Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeMaintenance digitalization is changing how companies maintain their equipment. Businesses can streamline maintenance processes and enhance operational efficiency by leveraging digital technologies such as IoT and machine learning. This new approach helps companies save money and avoid problems.

Digital technologies let workers spot issues before they become big headaches. They can fix things faster and keep machines running smoothly. This means less downtime and more productivity.

Smart systems can even predict when parts will wear out. This helps companies plan and order supplies at the right time. It’s a smarter way to manage maintenance that keeps businesses ahead of the game.

Evolution of Maintenance in the Digital Era

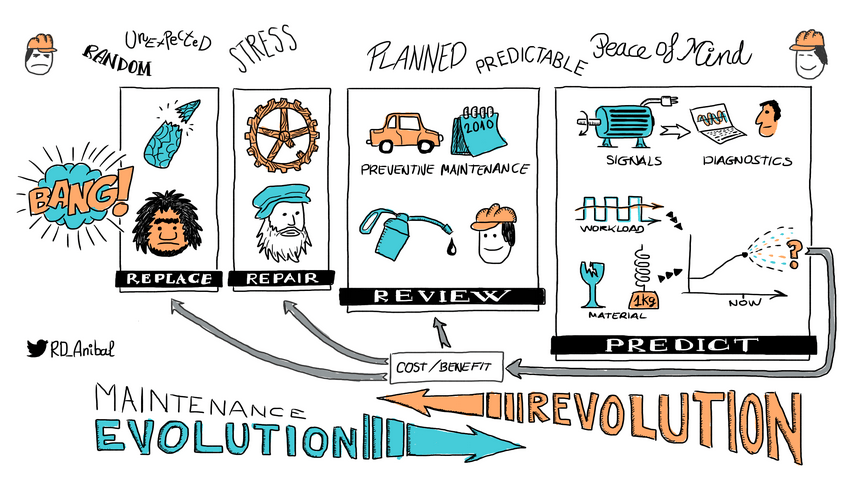

Maintenance practices have changed a lot over the years. In the past, companies fixed things only when they broke down. This was called reactive maintenance.

Then came preventive maintenance. Companies started doing regular checks and repairs to avoid breakdowns. This worked better but wasn’t perfect.

The digital age brought new tools and methods. Sensors and data collection became common in factories, leading to predictive maintenance.

Predictive maintenance uses data to spot problems before they happen. It’s more efficient than older methods. Companies can fix issues at the right time, not too early or too late. Computerized maintenance management systems (CMMS) play a crucial role in modern maintenance by enabling real-time monitoring and predictive analytics.

Source: Blog CARTIF

Key benefits of digital maintenance:

- Less downtime

- Lower costs

- Longer equipment life

- Better safety

- Optimized Maintenance Process

- Improved Maintenance Practices

Today, maintenance is getting even smarter. Artificial intelligence and machine learning help make better predictions, and these tools can find patterns humans might miss.

The Internet of Things (IoT) connects machines to the internet. This lets companies track equipment performance in real-time. They can make decisions faster and smarter and reduce costly repairs.

Benefits of Digital Tools

Digital tools also help maintenance teams work better. Mobile apps and tablets make it easy to access information on the job, saving time and reducing errors. Maintenance managers leverage these technologies to digitize operations, improve efficiency, and reduce costs.

As technology advances, maintenance will continue to change. The goal is to make equipment last longer and work better; digital tools are key to this goal.

Benefits of Maintenance Digitalization

Maintenance digitalization brings key advantages to industries. It boosts asset reliability, enhances scheduling, enables data-driven decisions, cuts costs, and improves safety standards.

Enhanced Asset Reliability

Digital tools boost asset reliability and reduce maintenance costs. Sensors track equipment health in real time, allowing teams to spot issues early.

Predictive maintenance becomes possible. It uses data to forecast when parts might fail, helping to prevent equipment failures. Teams can fix problems before they cause breakdowns.

Digital systems also keep detailed repair histories, which help identify recurring issues and allow managers to make better choices about equipment upgrades or replacements.

Illustration: WorkTrek / Quote: Power MI

Optimization of Maintenance Schedules

Digital systems make maintenance schedules smarter. They use data to predict when maintenance is truly needed.

This approach cuts unnecessary work and prevents unexpected breakdowns. The result is less downtime and more efficient operations.

Digital schedules can also factor in production demands. This ensures maintenance happens at the best times. It minimizes disruptions to workflow.

Real-time Data Analysis

Digital tools collect and analyze data constantly. This gives teams up-to-the-minute insights.

Managers can see how assets are performing right now. They can spot trends and patterns over time.

This data helps in making quick, informed decisions. It can show which machines need attention first and reveal ways to improve overall efficiency. Real-time data analysis significantly enhances maintenance performance by identifying areas for improvement and optimizing maintenance processes.

Source: WorkTrek

Maintenance Costs Reduction and Value Creation

Digitalization cuts maintenance costs in several ways:

- It reduces unexpected breakdowns

- It extends equipment life

- It optimizes the inventory of spare parts

- It improves maintenance effectiveness

- It improves safety procedures

- It improves safety practices

These savings add up fast. They often outweigh the initial cost of digital systems.

Digital tools also create value. They boost productivity and quality. This can lead to higher customer satisfaction and more business.

Digital maintenance services contribute to cost reduction and value creation by utilizing real-time data and analytics to enhance equipment management and decision-making.

Safety and Compliance

Digital systems enhance workplace safety. They can:

- Alert workers to dangerous conditions

- Ensure safety protocols are followed

- Track and report incidents automatically

- Improves safety procedures

This leads to fewer accidents and injuries.

Digital tools also help with compliance. They can:

- Keep accurate records

- Generate required reports

- Ensure all maintenance meets regulations

This reduces the risk of fines or legal issues. Additionally, strong data and communication security measures are essential to protect against data breaches and unauthorized access, ensuring the safety and compliance of digitalized maintenance operations.

Source: indimart

Digital Maintenance Technologies

Digital tools are changing how companies maintain equipment. These new technologies help predict problems, automate tasks, and provide better training. They make maintenance work faster and more accurate.

Digitalized maintenance leverages various digital technologies, such as predictive maintenance, real-time monitoring, and enterprise asset management software, to enhance maintenance performance.

Internet of Things (IoT) in Maintenance

IoT devices connect machines to the Internet and collect data on how the equipment is working. Sensors track things like temperature, vibration, and pressure. This data helps spot issues before they cause breakdowns.

IoT systems can send alerts when something is wrong and create logs of machine performance over time, which helps technicians better understand equipment.

Some IoT devices can even order parts automatically when needed. This keeps inventory stocked without human input.

Illustration: WorkTrek / Quote: ptc

Predictive Maintenance Analytics Tools

These tools use data to predict when machines might break. They examine past breakdowns and current conditions and make guesses about future problems.

Predictive analytics can tell when parts are likely to fail. This lets companies replace them before they break, reducing surprise failures and downtime.

These tools also help plan maintenance schedules. They show which machines need to be worked on as soon as possible, making maintenance more efficient.

Automation and Robotics

Robots and automated systems are taking on maintenance tasks. They can safely do dangerous or repetitive jobs, adding additional maintenance resources. For example, drones inspect hard-to-reach areas like tall towers or bridges.

Robots can also clean equipment or apply lubricants. They work consistently and don’t get tired, improving the overall maintenance effectiveness.

Some systems use AI to make repair decisions. They can diagnose problems and suggest fixes without human help.

Illustration: WorkTrek / Data: RS

Mobile and Cloud Computing

Mobile apps let technicians access information anywhere. They can look up manuals, part numbers, and repair history on their phones, saving time and reducing errors.

Cloud systems store all maintenance data in one place. Teams can easily share information, and managers can see reports and track work from any device.

These tools also make it easier to update records. Technicians can log their work right away, keeping everything up to date.

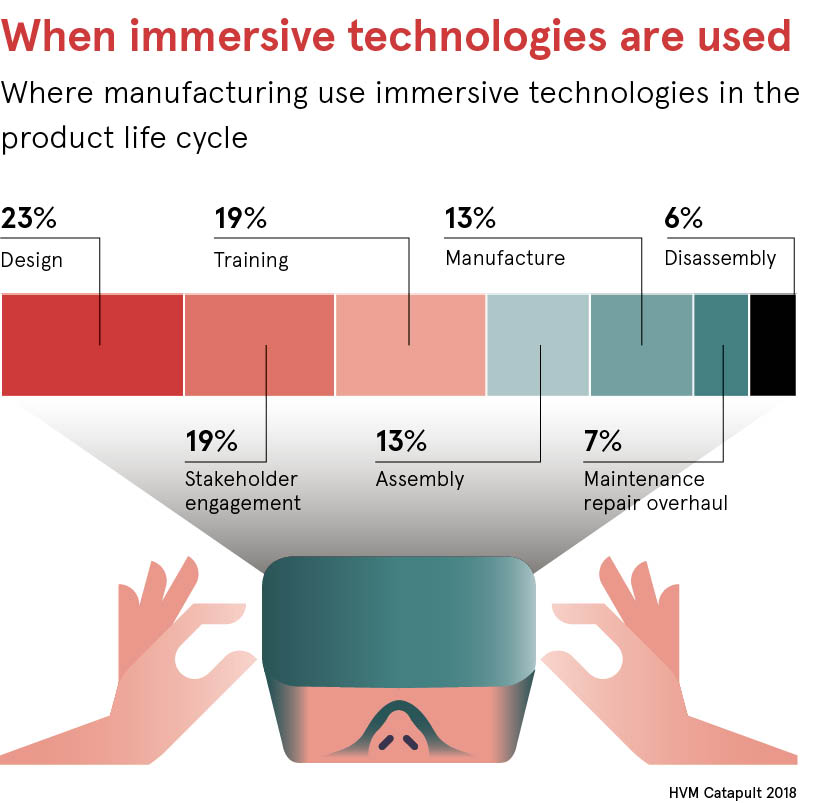

Augmented Reality for Training and Support

AR adds digital information to the real world. It helps train new technicians faster. They can see step-by-step instructions overlaid on actual equipment.

Experienced workers use AR for complex repairs. It can show them where to find parts or how to take things apart, making difficult jobs easier and quicker.

AR also lets remote experts guide on-site workers. They can see what the worker sees and draw on the screen to give directions, bringing expert help to any location.

Source: Recounter

Implementing a Digital Maintenance Strategy

Putting a digital maintenance strategy into action involves careful planning and execution. It requires assessing readiness, building data systems, connecting with existing tools, training staff, and always looking for improvement.

Assessing Organizational Readiness

Companies need to assess whether they’re ready for digital maintenance. This means examining current practices and identifying gaps.

Leaders should set clear goals for what they want to achieve. They need to think about costs and benefits. Effective maintenance management is crucial in assessing organizational readiness for digital maintenance.

A readiness check helps spot areas that need work, shows where training is needed, and helps plan the rollout of new systems.

Data Infrastructure and Management

Good data systems are key to digital maintenance. Companies need ways to collect, store, and use data safely. This often means setting up sensors on machines and creating either cloud or on-premise databases to hold information.

Data quality is very important. Bad data can lead to wrong choices. Companies should have plans to clean and check data regularly.

Integration with Existing Systems

New digital tools must work with systems already in place. This could mean linking to inventory software or work order systems. The goal is to have all parts of maintenance working together smoothly.

Integration can be tricky if the software does not offer a modern API platform. It may require custom coding or special connectors. Testing is crucial to ensure everything works correctly.

Illustration: WorkTrek / Quote: Forbes

Workforce Adaptation and Skills Development

Staff need new skills for digital maintenance. This often means training on new software and tools. Workers may need to learn about data analysis or how to use mobile apps.

Training should be ongoing. As systems change, skills need to keep up. Some companies create special roles for digital maintenance experts. Practical training and skills development are crucial for achieving sustainable maintenance services.

Continuous Improvement and Innovation

Digital maintenance strategies should always be getting better. This means tracking how well the system is working. Companies should set goals and measure progress.

Regular reviews help identify areas for improvement. New technology might offer better ways to do things, and staff ideas can lead to useful changes.

Innovation is key to staying ahead. Companies should monitor new trends in maintenance tech and be ready to test and adopt helpful new tools.

Challenges and Considerations

Maintenance digitalization has many benefits, but it also has hurdles. Organizations need to address several key issues as they implement digital maintenance systems.

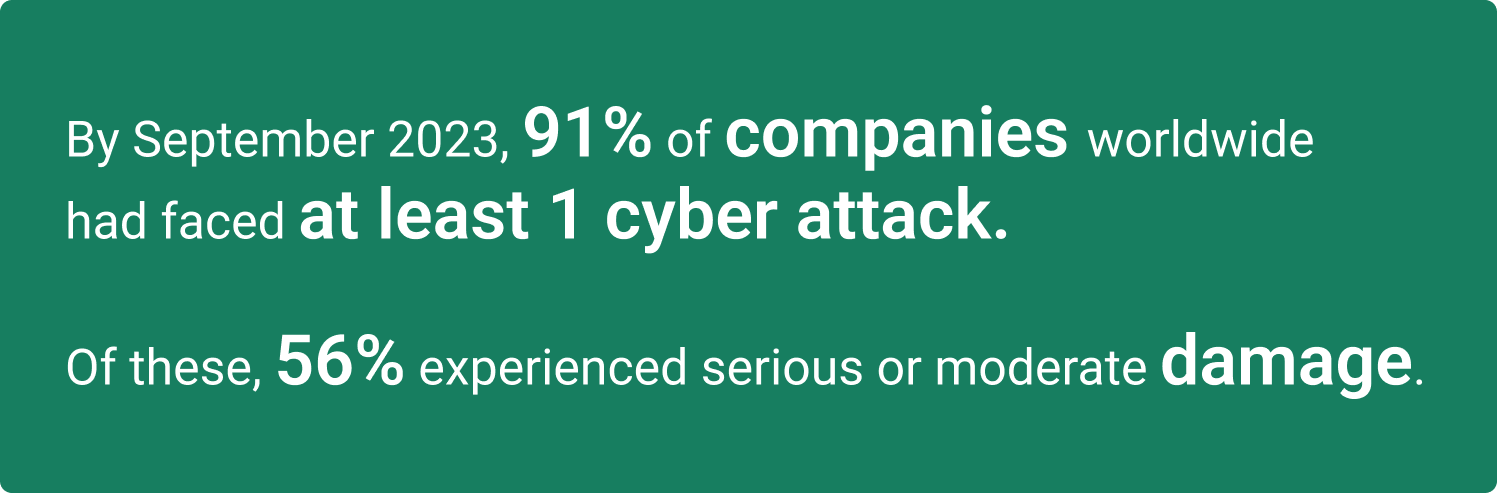

Cybersecurity Threats

Digital maintenance systems face cyber risks. Hackers may try to breach networks and steal data, disrupt operations, or damage equipment.

Companies must use strong security measures. This includes:

• Firewalls

• Encryption

• Multi-factor authentication

• Regular security audits

Staff training on cybersecurity is crucial. Employees need to spot phishing attempts and follow safe practices. Firms should also have incident response plans ready.

Illustration: WorkTrek / Data: Enterprise Apps Today

Data Privacy and Ethics

Digital maintenance creates a lot of data, which can include sensitive information about employees and operations. Companies must handle this data responsibly.

Privacy laws like GDPR or CCPA set rules for data use. Firms need clear policies on data collection and storage. They should only gather needed info and protect it well.

Ethical data use is key. Companies shouldn’t use maintenance data to unfairly judge workers, and they need to be open about how they use the information.

Regular privacy audits help ensure compliance. Getting employee buy-in on data practices builds trust.

Investment and ROI Concerns

Digital maintenance systems can be costly. The price tag may scare some companies. Upfront costs include:

• Software licenses

• New sensors and devices

• Staff training

• System integration

Proving return on investment (ROI) takes time. Benefits like less downtime aren’t always easy to measure right away.

Companies should start small and scale up. Pilot projects help show value before big rollouts, and tracking key metrics from the start is vital.

Setting realistic timelines for ROI is important. Full benefits may take months or years to appear.

Source: Inwedo

CMMS Vendor Selection and Partnership

Picking the right CMMS software can be tricky. There are many options with different features. Companies need to find a good fit for their needs.

Key factors in vendor choice include:

• System compatibility

• Scalability

• Customization options

• Support and training

• Vendor track record

Long-term partnership is crucial. The vendor should offer ongoing support and updates. They need to understand the company’s goals and industry.

Careful evaluation and trials are wise. Getting feedback from other users helps, too.

Change Management

Shifting to digital maintenance is a big change. It affects many workers and processes, and people may resist new technology or working methods.

Clear communication is vital. Leaders must explain the reasons for change and its benefits. Involving staff in planning builds support.

Training is key to smooth adoption. Workers need time to learn new systems, and ongoing support helps them get comfortable.

Setting achievable goals helps build momentum. Quick wins show the value of new systems. Recognizing staff who embrace change motivates others.

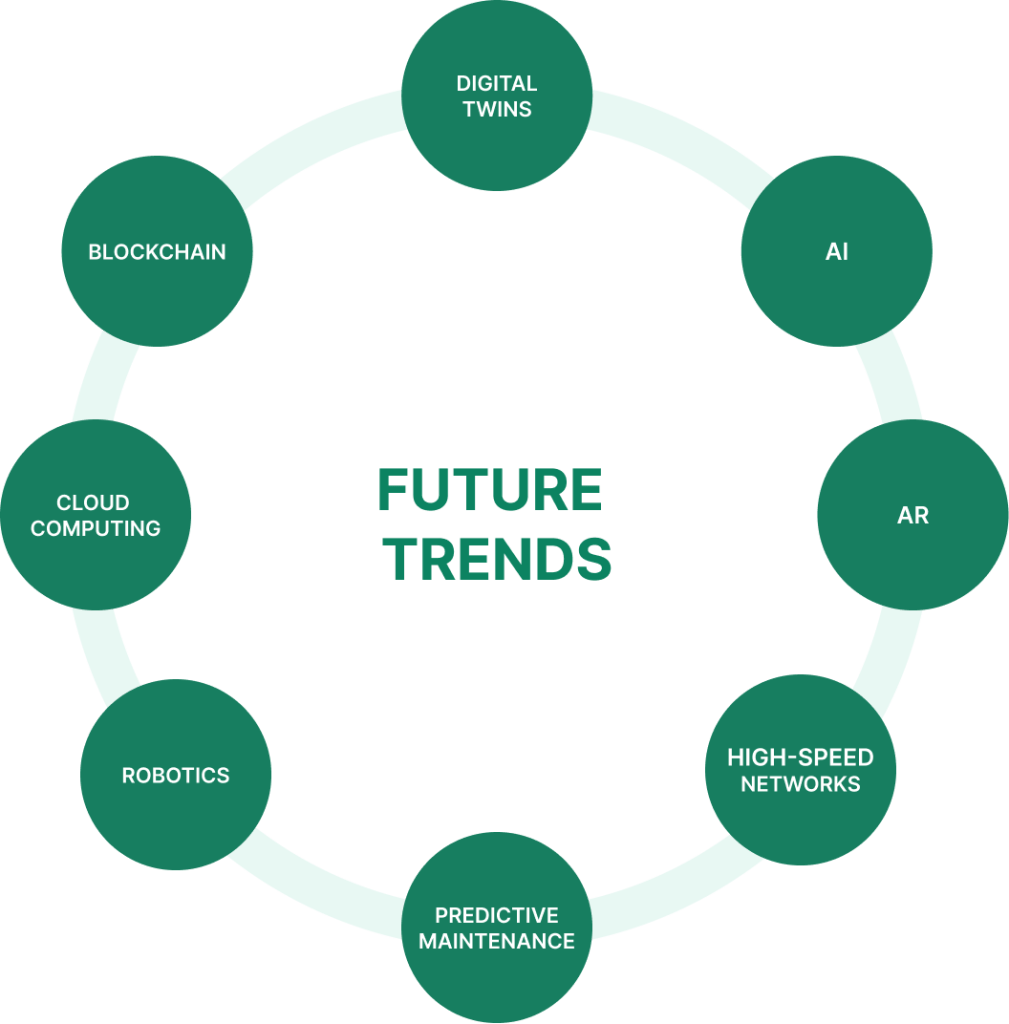

Future Trends in Maintenance Digitalization

Digital twins will play a more significant role in maintenance. These virtual replicas of physical assets help predict issues before they happen. They let teams test fixes without touching actual equipment.

Artificial intelligence and machine learning will get smarter. AI will spot patterns humans can’t see and better predict when machines need service.

Augmented reality will change how techs work. AR glasses will show step-by-step repair guides. This will speed up fixes and reduce mistakes.

High-speed networks will boost connectivity. Faster data transfer means quicker responses to problems; remote experts can help on-site workers in real-time.

Predictive maintenance will become more accurate. Advanced sensors and data analysis will pinpoint exactly when parts need replacement.

Robotics will take on more maintenance tasks, inspect hard-to-reach areas, and handle dangerous jobs, keeping humans safe.

Cloud computing will improve data sharing. Teams can access information from anywhere, helping companies make better maintenance choices.

Blockchain could make maintenance records more secure. It would create a tamper-proof history of all work done on equipment.

These trends will make maintenance faster, safer, and more efficient. Companies that adopt them will gain an edge over competitors.

Source: WorkTrek

Conclusion

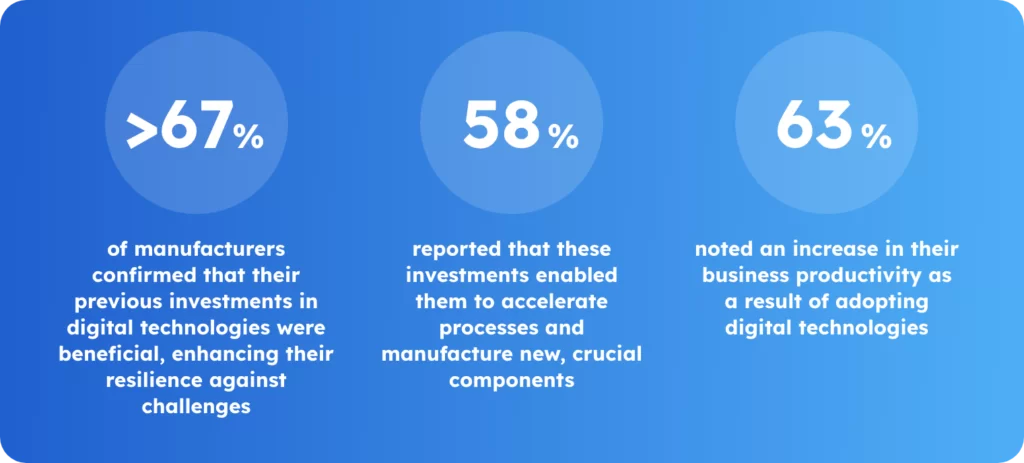

Maintenance digitalization is changing how companies manage their assets and operations. It brings many benefits to businesses of all sizes.

Digital tools make maintenance work more accessible and effective. They help catch problems early and prevent unexpected breakdowns, saving money and keeping equipment running smoothly.

Data from digital systems provides valuable insights. It allows better planning and smarter maintenance decisions, allowing companies to focus on the most important tasks and use resources wisely.

Going digital also improves safety. It reduces human error and helps follow the rules more easily. Workers get the information they need to do their jobs safely and correctly.

The future of maintenance is digital. As technology keeps improving, so will how we care for machines and buildings. Companies that embrace these changes will be ready for what’s ahead.

Maintenance digitalization is not just a trend. It’s becoming essential for staying competitive and efficient in today’s fast-paced world.

Illustration: WorkTrek