduction in maintenance labor costs

This approach transforms maintenance from a specialist function to a shared responsibility.

Strategic Outsourcing

Not all maintenance delivers equal value when performed in-house. Strategic outsourcing can reduce costs for:

- Specialized equipment requiring rare expertise

- Non-critical assets where downtime impact is minimal

- Peak demand periods requiring temporary capacity

- Regulatory inspections requiring certification

Evaluate each maintenance activity’s strategic value to optimize your resource allocation.

Measuring the Financial Impact

Demonstrating the value of preventive maintenance optimization requires tracking the right financial metrics.

ROI Calculation Framework

The data is clear: research shows preventive maintenance delivers an average 545% return on investment. Calculate your ROI using:

Investment Costs:

- CMMS software and technology

- Training and implementation

- Initial PM development time

- Condition monitoring equipment

Returns:

- Reduced emergency repair costs

- Decreased downtime losses

- Extended equipment life value

- Lower spare parts inventory

- Reduced energy consumption

- Avoided regulatory penalties

Most organizations achieve positive ROI within 8-16 months, with mature programs delivering annual returns of 300-500%.

Cost Avoidance Tracking

Not all savings appear directly in budgets. Track cost avoidance through:

- Prevented failures and their associated costs

- Avoided overtime and contractor expenses

- Prevented production losses

- Reduced warranty claims

- Avoided safety incidents

These “soft savings” often exceed direct cost reductions by 2-3 times.

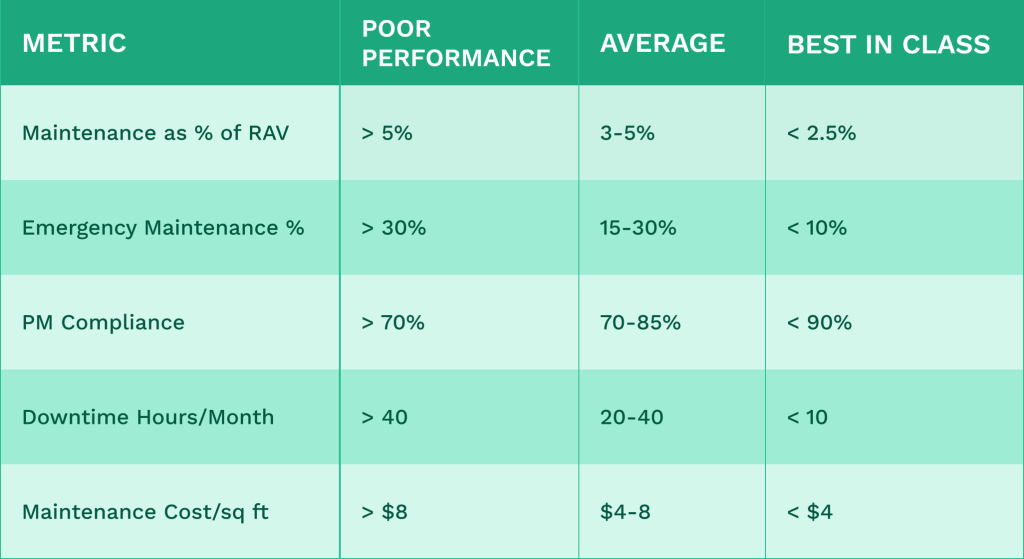

Benchmarking Performance

Compare your maintenance costs against industry standards:

WorkTrek’s reporting capabilities automatically track these benchmarks, providing real-time visibility into your cost optimization progress.

Overcoming Common Cost Optimization Challenges

Even proven strategies face implementation obstacles. Here’s how to overcome them:

Challenge: Budget Constraints

Solution:

Start small with the highest-ROI opportunities. Focus on critical equipment where failure costs are extreme. Use early wins to justify expanded investment. WorkTrek’s flexible pricing enables gradual scaling as savings accumulate.

Challenge: Resistance to Change

Solution:

Demonstrate value through pilot programs. Share success stories from similar organizations. Involve skeptics in planning to build buy-in. Celebrate cost savings publicly.

Challenge: Data Quality Issues

Solution:

Don’t wait for perfect data. Start collecting high-quality data moving forward, using industry benchmarks to identify gaps. Implement data validation processes to ensure accuracy.

Challenge: Competing Priorities

Solution:

Frame preventive maintenance as protecting production, not competing with it. Show how PM prevents the emergency repairs that truly disrupt operations. Make cost savings visible to leadership.

Conclusion

How preventive maintenance optimization reduces maintenance costs isn’t a mystery. When you prevent failures, extend equipment life, and operate efficiently, costs naturally decline.

Yet many organizations continue accepting excessive maintenance costs as inevitable.

The truth is, reducing maintenance costs through preventive maintenance optimization isn’t just possible, it’s proven.

Organizations worldwide are achieving these results daily using the strategies outlined here.

With the right preventive maintenance strategy, supported by technology like WorkTrek’s comprehensive CMMS platform, you can join the ranks of organizations that have transformed maintenance from a cost center into a competitive advantage.

The question isn’t whether a preventive maintenance plan can be optimized to reduce your costs. It’s how quickly you’ll start capturing these savings.

Every day of delay costs money. Every reactive repair drains your budget. Every missed PM task increases future expenses.

Start optimizing today. Your bottom line will thank you.