Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- Industrial boilers have an average lifespan of 15-25 years, but proper maintenance can extend this significantly

- Poor water quality causes 90% of boiler system failures, leading to scale buildup and reduced efficiency

- Annual inspection costs are 3-5 times less expensive than emergency repairs from boiler failure

Industrial boiler maintenance is one of those operational necessities that facility managers can’t afford to overlook.

When properly maintained, boilers operate efficiently, keep production running smoothly, and keep energy costs under control. Neglect them, and you’re looking at costly repairs, unexpected breakdowns, and potential safety hazards.

The good news?

Establishing a comprehensive boiler preventive maintenance program doesn’t have to be complicated. With the right practices in place, you can maximize boiler efficiency, extend equipment life, and ensure safe operation for your entire facility.

In this guide, we’ll walk you through essential best practices for industrial boiler maintenance to help you avoid costly surprises and keep your boiler system running at optimal efficiency.

Understanding Your Industrial Boiler System

Before talking about maintenance procedures, it’s important to understand the basic components of your industrial boiler system.

Modern industrial steam boilers consist of several critical elements that work together to generate steam or hot water for various industrial processes.

Anatomy of a Boiler system

The heart of any boiler system is the combustion chamber, where natural gas or other fuel sources burn to create heat. This heat transfers through boiler tubes and heat exchanger surfaces to convert water into steam. The burner assembly, complete with its ignition system and burner’s pilot tube, controls the combustion process and ensures efficient combustion.

Your boiler’s control system monitors everything from boiler pressure to water levels, adjusting operations automatically to maintain optimal efficiency. Safety valves and pressure relief valves serve as critical safeguards, preventing dangerous pressure buildup in the steam system.

According to industry experts, understanding how these components interact helps facility managers identify potential issues before they escalate into major problems. Small issues left unchecked can lead to unsafe conditions, higher fuel costs, or even costly repairs that could have been prevented with proper maintenance.

The flue gas vent piping system safely removes hot combustion gases from the boiler room, while the water treatment system ensures that boiler feedwater meets quality standards.

Water Quality

Poor water quality is responsible for roughly 90% of boiler failures, making this system absolutely critical to your equipment’s longevity.

Modern industrial settings often feature multiple boilers working in tandem, with sophisticated control systems managing load distribution and efficient operation across the entire fleet.

This modular approach provides redundancy and allows for scheduled maintenance without complete system shutdowns.

Daily Inspections: Your First Line of Defense

Daily inspections form the cornerstone of any effective boiler preventive maintenance program. These routine checks help catch problems early, maintain warranty compliance, and support safe, efficient operation.

Confirm Water Levels

Start each shift by checking the water gauge glass to confirm water levels are within the safe operating range.

Low water conditions can cause serious damage to boiler equipment and create dangerous situations. Research shows that water level issues are among the most common causes of unexpected breakdowns in industrial settings.

Boiler Pressure Monitoring

Monitor boiler pressure and temperature readings throughout the day, watching for unusual fluctuations that could indicate control system issues. Your boiler operation should show consistent patterns, and any deviation from normal parameters warrants immediate attention.

Unusual Noises

Listen for unusual noises during operation. Banging, whistling, or grinding sounds often signal issues with boiler tubes, scale buildup, or combustion air piping problems. These auditory cues can alert you to developing issues before they appear in performance metrics.

Burner Flame

Inspect the burner flame during startup and operation. A proper burner flame should be steady and blue. Yellow or flickering flames indicate incomplete combustion, which wastes fuel and can produce carbon monoxide. This can also be a serious safety concern.

Fuel Supply

Check the fuel supply system daily, ensuring adequate fuel is available, and that delivery systems are functioning correctly. Interruptions in fuel supply can cause unsafe conditions and require time-consuming restart procedures.

Safety Devices

Verify that safety devices are operational, including low-water cutoffs and pressure relief valves. These critical components protect your facility from catastrophic failures and must function reliably.

Detailed Record Maintenance

Finally, maintain detailed records in your maintenance log. Document all readings, observations, and any corrective actions taken. This historical data becomes invaluable for identifying trends and planning proactive maintenance interventions.

Water Treatment: The Foundation of Boiler Longevity

As explained earlier, water quality is one of the biggest factors affecting boiler efficiency and equipment lifespan.

Poorly treated water causes scale, corrosion, and carryover, which significantly reduce heat transfer, waste fuel, and shorten equipment life.

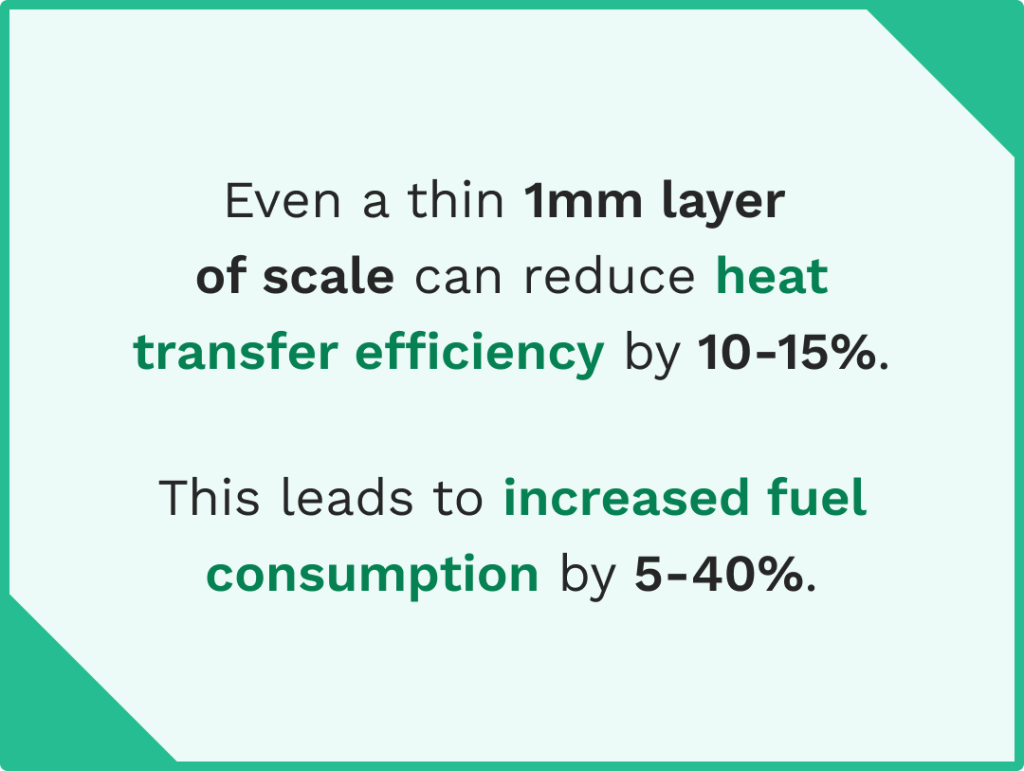

Reduce Scale Buildup

Scale buildup on heat exchanger surfaces acts as an insulating barrier, forcing your boiler to work harder to generate the same amount of steam. This reduced efficiency translates directly to higher fuel costs and increased wear on boiler components.

Industry research indicates that even a thin layer of scale can reduce heat transfer efficiency by 10-15%.

Water Treatment System

Your water treatment system should address several key concerns.

First, it must remove dissolved minerals that cause scale buildup on boiler tubes and other internal surfaces. Calcium and magnesium are the primary culprits, forming hard deposits that impair heat transfer and can eventually lead to tube failures.

Second, proper water treatment prevents corrosion by controlling pH levels and removing dissolved oxygen. Oxygen pitting occurs when non-condensable gases enter the boiler system and attack metal surfaces, eventually leading to leaks and costly repairs.

Regular maintenance and chemical treatment of your boiler feedwater prevent these issues from developing. Over time, impurities in city or well water can accumulate in your boiler system, creating serious problems if left unaddressed.

Water Chemistry Monitoring

Monitor water chemistry daily, testing for hardness, alkalinity, and dissolved solids. Keep detailed records of test results and chemical additions, as these logs help you identify trends and adjust treatment programs proactively.

Blowdown Schedule

Implement a blowdown schedule to remove concentrated solids from the boiler system. Controlled surface blowdown keeps dissolved solids in check, while bottom blowdown removes sludge and sediment buildup that settles at the bottom of the pressure vessel. Done correctly, this practice safeguards efficiency, water quality, and boiler longevity.

Automatic Chemical Feeders

Modern water treatment systems often include automated chemical feeders that continuously maintain optimal water quality. These systems reduce the risk of human error and ensure consistent treatment even during off-hours or when trained personnel aren’t available.

Regular Cleaning and Maintenance Tasks

Beyond daily inspections, industrial boilers require periodic cleaning and maintenance to ensure efficient combustion and prevent long-term damage.

Developing a regular maintenance schedule helps prevent unexpected failures and extends the operational life of your boiler equipment.

Test Low-Water Cutoff

Weekly maintenance tasks should include testing the low-water cutoff system to verify that it shuts down the burner when water levels drop too low. This safety device is your first line of defense against catastrophic failure, and testing it weekly ensures it remains functional.

Cleaning Gauges

Clean the water level gauge glass weekly to ensure accurate readings. Mineral deposits and residue can obscure the true water level, potentially leading operators to misjudge critical safety parameters.

Burner Components

Inspect and clean burner components monthly, including the pilot ignition system and fuel nozzles. Proper burner maintenance ensures efficient combustion and prevents fuel waste. Clean burners also reduce emissions and help maintain environmental regulatory compliance.

Checking Vents and Piping Systems

Check combustion air piping and vents for blockages or restrictions. Adequate airflow is essential for complete combustion and safe operation. Restricted air supply can lead to carbon monoxide production and dangerous operating conditions.

Examine the flue gas vent piping system for signs of corrosion or leaks. Hot combustion gases must vent safely from the boiler room, and any deterioration in this system poses serious safety risks.

Safety Valve Testing

Test safety valves and pressure relief valves according to manufacturer recommendations, typically quarterly. These critical safety devices must operate reliably, and regular testing ensures they’ll function when needed.

Boiler Tubes

Inspect boiler tubes and internal surfaces during scheduled shutdowns. Use boroscopes to perform internal tube checks and identify corrosion, scale buildup, or other damage that could compromise system integrity. Industry best practices recommend scheduling tube inspections during planned outages rather than waiting for suspected leaks.

Cleaning Procedures

Clean soot and debris from heat transfer surfaces annually or as needed based on fuel type and operating conditions. Accumulated soot reduces heat transfer efficiency and forces your boiler to burn more fuel for the same steam output.

Safety Inspections and Testing

Safety should always be the top priority when maintaining industrial boiler systems. Regular safety inspections help identify potential hazards before they can cause accidents or equipment damage.

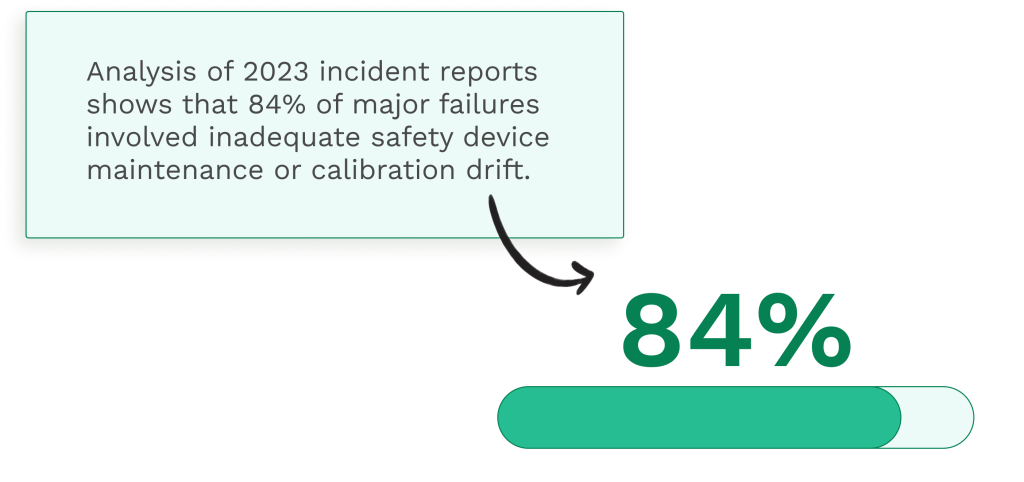

Safety Devices

Test safety devices systematically and document all results. Low-water cutoffs, flame safeguard systems, and emergency shutdown controls must all function reliably. Implement a testing schedule that regularly covers each safety component.

Testing Combustion Efficiency

Conduct combustion efficiency tests quarterly to ensure your boiler operates at optimal levels. These tests measure the ratio of fuel consumed to heat produced, identifying opportunities to improve energy efficiency and reduce fuel costs. Professional combustion analyzers can detect problems that aren’t visible during routine inspections.

Check Safety and Pressure Relief Valves

Verify that all safety valves and pressure relief valves are properly set and functioning. These devices prevent dangerous pressure buildup in pressure vessels, which could lead to catastrophic failures. Never disable or adjust these components without proper authorization and expertise.

Inspect the combustion chamber and refractory lining for damage. Damaged refractory leads to heat loss and tube overheating, while poor insulation increases operating costs. Use infrared thermography during operation to spot insulation damage without shutting down the system.

Improve Ventilation

Ensure proper ventilation in the boiler room at all times. Burners need adequate combustion air to prevent carbon monoxide production, which poses serious health risks to operators. Keep the boiler room clear of unnecessary items that could restrict airflow or present fire hazards.

Emergency Procedures

Review and update emergency procedures regularly with all personnel who work in or near the boiler room. Everyone should know how to respond to common emergency scenarios, including fire, steam leaks, or equipment malfunctions.

External Inspectors

Partner with certified inspectors to comply with ASME and NBIC standards for annual examinations. These professional inspections provide an objective assessment of your boiler’s condition and help maintain compliance with environmental regulations and safety standards.

Annual Inspection and Compliance

Industrial boilers are subject to strict safety and environmental regulations that require annual inspections by certified professionals. These comprehensive inspections go beyond routine maintenance to thoroughly assess your boiler system’s condition and compliance status.

According to industry standards, annual inspections by certified inspectors are often mandated by regulatory bodies. These inspections ensure your equipment meets current safety codes and operating standards.

Detailed Examination of Boiler Components

During an annual inspection, certified technicians conduct a thorough internal and external examination of all boiler components. This includes inspecting pressure vessels for corrosion, checking boiler tubes for scaling or damage, and verifying that all safety systems function properly.

Reviewing Maintenance Records

Inspectors also review your maintenance records, water treatment logs, and operational data. This documentation demonstrates your commitment to proper maintenance and helps identify any patterns that might indicate developing problems.

Maintenance Window

The inspection process typically requires a complete shutdown of the boiler system. Plan these shutdowns strategically to minimize disruption to your facility’s operations. Some modern boiler systems, such as modular designs, allow staged inspections, where individual units can be taken offline while others continue operating.

Compliance

Annual inspections also verify compliance with environmental regulations regarding emissions and efficiency. Many jurisdictions have specific requirements for NOx emissions and thermal efficiency that your boiler must meet.

Keep detailed records of all inspections, including any deficiencies noted and corrective actions taken. These records are essential for regulatory compliance and provide valuable historical data for planning future maintenance activities.

Budget Considerations

Budget appropriately for annual inspections and any repairs they might reveal. While inspection costs may seem significant, they’re far less expensive than emergency repairs resulting from undetected problems.

Research shows that annual inspection costs are typically 3-5 times less than the cost of emergency repairs due to equipment failure.

How CMMS Software Streamlines Boiler Maintenance

Managing all these maintenance requirements manually can be overwhelming. That’s where a Computerized Maintenance Management System (CMMS) becomes invaluable for facility managers overseeing industrial boiler operations.

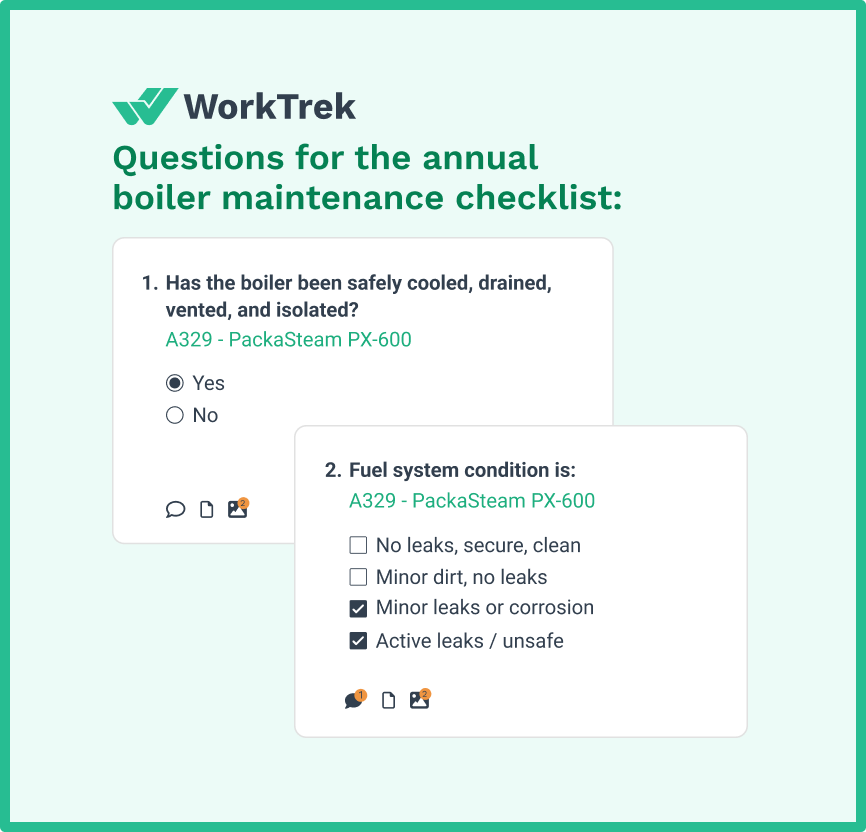

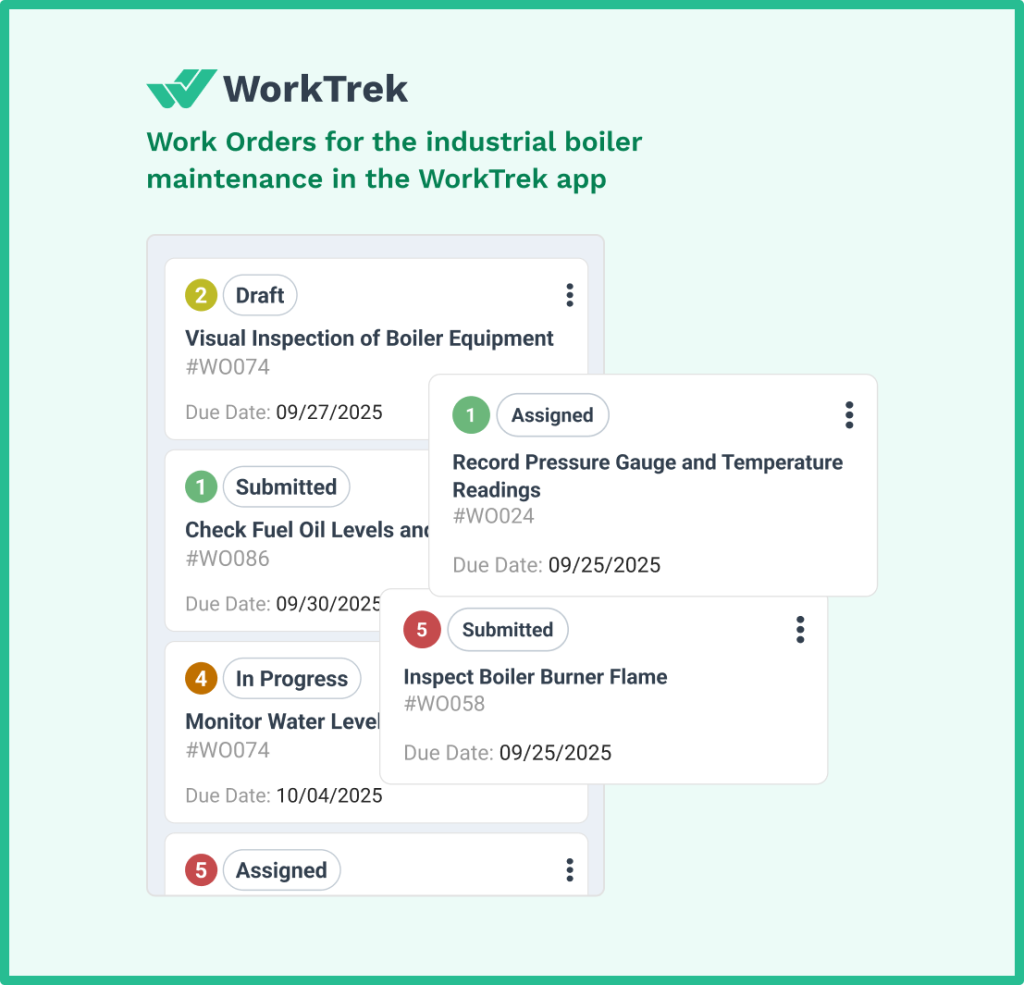

Modern CMMS platforms like WorkTrek centralize all aspects of boiler maintenance in one comprehensive system. Instead of juggling spreadsheets, paper checklists, and scattered maintenance records, everything you need is accessible from a single dashboard.

Automate Preventive Maintenance

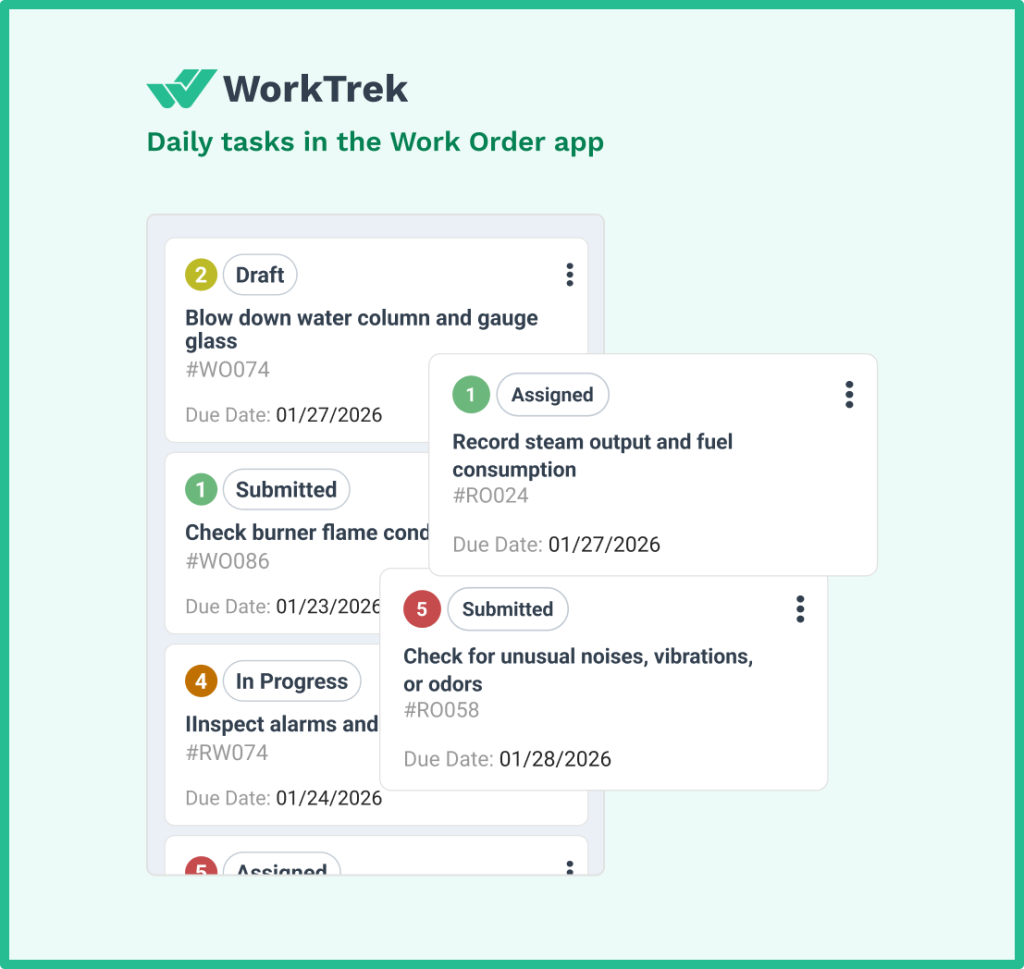

WorkTrek automates preventive maintenance scheduling for your entire boiler system maintenance program. Set up recurring tasks for daily inspections, weekly testing, monthly cleaning, and annual inspections. The system automatically generates work orders at the appropriate intervals, ensuring nothing falls through the cracks.

Work Order Management

Work order management becomes significantly more efficient with a CMMS. When technicians complete tasks, they can log details, attach photos of potential issues, and record meter readings directly from their mobile devices. This real-time documentation creates a comprehensive maintenance history for each piece of boiler equipment.

Spare Parts Management

Track critical spare parts and supplies through integrated inventory management. Know exactly when to reorder safety valves, burner components, water treatment chemicals, and other essential items. WorkTrek can automatically flag low inventory levels and generate purchase orders, preventing unexpected parts shortages that could delay critical repairs.

Key Performance Indicators

Monitor key performance indicators to identify efficiency trends and potential problems. Track metrics like fuel consumption, water treatment costs, and combustion efficiency over time. This data-driven approach helps you spot developing issues before they cause unexpected breakdowns or reduced efficiency.

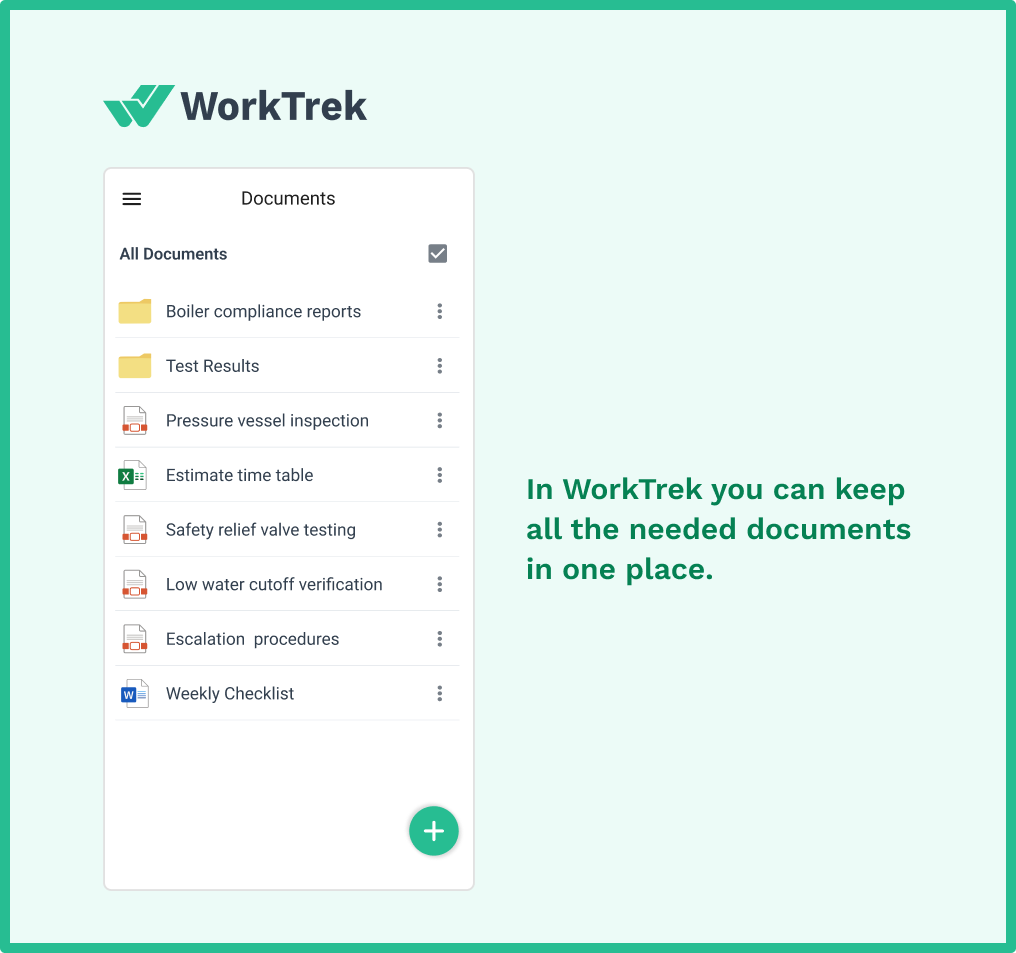

Document Storage

Store all compliance documentation in one secure location. Upload inspection reports, water quality test results, and certification documents. When regulators request records, you can produce comprehensive documentation instantly instead of searching through filing cabinets.

Conclusion

Key elements of an effective maintenance program include daily inspections, rigorous water treatment, regular cleaning, safety testing, and annual professional inspections.

Modern CMMS platforms like WorkTrek make managing these requirements much easier, automating scheduling, centralizing documentation, and providing the data insights you need for continuous improvement.

Remember that every dollar invested in preventive maintenance saves you several dollars in avoided breakdowns, emergency repairs, and lost production time. The cost savings from improved energy efficiency alone often justify a comprehensive maintenance program.

Whether you’re managing a single boiler or a complex multi-boiler system across multiple facilities, the principles remain the same.