Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

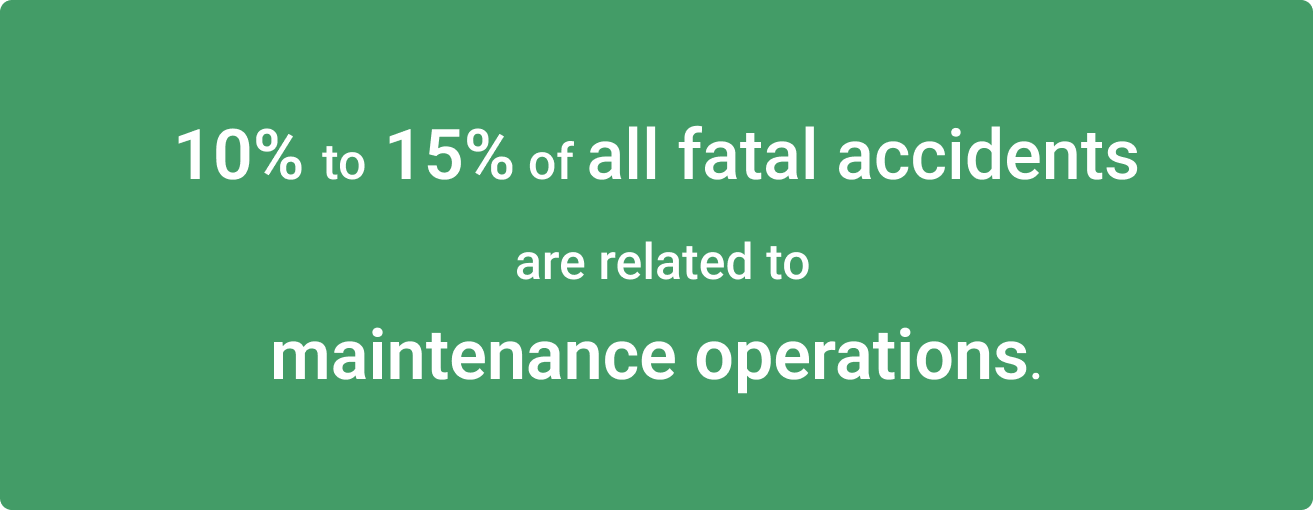

Try for freeLockout Tagout (LOTO) safety is a key part of workplace safety. It keeps workers safe when fixing or maintaining machines. The right steps can stop accidents and save lives.

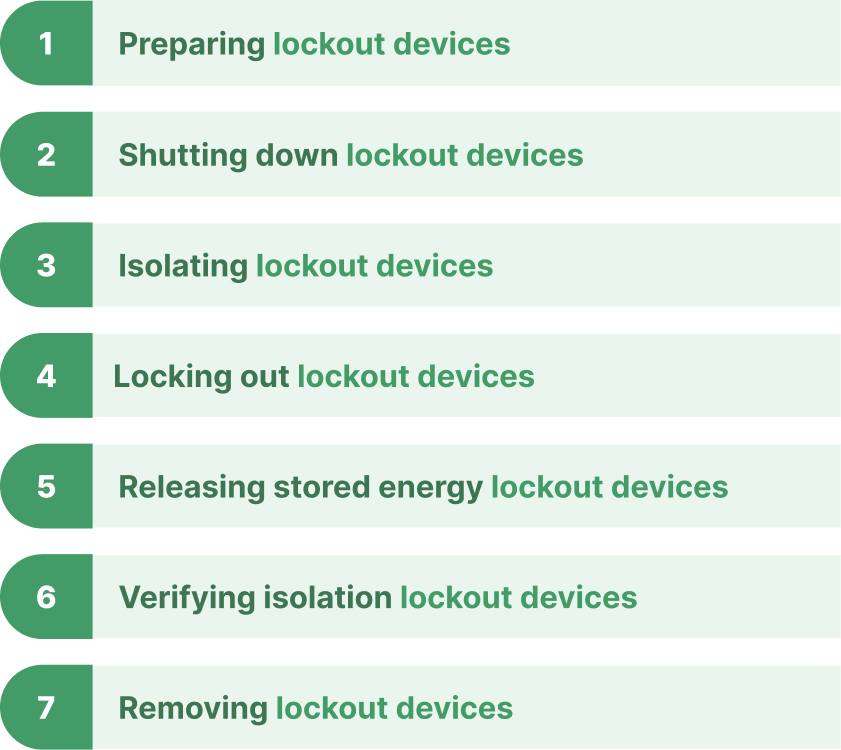

Illustration: WorkTrek / Data: Brady

LOTO safety has seven main steps. These steps include preparing, shutting down, isolating, locking out, releasing stored energy, verifying isolation, and removing lockout devices. Each step plays a vital role in keeping workers safe.

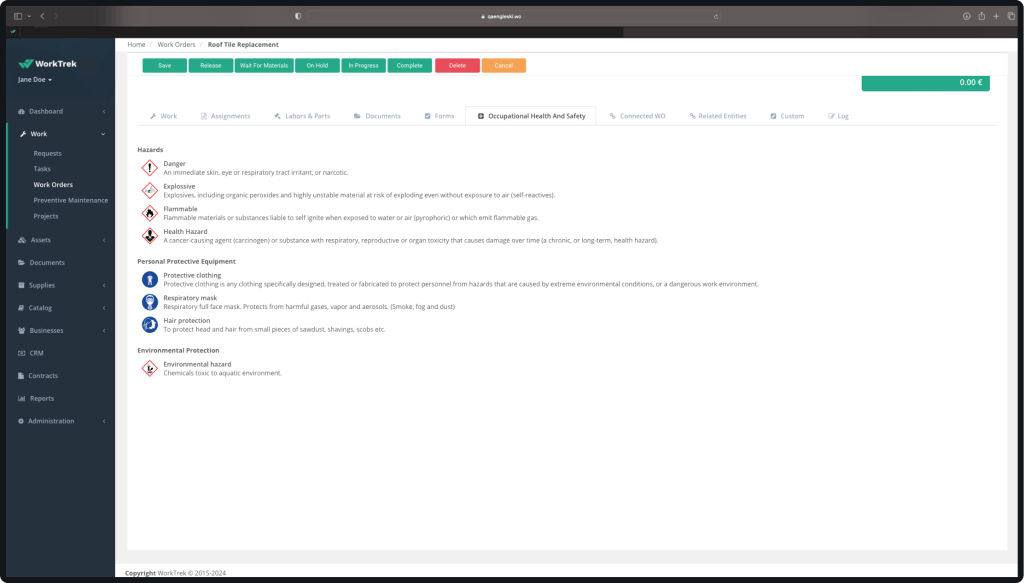

Source: WorkTrek

Any LOTO program should include additional items like employee training and team communication.

This article mainly covers several tips on implementing a LOTO safety process. If you are looking for more detailed information on LOTO, refer to our LOTO comprehensive LOTO guide.

Preparation for Lockout/Tagout

Preparing for lockout/tagout is a key step to keeping workers safe. It involves finding energy sources and getting the right tools.

Identifying Energy Control Points

Workers need to know where energy comes from in machines, including electricity, hydraulics, and other power types. A walk-through of the work area helps spot these points.

Illustration: WorkTrek / Data: CAHill

Hazardous energy sources must be listed. Each one needs a clear plan to shut it off. Workers should mark these points with signs or labels.

It’s also important to find hidden energy. Springs or raised parts can store energy and should be part of the lockout plan.

LOTO Devices and Equipment

The right tools are needed for safe lockout/tagout. Locks are a must. Each worker should have a lock with one key.

Tags are used with locks. They show who put the lock on and why. Tags should be easy to read and strong enough to last.

Other tools might include circuit testers or grounding wires. These help check if energy is off.

Proper LOTO devices are crucial. They should fit the machines locked out, and employers must provide enough devices for all workers.

LOTO Safety Procedures

LOTO safety procedures are critical for protecting workers from dangerous energy sources. These steps ensure equipment is properly shut down, isolated, and verified safe before maintenance or repairs begin.

1. Notification of Affected Employees

Before starting LOTO procedures, all affected employees must be informed. This includes workers who operate the equipment and those in the area.

Illustration: WorkTrek / Data: Morris Wilson Knepp Jacquette

The notification should explain:

- Which equipment will be locked out

- Why the lockout is necessary

- How long the lockout is expected to last

Clear communication helps prevent confusion and accidents. Managers should use multiple methods to notify staff, such as:

- Team meetings

- Posted notices

- Email alerts

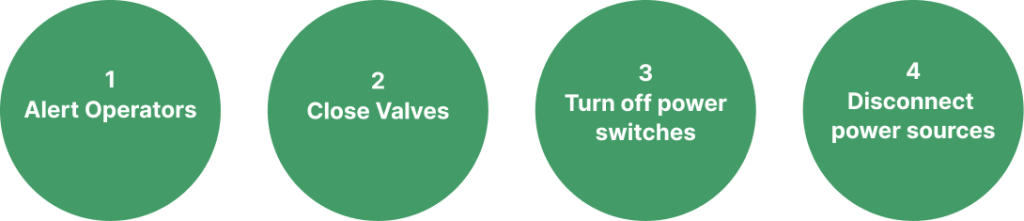

2. Shutting Down Equipment

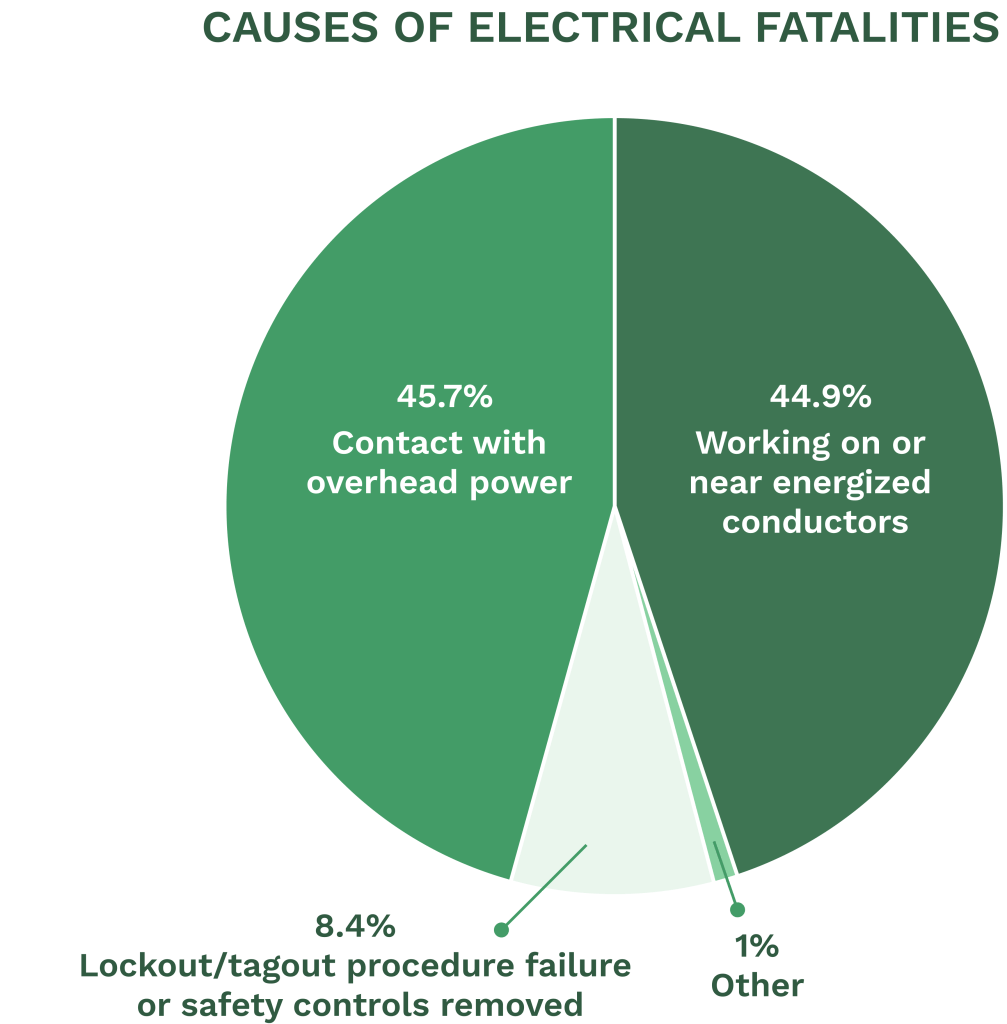

Illustration: WorkTrek / Data: Electrical Safety Fondation

Proper equipment shutdown is a key step in LOTO safety. The authorized employee should follow the correct shutdown sequence for each machine.

Steps typically include:

- Alerting operators

- Closing valves

- Turning off power switches

- Disconnecting power sources

Sources: WorkTrek

It’s important to let the equipment come to a complete stop. Rushing this step can lead to accidents.

Workers should refer to equipment manuals for specific shutdown instructions and be aware of any stored energy that could pose a risk.

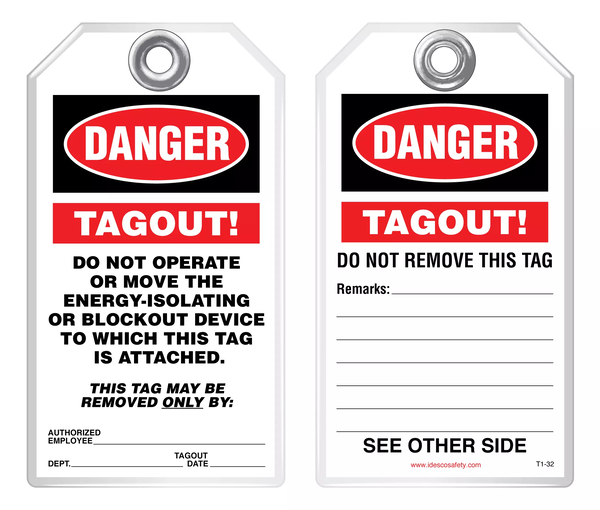

3. Applying Lockout/Tagout Devices

After shutdown, lockout/tagout devices must be applied to energy isolation points to prevent equipment from accidentally restarting.

Common LOTO devices include:

- Padlocks

- Lockout hasps

- Circuit breaker lockouts

- Valve lockouts

Source: Creative Safety Supply

Each device should be:

- Durable

- Standardized

- Substantial enough to prevent the removal

Source: Idesco Safety

Tags must be attached to lockout devices. They should clearly show:

- Who applied the lock

- Why the equipment is locked out

- Date and time of application

Only the person who applied the lock should have the key. This ensures the equipment stays off until work is complete.

4. Verifying Zero Energy State

After applying LOTO devices, verifying that the equipment is in a zero-energy state is crucial. This step confirms that all energy sources are fully controlled.

Verification methods include:

- Trying to start the equipment

- Testing with voltage meters

- Checking pressure gauges

- Inspecting for movement or stored energy

Workers should:

- Attempt to activate all controls

- Return controls to “off” position

- Test for any residual energy

The isolation process must be reviewed and corrected if any energy is detected. Work on the equipment can only begin safely when zero energy is confirmed.

5. Secure Storage of Devices

LOTO devices need a dedicated storage area. This space should be easily accessible to authorized workers but locked to prevent tampering. A wall-mounted cabinet or toolbox works well.

Inside, organize devices by type:

- Padlocks

- Hasps

- Tags

- Circuit breaker lockouts

- Valve lockouts

Label each section clearly. Keep extra devices on hand to replace damaged or lost ones. Check the storage area regularly to make sure it’s tidy and well-stocked.

6. Tracking and Auditing

Source: WorkTrek

A system for tracking LOTO devices helps prevent loss and misuse. Start by giving each device a unique ID number. Create a log to record:

- Device type and ID

- Date issued

- Employee name

- Equipment it’s used on

- Return date

Conduct regular audits to verify all devices are accounted for. This process also checks that devices are in good condition. Replace any that show wear and tear.

Use software or a spreadsheet to manage the tracking system. This makes it easy to spot trends and identify training needs. Update the log after each use of a LOTO device.

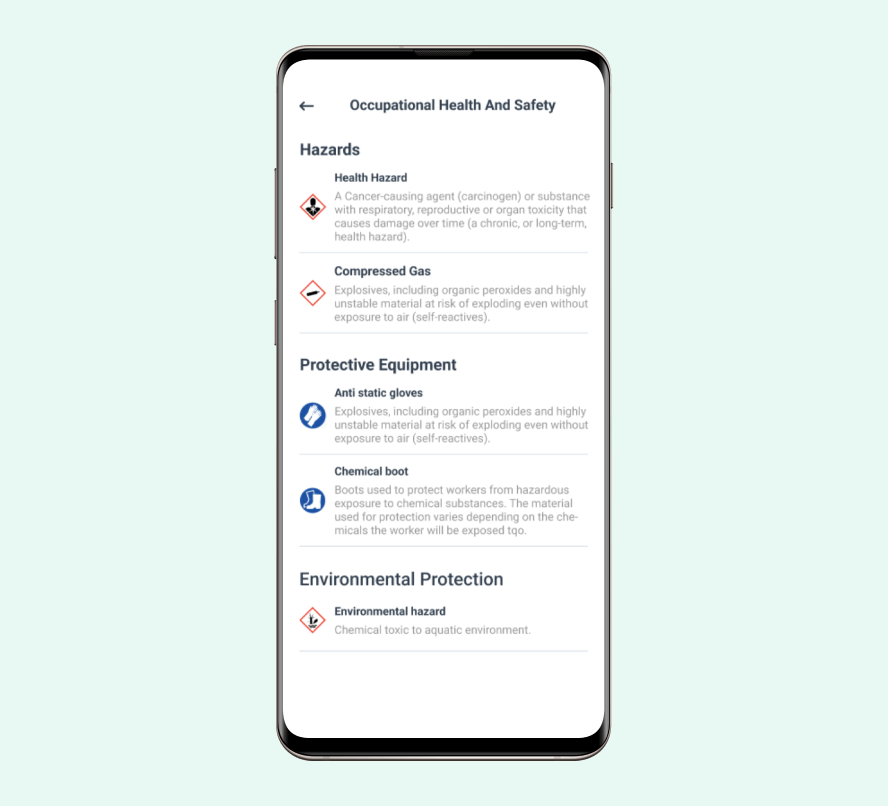

7. Training Requirements for Personnel

Illustration: WorkTrek / Data: Bearing & Machine.LTD

LOTO training is crucial for all workers involved in equipment maintenance or repair. Employers must provide comprehensive LOTO training to authrized employees who perform lockout procedures. This training should cover:

• Recognizing hazardous energy sources

• Understanding the type and magnitude of energy in the workplace

• Methods for isolating and controlling energy

• Proper use of lockout/tagout devices

Illustration: WorkTrek / Data: Bearing & Machine.LTD

Refresher training is necessary at least annually. It’s also required when job duties change, equipment or processes are modified, or employees show inadequate knowledge of LOTO procedures.

8. Inter-team Communication Protocols

Clear communication between teams is essential for LOTO safety. Establish protocols for sharing information about:

• Equipment status (locked out, under maintenance, ready for use)

• Shift changes and handovers

• Emergency procedures

Enhance communication with visual aids like tags, signs, and color-coded locks. Implement a system for documenting LOTO procedures and making them easily accessible to all relevant personnel.

Regular safety meetings can help reinforce communication practices. Encourage open dialogue among team members about LOTO concerns and improvements.

9. Removing LOTO Devices

Removing lockout/tagout devices requires a systematic approach.

First, inspect the work area to ensure all tools and materials have been removed. Check that all machine components are intact and properly reassembled.

Notify all affected employees that LOTO devices will be removed. This alert helps prevent unexpected startups.

Unless special circumstances apply, only the person who applied a lock or tag should remove it.

Remove locks, tags, and other energy-isolating devices in the reverse order they were applied.

Keep track of each device as it’s taken off.

Double-check that all devices have been accounted for before moving to restart procedures.

10. Equipment Restart Procedures

Source: Verified Market Reports

Before restarting, verify all controls are in the neutral or “off” position. This precaution helps prevent unexpected movement when power is restored.

Ensure all employees are safely positioned away from potential danger zones.

Gradually restore energy to the equipment, watching for any unusual sounds or movements.

If problems occur, immediately shut down and re-isolate the machine. Troubleshoot and address issues before attempting another restart.

Once the equipment runs normally, have operators perform a test run to verify the proper function.

Monitor the machinery closely during this initial period to catch any lingering problems.

If all checks out, the equipment can return to regular service.

Review and Continuous Improvement

LOTO programs need regular evaluation and updates. This ensures that safety procedures stay current and effective and helps catch any gaps in training or policies.

LOTO Program Review

Safety teams should review LOTO procedures regularly. Set a schedule, like every 6 months or yearly.

Look at accident reports and near-misses. Check if workers follow the steps correctly.

Ask employees for feedback. They often spot issues first.

Compare your program to new industry standards. Make sure all equipment has up-to-date LOTO instructions.

Source: WorkTrek

Use a checklist to review each part of the program. This helps catch small problems before they grow.

Keep records of all reviews and changes made.

Updating Policies and Training

When reviews show gaps, update policies right away.

Add new steps or change old ones that don’t work well. Make sure updates are clear and easy to follow.

Inform all workers about changes. Offer extra training on new procedures.

Use hands-on practice for complex updates. This helps workers learn faster.

Check that all training materials match the new policies.

Update any outdated info in handbooks or posters.

Consider using videos or apps to make training more engaging.

Conclusion

In conclusion, Lockout/Tagout (LOTO) can protect workers during machine maintenance. By following these essential steps and ensuring proper preparation, communication, and training, workplaces can significantly reduce the risk of accidents.