Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

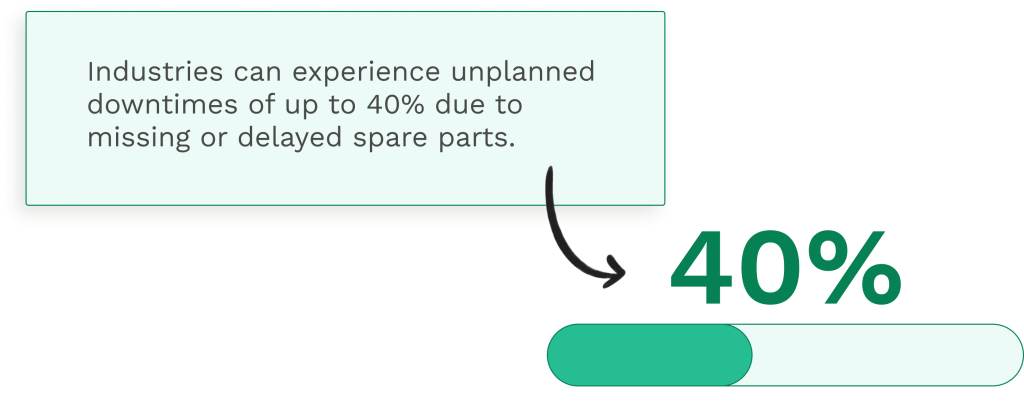

- Unplanned conveyor downtime costs manufacturing facilities between $10,000-$260,000 per hour depending on operation size

- 82% of companies have experienced unplanned equipment downtime in the past three years, with average outages lasting four hours and costing $2 million

- Emergency repairs cost 3-4 times more than routine preventive maintenance, yet 70% of facilities aren’t fully aware of when equipment needs servicing

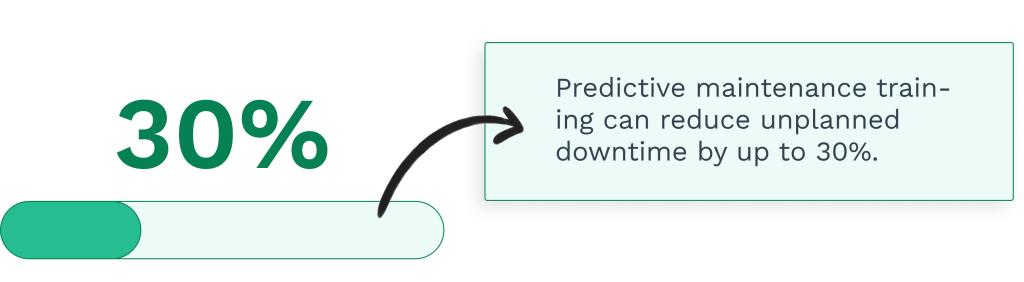

- Implementing a structured CMMS-based preventive maintenance program can reduce unexpected downtime by 30-50% and extend equipment lifespan by 20-40%

Conveyor belt systems are essential to material handling operations across manufacturing facilities, distribution centers, and assembly lines across many industries. These systems move everything from bulk materials to finished products, making them critical to operational efficiency and productivity.

However, even the most robust conveyor systems require regular attention to maintain optimal performance.

The good news?

Most conveyor issues are preventable. By understanding and avoiding the top conveyor maintenance mistakes, facility managers can significantly reduce downtime, extend equipment life, and protect their bottom line.

In this comprehensive guide, we’ll explore the top conveyor maintenance mistakes to avoid, along with proven strategies to avoid them.

1. Neglecting Preventive Maintenance Plans

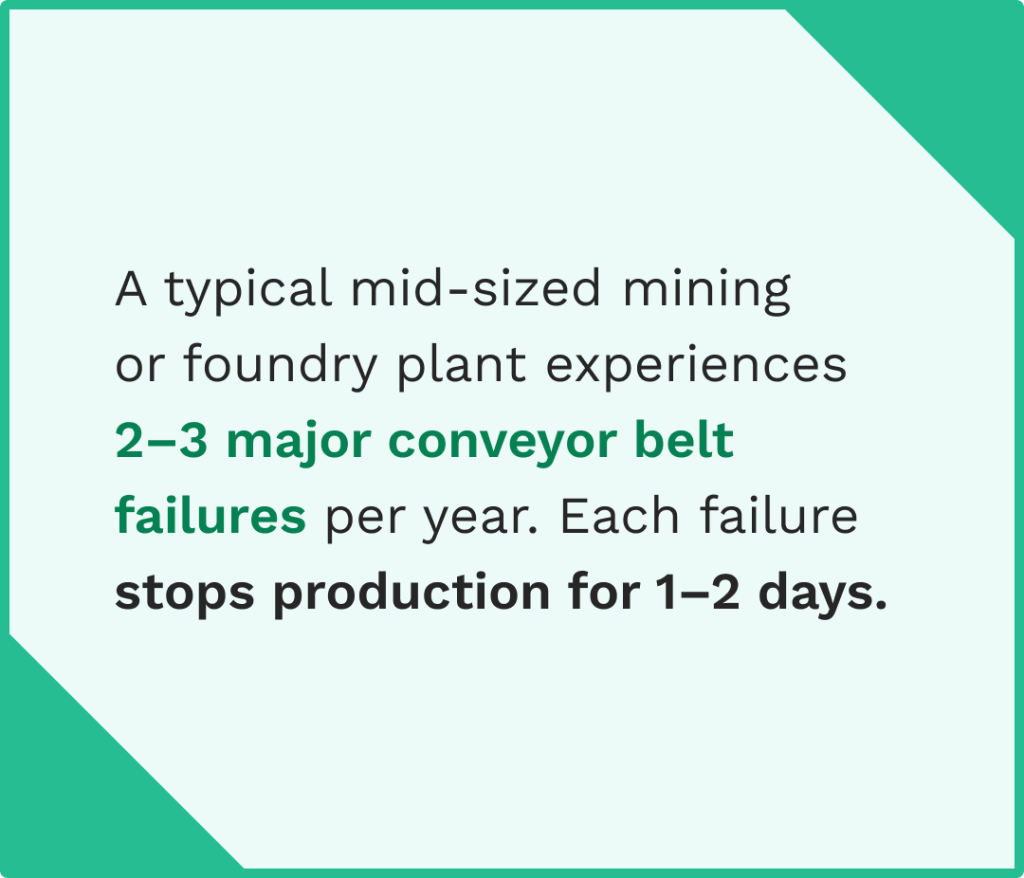

One of the biggest mistakes facility managers make is treating conveyor maintenance as a reactive task rather than a proactive strategy. The “run it until it breaks” mentality might seem cost-effective in the short term, but it’s a recipe for major failures and expensive emergency repairs down the line.

Without a structured preventative maintenance plan, small issues go unnoticed until they become significant problems. A worn roller that could have been replaced during scheduled maintenance instead causes belt damage, material spillage, and eventually complete system failure during peak production hours.

The financial impact of this reactive approach is staggering.

Research shows that emergency conveyor repairs and downtime cost between $10,000 to $100,000 per incident, while routine preventive maintenance averages just $7,500 to $20,000 annually, depending on system size. That’s a 3-4x difference in costs, not even accounting for lost orders, damaged reputation, or overtime expenses.

Consider the real-world example from a GE study, which found that manufacturing operations with reactive repair strategies experienced 58% more downtime per year than businesses that invested in planned maintenance.

How to Avoid This Mistake

Develop a comprehensive preventive maintenance program that includes:

Daily Inspections:

- Visual checks for belt wear, tracking issues, and unusual noises

- Debris removal from belt surfaces, pulleys, and rollers

- Quick assessment of belt tension and proper alignment

- Verification that safety guards and emergency stops function properly

Weekly Maintenance Tasks:

- Detailed inspection of idlers and rollers for wear, corrosion, or seizure

- Examination of pulleys for misalignment or lagging deterioration

- Checking drive systems for overheating, vibrations, or leaks

- Testing belt cleaners and scrapers for effectiveness

- Lubrication of bearings and moving parts per manufacturer specifications

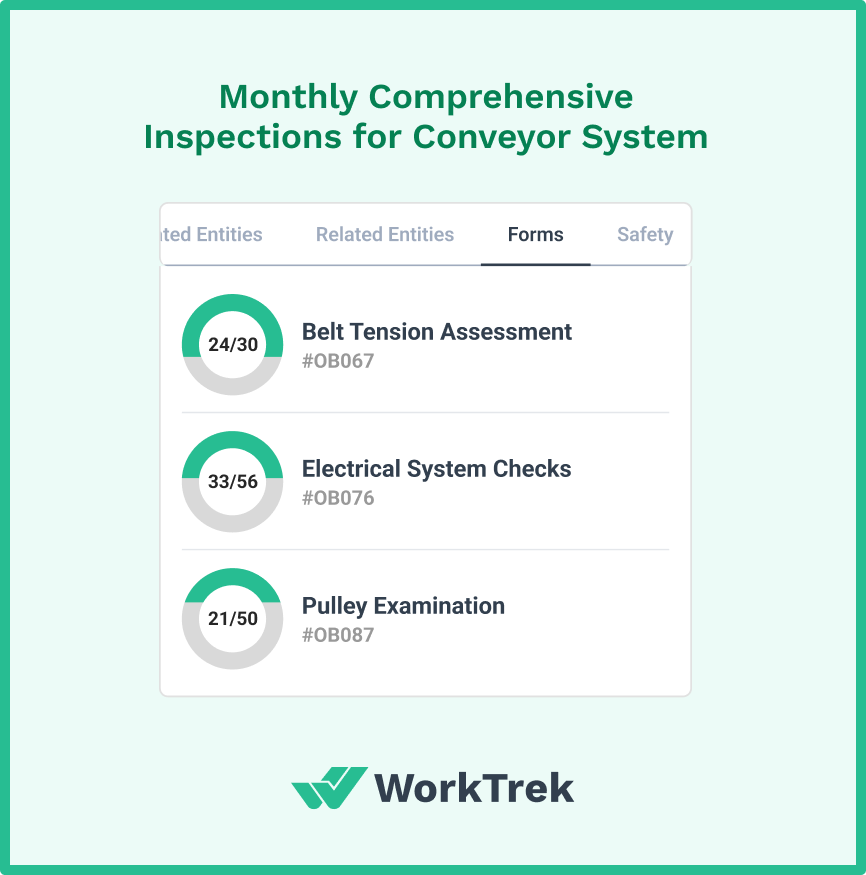

Monthly Deep Inspections:

- Comprehensive belt system examination (with conveyor shut down and locked out)

- Structural alignment checks of the conveyor frame

- Motor and gearbox inspection for abnormal temperature or vibration

- Review of maintenance logs to identify recurring issues

- Testing of all safety systems and sensors

Quarterly and Annual Reviews:

- Complete system audit, including all components

- Bearing and mounting bolt inspections alongthe entire length

- Replacement of worn components before they fail

- Review and update of maintenance procedures

- Analysis of maintenance costs vs. system performance

A structured maintenance plan not only prevents breakdown but also creates predictability.

Some strategies include scheduling downtime during slow periods rather than dealing with unexpected failures during your busiest hours. This level of control is essential for maintaining productivity and meeting customer commitments.

2. Ignoring Material Buildup and Carryback

Material carryback, which is the residual material that sticks to conveyor belts after discharge, is one of the most common yet overlooked maintenance issues.

When material clings to the belt and is carried back on the return side, it causes a cascade of problems that affect system efficiency, safety, and operational costs.

This seemingly minor issue creates significant challenges.

Material spillage occurs when carryback falls off the belt, creating cleanup costs and potential slip hazards. The accumulated material adds weight to the return side, causing premature wear on return rollers and increasing energy consumption.

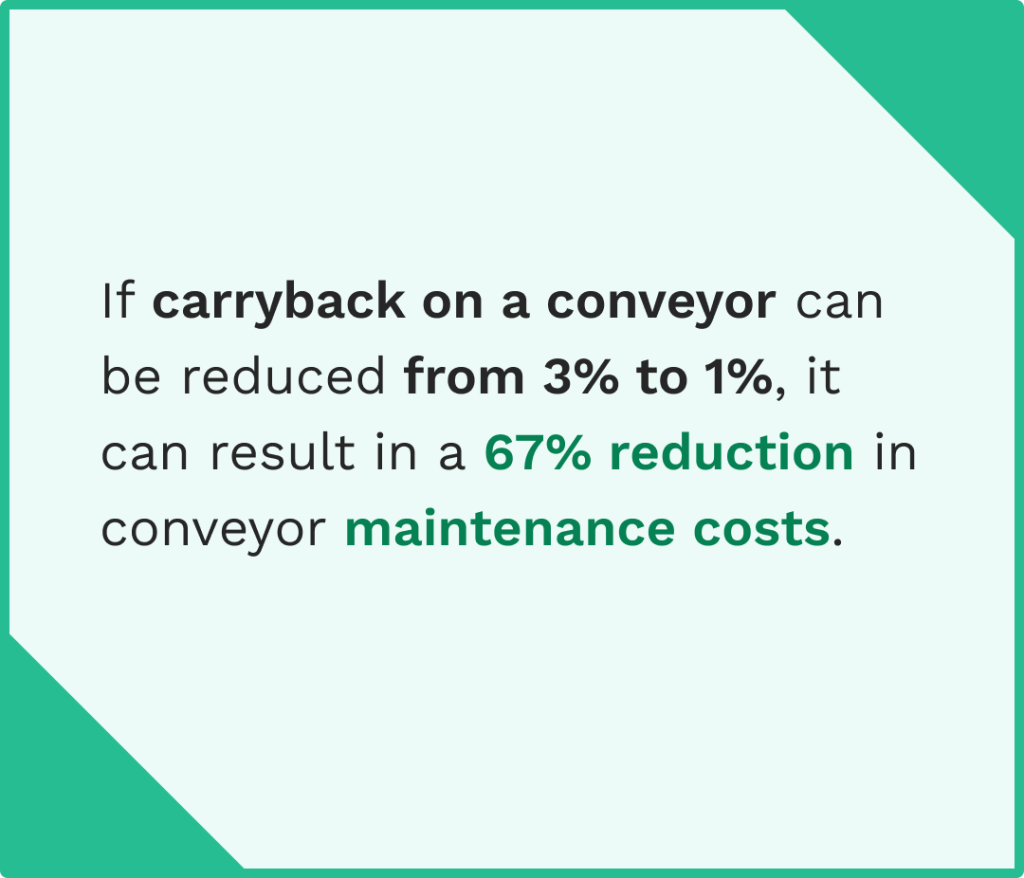

Studies show that carryback leads to roller build-up, increased belt wear, and long-term inefficiency that compounds over time.

The problem extends beyond just the belt itself. Material buildup on pulleys creates uneven surfaces that can cause belt mistracking.

Debris accumulating on sensors and photo eyes disrupts automated systems. In manufacturing facilities handling bulk materials, the lost product from spillage directly impacts material costs and productivity.

What makes carryback particularly insidious is that it often starts small. A little material sticking here and there doesn’t seem worth addressing.

But as carryback accumulates, it accelerates wear on multiple conveyor components, eventually requiring expensive repairs or complete belt replacement far sooner than expected.

How to Avoid This Mistake

Implement a comprehensive material containment and cleaning strategy:

Install Effective Belt Cleaners:

- Primary scrapers at the discharge point to remove bulk material

- Secondary cleaners on the return side for the remaining carryback

- Tungsten carbide or polyurethane belt scrapers are designed for your specific material type

- Proper installation at manufacturer-recommended angles and tension

Regular Cleaning Procedures:

- Daily inspection and cleaning of belt scrapers

- Removal of material buildup from return rollers, pulleys, and idlers

- Cleaning of chute areas and transfer points where spillage commonly occurs

- Use of proper cleaning tools that won’t damage belt surfaces

System Design Improvements:

- Install dust containment systems in areas where fine materials create carryback

- Add skirting systems at loading points to prevent spillage

- Consider belt cleaners with automatic tension adjustment for consistent performance

- Implement wash-down stations for belts handling sticky materials

Material Handling Considerations:

- Ensure proper loading techniques to minimize material scatter

- Control material moisture content when possible

- Use appropriate belt surface types (smooth, rough top, cleated) for the material being conveyed

- Maintain proper belt speed for the product being handled

By proactively addressing material buildup, you reduce cleanup labor, extend component life, and maintain system efficiency. The investment in quality belt cleaners typically pays for itself within months through reduced maintenance costs and improved uptime.

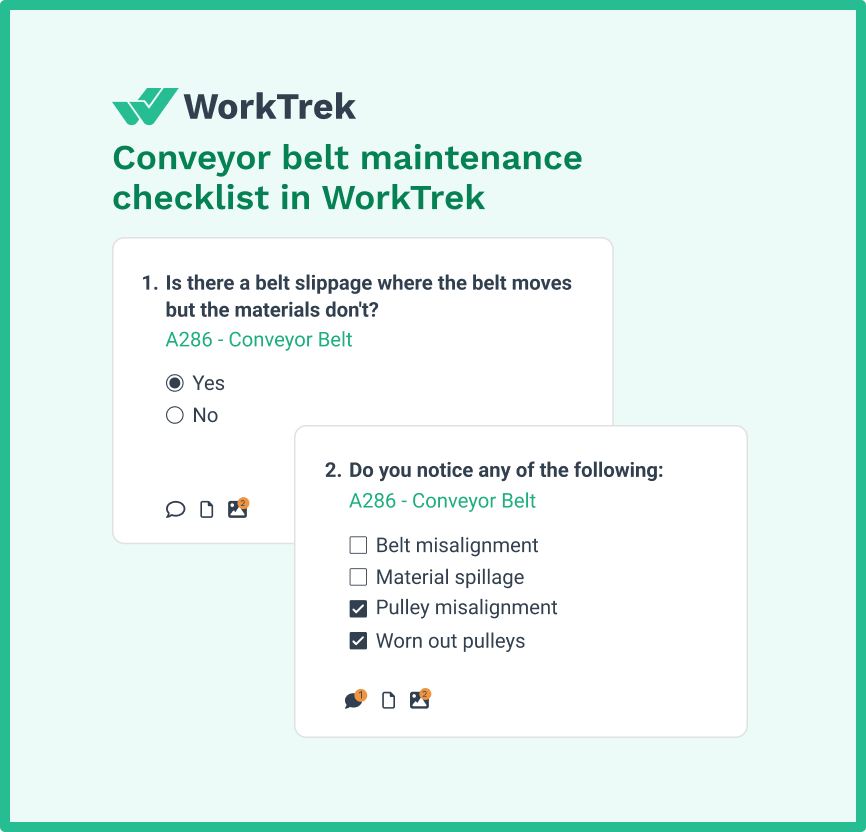

3. Improper Belt Tensioning

Belt tension might seem like a simple concept. However, getting it is critical for conveyor system performance.

Too much tension causes excessive strain on motors, bearings, and the belt itself, leading to premature failure. Too little tension results in belt slippage, inconsistent material flow, and tracking problems.

The challenge with belt tensioning is that it’s not a “set it and forget it” task.

Conveyor belts naturally stretch during operation, particularly when new. Temperature fluctuations, load variations, and everyday wear all affect tension over time.

According to conveyor maintenance experts, improper tension is one of the leading causes of belt slippage and tracking issues.

When tension is too high, the entire system suffers. Excessive force accelerates wear on pulley lagging, strains drive motors, and can even cause structural damage to the conveyor frame.

The belt itself experiences increased internal stress, leading to premature cracking or failure. Energy consumption rises as motors work harder to overcome the unnecessary resistance.

Conversely, insufficient tension allows the belt to slip around the drive pulley, especially under varying loads.

This slippage creates loud squealing noises, causes hot spots on the belt surface, and prevents proper material transport. Over time, repeated slipping damages both the belt and pulley surfaces, requiring costly repairs.

How to Avoid This Mistake

Develop a systematic approach to belt tensioning:

Initial Tensioning:

- Follow manufacturer specifications for your specific belt type and width

- Use proper tensioning equipment—never guess or eyeball tension

- Account for the new belt stretch during the break-in period

- Document initial tension settings for future reference

Regular Tension Monitoring:

- Check tension at least monthly during routine maintenance

- Inspect more frequently after belt installation or replacement

- Monitor for seasonal variations—ambient temperature affects belt tension

- Watch for visible signs like excessive sag in the return side or slip marks on pulleys

Proper Adjustment Techniques:

- Use adjustable tensioning systems or take-up assemblies

- Make small, incremental adjustments and test system operation

- Ensure equal tension across the entire belt width

- Recheck tension after adjustments and during operation

System Components:

- Inspect pulley lagging condition—worn lagging reduces grip

- Check take-up bearings and slides for smooth operation

- Verify that counterweights or springs in gravity take-ups function properly

- Monitor motor amperage—changes can indicate tension problems

Environmental Considerations:

- Account for temperature changes in facilities without climate control

- Adjust tension seasonally if needed

- Consider automatic tensioning systems for critical applications

- Document any correlation between ecological conditions and tension issues

Many facilities benefit from installing tension monitoring sensors that provide real-time data on belt tension.

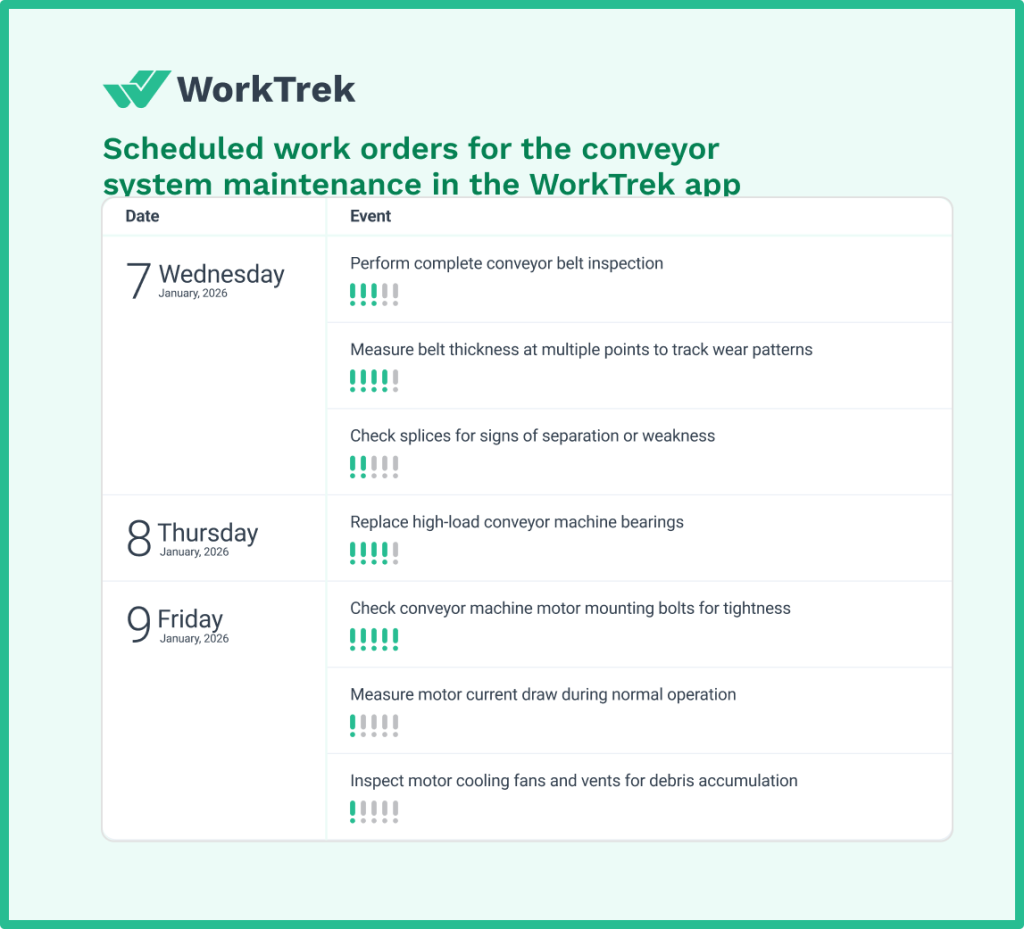

These sensors integrate with CMMS platforms like WorkTrek to alert maintenance teams when tension falls outside acceptable parameters, enabling proactive adjustments before problems occur.

4. Poor Belt Tracking and Alignment

Belt tracking refers to how the conveyor belt travels along its intended path.

When a belt “mistracks” or runs off-center, it creates a host of problems that compromise system performance, damage equipment, and pose serious safety hazards.

Mistracking is one of the most visible signs of conveyor trouble. Industry data shows that belt tracking problems often stem from misaligned components, but the consequences extend far beyond simple aesthetics.

A belt running off-center rubs against the conveyor frame, causing premature edge wear. Material spillage increases as the belt no longer properly contains the load. In severe cases, the belt can completely derail, requiring emergency shutdown and extensive repairs.

The root causes of tracking issues are numerous. Misaligned idlers or rollers create uneven support, causing the belt to shift to one side. Debris lodged in pulleys creates false crowns that redistribute weight incorrectly. Worn or damaged components no longer provide even support. Even poor splice quality or uneven loading can contribute to tracking problems.

What makes tracking issues particularly frustrating is their progressive nature. A slight misalignment might initially seem tolerable, but it accelerates wear on that section of the belt.

As wear increases, tracking worsens, creating a downward spiral that eventually demands costly belt replacement months or even years before the belt’s expected lifespan.

The safety implications can’t be overlooked either.

A mistracking belt poses pinch point hazards. Material spillage creates slip hazards on the floor. In extreme cases, a completely derailed belt can injure nearby workers or damage surrounding equipment.

How to Avoid This Mistake

Implement comprehensive tracking and alignment procedures:

Regular Alignment Checks:

- Visually inspect belt travel during daily walkthroughs

- Use laser alignment tools or string lines for precision measurements

- Check idler alignment along the entire conveyor length

- Verify that pulleys are square to the frame and parallel to each other

Proactive Adjustments:

- Make small, incremental corrections when tracking issues first appear

- Adjust only one component at a time and observe results

- Use the conveyor’s built-in adjustment mechanisms (take-up screws, adjustable idlers)

- Document adjustments made and their effects

Component Maintenance:

- Keep pulleys free of material buildup that creates false crowns

- Replace worn or damaged idlers promptly

- Ensure all rollers rotate freely without binding

- Inspect and maintain proper alignment of loading points and skirting

Belt Considerations:

- Verify proper belt installation with straight splices

- Check for even load distribution across the belt width

- Ensure belt cleaners don’t contact belt edges incorrectly

- Monitor belt condition for uneven wear patterns, indicating misalignment

Advanced Solutions:

- Install automatic belt tracking devices for critical conveyors

- Use training idlers at strategic points to correct minor tracking issues

- Consider remote monitoring systems that detect tracking problems early

- Implement routine belt tracking as part of scheduled maintenance

For conveyors handling bulk materials or operating at high speeds, proper alignment from installation through operation helps prevent a cascade of downstream issues. The time spent on routine tracking checks is minimal compared to the cost of emergency repairs, material loss, and production delays from tracking failures.

5. Using Inferior or Incorrect Replacement Parts

When conveyor components need replacement, the temptation to save money with cheaper aftermarket parts can be strong.

However, using inferior quality or incorrect replacement components is a false economy that often leads to greater expenses down the road.

High-quality replacement parts are engineered specifically for your conveyor system’s design parameters. They’re manufactured to precise tolerances, tested for durability, and guaranteed to perform under your operating conditions.

In contrast, cheap alternatives may fit physically but fail to meet performance requirements, leading to premature failure, safety issues, and potential warranty avoidance.

Industry experts emphasize that using OEM (Original Equipment Manufacturer) parts ensures compatibility, reliability, and optimal performance. OEM suppliers provide technical support, proper installation instructions, and documentation that aftermarket vendors often can’t match. This support becomes invaluable when troubleshooting issues or optimizing system performance.

The hidden costs of inferior parts extend beyond the component itself. A cheap roller that fails prematurely might damage the belt, incurring repair costs many times the original savings.

Low-quality bearings that seize can cause catastrophic motor failure. Incorrect belt specifications lead to poor performance, increased energy consumption, and shortened system lifespan.

Consider the total cost implications: A quality replacement roller might cost $200, while a cheap alternative costs $80. But if the cheap roller fails in 6 months instead of 3 years, you’ll replace it 6 times over the quality roller’s lifespan, costing $480 versus $200—plus the labor and downtime for each replacement. The math clearly favors quality components.

How to Avoid This Mistake

Develop a strategic approach to parts replacement:

Component Sourcing:

- Prioritize OEM parts for critical conveyor components

- Maintain relationships with authorized distributors

- Verify part specifications match manufacturer recommendations

- Be cautious of deals that seem too good to be true

Quality Standards:

- Use high-quality replacement parts from reputable suppliers

- Verify certifications and material specifications

- Check warranty coverage—quality parts come with meaningful warranties

- Review supplier reputation and industry standing

Parts Inventory Management:

- Stock critical wear items based on maintenance history

- Maintain adequate inventory of fast-wearing components (belts, rollers, bearings)

- Store parts properly to prevent deterioration

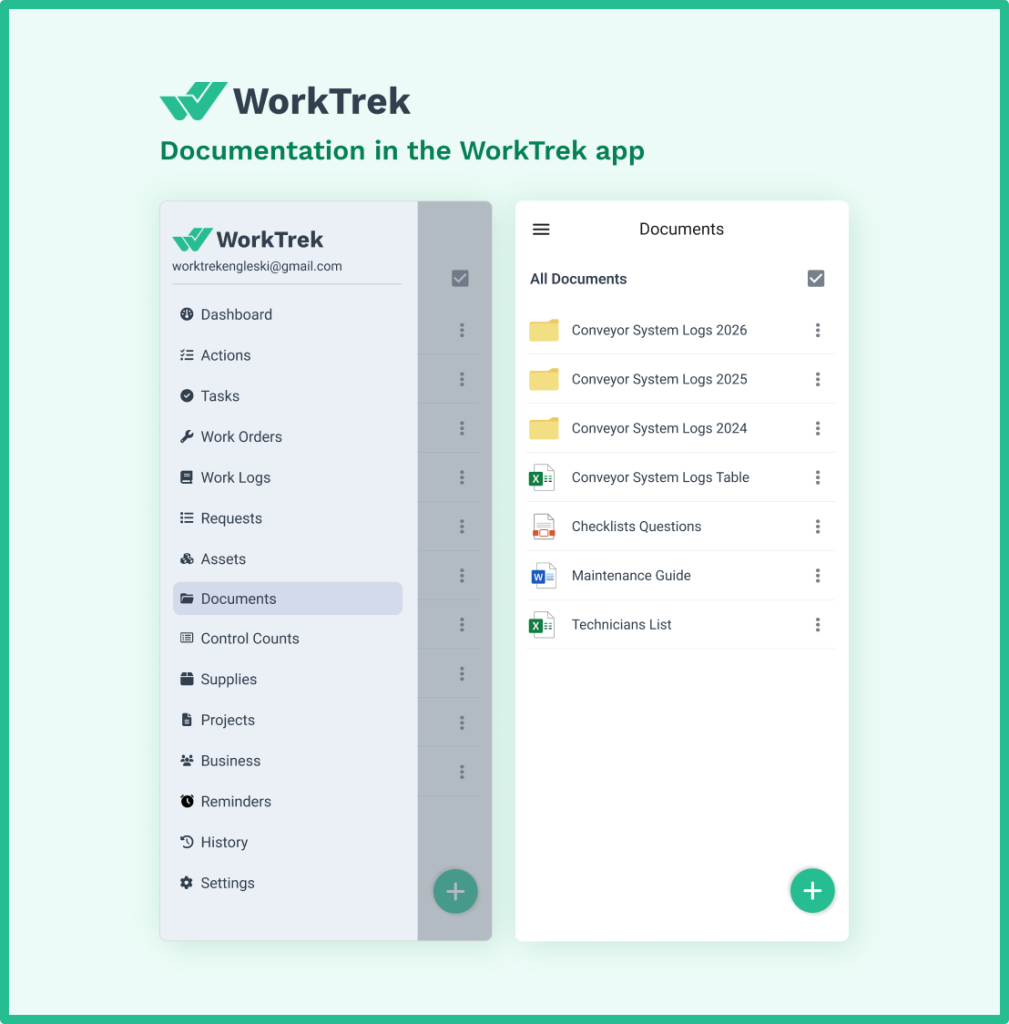

- Use CMMS software to track part usage, costs, and performance

- Set reorder points to avoid emergency purchases at premium prices

Documentation and Tracking:

- Record all part replacements with part numbers and suppliers

- Track component lifespan and failure patterns

- Compare OEM versus aftermarket performance when alternatives are used

- Maintain equipment manuals and parts lists for quick reference

Strategic Decisions:

- Evaluate the total cost of ownership, not just the initial purchase price

- Consider downtime costs when choosing between quality and price

- Factor in warranty coverage and supplier support

- Account for energy efficiency differences between components

Supplier Relationships:

- Work with suppliers who provide technical support

- Engage manufacturers for critical applications

- Seek suppliers who stock emergency parts for rapid delivery

- Value suppliers who offer training on proper installation

For truly critical conveyors in your facility—those whose downtime has the most significant operational impact—using anything less than OEM- or equivalent-quality parts is an unacceptable risk.

The small savings on individual components pale in comparison to the costs of unexpected failures during production runs.

6. Failing to Train Maintenance Staff Properly

Even the best maintenance plans and quality replacement parts can’t overcome inadequately trained personnel. Proper training is fundamental to effective conveyor maintenance, yet many businesses overlook this critical investment in their maintenance program.

Untrained or inadequately trained staff make costly mistakes. They might over-tighten bolts, causing fastener failure.

They may incorrectly tension belts, creating the problems discussed earlier. They could misdiagnose issues, leading to unnecessary repairs or overlooking the actual problem. In the worst cases, improper maintenance procedures create safety hazards that put workers at risk.

The complexity of modern conveyor systems demands specialized knowledge.

Today’s conveyors often incorporate advanced sensors, automated controls, and sophisticated drive systems. Maintenance personnel need to understand not only mechanical components but also electrical systems, programmable logic controllers, and condition-monitoring technologies.

Training deficiencies reveal themselves in multiple ways.

Research indicates that human error causes 18% of unscheduled downtime on average. This includes obvious mistakes, such as equipment damage, but also subtle errors, such as failing to recognize early warning signs of impending failure. When technicians don’t know what regular operation looks like, they can’t identify abnormal conditions until problems become critical.

The costs extend beyond just downtime.

Improperly maintained equipment consumes more energy, experiences accelerated wear, and requires more frequent repairs.

Documentation suffers when technicians don’t understand the importance of accurate record-keeping.

Safety incidents increase when personnel don’t follow proper lockout/tagout procedures or work around energized equipment incorrectly.

How to Avoid This Mistake

Invest in comprehensive training and development:

Initial Training:

- Provide manufacturer-specific training for all conveyor systems

- Cover proper maintenance procedures for each component type

- Include both mechanical and electrical system fundamentals

- Emphasize safety procedures, including lockout/tagout protocols

- Train on the proper use of maintenance tools and testing equipment

Specialized Skills Development:

- Belt splicing techniques appropriate for your belt types

- Proper alignment and tracking adjustment procedures

- Bearing installation and lubrication best practices

- Troubleshooting methodologies for common issues

- Emergency repair procedures for minimizing downtime

Ongoing Education:

- Regular refresher training on critical procedures

- Updates on new equipment or system modifications

- Cross-training to build depth in maintenance capabilities

- Industry certification programs, where applicable

- Vendor-provided training on new products or technologies

Knowledge Transfer:

- Document tribal knowledge from experienced technicians

- Create standard operating procedures for routine tasks

- Develop troubleshooting guides based on common issues

- Use photos and videos to illustrate proper techniques

- Establish mentorship programs pairing experienced and new personnel

Safety Emphasis:

- Comprehensive safety training for all maintenance activities

- Regular safety refreshers and hazard recognition exercises

- Proper personal protective equipment use and selection

- Emergency response procedures

- Incident investigation and root cause analysis training

Documentation Training:

- CMMS data entry procedures and importance

- Work order completion best practices

- Parts tracking and inventory management

- Maintenance metrics and reporting

- Use of mobile devices for real-time data capture

Continuous Improvement:

- Regular skills assessments to identify gaps

- Industry conference attendance for leading personnel

- Manufacturer training updates when equipment changes

- Internal knowledge sharing sessions

- Root cause analysis of maintenance failures to identify training needs

Training isn’t just about preventing mistakes; it’s about building a maintenance culture where personnel take pride in their work and understand how their efforts impact overall operations.

Well-trained technicians spot potential issues earlier, make better decisions, and work more efficiently, ultimately reducing maintenance costs while improving system reliability.

How CMMS Software Supports Successful Preventive Maintenance

The conveyor maintenance mistakes we’ve discussed share a common thread: they’re all easier to prevent with proper organization, documentation, and systematic approaches.

This is precisely where Computerized Maintenance Management System (CMMS) software delivers tremendous value.

Modern CMMS platforms transform maintenance from a reactive, paper-based process into a proactive, data-driven operation.

By centralizing asset information, automating routine tasks, and providing real-time visibility into maintenance activities, CMMS software addresses the root causes of most conveyor maintenance mistakes.

Benefits of a CMMS include:

- Preventive Maintenance Scheduling

- Work Order Management

- Asset Management

- Detailed Documentation

- Spare Parts Inventory

- Key Performance Indicators (KPI’s) and reporting and analytics

- Training and Knowledge Management

- Mobile Access for Real-Time Updates

- Extensive Integration with ERP and other critical systems

Conclusion

Conveyor belt maintenance mistakes cost manufacturing facilities and distribution centers millions of dollars annually in unplanned downtime, emergency repairs, and lost productivity.

Yet these expenses are largely preventable with proper maintenance strategies and the right tools.

The six mistakes covered in this guide—neglecting preventive maintenance, ignoring material buildup, improper tensioning, poor tracking, using inferior parts, and inadequate training—share common solutions.

They all improve dramatically when facilities adopt systematic approaches, clear documentation, and proactive management enabled by CMMS technology.

The data is clear: routine preventive maintenance costs 3-4 times less than emergency repairs, reduces downtime by 30-50%, and extends equipment life by 20-40%.

Facilities that invest in proper maintenance programs, quality parts, trained personnel, and CMMS systems like WorkTrek consistently outperform those that don’t.

Start addressing these mistakes today, and your conveyors will reliably support your operations for years to come.