Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- Without proper maintenance, boilers lose approximately 5% of their efficiency per year, directly increasing fuel consumption and energy costs.

- The global industrial boiler maintenance market was valued at $20.9 billion in 2023 and is projected to reach $32.7 billion by 2032.

- Upgrading to high-efficiency boilers through proper maintenance can reduce natural gas consumption in commercial buildings by up to 30% annually.

Industrial boilers are the workhorses of manufacturing, healthcare, hospitality, and countless other sectors. They generate the steam and hot water essential for heating, power generation, and critical industrial processes that keep operations running smoothly.

But here’s what many facility managers overlook: even the most reliable boiler systems require consistent, structured maintenance to operate safely, efficiently, and reliably.

Without it, you’re not just risking unexpected breakdowns and costly emergency repairs. Additionally, you’re also watching energy efficiency decline, fuel consumption rise, and your equipment’s lifespan shorten.

According to research from W.H. Riley & Son, a poorly maintained boiler can lose about 5% of its efficiency each year. That means higher energy bills, increased fuel consumption, and more wear on critical components.

This guide provides a comprehensive industrial boiler maintenance checklist based on industry best practices, manufacturer recommendations, and insights from maintenance experts. Whether you manage a commercial boiler in a hospital, a steam boiler in a manufacturing plant, or multiple boiler systems across facilities, this checklist will help you maintain optimal performance and prevent costly downtime.

Why Regular Boiler Maintenance Matters

Before diving into the checklist, let’s examine why routine boiler maintenance deserves your attention and investment.

Safety First: Preventing Catastrophic Failures

Boiler safety isn’t just about compliance—it’s about protecting lives and property.

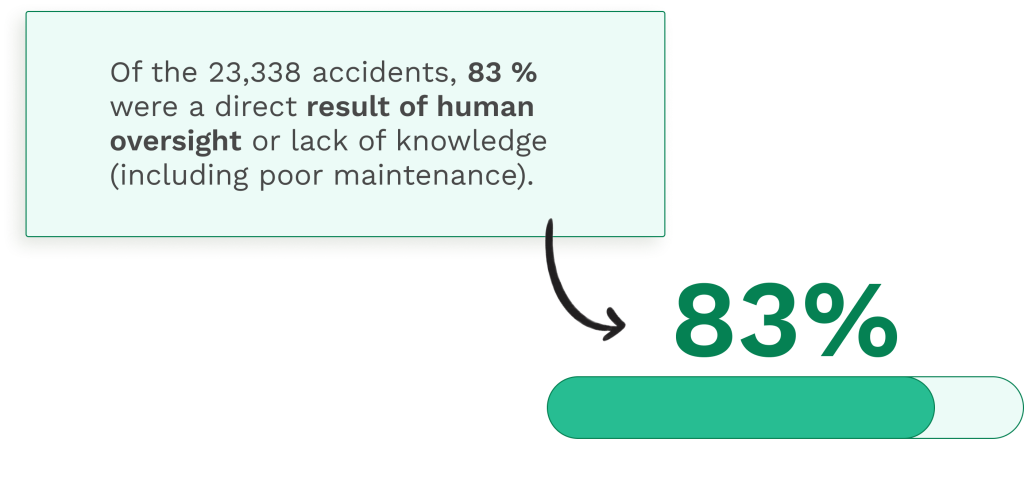

According to Joel Amato, Executive Director at The National Board of Boiler & Pressure Vessel Inspectors (NBBI), poor maintenance practices and defective low water cutoffs are the primary culprits behind most boiler incidents, including serious events that result in injuries and building damage.

The consequences of neglecting maintenance can be severe.

Boiler explosions, though relatively rare, typically result from pressure buildup when safety systems fail or maintenance is deferred. Regular inspection of safety valves, pressure relief valves, and operating controls helps prevent these potentially catastrophic events.

Beyond explosions, poorly maintained boilers pose other serious safety risks, including carbon monoxide leaks from cracked heat exchangers or faulty venting systems. This is why safety checks must be central to any preventive boiler maintenance program.

Energy Efficiency and Cost Savings

Energy efficiency directly impacts your bottom line.

Research from the American Council for an Energy-Efficient Economy (ACEEE) shows that upgrading to high-efficiency boilers and maintaining them properly can reduce natural gas consumption in commercial buildings by up to 30% annually.

Even without replacing your entire system, proper maintenance delivers substantial savings. A well-maintained boiler operates efficiently, consuming less fuel to produce the same amount of heat or steam.

Regular cleaning of burner assemblies, heat exchangers, and flue gas vent piping prevents the buildup of soot and scale that forces your boiler to work harder.

Tuning combustion air and fuel oil levels ensures optimal combustion, while testing and calibrating operating controls keep everything running at peak performance.

These maintenance activities translate directly to cost savings through reduced fuel consumption, lower energy bills, and fewer emergency repairs.

Equipment Longevity and Reliability

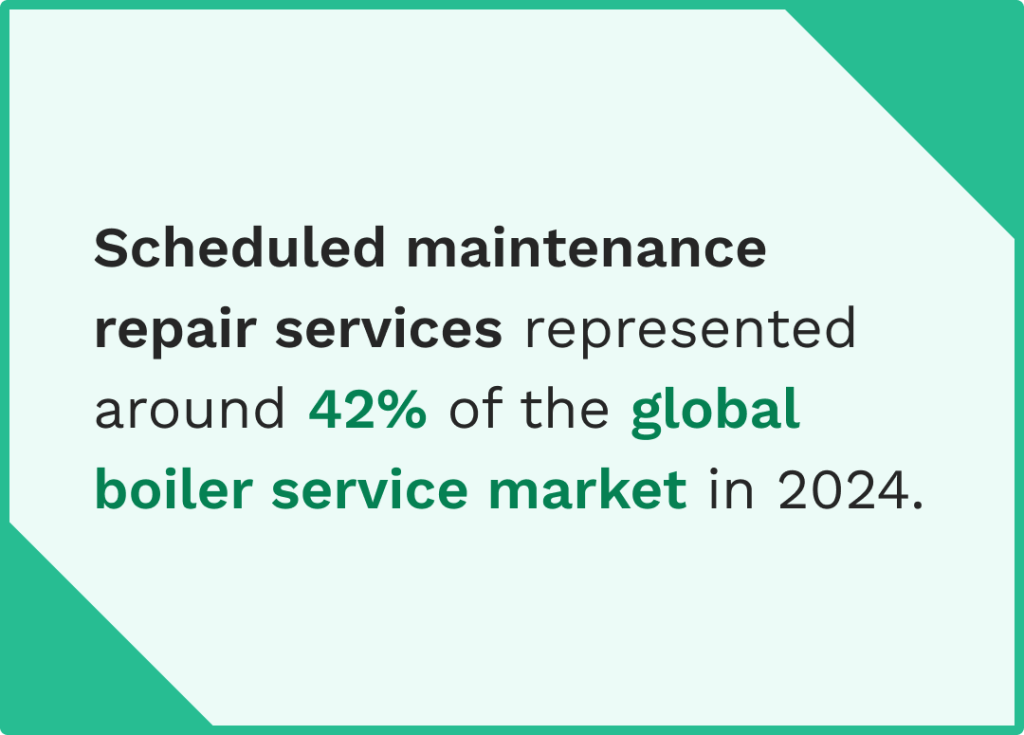

The global industrial boiler maintenance market was valued at $20.9 billion in 2023, demonstrating how seriously organizations worldwide take equipment preservation.

Regular maintenance extends boiler life significantly. Commercial boilers typically last 15-20 years with proper care, but neglect can cut that lifespan in half.

When you consider that boiler replacement costs range from $3,700 to $12,000 for most systems, and considerably more for large industrial installations, the investment in preventive maintenance becomes obvious.

Scheduled inspections catch small issues before they escalate into major failures. A worn gasket identified during routine inspection might cost $50 to replace. That same gasket, if left unchecked, could fail during operation, causing water damage, extended downtime, and hundreds or thousands of dollars in emergency repairs.

Understanding Your Boiler System Components

Before implementing a maintenance checklist, you need to understand the key components that require regular attention.

Critical Safety Components

Safety Relief Valves and Pressure Relief Valves

These critical safety devices regulate pressure levels in your boiler system. The safety release valve automatically opens to release excess pressure when the system exceeds safe operating thresholds, preventing dangerous pressure buildup. Regular testing ensures these valves function properly when needed.

Low Water Cutoff Devices (LWCO and ALWCO)

The low water cutoff automatically shuts down the burner when water levels drop too low, preventing catastrophic damage to the boiler. The auxiliary low water cutoff (ALWCO) provides additional protection. Testing these devices regularly is essential—many boiler failures occur when LWCOs malfunction.

Safety Controls and Operating Controls

Every boiler has maximum pressure and temperature limits enforced by safety controls. If these thresholds are exceeded, the fuel supply automatically cuts off. Operating controls manage routine functions like burner control switches and system valves, ensuring smooth operation within normal parameters.

Heat Generation and Transfer Components

Burner Assembly and Combustion Chamber

The burner assembly mixes combustion air with fuel (natural gas, fuel oil, or other sources) and ignites it in the combustion chamber, generating the heat needed to turn water into steam or hot water. The burner flame should burn cleanly and consistently—irregularities indicate problems with fuel supply, air dampers, or burner controls that require attention.

Heat Exchanger

The heat exchanger transfers heat from combustion gases to the water or steam. In fire-tube boilers, hot gases pass through tubes surrounded by water. In water-tube boilers, water flows through tubes exposed to combustion gases. Scale buildup or damage to the heat exchanger dramatically reduces boiler efficiency.

Flue Gas Vent Piping and Venting System

The venting system safely removes combustion byproducts from the boiler room. Proper maintenance of flue gas vent piping prevents dangerous gas buildup and ensures the boiler operates efficiently. Blockages from debris, ice, or snow can cause poor combustion and safety hazards.

Water and Steam System Components

Boiler Hydronic Piping and Steam Piping

This network of pipes distributes hot water or steam throughout your facility and returns condensate back to the boiler. Regular inspections for leaks, corrosion, and proper insulation help keep your heating system functioning reliably.

Water Level Glass Gauge

The gauge glass provides a visual indication of water levels inside the boiler. Maintaining proper water levels is crucial—too little water can damage the boiler, while too much reduces efficiency and can cause water hammer.

Condensate System and Blowdown Separator

The condensate system collects and returns condensed steam to the boiler, improving efficiency. The blowdown separator removes impurities from the boiler, preventing scale buildup and maintaining water quality.

The Comprehensive Industrial Boiler Maintenance Checklist

Now, let’s break down the specific maintenance tasks you should perform at different intervals. This checklist combines recommendations from industry experts, manufacturer guidelines, and established best practices, as well as insights from HVAC maintenance statistics that highlight the benefits of preventive maintenance.

Daily Maintenance Tasks

Performing these quick daily checks takes less than 30 minutes but can prevent major issues:

Visual Inspection of Boiler Equipment

Walk around your boiler system each day, looking for water leaks, unusual vibrations, or abnormal noises.

Check boiler equipment, components, and piping for any signs of water pooling, rust stains, or mineral deposits. Early detection of leaks prevents water damage and identifies failing gaskets or connections before they cause major problems. Following a preventive maintenance checklist can help ensure these issues are caught early and addressed promptly.

Check Fuel Oil Levels and Fuel Supply

For oil-fired boilers, verify that the fuel oil level is adequate in your tank. Running out of fuel can introduce air into the system, requiring burner purging and potentially damaging fuel pumps. For natural gas systems, ensure proper gas pressure and that all automatic draft controllers function correctly.

Monitor Water Level Glass Gauge

Check the water level glass gauge to ensure the water level remains within the manufacturer’s recommended range. Proper water levels are essential for safe boiler operation—too low risks damage to the heat exchanger, while too high reduces steam quality.

Record Pressure Gauge and Temperature Readings

Document boiler pressure and temperature readings in your logbook. These records help identify trends that might indicate developing problems. Ensure all readings fall within the manufacturer-specified operating ranges.

Inspect Burner Flame

Examine the burner flame through the sight port. The flame should burn cleanly with consistent color and pattern. A yellow or sooty flame indicates poor combustion, while an irregular flame suggests problems with burner controls, fuel delivery, or air dampers.

Check Venting System

Visually inspect the flue gas vent piping and venting system to ensure no blockages from debris, ice, or snow obstruct proper venting. Check the combustion air opening for obstructions that could affect air inlet flow.

Verify Display Panel and Service Codes

Check the display panel for any error codes or service notifications. Modern boilers alert operators to potential issues through diagnostic codes—promptly addressing these prevents minor problems from escalating.

Test Safety Valves

Ensure that all safety valves, including the boiler relief valve, remain free from obstruction and ready to operate if needed.

Weekly Maintenance Tasks

Weekly tasks require more detailed attention to critical components:

Test Low Water Cutoff Operation

Open the boiler blowdown valve to remove rust and sediment from the boiler mud leg or drum. Observe the burner—it should shut off automatically when the water reaches the low-water point in the sight glass. Record this test in your logbook. Testing LWCO and ALWCO operation weekly ensures these critical safety devices function when needed.

Inspect Pilot Assembly and Burner Components

For systems with pilot lights, check the pilot assembly. Center the ignition electrode in the igniter body, inspect and clean the ignition electrode if necessary, and examine the high-tension wire between the transformer and electrode for deterioration.

Test Control Circuit Operation

Verify all phases of the control circuit operate properly. Test the burner control switch and other burner controls to ensure they respond correctly to temperature and pressure changes.

Operate Manual Shutoff Valves

Exercise all burner manual shutoff valves to verify they work freely and properly. Lubricate system valves if necessary. Valves that sit unused can seize, preventing emergency shutdown when needed.

Clean Oil Filters

For oil-fired systems, clean oil filters at least twice weekly. Clogged oil filters restrict fuel flow, causing poor combustion and potentially damaging fuel pumps.

Inspect Air Filters and Air Inlet

Check and clean air filters that supply combustion air to the burner. Restricted air flow affects combustion efficiency and can cause incomplete combustion, producing dangerous carbon monoxide.

Check Electrical Components

Inspect visible electrical connections, switches, and wiring for signs of wear, corrosion, or damage. Loose electrical connections can cause intermittent operation or complete system failure.

Monthly Maintenance Tasks

Monthly tasks involve more intensive inspection and adjustment:

Inspect Boiler Hydronic Piping

Conduct a thorough inspection of boiler hydronic piping, checking for leaks, corrosion, or signs of stress. Look for water stains or mineral buildup that indicate slow leaks.

Examine Burner Flame Characteristics as part of your equipment assessment, and consider utilizing predictive maintenance tools to enhance reliability and prevent downtime.

Beyond daily visual checks, monthly inspections should analyze burner flame color, shape, and consistency for any abnormalities that might indicate developing problems with combustion air piping, fuel supply, or burner assembly.

Test Automatic Draft Controllers

Verify that automatic draft controllers maintain proper draft pressure throughout the combustion cycle. Improper draft affects combustion efficiency and can cause poor boiler performance.

Check Gauge Glass and Water Treatment

Clean the water level glass gauge to ensure accurate readings. Test water treatment systems to verify proper chemical levels that prevent scale and corrosion.

Inspect Condensate System

For steam boilers, check the condensate system, including return lines, pumps, and receivers. Verify the blowdown separator operates correctly.

Test Burner’s Pilot Tube and Ignition System

Inspect the burner’s pilot tube for blockages or damage. Test the complete ignition sequence to ensure reliable startup.

Clean Air Filters and Combustion Air Piping

Replace or thoroughly clean air filters. Inspect combustion air piping for obstructions or damage that could restrict airflow.

Recalibrate Operating Controls with work order software

Monthly recalibration of thermostats, pressure controls, and level controls maintains boiler efficiency. Use calibrated instruments to adjust controls to manufacturer specifications.

Inspect Burner Refractory Material

Check burner refractory material in the combustion chamber for cracks, fallen chunks, or deterioration. Damaged refractory affects combustion efficiency and heat transfer.

Review Manufacturer Recommended Maintenance and learn how to build a predictive maintenance program

Review the manufacturer’s operation and maintenance manual to ensure all manufacturer-recommended maintenance tasks are up to date. Different boiler systems may have specific requirements beyond general guidelines.

Periodic Maintenance (Quarterly/Seasonal)

Quarterly or seasonal inspections address issues that develop over longer periods:

Test Water Levels Using Low Water Cutoff Devices

Conduct comprehensive testing of all low-water cutoff devices to ensure they operate within the manufacturer’s recommended levels under various conditions and to support the continuous operation of critical equipment.

Clean Control Piping Plugs

Remove, inspect, clean, and reinstall plugs in the control piping to prevent blockages that affect system operation.

Reset Combustion Using a Combustion Analyzer

Use a combustion analyzer to measure oxygen, carbon monoxide, and nitrogen oxide emissions. Adjust air-to-fuel ratios and other settings to optimize combustion efficiency. This periodic maintenance task significantly impacts fuel consumption and operating costs.

Check Scaling and Corrosion

Inspect inside boiler components for scale buildup and assess corrosion levels in the boiler and transport tubes. Scale acts as insulation, reducing heat transfer and forcing the boiler to consume more fuel to achieve the same output.

Inspect Boiler Pumps

Check the operational characteristics of various boiler pumps, including feedwater pumps, circulation pumps, and condensate pumps. Listen for unusual noises and verify proper operation.

Verify Gas Train Components

For gas-fired systems, inspect the gas train, including valves, regulators, and pressure switches, to ensure safe, reliable fuel delivery.

Test Air Damper Operation

Verify that air dampers open and close properly throughout their full range of motion, maintaining proper combustion air flow under all operating conditions as part of your plant maintenance routine.

Annual Maintenance (Professional Service)

Annual maintenance tasks typically require certified technicians and more extensive system access:

Comprehensive Burner Inspection and Tuning

Have qualified service representatives thoroughly inspect, clean, and tune the burner assembly. This includes adjusting combustion for optimal performance, cleaning all burner components, and verifying proper valve operation.

Hydro Test Boiler

For efficient facility management, consider tools that streamline maintenance and inspection routines for hydro test boilers.

Conduct hydrostatic testing to verify boiler structural integrity. This test involves filling the boiler with water and pressurizing it above normal operating pressure (but not exceeding design pressure) to identify leaks in tube joints and piping.

Inspect and Clean Heat Exchanger

Professional cleaning of the heat exchanger removes soot and scale buildup from both fireside surfaces (combustion side) and waterside surfaces. This annual cleaning can restore significant efficiency losses.

Thoroughly Inspect Electrical Components

Technicians should check all electrical connections, switches, controls, and wiring throughout the boiler system. Test the amperage draw of electrical components and compare to the nameplate data.

Perform Non-Destructive Testing

Conduct non-destructive testing on critical boiler component materials to assess thickness, identify stress points, and detect hidden defects before they cause failures.

Inspect and Test Safety Relief Valves

Pressure vessel inspectors should pop-test safety relief valves annually to verify they open at the correct pressure settings and reseat properly. This testing ensures these critical safety devices will protect the boiler if operating pressure exceeds safe limits.

Clean and Inspect Refractory

Remove and replace any damaged burner refractory material and inspect fire brick linings for cracks or deterioration.

Comprehensive Cleaning

Professional service should include cleaning oil filters, air filters, flame sensor assemblies, and all accessible components. For oil-fired systems, clean and inspect fuel oil pumps and strainers.

Verify All System Valves

Test all manual and automatic valves throughout the system, including fuel supply valves, water feed valves, and steam or hot water distribution valves.

Check Steam Pressure and System Capacity

For steam boilers, verify that the system maintains proper steam pressure under various load conditions and that the steam pressure controls function correctly.

Review Emergency Preparedness

Annually review emergency procedures with staff and verify that all emergency shutoff switches, including the burner control switch, operate properly.

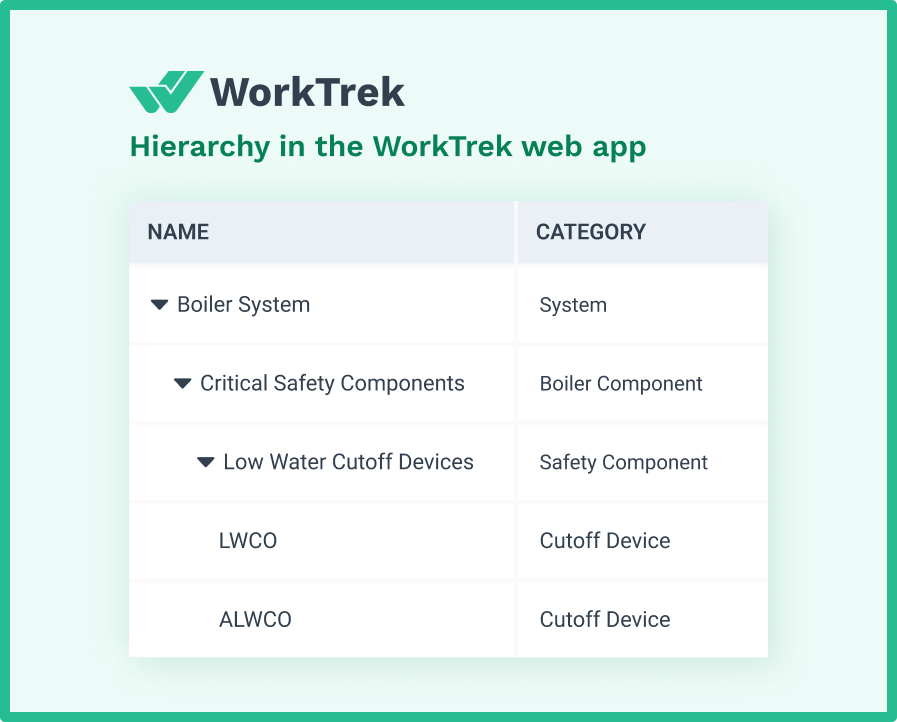

How CMMS Software Transforms Boiler Maintenance

Maintaining a comprehensive industrial boiler maintenance program, including daily, weekly, monthly, and annual tasks, can quickly become overwhelming. This is even more difficult if you manage multiple boiler systems or facilities.

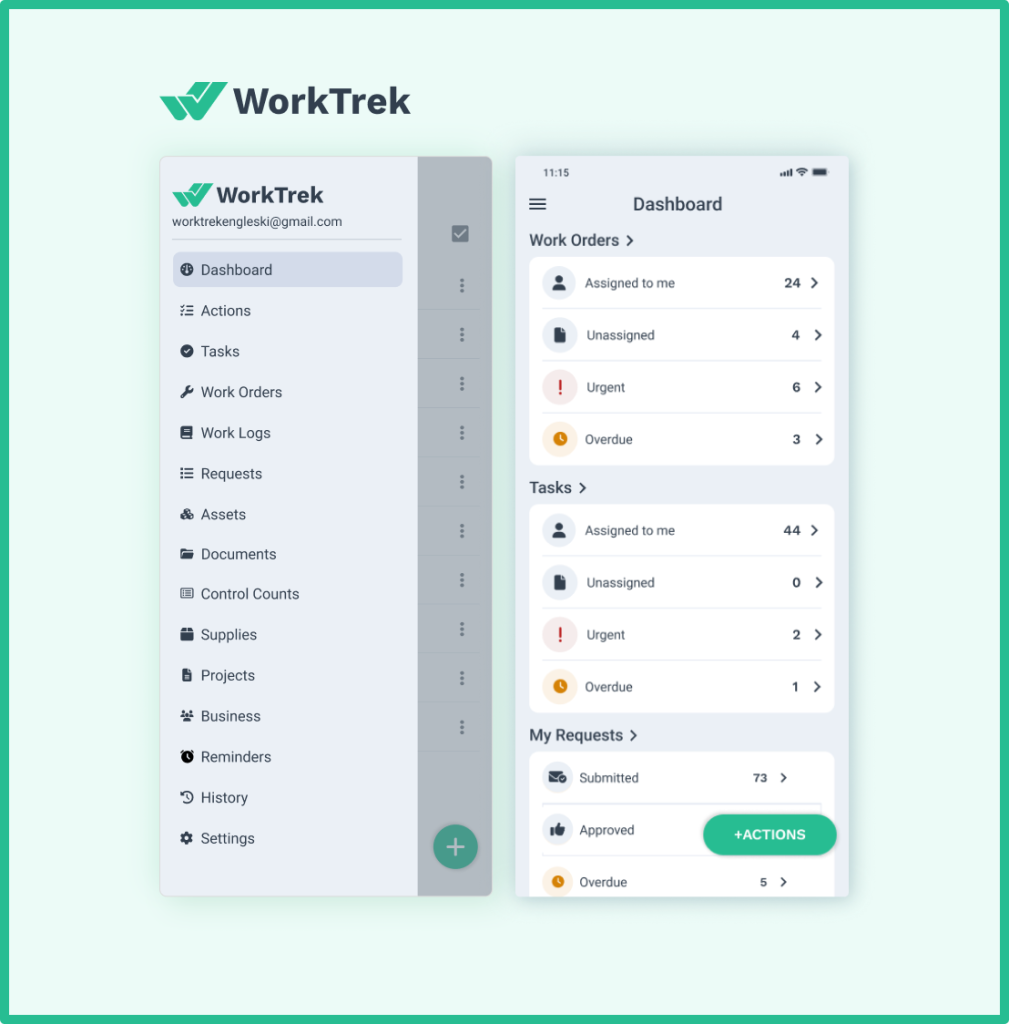

This is where Computerized Maintenance Management System (CMMS) software like WorkTrek makes a transformative difference. Rather than juggling spreadsheets, paper checklists, and calendar reminders, a CMMS centralizes all aspects of your boiler system maintenance on a single intelligent platform.

Automated Preventive Maintenance Scheduling

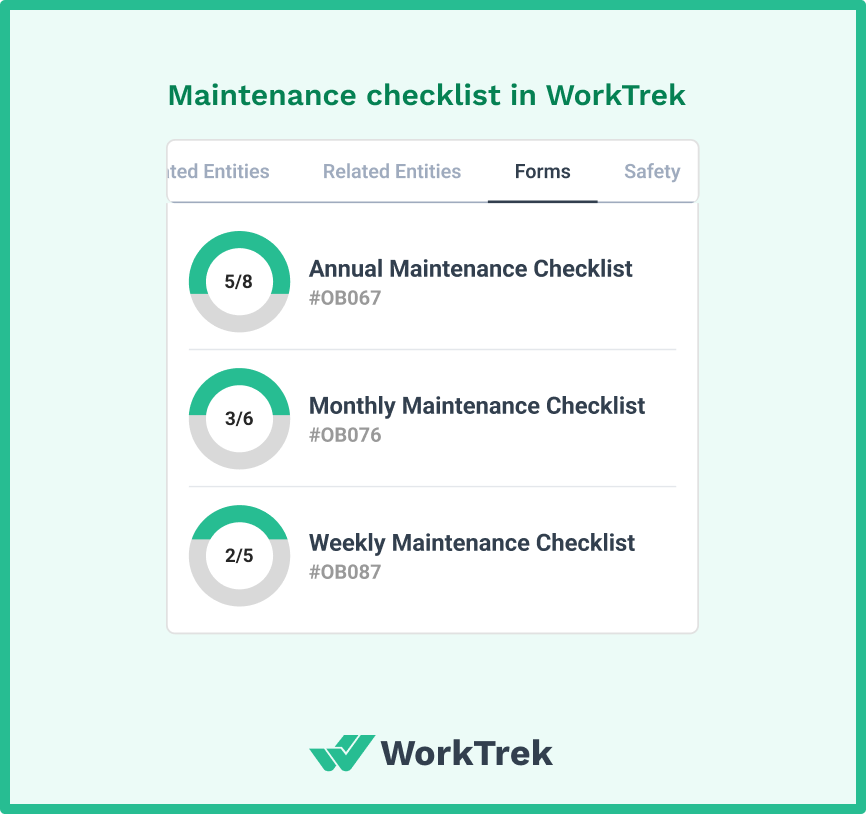

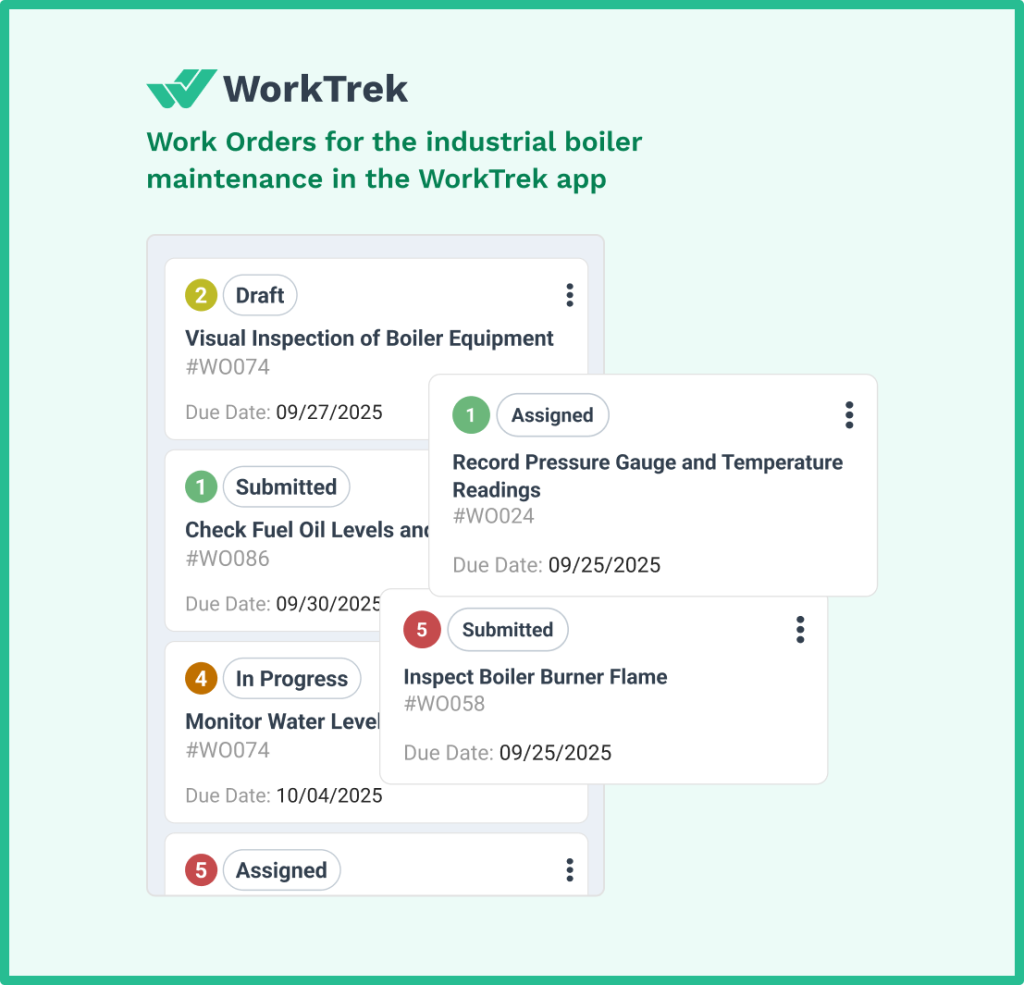

The core strength of a CMMS is its ability to automate preventive boiler maintenance scheduling.

Instead of manually tracking when each boiler requires service, the system automatically generates work orders based on time intervals, operating hours, or equipment conditions. When a steam boiler reaches its weekly LWCO testing interval or a commercial boiler is due for a monthly combustion analysis, the CMMS automatically creates the work order and assigns it to the appropriate technician.

This automation ensures no maintenance task falls through the cracks. According to industry research, companies using preventive maintenance software report significantly fewer unplanned downtime incidents and improved overall equipment reliability.

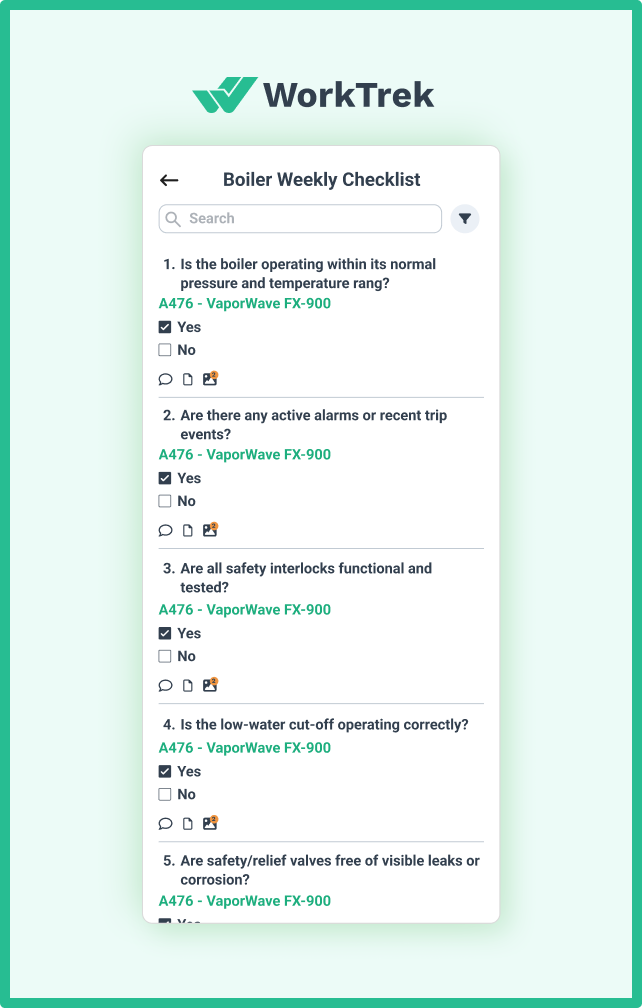

Digital Checklists for Consistent Execution

WorkTrek takes preventive boiler maintenance to the next level with digital maintenance checklists accessible via mobile devices.

Technicians performing routine boiler maintenance receive step-by-step instructions directly on their smartphone or tablet. Each checklist guides them through every required task—checking fuel oil levels, inspecting the burner flame, testing safety valves, recording pressure gauge readings, and documenting any issues discovered.

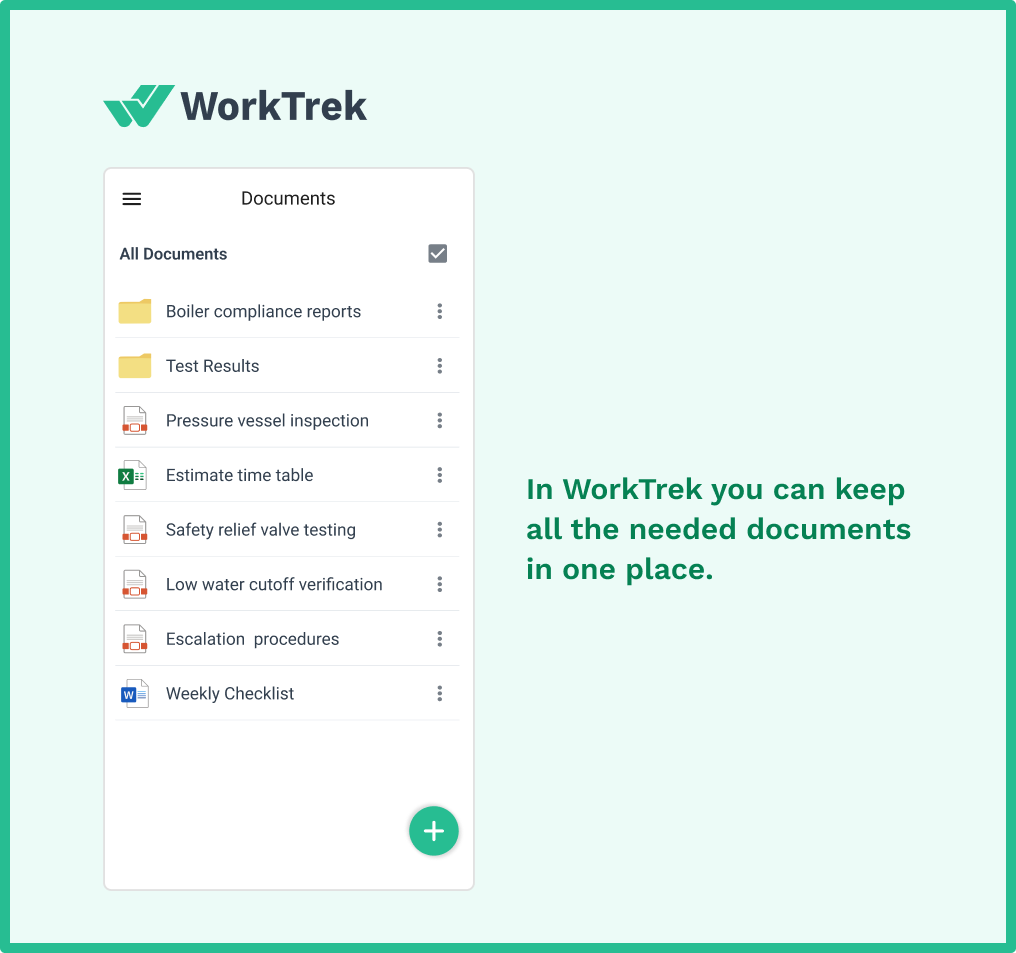

Complete Maintenance History and Asset Documentation

WorkTrek maintains comprehensive records for each boiler in your facility.

Every inspection, repair, part replacement, and service call is automatically logged with dates, technician notes, photos, and relevant documentation. This complete maintenance history proves invaluable when diagnosing recurring issues or planning major service.

The system stores manufacturer-recommended maintenance schedules, warranty information, operating manuals, and technical specifications for instant access. When a technician needs to reference the correct procedure for testing automatic draft controllers or find specifications for replacement parts, everything is available at their fingertips.

Predictive Maintenance Through Data Analysis

WorkTrek doesn’t just track maintenance—it helps you understand patterns and optimize your program.

By analyzing historical data on fuel consumption, repair frequency, and efficiency metrics, the system identifies trends that indicate developing problems. When a particular boiler shows a gradual increase in fuel consumption despite regular maintenance, it might indicate scaling in the heat exchanger or degrading burner refractory material, both of which require attention before causing a breakdown.

This data-driven approach shifts maintenance from reactive to truly preventive, catching issues in early stages when they’re easier and less expensive to address.

Inventory Management for Critical Spare Parts

Effective boiler system maintenance requires having the right parts available when needed.

WorkTrek’s inventory management tracks spare parts, consumables, and supplies specific to each boiler system. The software knows which parts are used in routine maintenance—oil filters, air filters, gaskets, burner components—and can automatically trigger reorder notifications when stock levels run low.

When an emergency repair requires a specific valve or control component, technicians can immediately check inventory availability rather than wasting time searching or ordering parts that might already be in stock.

Compliance Documentation and Reporting

Many industries face strict regulations around boiler safety, emissions, and maintenance documentation.

WorkTrek automatically generates compliance reports showing all required inspections, testing, and service activities. When pressure vessel inspectors need evidence of safety relief valve testing or auditors require proof of regular low water cutoff verification, WorkTrek produces comprehensive documentation instantly.

This automated compliance documentation reduces the administrative burden on your team while ensuring you meet all regulatory requirements.

Mobile Access for Maximum Efficiency

WorkTrek’s mobile capabilities transform how technicians perform boiler maintenance.

Rather than printing paper checklists, collecting readings on clipboards, and later transcribing everything into a computer system, technicians work directly in WorkTrek’s mobile app. They can:

- View their assigned boiler maintenance tasks

- Follow detailed digital checklists

- Record gauge readings and observations

- Take photos of issues or completed work

- Update work order status in real-time

- Access equipment manuals and technical documentation

- Order parts from inventory

This mobile-first approach eliminates duplicate data entry, reduces errors, and gives managers real-time visibility into maintenance progress across all facilities.

Conclusion

Industrial boiler maintenance isn’t optional—it’s essential for safety, efficiency, and long-term cost management.

A comprehensive maintenance program built around daily inspections, weekly testing, monthly service, and annual professional maintenance keeps your boiler systems running reliably while preventing costly failures from deferred maintenance.

The checklist outlined in this guide provides a solid foundation, but remember that every boiler system has unique requirements based on its type, age, fuel source, and operating conditions. Always consult the manufacturer’s recommended maintenance guidelines and work with certified professionals for complex tasks and annual service.

Technology has transformed maintenance management. Modern CMMS platforms like WorkTrek eliminate the manual tracking, paper documentation, and scheduling headaches that once made comprehensive preventive maintenance programs difficult to sustain.

By automating scheduling, standardizing procedures with digital checklists, maintaining complete equipment histories, and enabling mobile access for technicians, WorkTrek ensures your boiler system maintenance is consistent and complete—protecting your investment, your facility, and, most importantly, your people.