Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways

- Equipment failure costs industrial operations billions annually with most failures being preventable with proactive maintenance strategies

- Understanding failure modes—from gradual degradation to catastrophic failure—helps you build targeted prevention plans for critical assets

- Early detection through continuous monitoring and vibration analysis can identify potential failure weeks or months before equipment fails

- Proper operator training catches problems before they escalate into costly downtime

Equipment doesn’t just fail overnight. There’s almost always a warning sign. It can start with a strange noise here, unusual vibration there, or performance that’s steadily declining.

Yet despite these early signs, equipment breakdown remains one of the costliest challenges in industrial operations.

Here’s the reality: unplanned downtime costs industrial manufacturers an estimated $50 billion annually. That’s not a typo. Fifty billion dollars lost because equipment fails when you least expect it.

But here’s what most maintenance managers don’t realize, 70% of equipment failures follow predictable patterns that can be identified and prevented through systematic failure analysis.

This guide breaks down everything you need to know about equipment failure: what causes it, how to spot it early, and most importantly, how to prevent it before it derails your operations.

What Is Equipment Failure?

In simple terms, equipment failure happens when a machine or asset can no longer perform its intended function.

It’s not always dramatic. You know that a catastrophic failure that brings everything to a halt. Sometimes it’s subtle, like a gradual decline in performance that chips away at your operational efficiency.

You’ve probably seen both types.

There’s the sudden breakdown that stops production cold.

On the other there is a slower deterioration, like when the pump starts losing pressure, the motor starts running hotter than normal, or the conveyor belt develops an unusual wobble.

The distinction matters because different failure types require different prevention approaches.

For example, a bearing that’s slowly wearing out gives you time to schedule component replacement during planned downtime. An electrical fault that triggers immediate shutdown? That’s an emergency repair situation that costs you money, time, and productivity.

Research shows that organizations with mature maintenance programs experience 20% less downtime than those relying primarily on reactive repairs. The difference comes down to one thing: understanding why assets fail and catching problems early.

Common Types of Equipment Failure

Equipment can fail in several distinct ways, and recognizing these patterns helps you build a better maintenance strategy.

Wear and Tear Degradation

This is the most common cause of equipment failure in industrial settings. Parts wear down through normal use. For instance, bearings lose lubrication, belts stretch, and seals crack.

All of this is inevitable if you run a maintenance organization, but it’s also predictable.

The key is knowing your asset lifespans.

A bearing rated for 10,000 operating hours won’t suddenly fail at hour 9,999, but it will show warning signs long before complete failure. Studies indicate that improper lubrication leads to 40-50% of bearing failures, and proper lubrication practices can extend equipment life by 30-50%.

Fatigue Failure

Repeated stress cycles cause microscopic cracks that eventually lead to failure. You’ll see this in equipment with moving parts such as pistons, crankshafts, and suspension components. The failure seems sudden, but it’s been building for months or years.

Vibration analysis excels at catching fatigue failure before it happens. Those tiny cracks create detectable changes in vibration patterns that your maintenance technicians can spot with the right tools.

Corrosion and Environmental Damage

Environmental factors don’t care about your production schedule. Moisture corrodes metal, chemicals degrade seals, and dust clogs filters. Equipment operating in harsh conditions fails faster than identical machines in controlled environments.

Corrosion and environmental degradation contribute significantly to equipment deterioration across all industrial sectors, making proper protective measures essential.

Overload and Misuse

Running equipment beyond design specifications accelerates failure. Overloading a conveyor, cycling a compressor too frequently, or operating machinery outside temperature parameters—these choices have consequences.

Operator training makes a huge difference here. Properly trained operators understand equipment limitations and recognize when something’s wrong. They’re your first line of defense against unnecessary costs.

Age-Related Deterioration

Aging equipment simply wears out. Components designed for a 20-year service life won’t last forever, no matter how well you maintain them. The challenge is knowing when repair costs exceed replacement value.

Industry data suggests that equipment older than 15 years requires 2-3 times as much maintenance as newer assets. At some point, you’re throwing good money after bad.

Root Causes of Equipment Failure

Understanding why equipment fails goes deeper than the failure modes themselves. Let’s look at what’s really driving those breakdowns.

Inadequate Lubrication

Poor lubrication practices are usually one of the key reasons for failure. However, this is highly preventable.

The problem is beyond just missing lubrication. A lot times it is related to using the wrong lubricants, contaminated oil, or improper application of lubricants.

Your maintenance schedules need to specify not just “lubricate bearing,” but also the lubricant, the amount, and the conditions.

Lack of Preventive Maintenance

Here’s a frustrating truth: companies often skip preventive maintenance to save money, then spend far more on emergency repairs. Research shows that preventive maintenance reduces costs by 12-18% compared to reactive approaches.

When you defer maintenance tasks, you’re not eliminating costs; you’re actually multiplying them.

That skipped oil change leads to engine damage. The postponed filter replacement causes system contamination. Small problems become big problems.

Poor Installation and Commissioning

Equipment failure often starts on day one.

Improper installation such as misaligned shafts, incorrect electrical connections, and inadequate foundation support can create stress points that accelerate failure.

Industry experts estimate that misalignment causes up to 50% of all machinery breakdowns. Yet it’s completely avoidable with proper installation procedures and alignment verification.

Inadequate Monitoring and Inspection

You can’t fix what you don’t know is broken. Organizations without continuous monitoring programs miss the early warning signs that predict imminent failure.

Modern sensor technology makes this inexcusable. Temperature sensors, vibration monitors, and oil analysis programs provide constant feedback on asset health. The question isn’t whether you can afford these technologies—it’s whether you can afford not to use them.

Insufficient Operator Training

Machine operators interact with equipment daily. They’re positioned to catch problems early—unusual sounds, performance changes, minor leaks. But only if they know what to look for and feel empowered to report issues.

Comprehensive operator training programs help catch equipment issues before they escalate. Your operators are either an asset or a liability. Training makes the difference.

Recognizing the Warning Signs of Equipment Failure

Equipment rarely fails without warning. The trick is knowing what to watch for.

Abnormal Sounds and Vibrations

That grinding noise isn’t normal. Neither is the new vibration you’ve started feeling. These are your equipment’s way of screaming for help.

Excessive vibration often indicates bearing wear, imbalance, or misalignment.

Each problem has a characteristic frequency signature that vibration analysis can identify. Catching these issues early prevents catastrophic failure and costly downtime.

Temperature Fluctuations

Equipment running hotter than normal is working harder than it should, or maybe has a clogged cooling system or poor lubrication. This can cause a rapid decline in equipment health.

Thermal imaging makes temperature monitoring straightforward. A quick scan identifies hot spots before they cause damage. Many facilities now use thermal cameras as part of their routine inspections.

Performance Degradation

Declining output, reduced efficiency, or quality issues often signal equipment problems.

A pump moving less fluid, a motor drawing more current, or a press requiring more force—these changes indicate deterioration.

The challenge is establishing baseline performance metrics so you can identify when things change. That’s where your key performance indicators become essential tools for early detection.

Unusual Leaks and Contamination

Hydraulic fluid on the floor, coolant in the oil, metal particles in the lubricant. All of these are signs of serious problems to come.

Oil analysis programs can detect contamination long before it causes failure. A simple fluid sample reveals wear metals, water contamination, and additive depletion. The cost of oil analysis is minimal compared to the failures it prevents.

Increased Energy Consumption

Equipment drawing more power than usual is working inefficiently. Worn bearings, belt slippage, or mechanical binding all increase energy demand.

Smart facilities monitor energy consumption at the equipment level. Unexpected increases trigger an investigation before failure occurs.

Some organizations report 15-20% energy savings through better maintenance practices alone.

Building an Equipment Failure Prevention Strategy

Preventing equipment failure requires a holistic approach. Performing random maintenance activities won’t cut it. You need to develop and follow a comprehensive strategy built on proven principles.

Implement Preventive Maintenance Programs

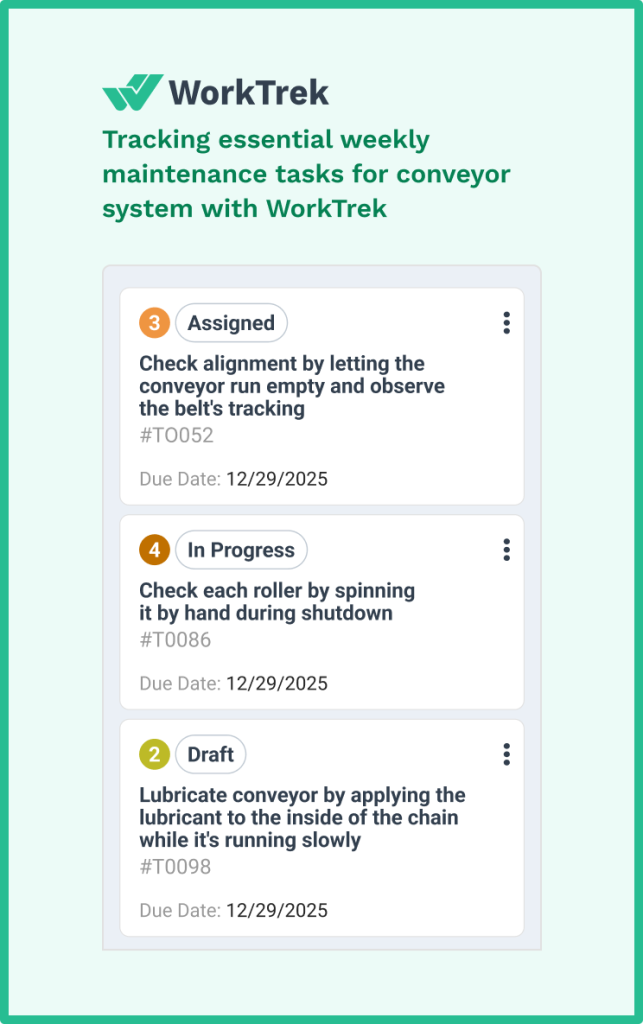

Preventive maintenance forms the foundation of equipment reliability. Regular inspections, scheduled component replacement, and routine maintenance tasks keep equipment running.

The key is basing your preventive maintenance schedule on actual equipment requirements, not arbitrary intervals. Manufacturer recommendations, historical data, and condition monitoring all inform optimal maintenance timing.

Organizations with mature preventive programs report maintenance costs 25-30% lower than those with reactive approaches.

Adopt Predictive Maintenance Technologies

Predictive maintenance takes prevention to the next level. Instead of maintaining equipment on a fixed schedule, you perform maintenance based on actual condition.

Sensor data, vibration analysis, thermal imaging, and oil analysis all feed predictive programs. Machine learning algorithms identify failure trends before humans can spot them.

Studies show predictive maintenance can reduce equipment breakdowns by 70% and increase asset lifespans by 20-40%. The good news is that the ROI typically materializes within months.

Develop a Proactive Maintenance Strategy

Proactive maintenance goes beyond fixing and preventing failures—it eliminates root causes. You’re not just replacing worn bearings; you’re understanding why they wore prematurely and fixing that underlying issue.

This requires detailed failure analysis, root cause investigation, and continuous improvement processes.

It’s more work upfront, but it dramatically reduces frequent repairs and unexpected breakdowns.

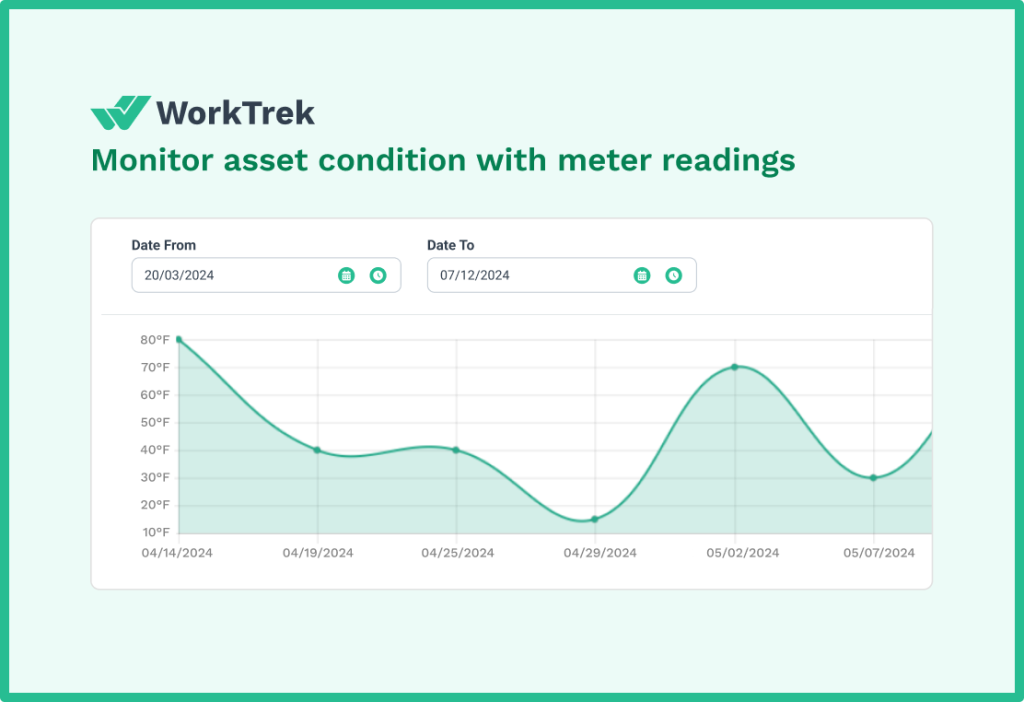

Establish Continuous Monitoring Systems

Continuous monitoring transforms maintenance from periodic activities to constant vigilance. Sensors track vibration, temperature, pressure, and other critical parameters 24/7.

When values exceed normal ranges, alerts notify maintenance teams immediately. You’re catching potential failure in its earliest stages, when intervention is cheapest and least disruptive.

The Industrial Internet of Things makes continuous monitoring affordable even for smaller operations. Connected sensors cost a fraction of a single unplanned shutdown.

Prioritize Critical Assets

Not all equipment deserves equal attention. Your critical equipment, which can include assets whose failure stops production or creates safety risks, requires intensive monitoring and maintenance.

Criticality analysis helps identify these assets and allocate resources appropriately. A critical pump might receive monthly vibration analysis and weekly inspections, while non-critical equipment gets quarterly preventive tasks.

This targeted approach improves equipment reliability where it matters most without excessive maintenance spending on every asset.

Invest in Operator and Technician Training

Your people make or break your maintenance program. Reliability engineers, maintenance managers, and maintenance technicians need current knowledge of advanced monitoring technologies and best practices.

But don’t overlook operator training. Operators who understand equipment operation, recognize warning signs, and follow proper procedures prevent countless failures.

Companies that invest in comprehensive training programs achieve improved asset reliability and safety outcomes. Employee safety and operational excellence go hand in hand.

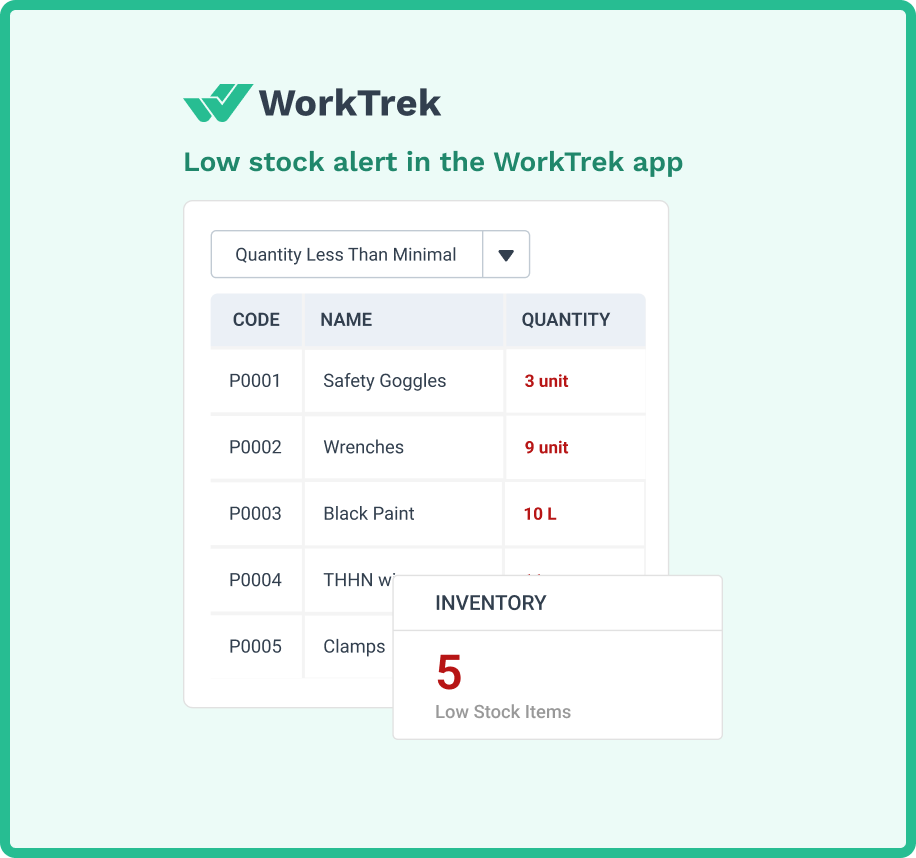

Maintain Adequate Spare Parts Inventory

Nothing extends downtime like waiting for parts. Strategic spare parts inventory ensures critical components are available when needed.

The balance can be tricky—too few parts cause delays, too many tie up capital. An effective spare parts management system uses failure data, lead times, and criticality to optimize inventory levels.

Standardize Maintenance Procedures

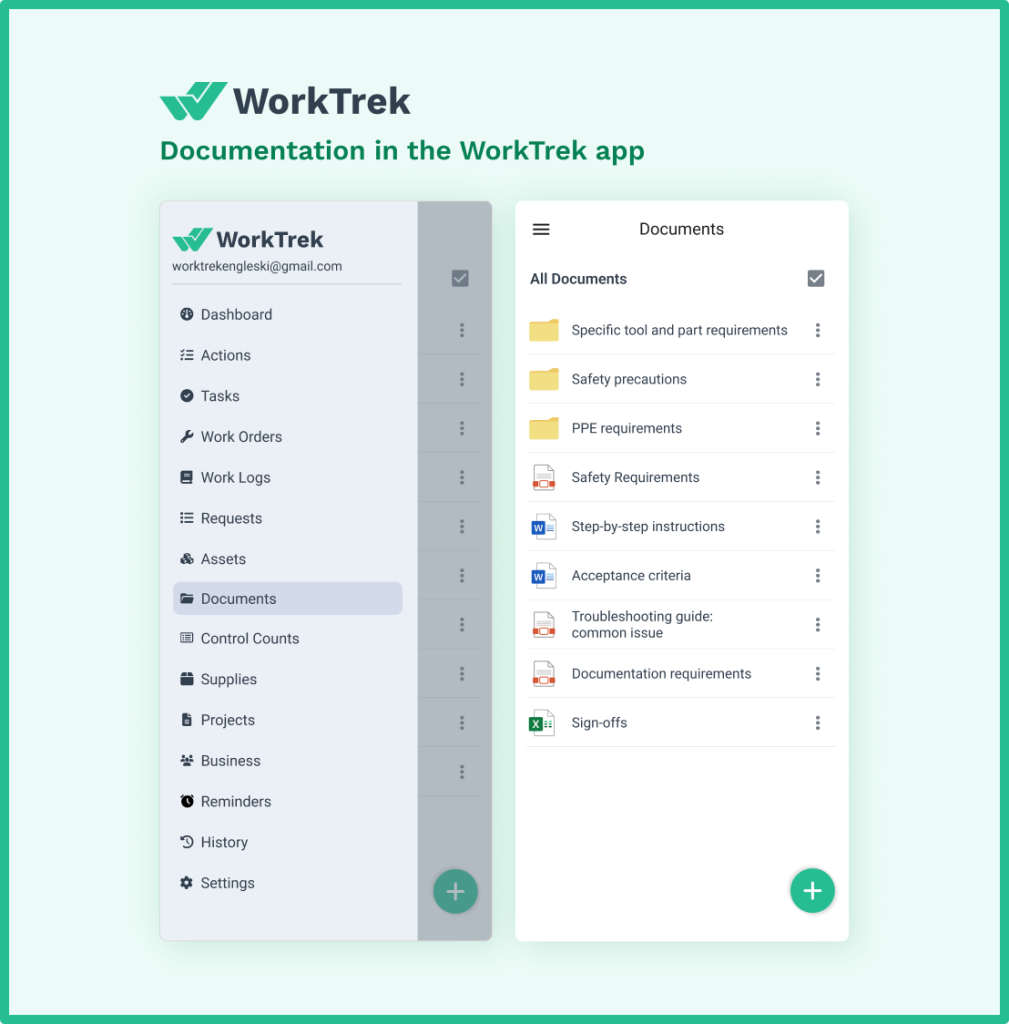

Inconsistent maintenance practices lead to inconsistent results. Standardized procedures ensure every maintenance technician performs tasks the same way, following proven methods.

Detailed work instructions, checklists, and quality verification steps reduce errors and improve reliability. When everyone follows the same process, you can identify and systematically improve it.

How CMMS Software Prevents Equipment Failure

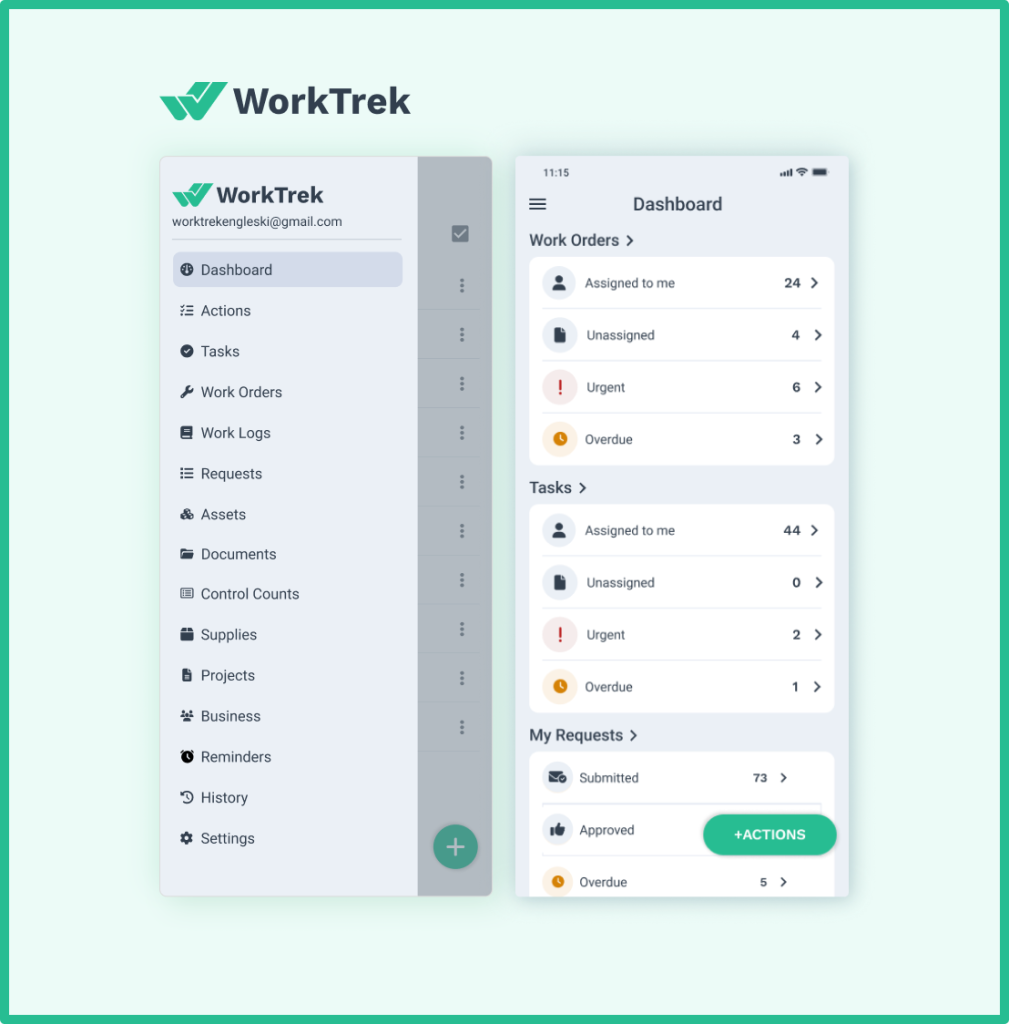

Modern maintenance relies on technology, and a computerized maintenance management system sits at the center of an effective maintenance strategy.

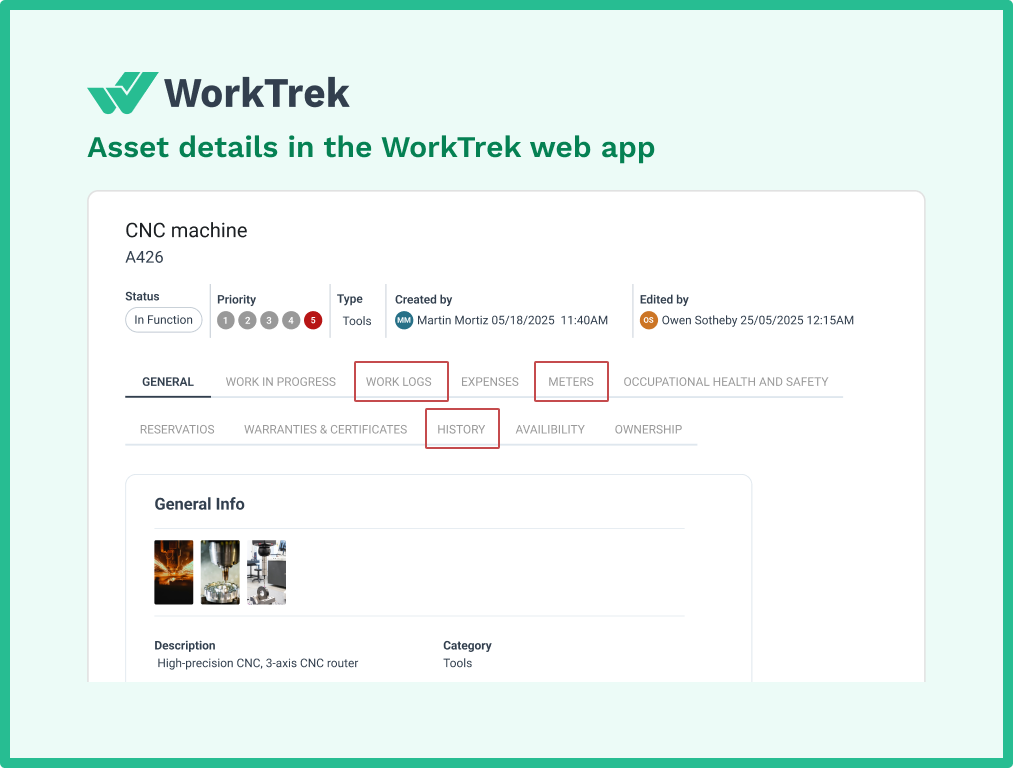

Centralized Asset Management

A CMMS creates a single source of truth for all your assets. Complete equipment history, maintenance records, failure trends, and performance data all live in one place.

This visibility transforms decision-making.

Should you repair or replace that aging compressor? The CMMS shows total repair costs, failure frequency, and remaining service life. Data drives the decision, not guesswork.

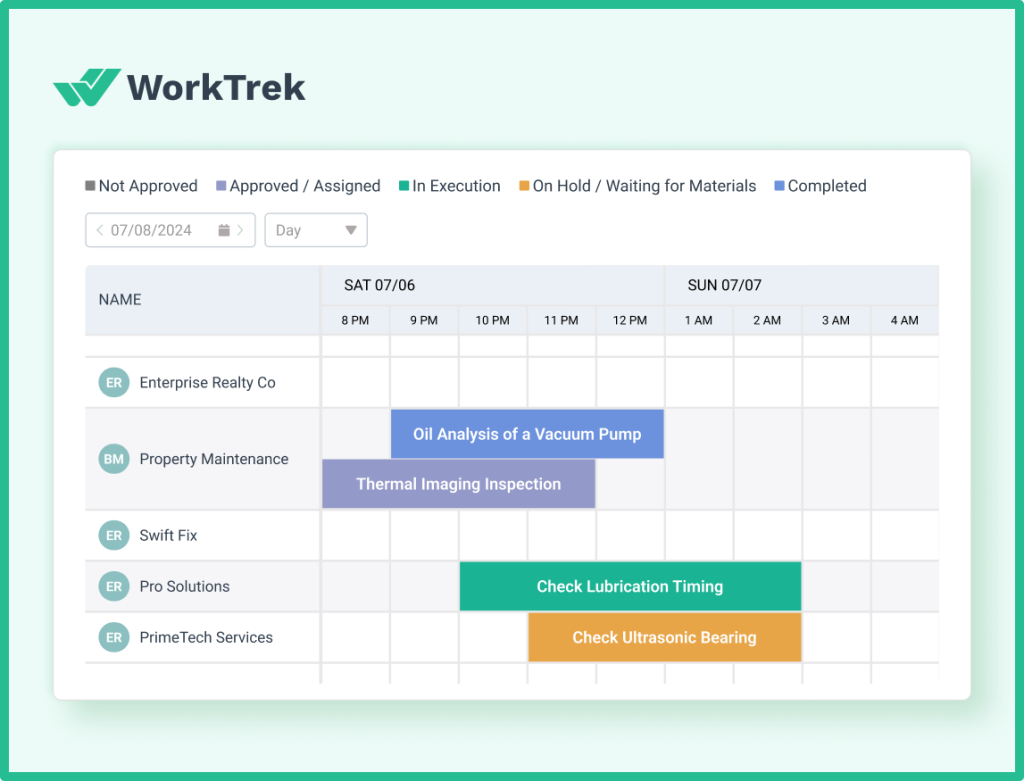

Automated Preventive Maintenance Scheduling

Manual scheduling fails. Tasks get missed, duplicated, or performed at the wrong intervals. CMMS automation ensures preventive tasks are performed on schedule, whether triggered by time, usage, or condition.

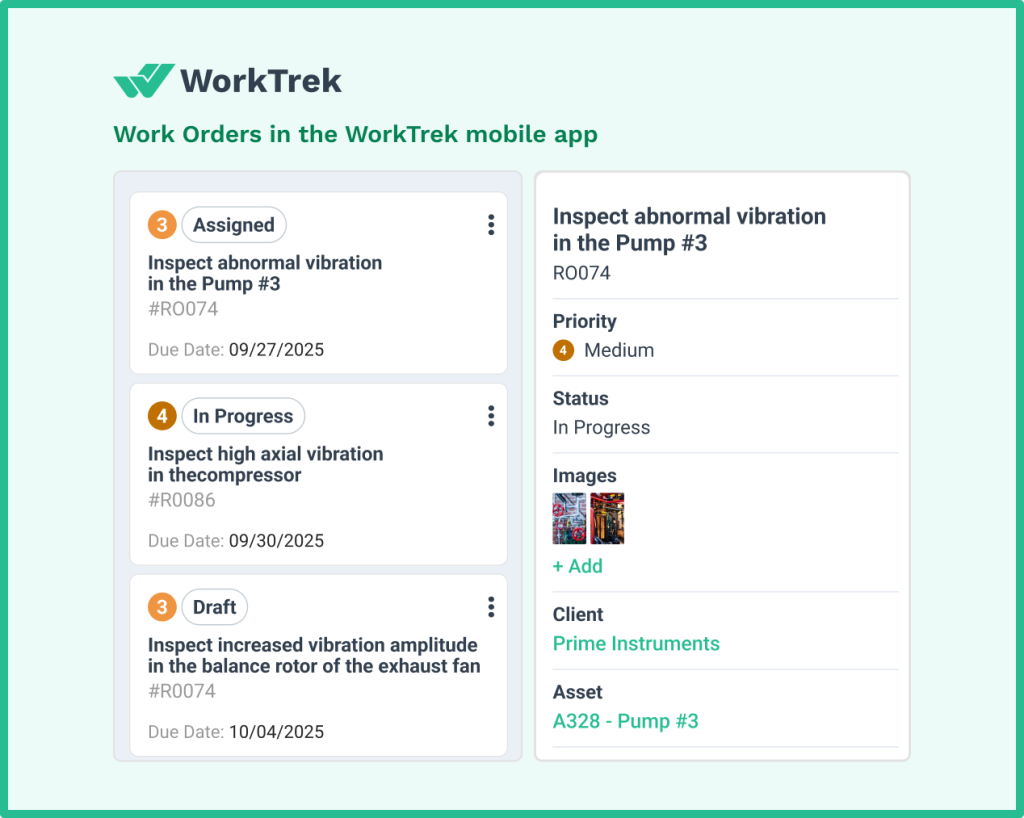

WorkTrek excels here, automatically generating work orders based on equipment runtime hours, calendar intervals, or sensor readings.

Your maintenance teams focus on executing tasks, not managing spreadsheets.

Predictive Analytics and Failure Forecasting

Advanced CMMS platforms like WorkTrek integrate with condition monitoring systems, analyzing sensor data to predict failures before they occur.

Machine learning algorithms identify patterns humans miss. Subtle changes in vibration, temperature drift, or performance degradation trigger alerts and automatically schedule preventive tasks.

Organizations using predictive maintenance enabled by CMMS report 25-30% reductions in maintenance costs and 35-45% reductions in equipment downtime.

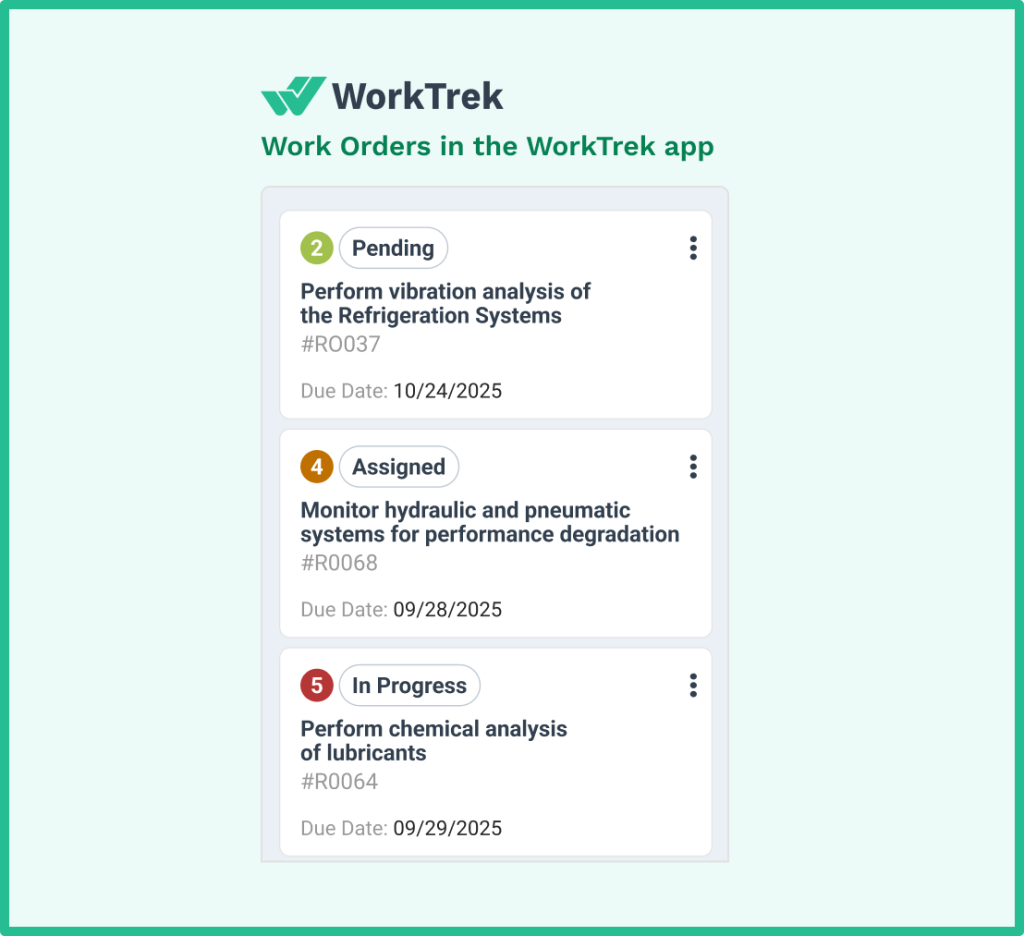

Real-Time Monitoring and Alerts

WorkTrek’s real-time monitoring capabilities keep you continuously informed about asset health. Temperature sensors, vibration monitors, and other IoT devices feed data directly into the system.

When parameters exceed thresholds indicating imminent failure, instant alerts notify relevant personnel. Your maintenance manager receives a notification, a work order automatically generates, and technicians can respond before minor issues become major problems.

Comprehensive Reporting and KPIs

You can’t improve what you don’t measure. WorkTrek tracks key performance indicators across all maintenance activities.

This includes mean time between failures, maintenance costs per asset, planned vs. unplanned maintenance ratios, and more.

These metrics identify trends, benchmark performance, and justify maintenance investments. When you show executives that predictive maintenance reduced costly downtime by 40%, budget conversations get easier.

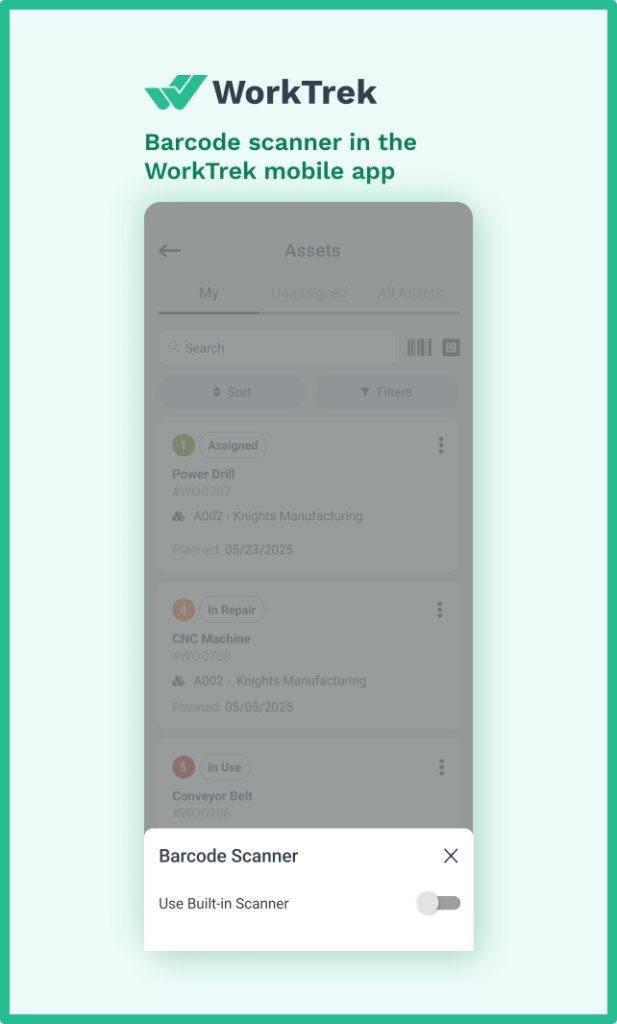

Mobile Access for Field Technicians

Maintenance doesn’t happen at a desk. WorkTrek’s mobile capabilities put complete asset information, work instructions, and reporting tools in technicians’ hands wherever they’re working.

Scan a barcode, pull up maintenance history, record observations, and close work orders—all from a smartphone or tablet. This real-time data capture improves accuracy and accelerates response times.

Integration with Monitoring Technologies

WorkTrek integrates seamlessly with advanced monitoring technologies, including vibration analyzers, thermal cameras, ultrasonic detectors, and oil analysis labs. Data flows automatically into asset records, creating comprehensive condition histories.

This integration eliminates manual data entry and ensures nothing falls through the cracks. When vibration analysis detects bearing wear, WorkTrek schedules the replacement automatically and orders the necessary spare parts.

The True Cost of Equipment Failure

Let’s talk numbers. Equipment failure costs far more than repair bills.

Direct costs include emergency repairs, component replacement, and maintenance labor. But the real damage comes from indirect costs.

This includes lost production, reduced operational efficiency, compromised product quality, and safety risks.

Studies estimate that unplanned downtime costs Fortune Global 500 companies $1.4 trillion annually, representing 11% of their yearly turnover. For individual facilities, a single critical asset failure can cost $250,000 or more.

Then there’s the ripple effect. Production delays cause missed deliveries, unhappy customers, and lost contracts. Frequent failures damage your reputation and competitive position.

Regulatory compliance adds another layer. Equipment failures that pose safety risks or result in environmental releases trigger fines, legal liability, and increased insurance costs.

Compare this to the cost of prevention. Preventive maintenance typically costs 12-18% less than reactive repairs. Predictive programs cost more upfront but deliver even greater savings through optimized maintenance timing.

Conclusion

Organizations that minimize downtime, reduce costly downtime, and maximize asset lifespans operate more efficiently and profitably.

The path forward requires commitment to proactive maintenance strategies, investment in advanced monitoring technologies, and adoption of comprehensive CMMS platforms like WorkTrek.

Start by identifying your critical assets and their failure modes. Implement continuous monitoring on equipment where failures create the greatest impact. Develop preventive maintenance schedules based on manufacturer recommendations and failure data.

Train your operators to recognize early warning signs and empower them to report concerns.

Most importantly, use technology to your advantage. Modern CMMS platforms transform maintenance from reactive firefighting to strategic asset management. WorkTrek’s predictive capabilities, automated scheduling, and comprehensive reporting give you the tools to prevent failures before they disrupt operations.