Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- OSHA increased its penalties, raising the maximum fine from $16,131 to $16,550.

- A U.S. beverage packaging firm saved $1 million on spare parts by digitizing its records.

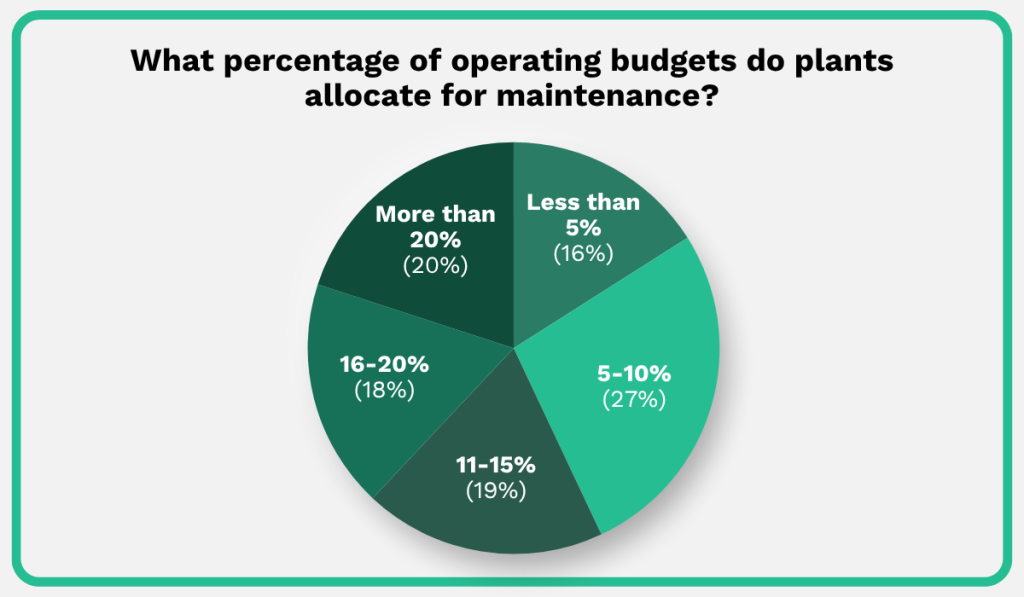

- Plants allocate between 5% and 20% of their annual operating budget to maintenance.

Maintenance record-keeping. Not the most exciting part of the job, right?

But by optimizing this one process, you could save thousands, even hundreds of thousands of dollars, all while improving operational efficiency and productivity.

That’s right. Your upkeep records hold that kind of power.

Want to know more?

Keep reading to discover all the benefits of effective maintenance record-keeping.

Streamlined Maintenance Planning

By keeping detailed records of past maintenance, including dates, service types, parts replaced, and recurring issues, you can schedule future maintenance more efficiently.

More specifically, you can allocate maintenance staff and resources more strategically, avoiding over- or undermaintaining your valuable assets.

This ultimately boosts operational efficiency and reduces that costly unplanned downtime.

The planning process is even smoother with a CMMS solution, which stores all documentation in one digital location and automatically updates information.

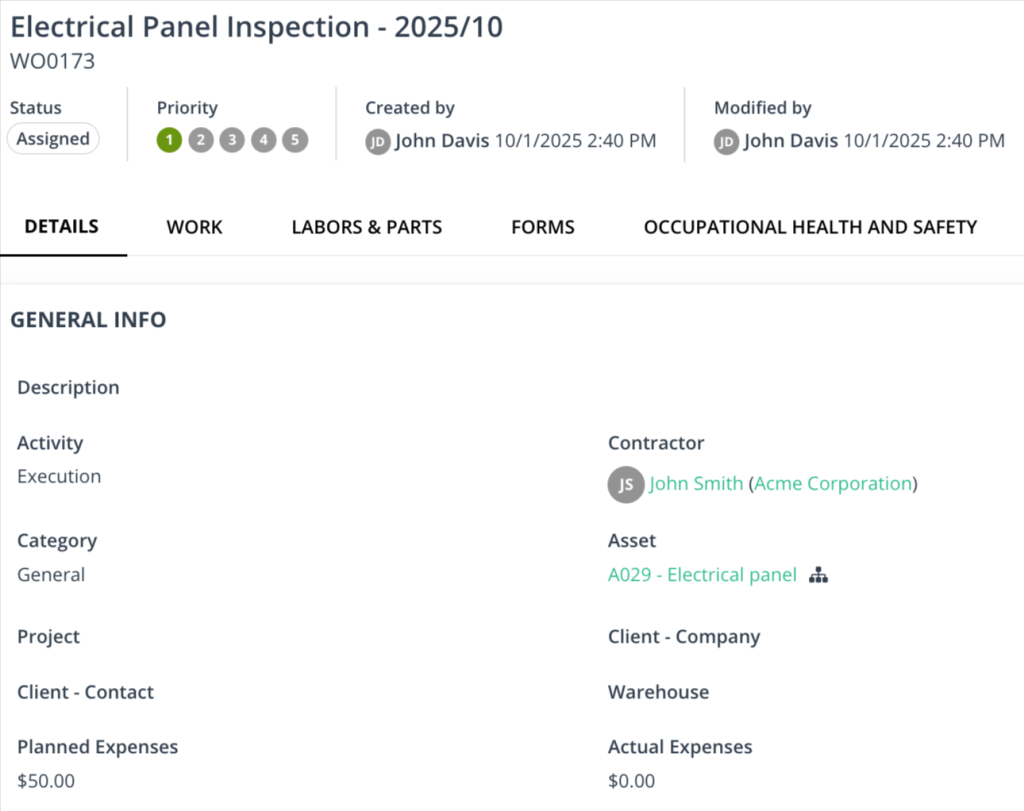

Take our own CMMS solution, WorkTrek, for example.

It lets you easily view all past, present, and upcoming tasks, work orders, and requests, along with their relevant details.

You can quickly check who the contractors and supervisors were, how much each job cost, how long it took, what the issue was, where it occurred, and even view photos of the problem.

These records can also be updated in real time by the responsible personnel through our mobile app.

Over time, these detailed documents help you create a complete overview of your upkeep activities, assets, and recurring issues, making it easier to plan future work and identify problem areas.

Take it from Matjaž Valenčič, Operations & Maintenance Manager at interEnergo, an international Ljubljana-based energy company.

Thanks to WorkTrek’s efficient record-keeping, they were able to eliminate inefficiencies in their information management processes and gained full control over their operations.

Valenčič explains:

“Before using WorkTrek, we had most of the data on assets in Excel and various documents and had to rely on people to carry out timely service, which sometimes resulted in mistakes, power plant shutdowns, loss of profit, and safety risks.”

With WorkTrek, such issues are a thing of the past.

It keeps your records accurate, complete, and up to date, giving you full visibility into your operations and enabling strategic planning for maximum efficiency and cost-effectiveness.

Increased Workplace Safety

Maintenance records don’t just track repair histories.

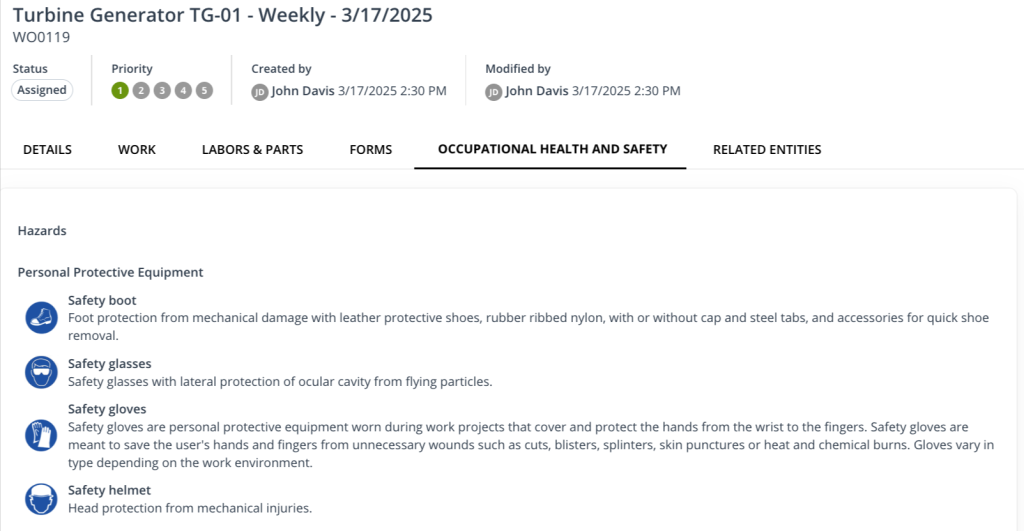

They can also include step-by-step instructions, LOTO procedures, and PPE or safety reminders for each asset or task, all of which play a major role in keeping operations safe.

Digitized records make it even easier.

Supervisors can typically attach safety instructions directly to work orders, ensuring technicians always have the correct procedures right in front of them:

So, instead of digging through piles of paperwork and binders to find the right information, they can access everything instantly on their phone or desktop.

And when workers have all the relevant information right in front of them, they’re far more likely to follow the necessary steps correctly.

That means fewer mistakes, fewer shortcuts, and fewer accidents and injuries.

In short, with accurate and accessible record-keeping, you’ll finally stop hearing excuses like “I didn’t know.”

Kristen Panella, founder of 2SAFE Consulting, a firm specializing in safety training and industrial hygiene testing, explains that this very lack of knowledge is often what leads to accidents.

In fact, he has witnessed it firsthand during his many years of work as a safety consultant:

“Let’s say an electrician is working at a facility […] There’s often no set SOP for that individual to follow that would give him the knowledge: ‘I’m supposed to do this. I’m supposed to shut it off and lock it out and then work in there.’”

That’s where serious, sometimes life-threatening, problems occur.

However, when you record these instructions and make them easy to find, you transform how your team works.

Safety stops being an afterthought and becomes second nature. Everyone knows what to do and how to do it efficiently and safely.

Reliable Compliance Assurance

For many industries, maintenance records aren’t optional.

Regulations from agencies such as OSHA, ISO standards, and environmental authorities require proof that inspections and repairs are conducted in accordance with established standards.

Daren Hansen, Sr. Editor of Transportation Safety at J. J. Keller & Associates, Inc., a consulting firm for the transportation industry, sums it up well:

That’s right. Ensuring compliance is only half the job.

You must also be able to prove it, which is where your maintenance records come in.

When records are complete, organized, accurate, and up to date, audits and inspections run more smoothly, protecting your organization from serious consequences.

The most common risks include legal action and fines, but they are only part of the story.

Paul Bullard, Product Director at SFG20, a building maintenance software solution, explains:

In other words, a lot is at stake. And that’s not changing anytime soon.

In fact, the consequences may only grow more severe.

For example, OSHA recently increased its penalties for 2025, raising the maximum fine for serious violations from $16,131 to $16,550.

With effective record-keeping, though, you don’t need to worry about unpleasant surprises like these.

Your records serve as clear, timestamped evidence that everything’s up to standard.

Even if something’s not, they’ll help you spot it long before an inspector does, giving you the chance to fix it fast and stay in control.

Improved Employee Accountability

Upkeep records provide a clear, trackable history of who performed which tasks.

This makes it easier to evaluate performance, assign responsibility, and ensure transparency.

And transparency encourages employees to perform tasks carefully and on time, minimizing errors and oversight.

Many digital maintenance management systems also track who used specific equipment, when, and where, prompting workers to handle company assets more responsibly.

Glenn Talbot, Managing Director at Verified, a QR code-based solution that provides actionable data and insights for visitor, contractor, and safety management, elaborates:

The bottom line is this: transparency through diligent record-keeping directly translates into higher employee accountability.

Take the Dallas Zoo, for example.

Before implementing effective document management, they had little visibility into what work was done and by whom.

Sheilah Spencir, the zoo’s Office Assistant, recalls:

“Maintenance was tracked on individual handwritten work requests. Often they would get lost […]. Assets were tracked on a spreadsheet by several individuals with varying amounts of information. Labor hours were not tracked or recorded.”

Once they went digital, everything changed.

They could now track each operator and technician’s performance in great detail.

Spencir noted:

This capability allowed them to identify inefficiencies early, make timely corrections, and boost overall worker productivity.

Optimized Inventory Management

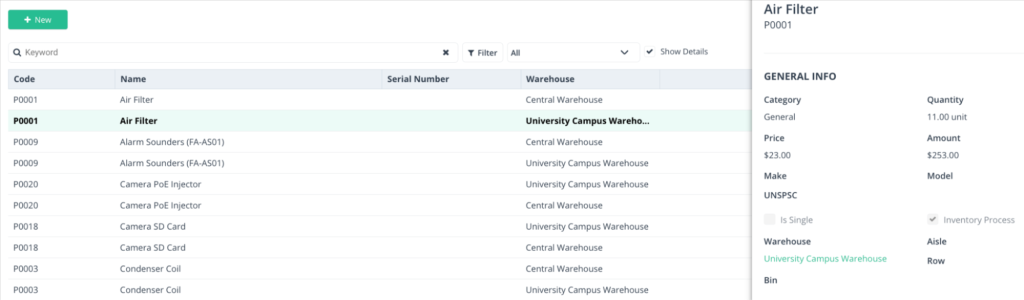

By carefully tracking parts usage, replacement schedules, and recurring issues, you can better predict which spare parts are needed and when.

Here’s what that might look like with a dedicated maintenance management solution:

This reduces excess inventory and associated costs while ensuring critical components are always on hand.

In other words, no more overstocking or understocking, all thanks to efficient record-keeping.

Nobody understands this better than Crown Cork & Seal, a U.S. beverage packaging company.

They saved $1 million on spare parts by digitizing their records.

Operating 16 beverage packaging facilities across the country, their inventory was previously unstandardized, and monitoring non-local sites was cumbersome.

Part requests involved lengthy phone calls and time-consuming searches through separate storerooms.

Everything was siloed.

However, with a digital system, all inventory data became centralized.

Technicians could easily search the records to locate and share parts stored at any location.

This eliminated the need for each plant to maintain a complete inventory, helping Crown avoid purchasing duplicate parts and saving $1 million over a few years.

The lesson here is clear: you don’t know what you don’t know.

Without proper tracking, you may be buying multiple parts and tools unnecessarily, overspending, and hurting your company’s profitability.

But with meticulous record-keeping, you gain transparency.

And with transparency comes more control and cost savings.

Simplified Warranty Claim Processing

Maintenance records provide all the information you need for successful warranty claim processing.

This includes:

- Proof of purchase

- The warranty document itself

- Details of the issue encountered

- Equipment details, such as model and serial number

- All operating, installation, and maintenance procedures required to keep the warranty valid

By carefully recording, organizing, and making these details easily retrievable, you increase the likelihood of successful warranty claims and reduce out-of-pocket repair costs.

After all, why spend more on maintenance than necessary? Maintenance is already costly.

For example, recent research shows that 64.4% of plants allocate 5%-20% of their annual operating budget to maintenance, while nearly 20% of facilities allocate over 20% of their budget to it.

Taking full advantage of warranties can help offset these costs, but only if you properly document everything.

Consider, for instance, Caterpillar’s warranties, which clearly state that the user is responsible for:

“Performance of all required maintenance and inspections at scheduled intervals per Caterpillar specifications.”

They also note that the company is not responsible for:

“Failures resulting from abuse, neglect, and/or improper storage or repair.”

How do you prove compliance? Only through diligent record-keeping.

Without detailed records, even valid claims can be denied, costing you time and money.

Increased Equipment Resale Value

A detailed maintenance history shows prospective buyers that the equipment you’re selling has been well cared for, building trust and confidence.

After all, when it comes to selling heavy equipment, buyers want one thing above all else: proof that the machine has been properly maintained.

Maintenance records provide exactly that, giving buyers a clear view of the equipment’s history, current condition, and future reliability potential.

According to the 2025 EquipmentWatch survey, interest in used equipment is growing, particularly in the construction industry.

This comes as no surprise, since buying used can be an attractive option for those seeking lower upfront costs and greater availability.

However, this doesn’t mean buyers are willing to purchase just anything.

Bleecker Wheeler, founder and cider maker at Watson Wheeler Cider, offers some insight from a buyer’s point of view:

Your maintenance records help establish that trust.

They detail all routine service, major repairs, and part replacements, demonstrating that the asset has been well-maintained, reducing buyer skepticism and, ultimately, justifying a higher price.

Conclusion

Effective maintenance record-keeping offers numerous benefits, but only if it’s done right.

That means minimizing manual entry, enabling real-time updates, ensuring easy access, and, most importantly, maintaining data accuracy.

The best way to achieve this is to move away from outdated manual methods, such as paper logs, and adopt a modern maintenance management system.

These digital solutions are fast, efficient, and virtually error-free.

Most also include data analytics features that automatically review your records, identify trends, and provide actionable insights.

So, if you haven’t already, consider digitizing your maintenance records and watch your operations transform beyond your imagination.