Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- Honda, GE, Boeing, and Toyota all use lean maintenance to increase productivity.

- 64% of consumers wish companies would respond faster to their needs.

- The majority of consumers will abandon a brand for a better-quality alternative.

The main goal of lean maintenance is to make upkeep processes smarter, faster, and more cost-effective.

In short, it makes them better.

But how does it actually work, and why should companies even care?

That’s exactly what this article sets out to uncover.

We’ll not only break down the benefits of lean maintenance, but also explore real-world examples of industry leaders that have put it into practice and reaped impressive results.

Ready to see what lean maintenance can really do?

Let’s begin.

Eliminates Waste in Maintenance Processes

Lean maintenance focuses on identifying and eliminating non-value-added activities in maintenance work, such as:

- Waiting for spare parts, permits, or approvals

- Unnecessary preventive maintenance

- Excess motion (searching for tools, poor layout)

- Rework due to poor repairs or lack of standards

These activities can consume significant time, money, and resources without improving asset reliability or performance.

They are more than just unnecessary. They are pure waste.

Take missing tools, for example.

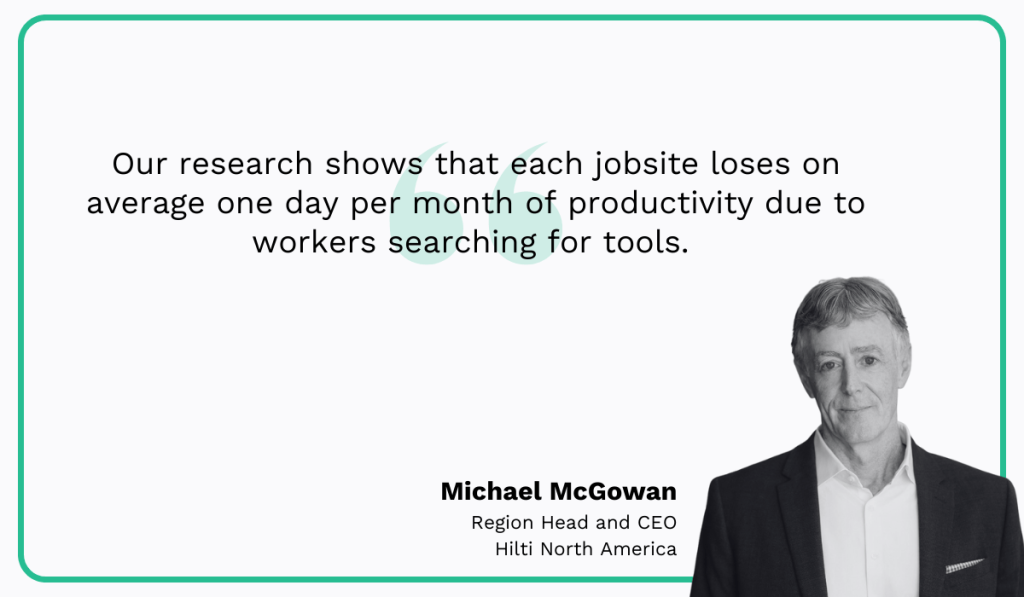

According to Michael McGowan, Region Head and CEO of Hilti North America, a provider of tools, software, and services for the construction industry, searching for tools can be extremely time-consuming:

That’s one full day not spent doing actual value-adding work.

Lean maintenance seeks to eliminate such inefficiencies, boosting a company’s productivity and agility.

Few organizations exemplify lean thinking better than Toyota, the pioneer of lean maintenance and manufacturing.

In 2025, Toyota updated its lean model by integrating digital tools to strengthen EV readiness and increase operational agility in an increasingly turbulent global landscape.

One key change was the implementation of digital twin technology, which simulates production flows, anticipates bottlenecks, and optimizes layouts, reducing even the need for physical travel.

Kevin Anderson, Toyota Senior Manager of Production Engineering, explained:

In short, this technology allows Toyota to plan work and allocate resources more strategically.

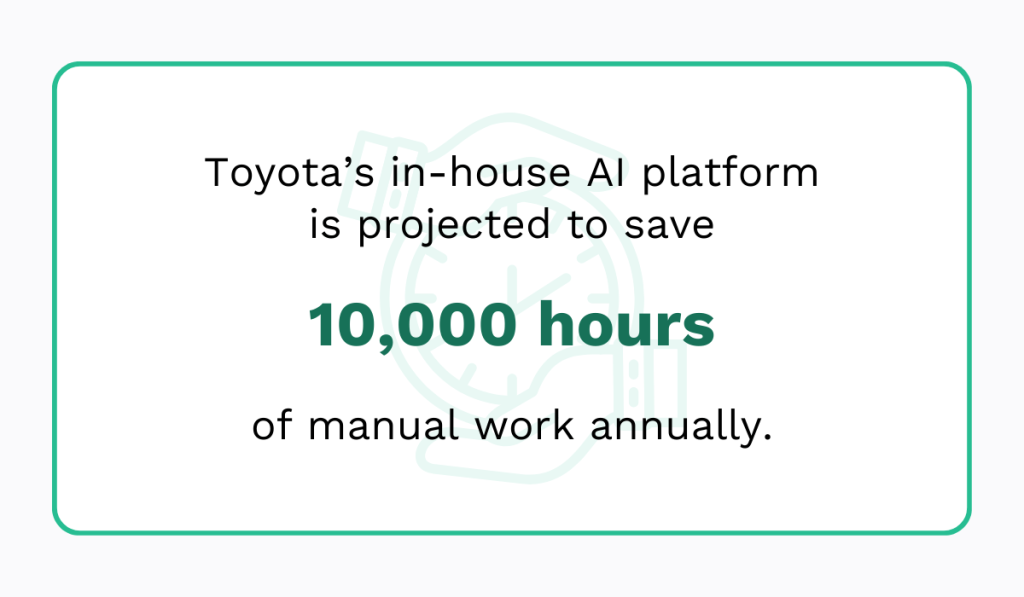

Alongside digital twins, Toyota also introduced predictive maintenance powered by IoT sensors and machine learning.

This system anticipates equipment failures, significantly reducing unplanned downtime and maintenance costs.

In fact, their AI platform is projected to save 10,000 hours of manual work annually, freeing employees to focus on higher-value problem-solving.

With this updated lean model, Toyota wastes less time, less money, and fewer resources.

It enables the company to produce more with existing assets, reduce risk, and reinvest savings into innovation and growth rather than constant firefighting.

Improves Equipment Uptime

Lean maintenance improves asset reliability and availability by prioritizing planned and condition-based upkeep, along with more strategic, efficient scheduling.

Such a proactive approach works because it addresses potential problems and major failure risks before they escalate into costly disruptions.

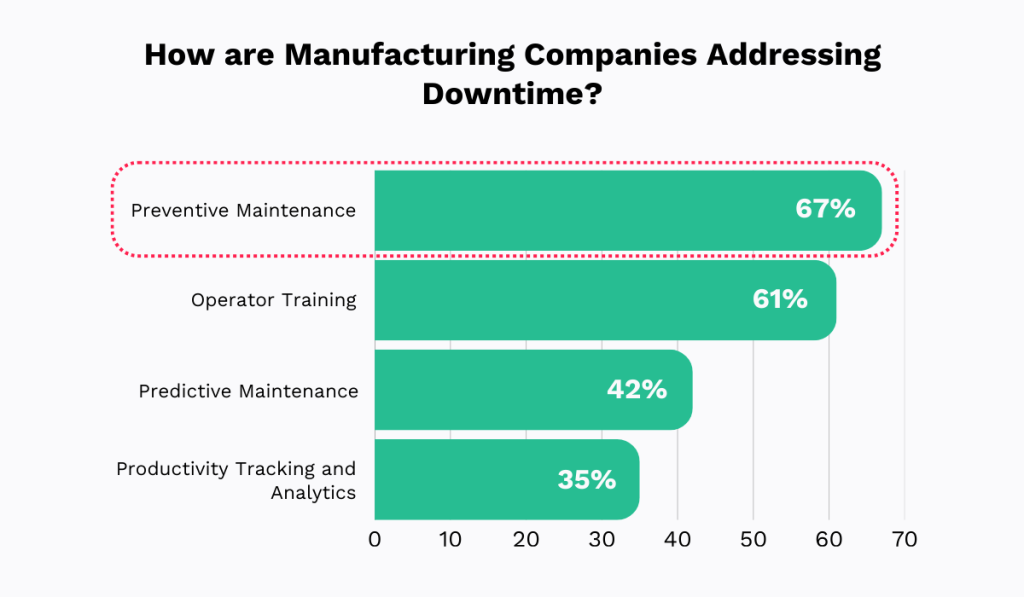

In fact, research shows that preventive maintenance is the primary strategy most manufacturing businesses use to reduce downtime.

To ensure efficient execution of planned maintenance, lean experts typically rely on computerized maintenance management systems (CMMS).

These digital platforms centralize maintenance data, supporting strategic planning and safe and efficient execution of maintenance tasks.

Take it from interEnergo, an international energy company based in Slovenia.

Before implementing a CMMS, their maintenance data was scattered across Excel files and various documents, and they depended heavily on individuals to perform tasks on time.

This often led to mistakes, power plant shutdowns, and reduced asset uptime.

However, all that changed after they implemented WorkTrek CMMS, explains Matjaž Valenčič, Operations & Maintenance Manager at interEnergo:

“WorkTrek gives us complete control over all maintenance activities on our assets so we can ensure that our energy plants and devices are safe and operate reliably, and in this way we achieve the desired return on investment.”

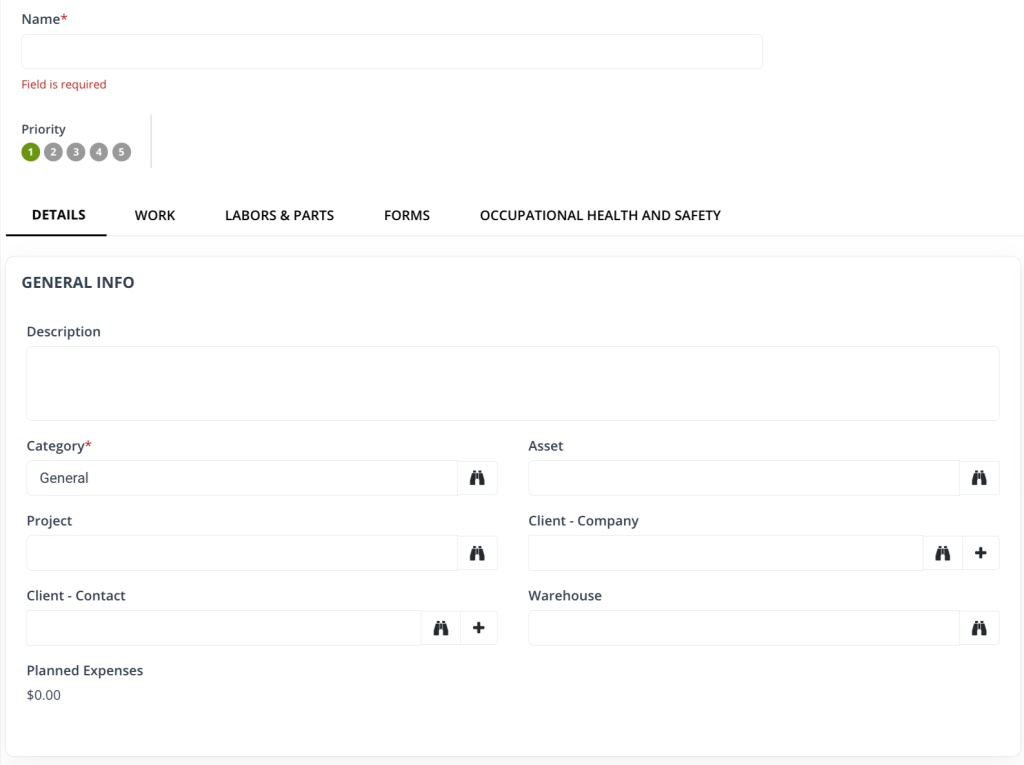

WorkTrek’s preventive maintenance feature allows them to create and schedule maintenance templates that include SOPs, checklists, photos, detailed instructions, and more.

These templates use customizable required fields, which means no work order can be submitted until all critical information is entered.

This ensures technicians have everything they need to perform their work safely and efficiently.

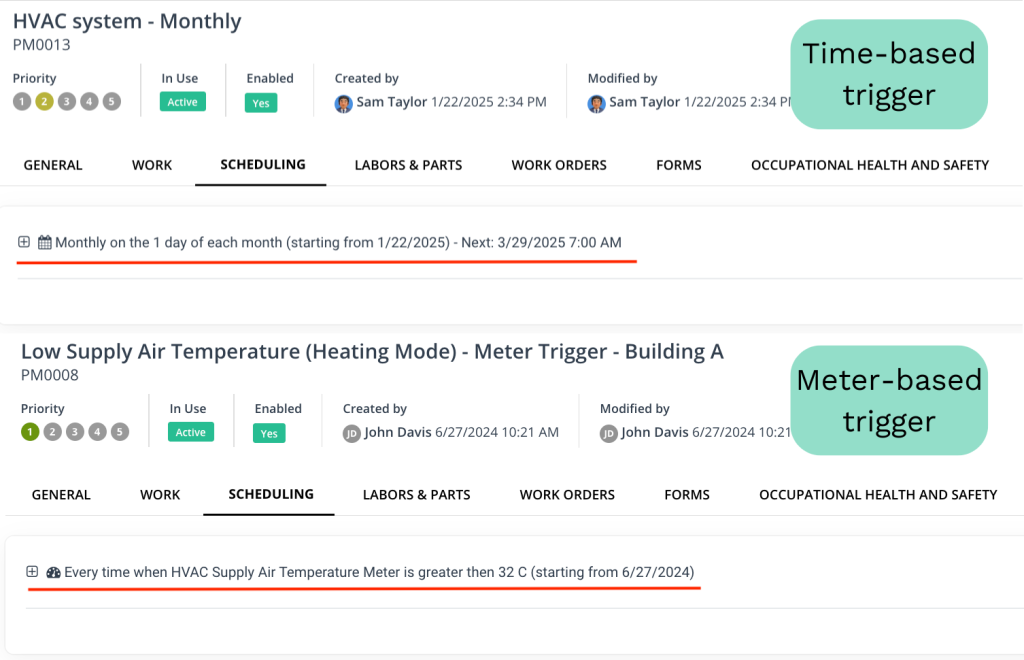

The platform also offers flexible scheduling options.

Users can choose time-based or meter-based triggers (such as temperature, mileage, or usage hours) and define planned durations and end rules.

When maintenance is due, the assigned worker receives a notification.

As a result, each asset receives timely care based on its actual needs, eliminating the risk of over-maintenance, under-maintenance, or missed tasks altogether.

The outcome is longer-lasting equipment, fewer breakdowns, and higher asset availability and productivity.

Reduces Lead Times

With lean maintenance, you don’t just improve task planning. You complete the work itself faster and more efficiently.

That’s because lean strategies emphasize clear prioritization and standardized workflows.

Workers know exactly what to do, when to do it, and how to do it, with a shared understanding of which assets and activities are most critical and which can take a back seat.

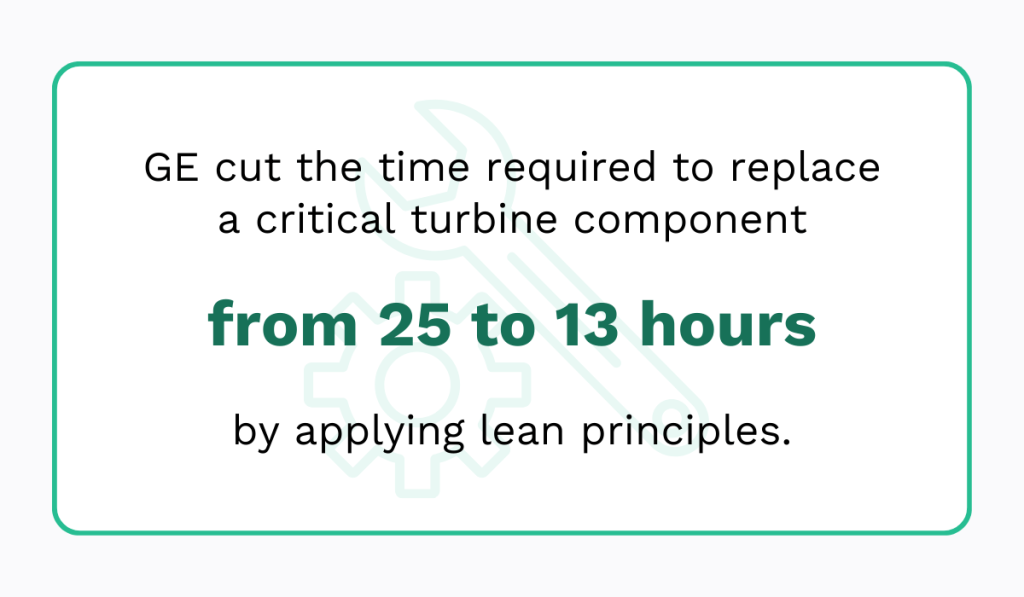

Few organizations understand the importance of this better than GE.

Its gas turbines are deployed around the world, and each requires regular maintenance that often forces power plants offline for weeks at a time.

Naturally, this makes careful planning essential to minimize disruption and restore operations as quickly as possible.

By applying lean principles, GE achieved exactly that, cutting the time required to replace a critical turbine component from 25 hours to just 13.

GE also digitized its SOPs and best practices, making them easily accessible and consistently reproducible across all facilities worldwide.

This initiative delivered a 20%–25% reduction in cycle time for core work.

As a result, outages that once lasted six weeks can now be completed in as little as four.

As Jeremiah Smedra, Operations Director at FieldCore, GE Gas Power’s field services unit, explains:

“By using lean management and simplifying our procedures, we put information in the hands of those doing the work, with an increased focus on safety and quality. This marks a massive shift from previous field practices, leading to continuous improvements in safety, quality, delivery, and cycle time.”

For power plant operators, these improvements mean getting back online faster, allowing them to produce power sooner, deliver electricity reliably, and generate revenue more quickly.

In short, faster repairs mean less disruption, greater agility, and a stronger ability to respond to customer needs.

That matters more than ever.

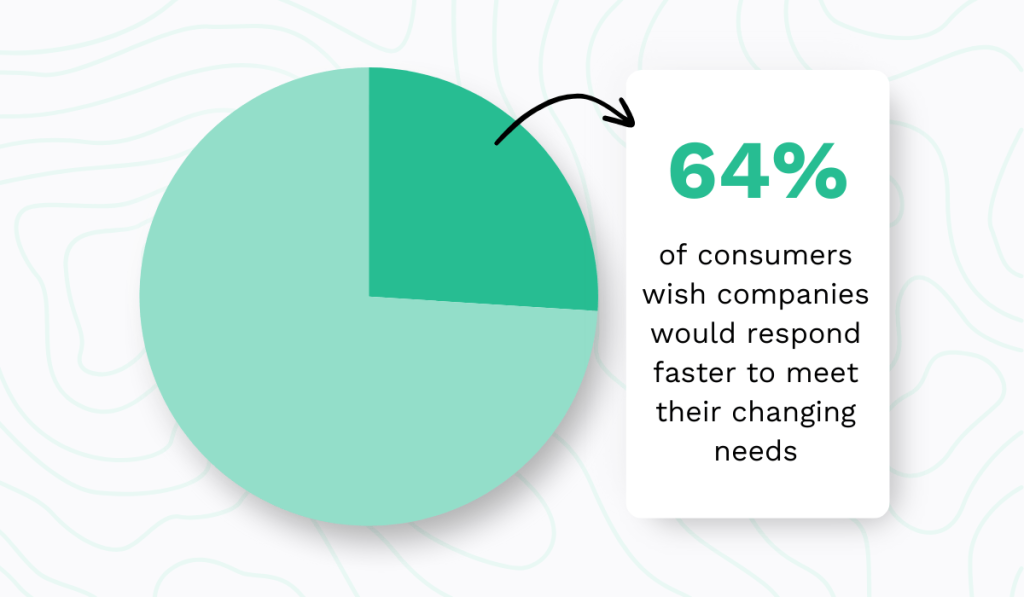

According to a 2022 Accenture survey, most consumers want companies to respond to their needs more quickly.

Lean maintenance helps organizations do exactly that, speeding up upkeep and ensuring they’re always prepared for whatever comes next.

Improves Safety

Lean maintenance emphasizes safe, standardized, and predictable work.

In lean operations, work orders always include detailed instructions, PPE requirements, hazard warnings, and lockout/tagout (LOTO) procedures.

This ensures technicians follow a consistent, proven approach every time, thus minimizing the risk of accidents and injuries.

Lean maintenance also leverages the 5S methodology for workplace organization, ensuring tools are properly stored, and work areas remain clean and free from obstructions.

The methodology consists of the following elements:

| Sort | Separate essential from non-essential items, removing unnecessary tools, parts, and clutter to free up space and minimize distractions. |

| Set in Order | Arrange necessary items logically so they are easy to find, use, and return, reducing wasted motion. |

| Shine | Clean the workspace and equipment regularly, treating cleaning as a form of inspection to detect issues like leaks or wear before they lead to breakdowns. |

| Standardize | Establish consistent procedures and visual controls (such as labels and color-coding) for the first three steps, turning them into habits. |

| Sustain | Build the discipline to maintain these standards through audits, training, and integration into the company culture, ensuring long-term success. |

While this approach may seem somewhat straightforward, it is highly effective at reducing slips, falls, and other common workplace accidents while also speeding up work.

Honda’s minivan and sport utility vehicle assembly plant in Lincoln, Alabama, is clear proof of this methodology’s effectiveness.

Their lean program prioritizes cleanliness and tidiness as key drivers of both safety and efficiency.

Paul V. Arnold, Digital Content Manager and Strategist at WorldatWork, described his 2018 tour of the facility as follows:

The overarching goal is to eliminate distractions that could pull employees’ attention away from their work.

That’s why Honda invests heavily in landscaping, common areas, and other aspects of the work environment.

Their Chief Technical Specialist at the time, Mark LaRue, explained it this way:

“You must have reliable utilities. You must have a comfortable workspace. You must have clean, functional common areas. That really sets the tone for how we want to be making a vehicle. We remove the distractions.”

There is no greater distraction than a safety incident.

However, at Honda, there is very little room for those, thanks to their commitment to cleanliness and organization.

As a result, employees feel safer and more valued, which boosts motivation and productivity while reducing turnover and recruitment costs.

After all, people are a company’s most valuable asset, and Honda understands this very well.

Helps Outpace Competition

Ultimately, lean maintenance directly supports operational excellence by giving organizations a sustained competitive advantage.

It drives lower maintenance and operating costs while improving equipment reliability and throughput, leading to higher product quality and faster responses to customer demand.

In short, it enables organizations to deliver products faster, cheaper, and more reliably than their competitors.

Just ask Boeing.

According to Scott Stocker, Vice President and General Manager of the 787 Program, lean is central to customer satisfaction:

“By reducing waste and streamlining processes, Lean helps increase efficiency and productivity. Every Lean improvement […] helps us deliver on our quality, safety, and on-time delivery commitments to our customers.”

However, lean maintenance isn’t only about meeting customer expectations.

At Boeing, it is also a powerful driver of innovation.

As Stocker explains:

By eliminating unnecessary work, he adds, teams are energized to think creatively and develop new solutions to the complex challenges of the aerospace industry.

This is what enables them to develop better, more relevant products for their customers.

After all, product quality is a decisive competitive factor.

According to Forbes, the majority of consumers are willing to switch brands for better quality and selection.

Overall, while many companies try to outperform competitors through pricing and marketing alone, lean maintenance enables organizations to win through superior execution.

It allows them to lower costs without cutting corners and increase reliability without adding assets, delivering the reliability, predictability, and stability customers value.

That’s how you keep winning over the long term.

Conclusion

Lean maintenance is more complex than a traditional time-based maintenance program.

It requires more than a static schedule. It calls for a company-wide mindset shift that prioritizes condition monitoring, efficiency, and waste reduction.

The effort, however, is well worth it.

Lean maintenance creates the space for organizations to innovate and lead, rather than constantly struggle to keep up with competitors.

In environments where speed, quality, and reliability define success, such as manufacturing, this is invaluable.