Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeFacility and plant managers often dread audits, especially when conducted by external auditors.

But why, when maintenance audits offer so many benefits?

Audits aren’t about pointing fingers, assigning blame, or highlighting mistakes.

They are valuable tools for reducing costs, improving maintenance procedures, and, most importantly, ensuring the safety of your team.

In this article, we’ll go deeper into these benefits.

We’ll also touch on what can happen when you don’t give them the attention they deserve.

Cuts Down Your Costs

You might be wondering how this works, so let’s break it down.

First, regular audits give you a chance to review everything about your maintenance practices.

This includes how you plan and schedule maintenance, the types of maintenance you use, and how much that costs you.

By doing this, you can pinpoint areas where better practices could save you money without compromising the quality of your work.

For example, imagine you discover that you’re frequently replacing a certain motor component. This part is expensive, and the cost of replacements across multiple facilities is adding up.

The audit reveals you’re replacing it every 4 months, although the wear and tear analysis shows it could last up to 9 months. There’s your savings opportunity.

Moreover, when you are on top of your maintenance regime, you keep equipment in good shape.

This means fewer breakdowns and, consequently, less need for expensive emergency repairs and costly downtime.

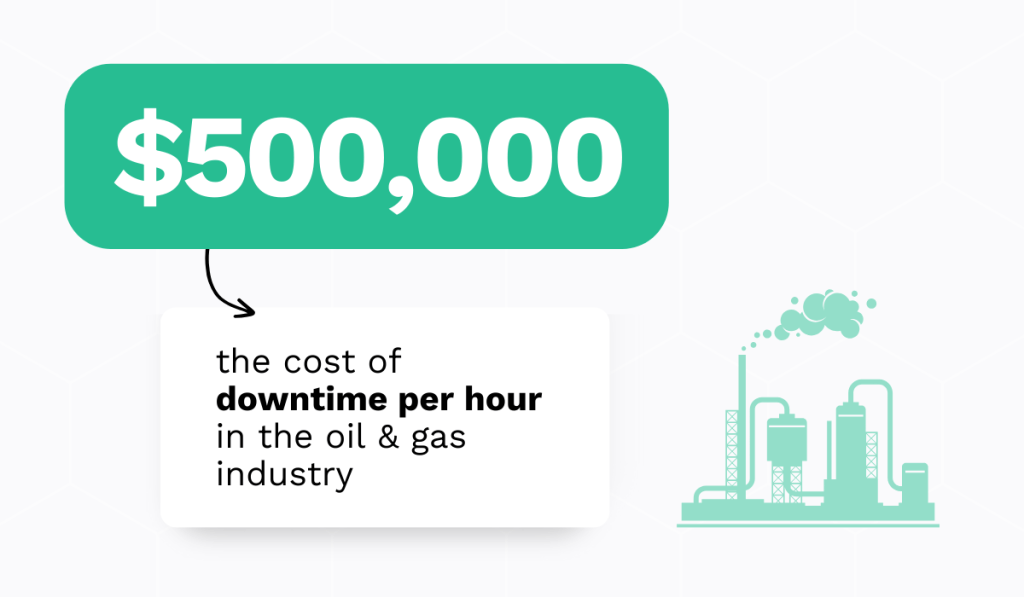

For example, in the oil and gas industry, downtime can cost as much as $500,000 per hour.

Imagine avoiding that kind of money loss.

Well, regular maintenance audits can help make that possible.

Good maintenance also means you won’t need to buy new equipment as frequently, which lowers your purchase costs.

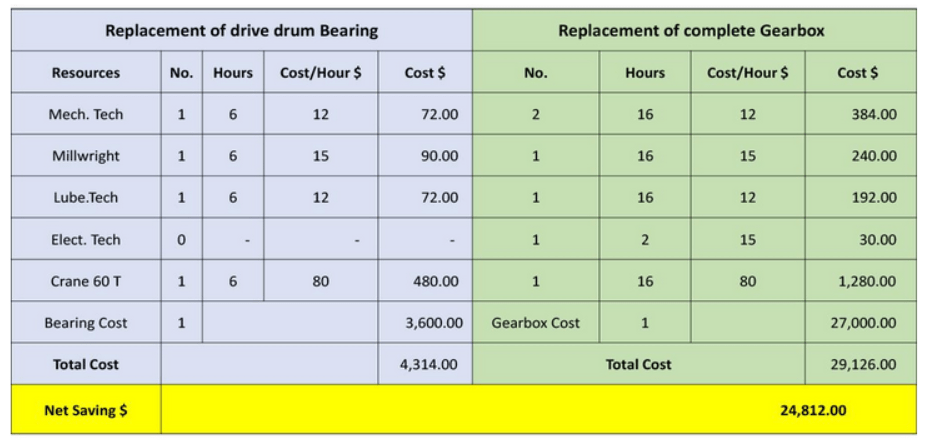

Take, for example, a company that had issues with its limestone transport belt conveyor gearbox.

Initially, the problem seemed serious, but a detailed inspection revealed that the issue was a faulty drive drum bearing, not the gearbox itself.

By replacing the bearing for just $4,000, they avoided a costly $27,000 gearbox replacement and significant downtime.

Another way to save money is to lower your energy bills. Well-kept equipment runs more efficiently and uses less power.

All these things reflect on labor costs. When your machinery runs smoothly, your workers can be more productive, and you spend less on maintenance technicians.

In short, maintenance audits, especially internal ones, are smart investments.

They help save money in the long run in more ways than one.

Helps Your Company Perform Better

Efficiency is where maintenance audits can make a significant difference.

Operational efficiency refers to how effectively your company uses its resources—like time, money, and equipment—to achieve results.

It’s about getting the best possible outcomes and doing more with less.

So, how do maintenance audits fit into this picture?

It’s simple.

By conducting a maintenance audit, you can detect areas where you waste too many resources.

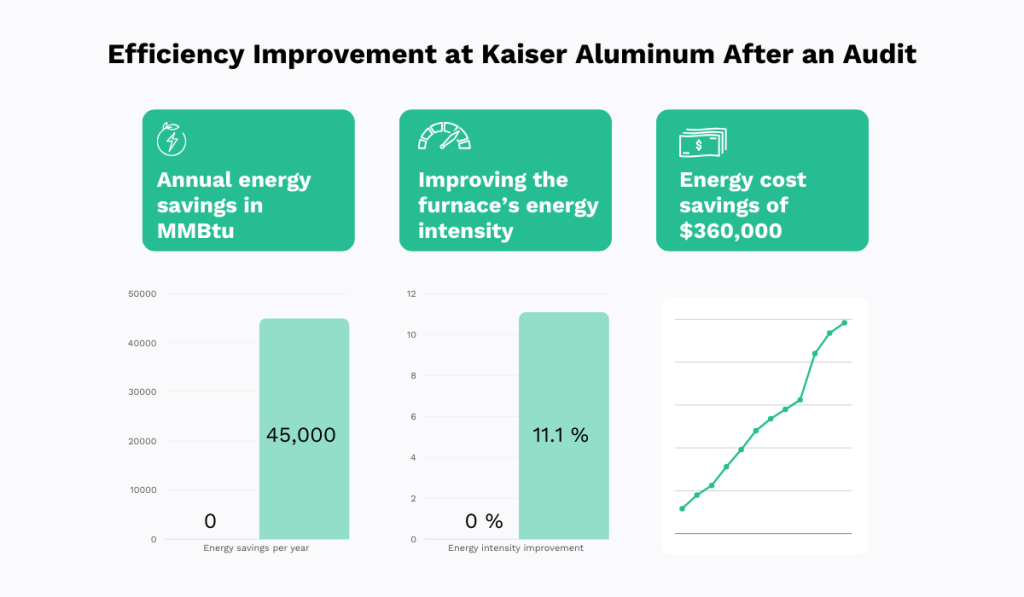

This happened to Kaiser Aluminum’s extrusion plant in Sherman, Texas, a few years ago.

A maintenance audit conducted by the U.S. Department of Energy (DOE) revealed that simple fixes—like adjusting burner controls and repairing furnace door seals—could save them substantial energy.

So they fixed them.

The outcome?

They reduced their energy use by about 45,000 MMBtu annually and improved furnace efficiency by 11.1%.

This also resulted in big financial gains.

The company invested $28,000 in these improvements and saved $360,000 on energy costs, paying the investment off in less than a month.

This success led Kaiser Aluminum to apply these findings across its other plants, showing that an effective audit can result in impressive savings and boost performance.

However, you don’t always need to wait for an external audit to find areas for improvement.

Sometimes, an in-house tool can do the job.

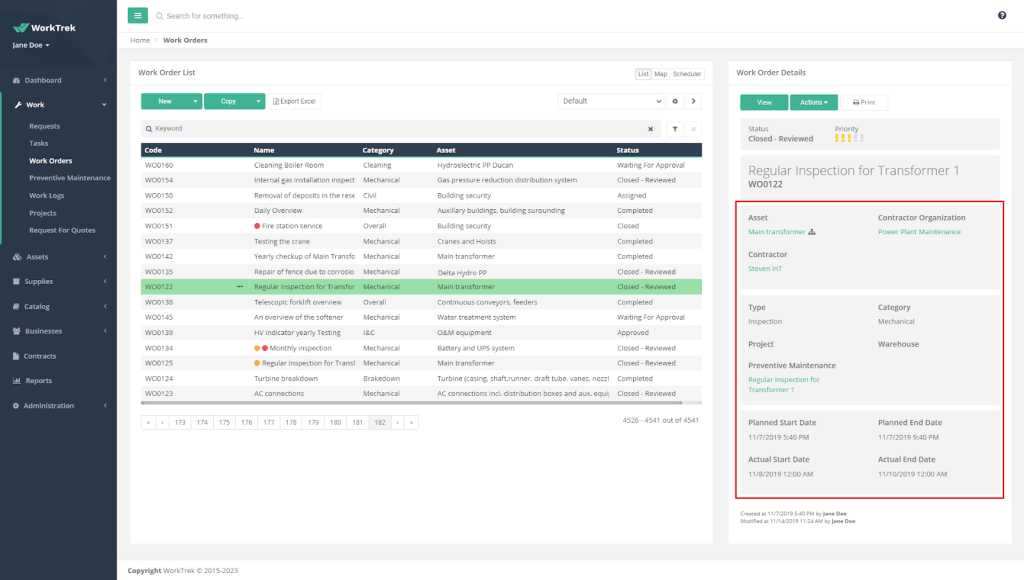

One such tool is a computerized maintenance management system (CMMS), like our WorkTrek.

Here’s how it helps.

First, with a CMMS like our WorkTrek, you can easily plan and schedule maintenance tasks in one place and assign work orders to your technicians.

You can also monitor your equipment conditions and identify patterns that point to maintenance inefficiencies.

Second, WorkTrek logs all maintenance activities, including work orders and changes.

This acts as an audit trail, showing exactly what was done, by whom, and when.

At the end of the day, this audit trail is crucial for passing audits and keeping everything transparent.

So it’s best when maintenance audits and a good CMMS work together. Their synergy can lead to improved performance and best use of resources.

Ensures You Comply with Regulations

Maintenance audits are crucial for keeping your business on the right side of the law and avoiding serious consequences.

Often, these audits are part of larger inspections, like health and safety audits, which are designed to ensure that your company is following all the necessary regulations.

Failing to comply with these regulations can have devastating consequences, both financially and operationally.

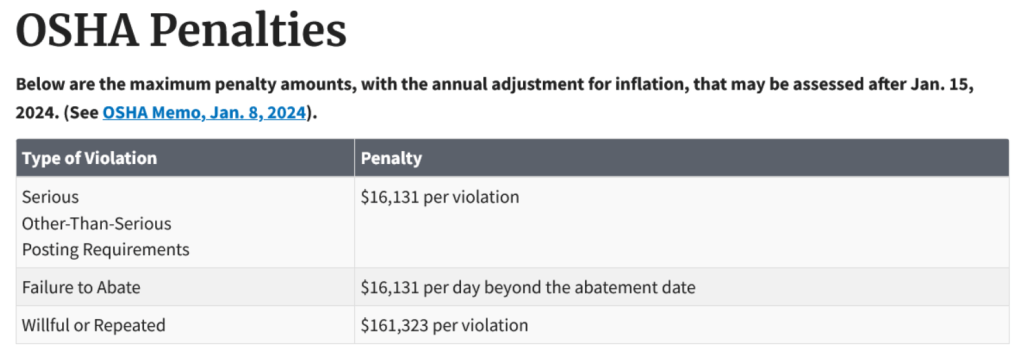

In the U.S., for instance, the Occupational Safety and Health Administration (OSHA) is the federal agency responsible for ensuring workplace safety.

Under the OSH Act of 1970, private companies are required to provide a safe and healthy work environment for their employees.

OSHA’s audits often focus on maintenance practices to determine whether safety regulations are being followed.

If your company is found lacking, the fines can be hefty.

Currently, penalties stand at $16,131 per violation, with willful or repeated violations costing up to $161,323 each.

Across the Atlantic in the U.K., the Health and Safety Executive (HSE) plays a similar role.

They also perform audits to check whether companies provide a safe and healthy environment for workers.

When accidents occur, the fines can reach millions.

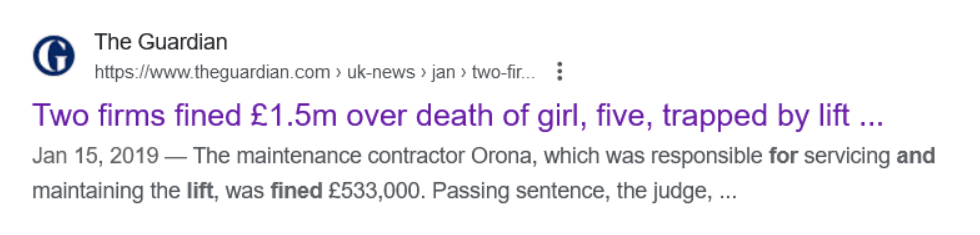

A tragic example of what can happen when maintenance is neglected occurred in January 2019, involving Synergy Housing Limited and Orona Limited, a company responsible for lift maintenance.

A five-year-old girl lost her life after she put her head through a broken vision panel in her home’s lift, which was ascending.

The HSE investigation revealed critical failures by both companies, including a lack of inspections, failure to repair the broken panel, no risk assessments, missing safety mechanisms, and insufficient safety information for tenants.

As a result, Synergy Housing was fined £1 million plus £40,000 in costs, while Orona was fined £533,000 plus £40,000 in costs.

Another example is the 2009 fire at Lakanal House in Southwark, a borough in Greater London, which tragically claimed the lives of six people.

Poor maintenance, combined with inherent structural deficiencies, led to this disaster.

Southwark Council was fined £570,000 for safety failings, which included the absence of a proper fire risk assessment, breaches in fire-resistant structures, lack of compartmentation in ceilings, and missing fire door seals.

These issues could have been identified and addressed through regular maintenance audits.

As Dan Daly, London Fire Brigade’s assistant commissioner for fire safety, pointed out:

If buildings are built and maintained correctly, walls, floors and doors in flats and maisonettes give you protection from fire – a minimum of 30 to 60 minutes.

The lesson here is clear: preventive maintenance and regular audits are not just about staying compliant with regulations—they’re about saving lives.

Regular maintenance audits help you identify potential risks before they escalate, ensuring that your company stays within legal requirements, avoids hefty fines, and most importantly, keeps people safe.

Reduces Risky Situations

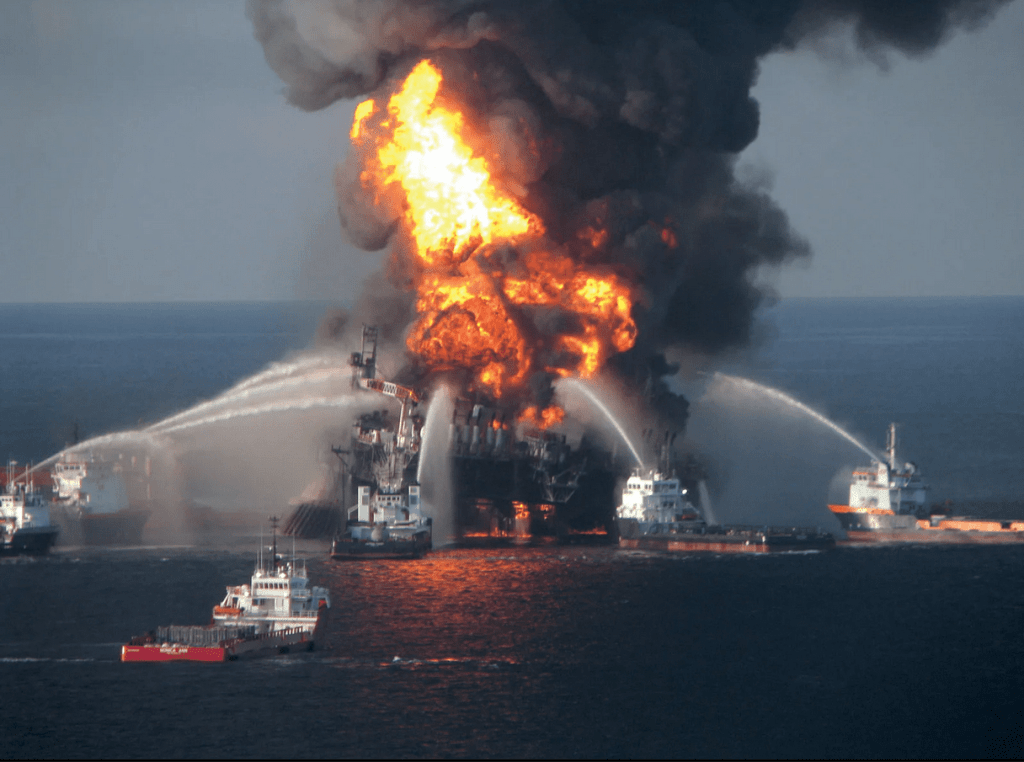

Even more, regular maintenance audits can prevent catastrophic incidents that lead to environmental harm.

This is especially crucial in high-risk industries like oil and gas, where even a small failure can have devastating consequences.

Take the Deepwater Horizon oil spill as a sobering example.

On April 20, 2010, this oil rig, operated by BP, a British multinational oil and gas company, suffered a blowout, causing one of the largest environmental disasters in history.

What went wrong?

A series of maintenance failures and safety oversights.

BP’s former Chief Executive, Tony Hayward, sums it up:

To put it simply, there was a bad cement job and a failure of the shoe track barrier at the bottom of the well, which let hydrocarbons from the reservoir into the production casing. The negative pressure test was accepted when it should not have been, there were failures in well control procedures and in the blowout preventer; and the rig’s fire and gas system did not prevent ignition.

The blowout resulted in the deaths of 11 workers and released millions of barrels of oil into the Gulf of Mexico, causing extensive environmental and economic damage.

The fallout from this disaster was immense, leading to major regulatory changes and significant fines for BP.

But more importantly, it is a powerful reminder of why regular maintenance audits are vital.

They help detect anomalies early, prevent escalation, and ensure that safety protocols are in place, thereby protecting lives, equipment, and the environment.

So, just as regular audits could have prevented the Lakanal House fire, they could have also prevented the Deepwater Horizon spill.

Enables You to Make Good Decisions

Maintenance audits don’t just keep your operations running smoothly but help you make smart, strategic decisions that benefit your company in the long run.

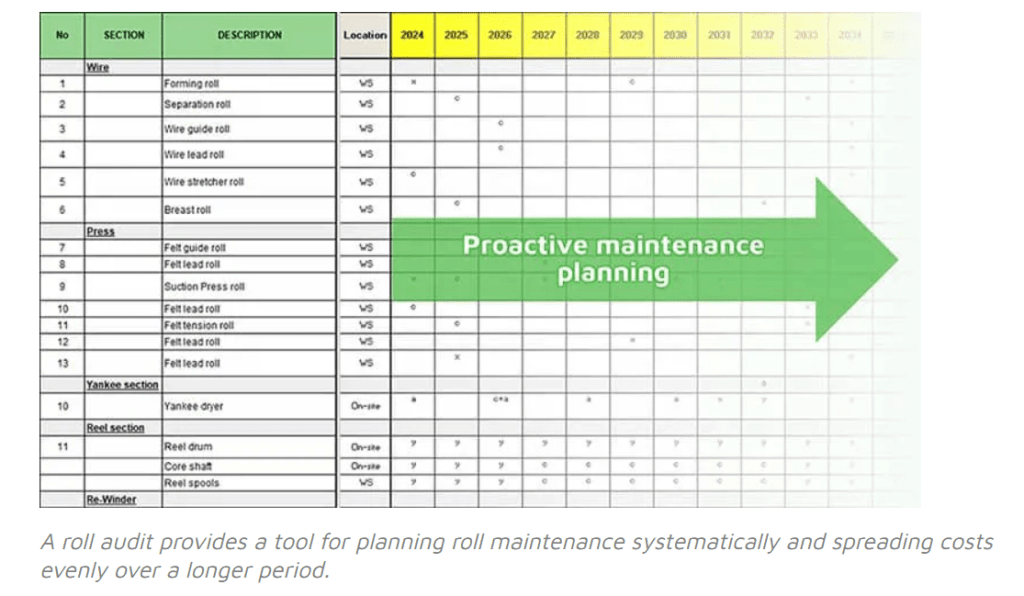

Take this real-world example: a tissue producer was dealing with repeated issues on their press suction roll cover, which was disrupting production.

Seeking a solution, they turned to an external auditor—Valmet.

The audit revealed several critical issues.

They discovered that the groove design on the roll was flawed, and the roll cover showed edge damage because of high temperature and nip pressure.

Based on this, Valmet recommended changes to the groove design and improvements in the chamfer design at the roll’s ends.

When these recommendations were implemented during the next scheduled maintenance, the results were clear: better performance without any extra costs.

This example shows how maintenance audits can guide you in making better decisions for your operations.

So, whether it’s upgrading outdated equipment, maintaining equipment more frequently, or investing in new technologies, the insights you gain from these audits help you steer your company in the right direction.

And if you’re using a CMMS, this process becomes even easier.

The software keeps all your maintenance data organized, making it simpler to analyze and turn into actionable plans.

In the end, maintenance audits, especially when paired with a CMMS, give you the knowledge and foresight to make decisions that truly benefit your business.

Conclusion

Maintenance audits are really nothing to fear.

In fact, they’re incredibly valuable tools that can benefit your facility or plant in numerous ways.

They help improve efficiency, cut costs, prevent risks, and provide a safe working environment for your whole team.

So, make maintenance audits a regular part of your routine, and you’ll quickly start seeing these benefits for yourself.