Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeIf you run a maintenance organization, you know the importance of creating and maintaining an Operation and Maintenance (O&M) Manual.

It provides clear instructions and detailed guidance for efficiently running equipment and systems. This article offers a step-by-step guide for creating an O&M Manual.

There are several reasons a maintenance organization needs an O&M manual. It can help define the process of maintaining machine property and the process for staff to operate and maintain necessary equipment safely.

In short, it is a valuable resource and training tool for new employees.

Key Takeaways

- O&M manuals provide important guidance for equipment operation and upkeep

- Clear organization and simple language make manuals more effective

- Regular updates ensure the manual stays relevant and useful

What are Operational and Maintenance Manuals?

You need an Operation and maintenance manual if you run a maintenance organization. There are several reasons for this:

Purpose and Importance

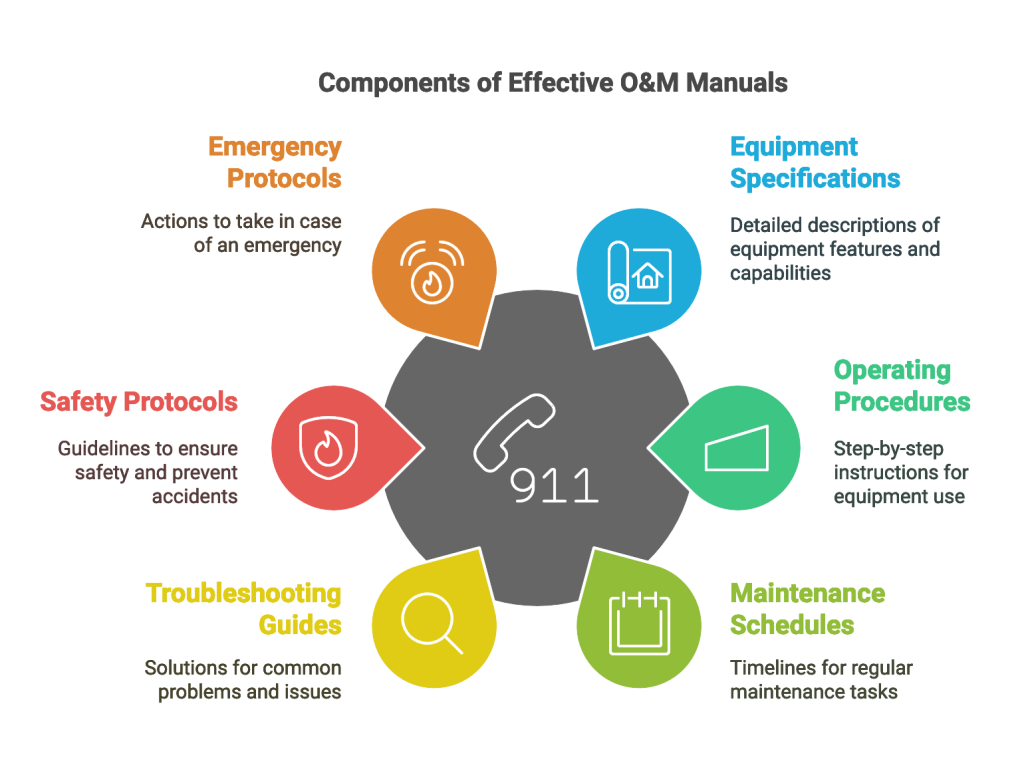

O&M manuals serve as comprehensive guides for operating and maintaining equipment or systems. The key components ensure that these manuals are thorough and effective.

They help ensure safe and efficient operations in facilities. These manuals contain vital details on:

- Equipment specifications

- Operating procedures

- Maintenance schedules

- Troubleshooting guides

- Safety and Emergency Protocols

- Operating Equipment

Data and Illustration: worktrek.com

Well-crafted O&M manuals reduce downtime, extend equipment life, and improve workplace safety. They also aid in training new staff and preserving institutional knowledge.

Audience and Accessibility

O&M manuals cater to various users, including:

- Maintenance technicians

- Maintenance Staff

- Operators

- Facility managers

- Safety personnel

- Third-party contractors

- All relevant stakeholders

The manual is valuable, enabling new employees to adapt quickly and ensuring maintenance teams have all critical information readily accessible.

The content should be clear and easy to understand for all potential users. Organizing the manual with a logical structure and table of contents improves accessibility.

Digital formats allow for easy updates and quick searches.

This ensures users can find needed information quickly during urgent situations.

Compliance and Legal Considerations

O&M manuals play a crucial role in meeting regulatory requirements. They help organizations:

- Comply with industry standards

- Meet safety regulations

- Fulfill warranty conditions

Additionally, these manuals are instrumental in reducing maintenance costs by guiding maintenance personnel in their tasks and preventing unplanned shutdowns.

Documenting procedures and maintenance records can protect companies in case of audits or legal issues.

While it is time-consuming, keep O&M manuals up-to-date with current regulations and best practices.

This includes safety guidelines and emergency procedures.

Preparation for Creating a Manual

Creating an operation and maintenance manual involves key steps.

These include gathering essential information, selecting the right tools, and outlining the content structure.

Gather Necessary Information

Start by collecting all relevant documents about the equipment or processes.

This includes technical specifications, user guides, and safety protocols. Talk to experts who work with the systems daily. Their insights are invaluable.

Set up meetings with different departments. Each may have unique needs for the manual and have other maintenance procedures and maintenance workflows.

Take detailed notes during these discussions and share them with maintenance personnel.

Review existing manuals or documentation since they can provide a helpful template or highlight areas for improvement.

These documents could be valuable for defining routine maintenance and implementing quality control.

Tools and Software Requirements

Choose the right software to create your manual. Word processors work for simple documents. For more complex manuals, consider specialized documentation software.

Additionally, many AI-based large language models, like ChatGPT and Claude AI, can help you create the outline for O&M manual templates. Use this as a starting outline and modify it to meet your requirements.

Ensure you have access to the necessary design tools. These might include flowchart makers or image editing software.

Pick a tool that allows for easy updates. Manuals often need frequent revisions.

Consider collaboration features if multiple team members will work on the manual.

Defining Scope and Content Structure

Outline the main sections of your manual. Common areas include equipment descriptions, operational procedures, and maintenance schedules.

Create a detailed table of contents. This helps organize information and guides the writing process.

Decide on the level of detail for each section. Some parts may need step-by-step instructions, while others might be more general.

Include troubleshooting processes to ensure company assets remain functional and practical, particularly during unplanned downtime.

Plan for visual aids like diagrams or photos.

These can significantly enhance understanding of complex processes.

Consider the end-users when structuring content. Organize information in a way that makes sense for their daily tasks.

Sample O&M Manual Template

To help you get started, below is a sample O&M Manual templates:

Writing the Operation Manual

Creating a practical operation manual involves documenting key processes, safety guidelines, and standard procedures. This ensures consistency and efficiency in daily operations.

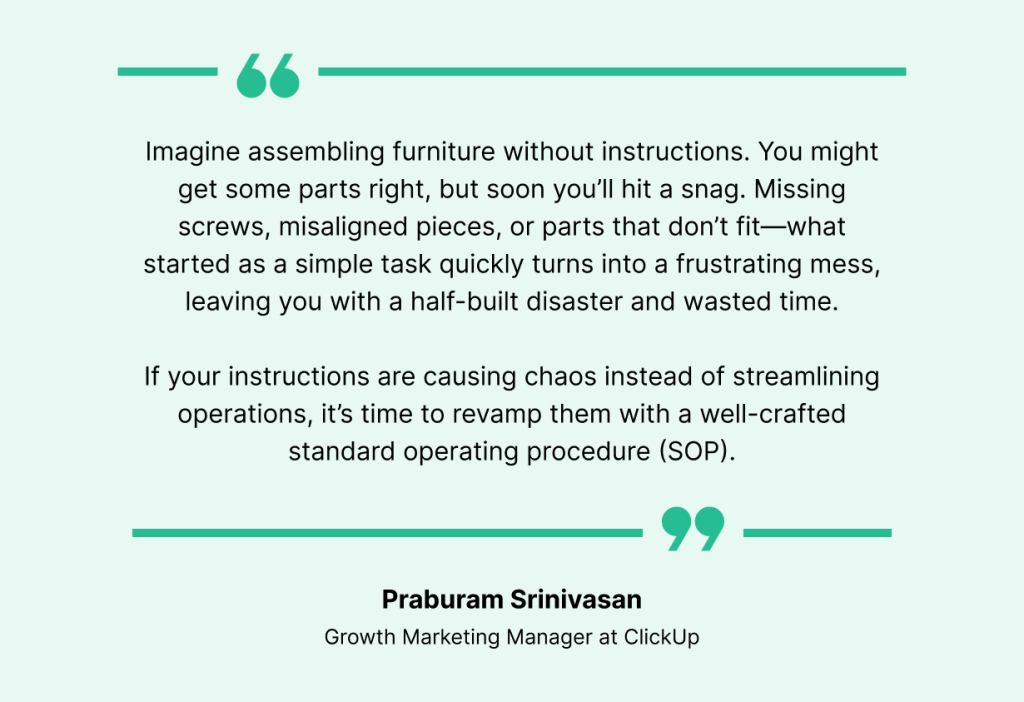

Creating Standard Operating Procedures

Standard Operating Procedures (SOPs) form the backbone of an operation manual. Start by listing all key tasks and processes. Break each task down into clear, step-by-step instructions.

Keep it simple – use easy-to-understand language and avoid jargon.

A picture is worth 1000 words. Don’t forget to include visuals like flowcharts or diagrams to illustrate complex processes. This helps readers grasp information quickly.

Number each step to make the sequence clear.

Test the SOPs with staff members. Ask them to follow the instructions and provide feedback. This helps identify any gaps or unclear sections.

Based on this input, update the SOPs to ensure they are practical and easy to follow.

Documenting Key Processes and Workflows

Start by identifying the core processes that keep your operation running.

These might include:

- Manufacturing steps

- Customer service protocols

- Maintenance routines

- Steps to improve maintenance operations

- Preventative maintenance guides

- Relevant information regarding equipment handling

Write detailed descriptions of each process, including inputs, outputs, and responsible parties.

Create workflow diagrams to represent these processes visually.

Use software tools to make professional-looking diagrams. Include decision points and alternate paths where applicable.

Remember to document troubleshooting procedures and list common issues and their solutions. This will help staff handle problems efficiently without always needing supervisor input.

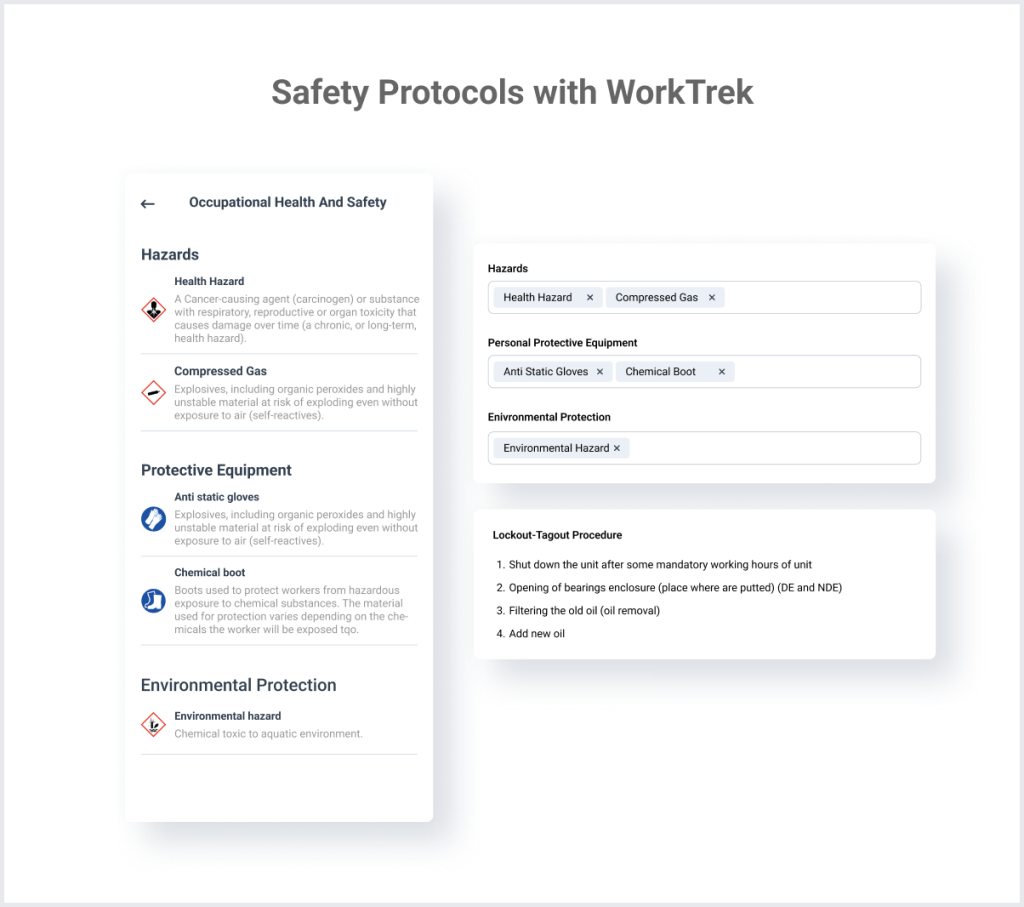

Incorporating Safety Guidelines

Don’t forget to incorporate safety guidelines into your O&M manual.

List all potential hazards in the workplace and provide clear instructions on how to avoid or mitigate risks for each hazard.

This might include Lockout/Tagout operations and other safety protocols.

Include information on required personal protective equipment (PPE). Specify when and how to use each item.

Create checklists for safety inspections and regular maintenance tasks.

Define emergency procedures in detail, including evacuation routes and assembly points. Provide contact information for emergency services and key personnel.

Include a section on first aid procedures and the location of medical supplies.

Developing the Maintenance Manual

Defining and creating a detailed operating and maintenance manual is crucial for keeping equipment running smoothly. It provides essential information for technicians and operators, helps prevent breakdowns, and extends the life of machinery.

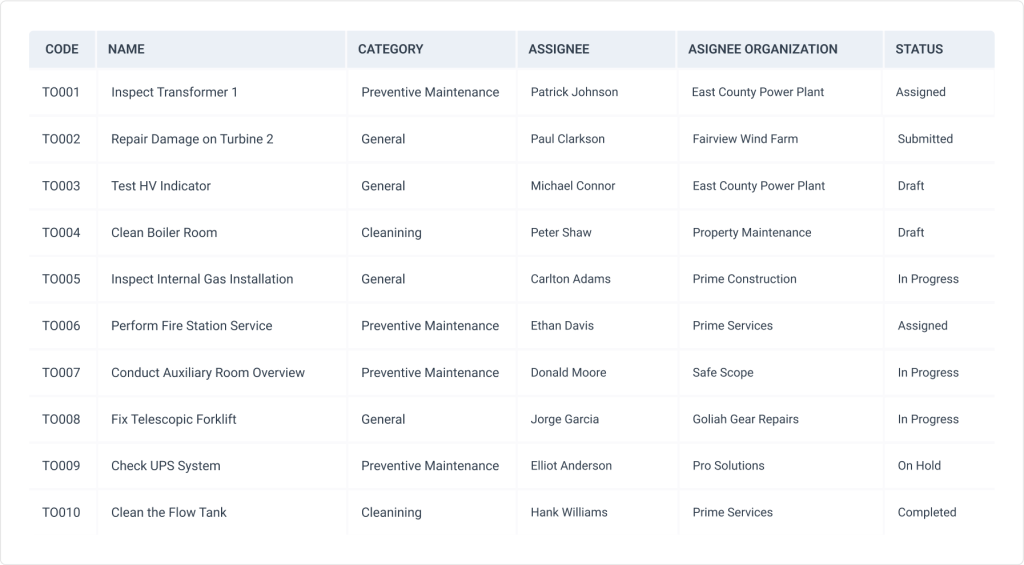

Detailing Maintenance Schedules

Maintenance schedules are the backbone of any good manual. They outline when to perform specific tasks on each piece of equipment. Start by listing all equipment that needs regular upkeep.

Create a table with columns for:

- Equipment name

- Maintenance task

- Frequency (daily, weekly, monthly, etc.)

- Time required

- Skill level needed

Include both preventive and predictive maintenance tasks. Preventive tasks might include regular cleaning or lubrication, while predictive tasks could involve checking for signs of wear.

Always follow manufacturer recommendations for maintenance intervals. Adjust schedules based on equipment usage and environmental factors.

Listing Required Tools and Equipment

A comprehensive list of tools and equipment is essential for efficient maintenance. Organize this section by maintenance task or equipment type.

Include:

- Tool name

- Size or specification

- Quantity needed

- Any special instructions for use

Consider creating a checklist for each maintenance task. This helps technicians gather all necessary items before starting work.

Don’t forget to mention safety equipment like gloves, goggles, or hearing protection. Proper tools and safety gear are key to preventing accidents and injuries.

Troubleshooting Common Issues

A good troubleshooting guide can save time and reduce downtime.

Start by identifying common problems for each piece of equipment.

Understanding the company’s history can also provide valuable context for troubleshooting processes.

Create a table with these columns:

- Problem description

- Possible causes

- Diagnostic steps

- Solutions

Use clear, simple language to describe each step. Avoid technical jargon when possible. If jargon is necessary, include a glossary of terms.

Include diagrams or photos to illustrate complex procedures. Visual aids can significantly improve understanding and reduce errors.

Emphasize safety precautions for each troubleshooting task. Remind users to consult with experts for complex issues beyond their skill level.

Formatting and Designing the Manual

An operation and maintenance manual’s visual layout and structure play a key role in its usability. Clear formatting and thoughtful design choices help readers find information quickly and understand complex procedures easily.

Layout Considerations

When designing the manual’s layout, focus on readability and ease of navigation.

Use a clear, legible font like Arial or Calibri for body text in an 11-12 point size. Larger fonts can be used for headings to create a clear hierarchy.

Break up text into short paragraphs and use bullet points for lists. This makes the content easier to scan and digest.

Include plenty of white space to avoid overwhelming the reader. Margins should be at least 1 inch on all sides.

Use headers and footers to display page numbers, section titles, and other helpful navigation aids.

Utilizing Visuals and Diagrams

Visuals are crucial for explaining complex procedures or equipment layouts. Where appropriate, use high-quality photos, illustrations, and diagrams.

Label all visuals clearly and refer to them in the text. Place images close to the relevant text to avoid confusion.

Consider using flowcharts for multi-step processes. These can help readers understand the sequence of actions at a glance.

Tables are useful for presenting data or comparing different options. Keep tables simple and use clear headings for each column.

Ensuring Consistency in Design

Maintain a consistent design throughout the manual to create a professional look and aid navigation.

Use the same fonts, colors, and heading styles across all sections. Use charts and images to help the reader better understand the content.

Create a style guide that outlines formatting rules for headings, captions, lists, and other elements. This ensures uniformity even if multiple people work on the manual.

Use templates for recurring elements like procedure steps or safety warnings. This saves time and maintains a cohesive look.

Consider using color coding to differentiate between sections or types of information. Just be sure to choose easily distinguishable colors and print well in black and white.

Reviewing and Revising the Manual

A thorough review and revision process ensures the Operation and Maintenance Manual is accurate, user-friendly, and meets its intended purpose.

This critical step involves verifying technical details, gathering feedback, and making necessary improvements.

Technical Accuracy Verification

Make sure to review your O&M manual technically.

Start by cross-checking all technical specifications, procedures, and data against original equipment documentation and industry standards.

Verify that all diagrams, schematics, and illustrations are correct and up-to-date.

Engage subject matter experts to review specific sections related to their areas of expertise. They can spot errors or outdated information that might not be obvious to others.

Use a checklist to ensure all critical elements are covered. This includes safety procedures, operational guidelines, maintenance schedules, and troubleshooting steps.

Conducting Peer Reviews

Peer reviews play a vital role in improving the quality of the manual. Select reviewers from different departments or roles who will be using the manual.

Provide clear guidelines on what aspects to focus on during the review. This might include:

- Clarity of instructions

- Logical flow of information

- Completeness of content

- Consistency in terminology

Set a realistic timeline for the review process. Allow enough time for thorough examination but maintain momentum to complete the project.

Encourage reviewers to test procedures and instructions hands-on when possible. This practical approach often reveals issues that may not be apparent from reading alone.

Incorporating Feedback and Improvements

Collect all feedback from technical verifications and peer reviews. Organize comments and suggestions into categories for easier processing.

Prioritize changes based on their impact on safety, operational efficiency, and user understanding. Address critical issues first.

Make revisions systematically, ensuring each change aligns with the overall structure and purpose of the manual. Update related sections to maintain consistency throughout the document.

Consider creating a system for regular updates to keep the manual current. This might involve scheduled reviews or a process for users to submit change requests.

Test the revised manual with end-users to confirm improvements have addressed initial concerns. This final check helps ensure the manual meets its intended goals.

Manual Testing and Validation

Manual testing and validation are key to creating an effective operations and maintenance manual. These processes ensure the document is user-friendly and meets its intended purpose.

Real-world Usability Testing

Real-world usability testing involves actual users evaluating the manual hands-on. This step is vital for identifying any gaps or unclear instructions.

Start by selecting a diverse group of testers who match the manual’s target audience.

Give them specific tasks to complete using only the manual as a guide. Observe their actions and note any difficulties they encounter.

Ask testers to think aloud as they work through the manual. This will provide insight into their thought processes and highlight areas of confusion.

After testing, gather feedback through surveys or interviews. Ask about the manual’s clarity, organization, and completeness. Use this input to make necessary revisions.

Effectiveness Assessments

Effectiveness assessments measure how well the manual achieves its goals. These evaluations help refine the document to serve its users better.

Begin by setting clear objectives for the manual. These might include reducing equipment downtime or improving safety compliance. Develop metrics to measure these goals.

Conduct before-and-after comparisons. Track relevant data before implementing the new manual, then compare it to results after its introduction. This shows the document’s impact on operations.

Use error logs and help desk requests to identify common issues. If specific problems persist after the manual’s release, updates may be needed in those areas.

Don’t forget to review and update the manual regularly based on assessment results. This ensures it remains relevant and effective over time.

Publishing the Manual

Publishing and distributing the operation and maintenance manual is a key step. It ensures the manual reaches its intended users and remains easily accessible.

The format and distribution methods chosen impact how effectively the information is used.

Choosing a Publication Format

Digital formats like PDFs offer flexibility and easy updates. They allow for quick searches and hyperlinks between sections.

Print manuals work well in environments without computer access. Some companies use both digital and print versions.

When picking a format, consider the end user’s needs. Field technicians may prefer a sturdy printed manual, while office staff might find a searchable digital version more useful.

Cloud-based solutions can provide real-time updates and mobile access.

Distribution Strategies

Effective distribution ensures the manual reaches all relevant personnel. Email the digital version to staff and post it on the company intranet. For print copies, mail them directly to work sites or hand them out during training sessions.

Set up a system to track who has received the manual. This helps ensure everyone has the latest version. Consider creating a sign-off process where employees confirm they’ve read and understood the content.

Regular updates are crucial. Establish a schedule for reviewing and revising the manual. Communicate changes clearly to all users. Digital formats make updates more straightforward, but printed versions need a system for replacing outdated pages.

Training and Support

Provide training and support for staff, helping them understand the manual’s content and assisting when needed.

Conducting Training Sessions

Training sessions introduce staff to the manual’s structure and contents. They begin with an overview of the manual’s purpose and organization.

Then, they show employees how to quickly navigate sections and find key information.

Break training into smaller modules focused on specific topics. This helps prevent information overload. Use hands-on exercises to reinforce learning.

For example, have staff lookup procedures in the manual during simulated scenarios.

Create a training schedule that works for different shifts and departments. Consider recording sessions for those who can’t attend in person.

Follow-up training with quizzes to check understanding of the material. Encourage staff with prizes or gifts to engage in the process.

Setting Up Support Channels

Establish clear support channels for manual-related questions—designate point persons in each department who are well-versed in the manual’s contents.

These individuals can answer questions and provide guidance.

Set up an internal help desk or ticketing system for manual-related inquiries. This will ensure questions are tracked and answered promptly. Also, create an FAQ section based on common issues that arise.

Consider implementing a chat system for quick questions. This can be particularly helpful in urgent situations. Based on feedback received through support channels, regularly update the manual.

Provide ongoing refresher training to keep staff up-to-date on manual changes. This helps maintain consistent knowledge across the organization.

Ongoing Updates and Revisions

Keeping an Operation and Maintenance Manual current is key for its usefulness.

Regular reviews and timely updates ensure the manual stays relevant as equipment and processes change over time.

Scheduling Periodic Reviews

Set up a review schedule for the O&M manual. This could be yearly, quarterly, or monthly, depending on how often things change. Put someone in charge of these reviews. They should check each section for accuracy.

During reviews, look for outdated information, check if procedures still work, and ensure correct contact details. Ask staff for feedback on what needs updating. Keep a log of when reviews happen and what changes are made.

Use digital tools to make reviews easier. Set reminders for review dates. Use version control software to track changes. This helps see what’s been updated and when.

Updating for Equipment or Process Changes

When new equipment arrives or processes change, update the manual right away.

Don’t wait for the next review—train staff to report changes that affect the manual.

Create a change form for updates. Include:

- What changed

- Why it changed

- How it affects current procedures

- New instructions or info needed

Add new sections for new equipment, update old sections for process changes, remove outdated information to avoid confusion, and ensure that safety procedures are current.

Use clear language in updates. Avoid jargon.

Test new procedures before adding them to the manual. Get feedback from workers who use the equipment or follow the processes.

Summary

An O&M manual guides equipment operation and maintenance.

It is a comprehensive resource for safe, efficient operations, including specs, procedures, schedules, and troubleshooting. The manual caters to technicians, operators, and managers, helping them comply with regulations and reduce costs.

Creating one involves gathering information, defining structure, documenting processes, and using clear formatting and visuals. Publishing in accessible formats, providing training, and conducting periodic reviews keep the manual relevant.