Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- Emergency maintenance is one of the most expensive maintenance strategies, costing 2–5 times more than planned work.

- Proactive practices like preventive maintenance can reduce unscheduled incidents by up to 41%.

- Tools like WorkTrek automate maintenance schedules and centralize data to provide timely alerts and prevent emergency breakdowns.

When critical equipment fails unexpectedly, it can plunge your entire business into chaos.

Such situations, which stop production or disrupt services, require immediate, unscheduled attention.

This is known as emergency maintenance.

If you are a facility or maintenance manager looking for better ways to handle these high-pressure situations effectively, this article is for you.

Let’s explore what emergency maintenance is and how and when to perform it.

What Is Emergency Maintenance?

Before anything else, let’s explain exactly what emergency maintenance is.

It’s important to clearly distinguish this type of maintenance from proactive, planned maintenance, and from semi-reactive approaches like run-to-failure strategies.

While run-to-failure practices involve intentionally allowing non-critical components to fail before repair or replacement, emergency maintenance is never planned.

As our definition suggests, this is a reactive, unplanned form of maintenance.

But it’s important to emphasize that it occurs only in specific, unexpected, and critical situations.

One example would be a situation where a vital piece of equipment breaks down on a production line and prevents operations from continuing at a manufacturing plant.

Or, it could involve an HVAC system failing during extreme weather, creating unsafe temperature conditions for employees.

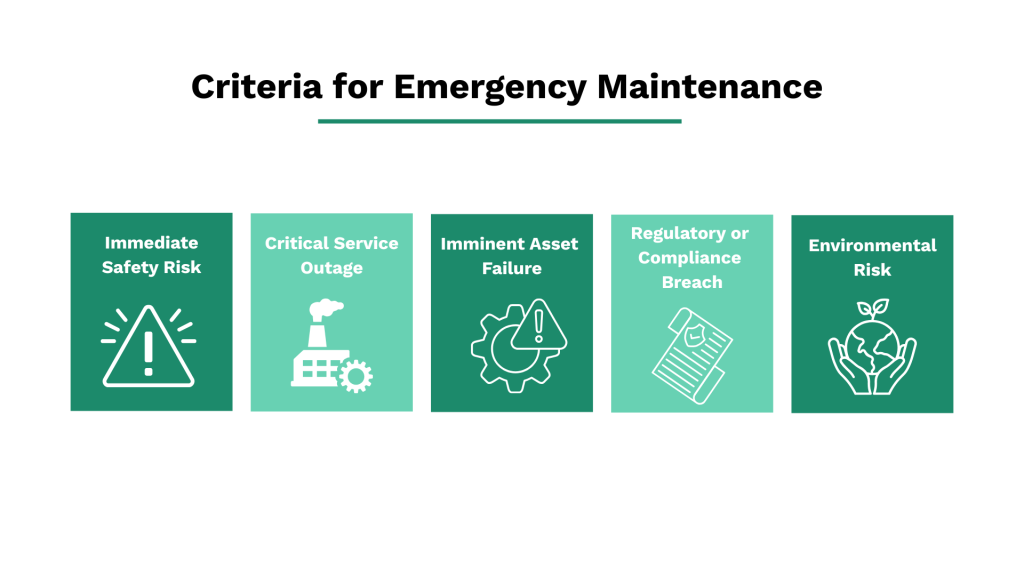

Either way, for a task to be classified as emergency maintenance, it usually requires one or several specific criteria to be met.

Some of these criteria are shown below.

Simply put, emergency maintenance requires a faster or even instant response to the issue because it involves very high stakes regarding safety, environment, or profit.

As such, it is a practice that is rarely used.

Why Emergency Maintenance Should Be a Last Resort

While emergency maintenance is sometimes necessary to fix critical failures, it should never be your primary strategy.

Relying on it brings significant downsides that can hurt your business, which we will explore in the following sections.

Let’s take a look at three of the main disadvantages of this practice.

Unpredictable Costs

For starters, let’s talk about the cost.

It is well-known in the industry that even reactive maintenance costs significantly more than planned maintenance.

According to a report from Nexus Controls, unplanned maintenance can be 2–5 times more expensive than planned maintenance practices.

With that in mind, we can safely assume that emergency maintenance sits at the higher end of this cost range.

This is because, unlike standard reactive fixes, maintenance technicians must respond immediately to these types of issues.

Workers might be called in outside of regular working hours, meaning you pay overtime rates and use far more resources than you would during a standard repair.

And that’s not all.

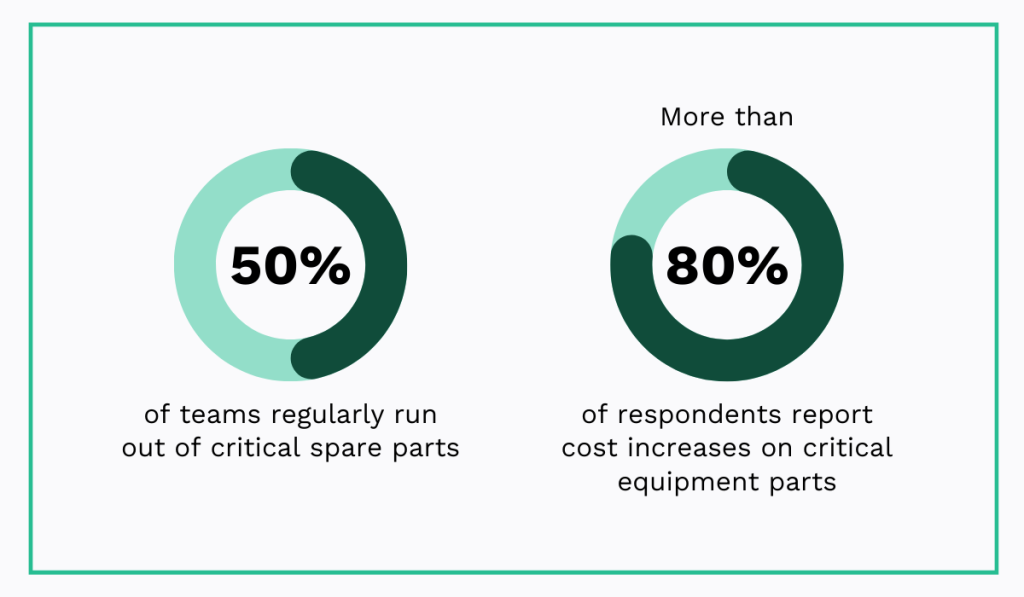

These costs are further compounded when spare parts for critical equipment aren’t available, requiring urgent sourcing and replacement.

Unfortunately, this worsens an already existing problem concerning sourcing equipment parts.

According to data from Limble, maintenance crews regularly run out of parts, and they often experience corresponding increases in inventory costs.

When you combine missing inventory with the need for expedited shipping during an emergency, you create a very expensive process.

You end up spending money reactively and going far outside your planned maintenance budgets.

It is an unpredictable and costly scenario, to say the least.

Increased Safety Risks

Emergency maintenance typically arises when something has gone seriously wrong, meaning the equipment may be in a potentially hazardous condition.

What does this mean?

Consider situations involving chemical leaks, electrical failures, or severely damaged equipment with structural issues.

It could also involve overheating machinery or high-pressure bursts.

All of this poses significant safety risks to maintenance workers and other employees nearby, and can even lead to environmental issues.

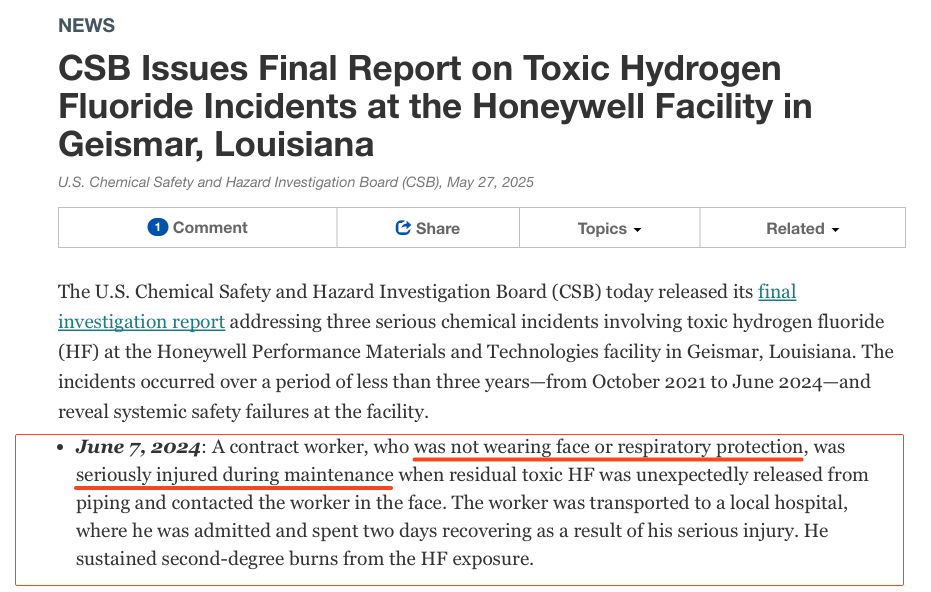

One case worth highlighting is the June 2024 incident at the Honeywell Facility in Louisiana, where a worker was seriously injured during maintenance due to not wearing sufficient personal protective equipment (PPE).

It’s important to note that no details are known about the nature of the maintenance work and whether it was an emergency job or planned maintenance.

However, with safety incidents like these occurring regularly, the risk increases when a crucial piece of equipment needs immediate repair.

There is no simple solution to this issue, as panic-driven environments in emergency situations often reduce technicians’ ability to follow proper safety protocols.

OSHA regularly publishes the standards that are the most frequently violated.

These pose the greatest risk during rushed maintenance, when workers might cut corners to get equipment running again.

Here’s the top 5 safety standards cited in 2024:

| Rank | Safety Standard | Violations |

|---|---|---|

| 1 | Fall Protection: General Requirements (1926.501) | 7,036 |

| 2 | Hazard Communication (1910.1200) | 3,277 |

| 3 | Control of Hazardous Energy – Lockout/Tagout (1910.147) | 2,967 |

| 4 | Ladders (1926.1053) | 2,897 |

| 5 | Respiratory Protection (1910.134) | 2,835 |

Although these standards should ideally be followed even during emergencies, the best approach is to prevent this type of maintenance altogether.

In scenarios where that is unavoidable, the guiding principle should be safety, which shouldn’t be sacrificed for a speedier resolution.

Major Operational Downtime

Unexpected failures can grind operations to a halt.

Whether it is shutting down production lines or interrupting essential services, the result can be major downtime.

Unfortunately, since emergency work is unplanned, every minute counts.

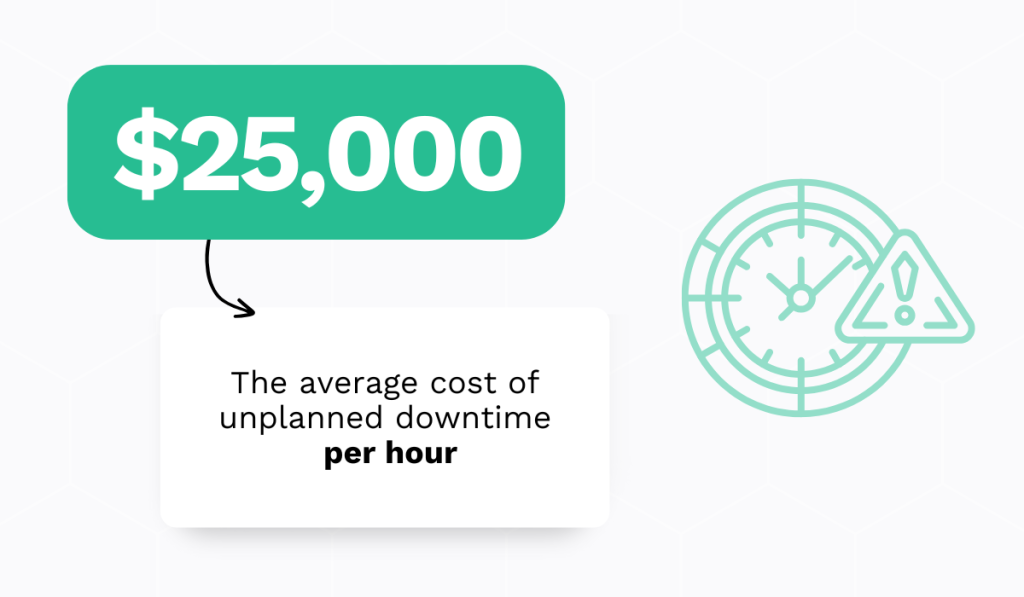

And, as the 2024 MaintainX report shows, every minute of downtime can be extremely costly.

This report cites an average cost of $25,000 per hour of unplanned downtime, rising to as much as half a million dollars for larger organizations.

Some reports may indicate even higher numbers, but even conservative estimates show that downtime can substantially affect your bottom line.

And these costs make sense, considering the consequences that can arise.

You lose production output, you might miss delivery deadlines, and you still have to pay staff and overhead costs while nothing is being produced.

As an example, take a look at the effects of a mill breakdown at a major cement manufacturer, Pacific Cement Limited.

The issue occurred earlier this year, when one of Fiji’s major cement manufacturers had to cease production for two to three months due to a mill breakdown.

The issue was so large that the company was looking at importing cement in anticipation of the potential shortage.

Considering how much a single day of downtime might cost, the financial loss from months of halted operations is bound to be staggering.

Extended downtime creates a ripple effect that damages both revenue and reputation, but avoiding emergency maintenance helps prevent these costly interruptions.

How to Reduce Emergency Maintenance

Now that the high costs and risks of emergency maintenance are clear, the question is: how can they be reduced?

The goal is to move from reacting to problems to preventing them.

So, here are three practical strategies to help you reduce the frequency of emergency maintenance in your facility.

Implement Preventive Maintenance

The obvious solution to a reactive, chaotic maintenance process is to focus more on prevention.

Preventive maintenance is one of the most reliable ways to reduce the number of emergencies.

This is achieved through regularly scheduled equipment inspections, which catch small problems before they escalate.

It also involves proactively addressing repairs, part replacements, and other maintenance tasks rather than waiting for complete failures.

The results of this approach speak for themselves.

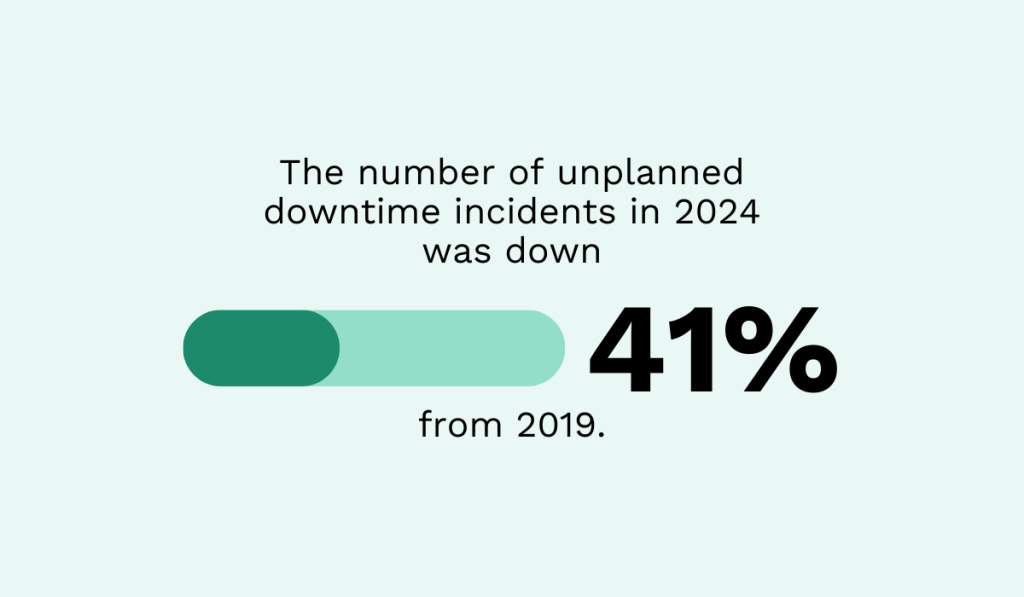

According to 2024 Siemens data, organizations reported roughly 25 downtime incidents a month per facility, down from 42 in 2019.

The report attributes this 41% reduction in incidents to the rise of predictive maintenance, which has enabled manufacturers to maintain machines proactively.

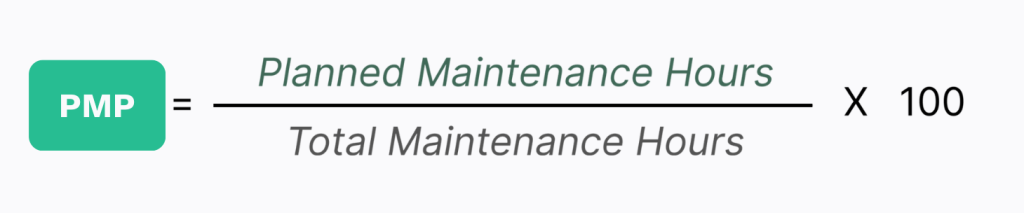

For organizations looking to get started with these preventive maintenance strategies, it is worth tracking your Planned Maintenance Percentage (PMP).

Take a look at the formula for PMP below.

Industry standards suggest that a world-class PMP should be at or above 80%.

If the percentage is lower, it might indicate that your maintenance practices are mostly reactive.

By switching to a more proactive practice, issues can be caught early, preventing them from escalating into hazardous or catastrophic failures.

And, with time freed from constantly putting out fires, maintenance crews can focus on improving operations.

Over time, shifting to proactive approaches can stabilize the entire facility and make operations smoother.

Use a CMMS

One of the most effective ways to implement preventive maintenance and organize maintenance work overall is by using a CMMS.

CMMS is a software solution that centralizes maintenance information and simplifies maintenance workflows.

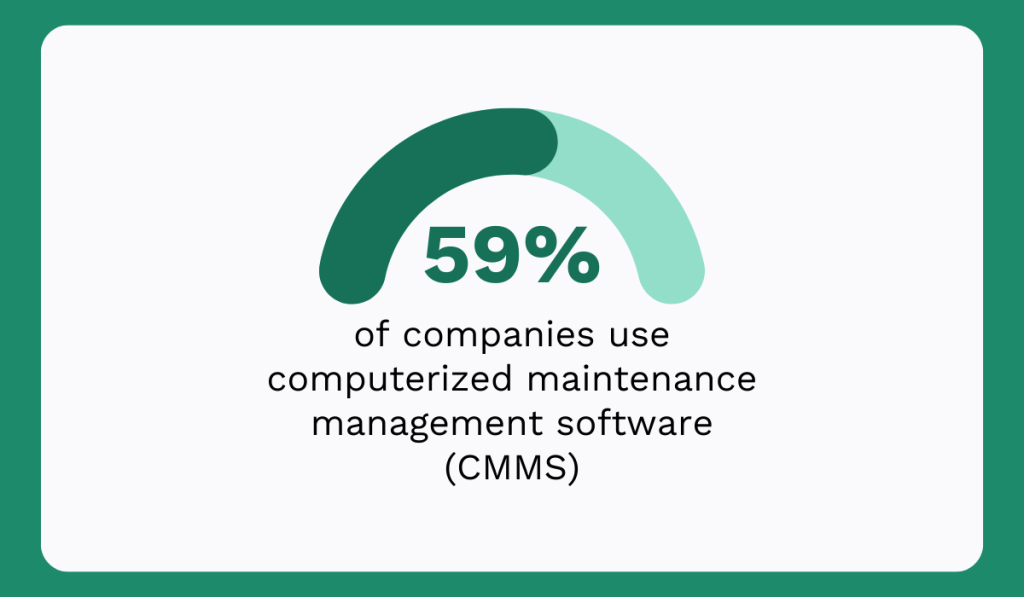

According to industry data, most companies are already utilizing CMMS to streamline their maintenance operations.

Considering the benefits, it is no surprise that adoption is high.

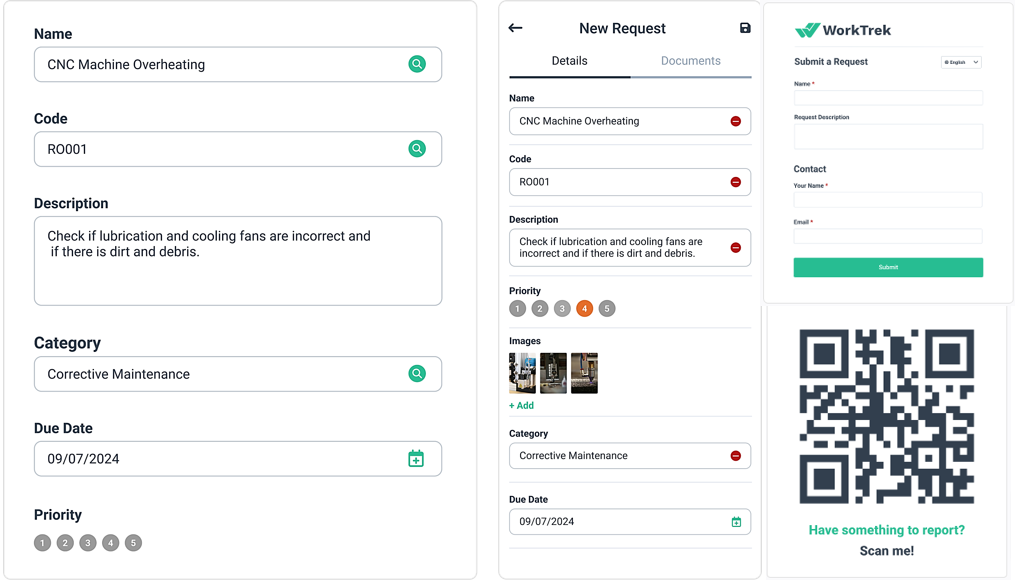

To illustrate this point, let’s take a look at WorkTrek, a modern CMMS platform.

This tool allows teams to store digital maintenance logs for all equipment, including equipment condition, repair history, and necessary documentation.

With all this data in one central location, it is easier to monitor the status of your assets than with paper files or spreadsheets.

Plus, when any equipment needs servicing, WorkTrek lets you create detailed work orders, like the one shown below.

And these don’t need to be one-off requests.

For instance, a water treatment plant could use a CMMS like WorkTrek to schedule recurring maintenance for a high-pressure pump every 500 operational hours.

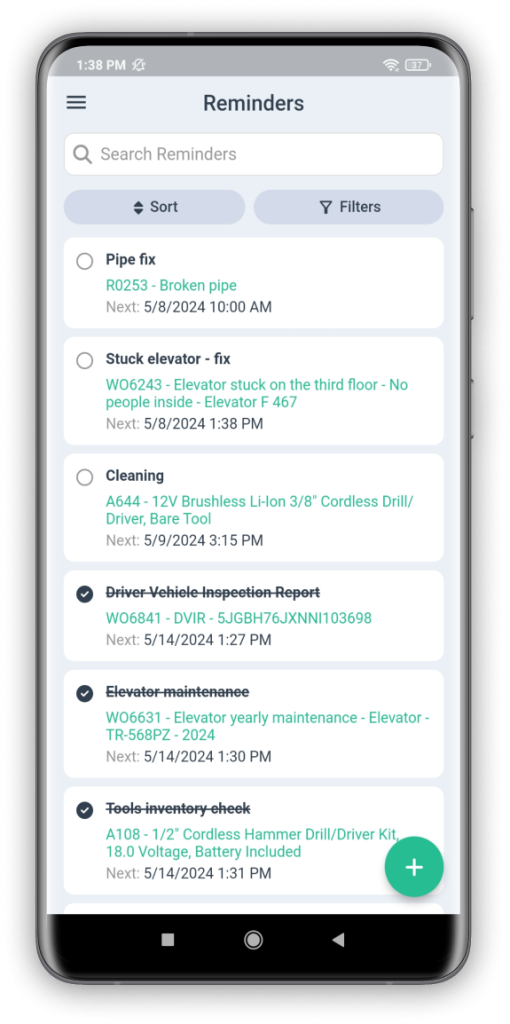

When maintenance is due, the system can instantly alert the assigned technician

These alerts and reminders can also be sent directly to a mobile device.

Timely alerts like these help prevent emergency maintenance by ensuring routine checks are never forgotten or skipped due to human error.

Ultimately, by centralizing data and automating maintenance schedules, you ensure consistent care for your assets, thereby drastically reducing the odds of a surprise breakdown.

Train Operators to Spot Early Warning Signs

Equipment operators play a crucial role in preventing emergency maintenance.

After all, they are the ones who interact with the equipment daily, so they are often the first ones to detect when something is wrong.

In fact, training operators to spot early warning signs that indicate a piece of equipment is failing is a big part of a practice called Total Productive Maintenance (TPM).

TPM is a strategy that involves everyone in the organization in the maintenance process, rather than leaving it solely to the maintenance technicians.

So, by design, TPM requires strong involvement from operators.

This can be a tough process to implement and even harder to pitch to executives.

For example, Keith Mobley, an executive advisor and thought leader in the field of predictive analytics, explains how he once proposed this very idea to a leadership team:

He recalls that this was met with some resistance or confusion from these executives.

However, he explains that this practice is the very essence that enables a more autonomous and proactive maintenance practice.

Unfortunately, even if leadership gets involved, this practice may face resistance from the operators themselves.

After all, you are essentially introducing a new responsibility into their job description.

They may feel that fixing machines is the technician’s job, not theirs, and view it as an unfair burden.

For that to work, operators need to be trained, provided with sufficient resources, and made aware of why this practice helps them and the company.

When implemented correctly, operators will view equipment monitoring as routine, with regular maintenance tasks becoming a natural part of their job.

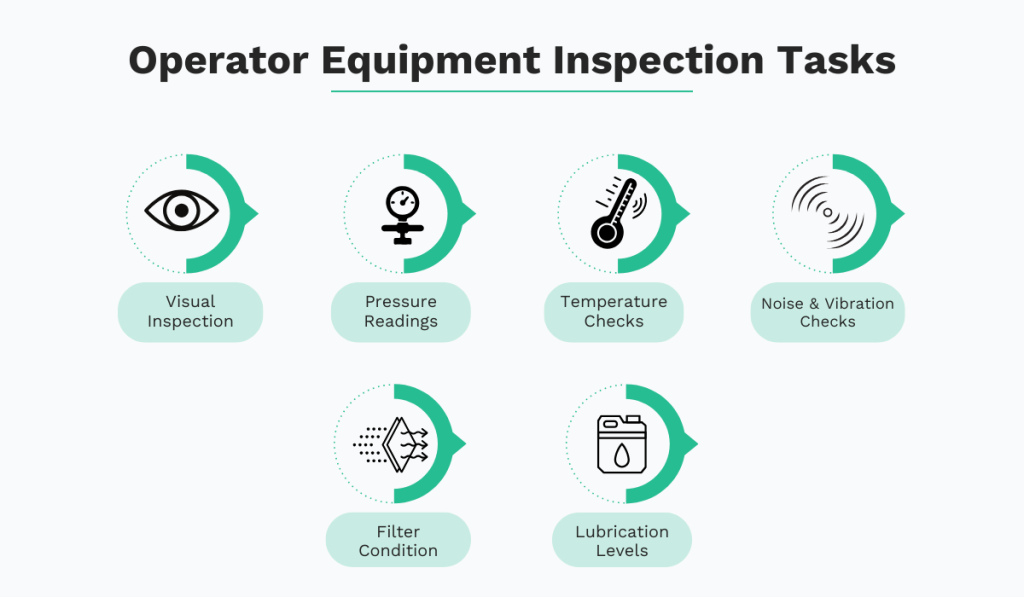

In general, these routine tasks do not involve complex repairs.

Instead, they focus on using the senses to inspect the machine during normal operation.

For example, an operator might notice a new rattling noise or excessive vibration, which can indicate a loose bearing or misalignment.

Or, they might spot abnormal pressure readings on a gauge that could indicate a blockage in a pipe.

While seemingly small tasks, they play a huge role.

By catching these subtle signs early, the operator can alert the maintenance team before the issue becomes a catastrophic emergency that requires immediate, rushed maintenance.

Conclusion

We have now covered what emergency maintenance is, why it is always a last resort, and the practical steps to reduce its frequency.

We hope this guide helps you focus on proactive, planned maintenance rather than waiting for chaotic equipment failure.

Use these insights to improve your asset reliability and convert unscheduled downtime into predictable, managed workflows that keep your operations running smoothly.