Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

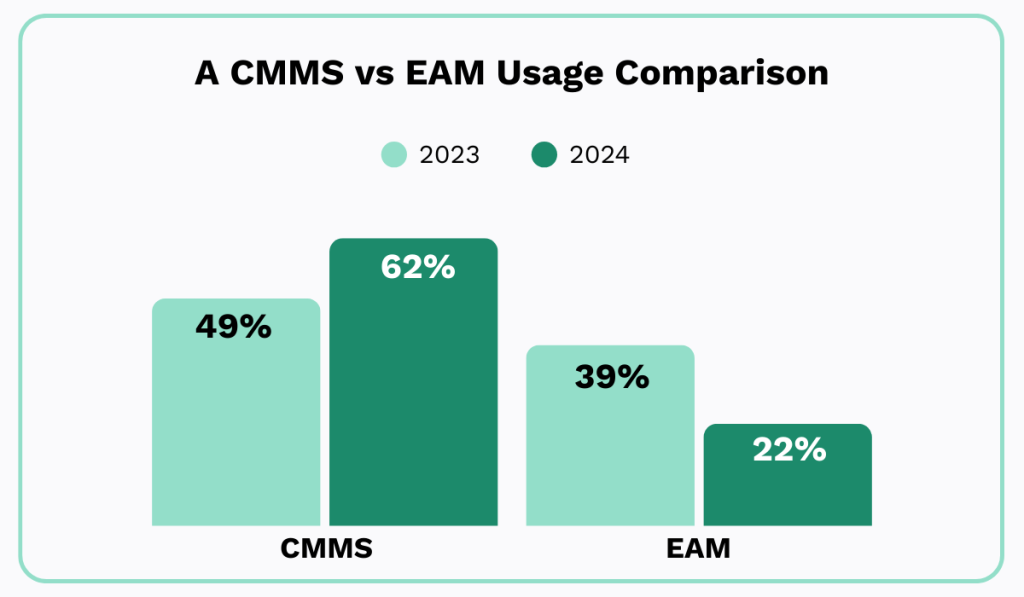

- 62% of companies reported using a CMMS in 2024.

- Small tools are the most frequently stolen items at construction sites.

- BlueScope avoided 2,000 hours of downtime after implementing predictive maintenance.

Being a maintenance supervisor comes with big responsibilities, but the job doesn’t have to feel like a constant uphill battle.

In this article, we introduce six digital tools designed to make your work easier, more accurate, and more efficient.

Each tool supports a different aspect of the job, from workforce planning to inventory management, and is suitable for a wide range of industries and sectors.

So, read on, and you may find one that becomes a complete game-changer for your own workflows.

Maintenance Management Software

Let’s start with the most essential tool: a maintenance management platform.

Whether it’s a CMMS or an EAM system, having software that centralizes all upkeep activities and asset information is no longer optional.

These systems automate nearly every aspect of maintenance operations, giving supervisors full visibility and control while reducing errors across the board.

According to the 2024 survey by the Institution of Mechanical Engineers, CMMS adoption continues to rise, while EAM usage is slowing.

And it makes sense.

CMMS (Computerized Maintenance Management Systems) are purpose-built for maintenance teams, whereas EAM systems have a broader focus.

As a result, CMMS platforms are often preferred by maintenance supervisors because they’re more intuitive and user-friendly, yet still deliver all the features they need.

For instance, our own CMMS, WorkTrek, offers:

| Work Order Management | Create, assign, track, and prioritize WOs from anywhere. Capture key details with customizable required fields. |

| Work Request Management | Submit requests through multiple channels: app, email, or request portal. Automatically notify stakeholders of updates, and collect feedback once work is completed. |

| Asset Management | Record and update all asset information, including physical location, performance history, warranties, maintenance logs, and costs. |

| Inventory Management | Track parts using barcodes or QR codes to reduce manual entry. Receive low-stock alerts to avoid delays. |

| Invoicing | Generate invoices from work orders in just a few clicks. Minimize errors by pulling accurate data directly from completed tasks. |

| Analytics | Unlock insights into your business with reports, KPIs, metrics, and customizable dashboards. |

With WorkTrek, decision-making becomes faster, smarter, and more data-driven across every aspect of maintenance.

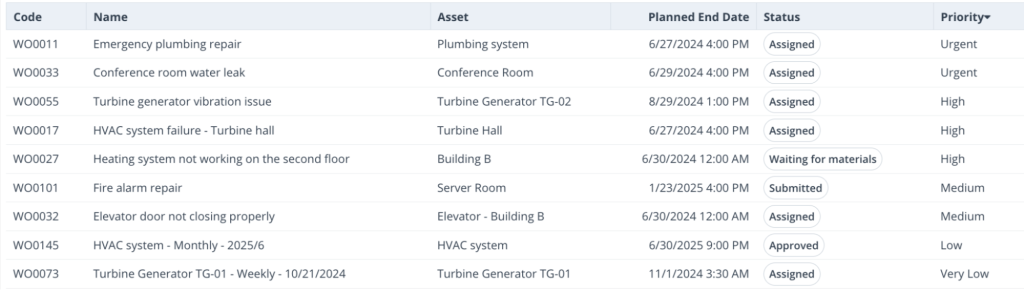

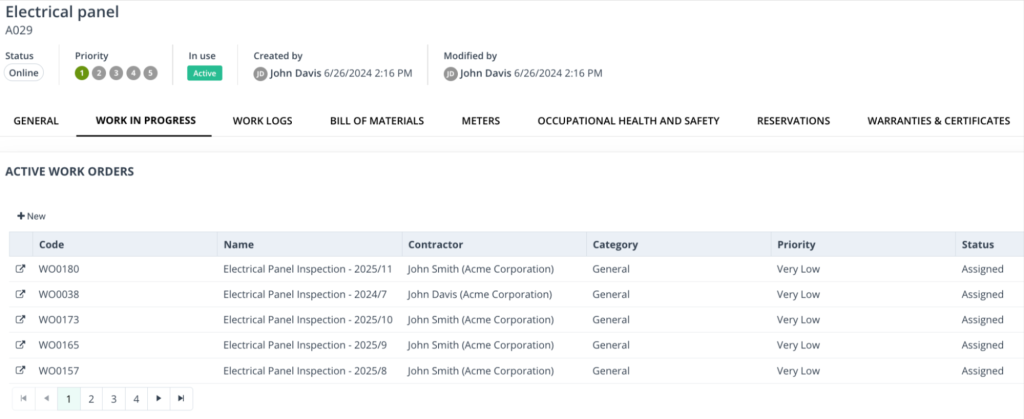

Take work orders, the heart of all maintenance efforts, as an example.

Without a CMMS, the WO process often looks like this:

- Information is unstandardized and scattered across papers, making it easy to get lost.

- Field technicians make unnecessary trips to and from the office.

- Supervisors have limited visibility into task progress.

It’s inefficient, error-prone, and leads to overlooked tasks and neglected assets.

With a CMMS like WorkTrek, that entire workflow transforms.

You can assign, prioritize, and track all work in one place:

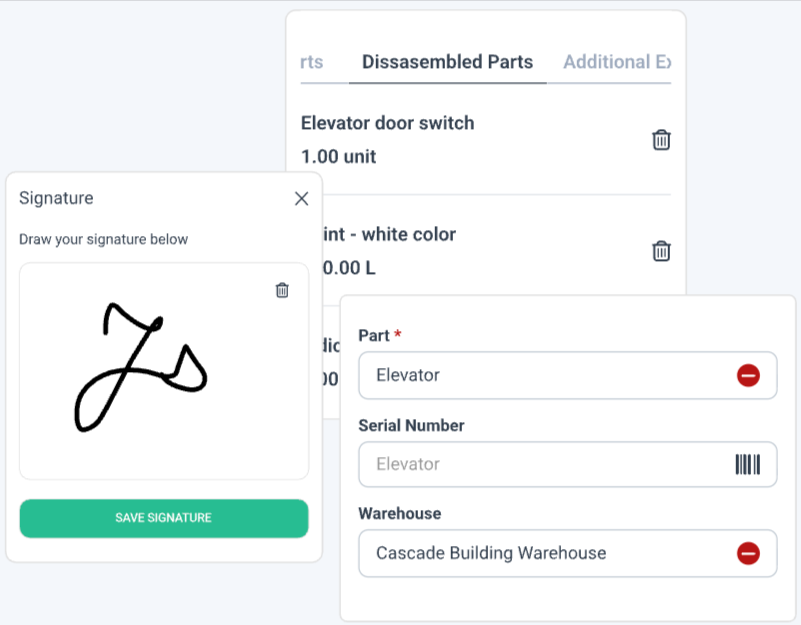

Technicians can access everything they need, from instructions to asset history, right from their phone.

They can also take photos, leave comments, close work orders, and collect multiple signatures onsite.

That’s a major boost in productivity and accuracy.

All in all, CMMS solutions have been around since the 1960s for a reason: maintenance work has always needed structure, organization, and traceability.

As these systems become more advanced, they’ve become indispensable tools in every supervisor’s toolkit.

QR Code-Based Asset Tracking

QR codes are a simple yet highly effective way to add visibility and accountability to daily maintenance operations.

Here’s how they work:

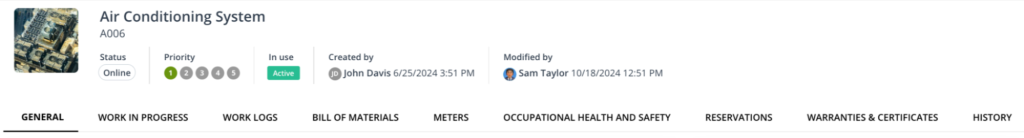

You start by creating an asset profile (shown below) in your CMMS that includes all relevant information about that asset, then generate a QR code linked to that profile.

After printing and attaching the code to the equipment, anyone can scan it with a smartphone or tablet to instantly access the asset’s digital record.

This includes details such as:

- Location

- Warranty information

- Usage history

- Maintenance history

- Serial numbers

- PPE requirements

Authorized users can also update this information on the spot, right from their phone.

A system like this boosts accountability in two significant ways.

First, it ensures that technicians always complete their work properly.

The system records who performed the task, when, where, and what was done.

It also shows all relevant instructions for that particular asset, such as LOTO procedures or PPE requirements:

This prevents technicians from taking shortcuts and ensures they always follow appropriate steps when working.

No more “I didn’t know” or “I forgot”.

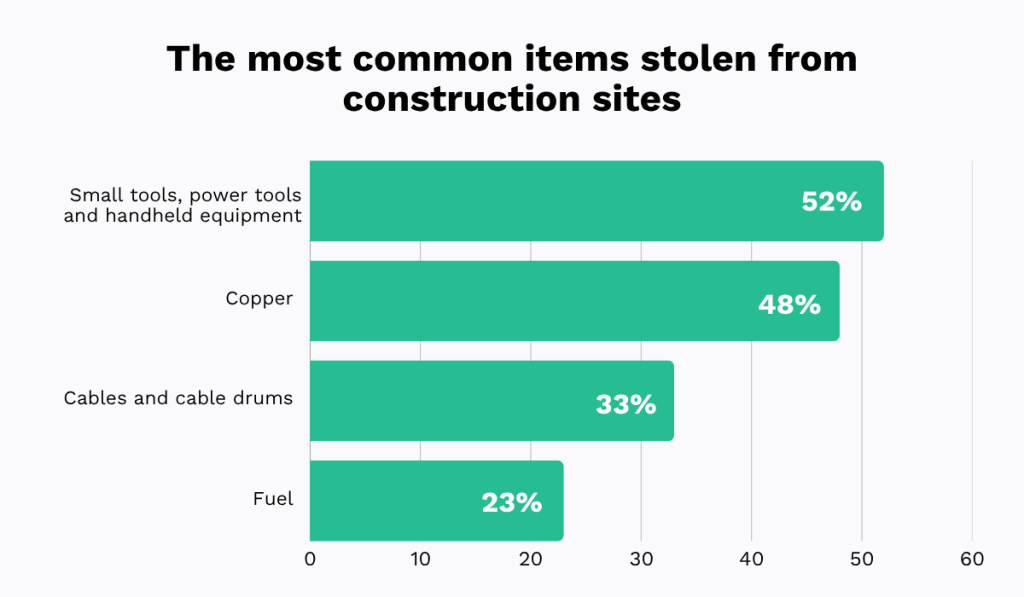

Second, QR codes help ensure the responsible use of MRO tools and materials.

These items, often small and inexpensive, tend to get misplaced or stolen.

The 2025 BauWatch survey even found that small tools and materials are among the most frequently stolen items on construction sites.

By tagging supplies with QR codes, you can easily track their location, who used them, and whether they were returned to the right place.

This acts as a strong deterrent to theft and greatly increases the likelihood of recovering missing items.

Additionally, when technicians know items are tracked, they’re far more likely to return them rather than leave them scattered across the site.

Overall, QR code systems are versatile and powerful yet cost-effective and simple to use.

That’s why they’ve become a go-to choice for supervisors looking to improve asset record accuracy and protect valuable equipment.

IoT Sensors

IoT (Internet of Things) sensors are internet-connected devices attached to equipment to collect real-time data on operating conditions.

They can measure a wide range of variables, including:

- Vibration

- Temperature

- Pressure

- Humidity

- Electrical current

- Motor speed

- Fluid levels

With these devices, maintenance supervisors can monitor asset health 24/7, even remotely.

This makes all the difference.

IoT data helps detect anomalies the moment they occur, enabling what is known as condition-based maintenance.

In other words, maintenance is performed only when it’s truly needed, rather than on a fixed schedule that risks under- or over-servicing assets.

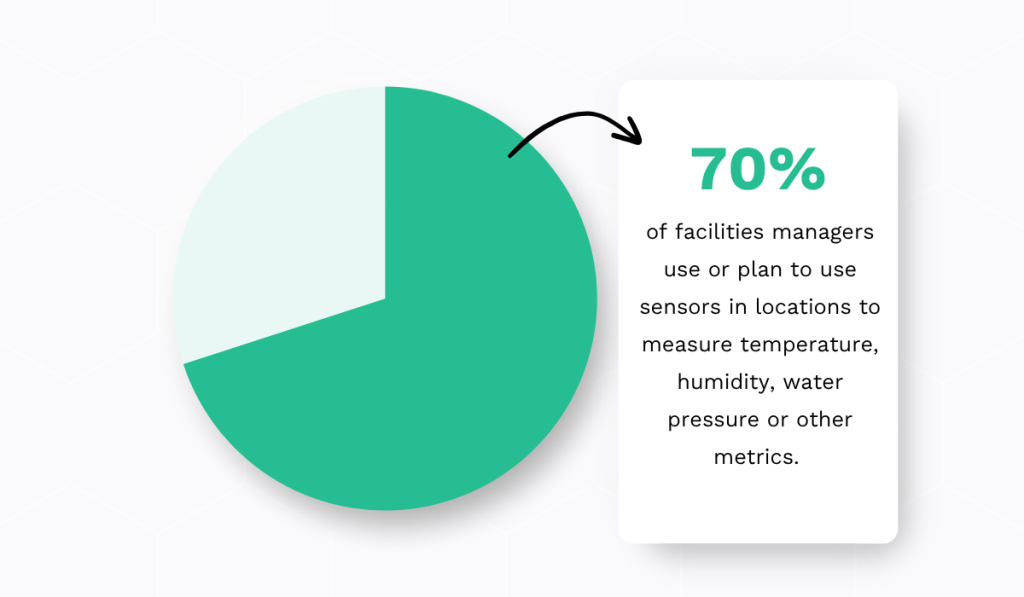

It’s no surprise, then, that supervisors across industries are adopting this technology.

For example, the 2025 Ecotrak survey reports that many facilities in the food service and similar sectors are already using, or planning to use, sensors to track temperature, humidity, and more.

IoT sensors are also widely used in heavier industries.

Take, for instance, the Volvo Group manufacturing facility in Lyon, France.

Producing large engines for trucks, industrial power systems, and boats, their manufacturing process relies heavily on Autonomous Guided Vehicles (AGVs), which are depicted below:

So, to proactively monitor AGV health and prevent unplanned shutdowns, the Volvo team installed LoRaWAN sensors on every AGV.

These devices send periodic voltage data, helping detect low battery levels or battery failures.

You can see one such sensor in the image below:

The system also sends automatic notifications to the maintenance team, giving them enough time to move AGVs to a charging station before they block the production line.

In environments like these, where production uptime is vital, these devices are invaluable.

They ensure that critical assets receive maintenance exactly when required, keeping them in top condition without causing unnecessary interruptions.

This is why IoT sensors have become so popular among supervisors working in manufacturing, in particular.

Predictive Analytics

IoT sensors go hand-in-hand with predictive analytics.

This technology combines historical data, IoT sensor readings, machine learning, and statistical models to predict when a piece of equipment is likely to fail.

By doing so, it further optimizes maintenance schedules and boosts overall operational efficiency.

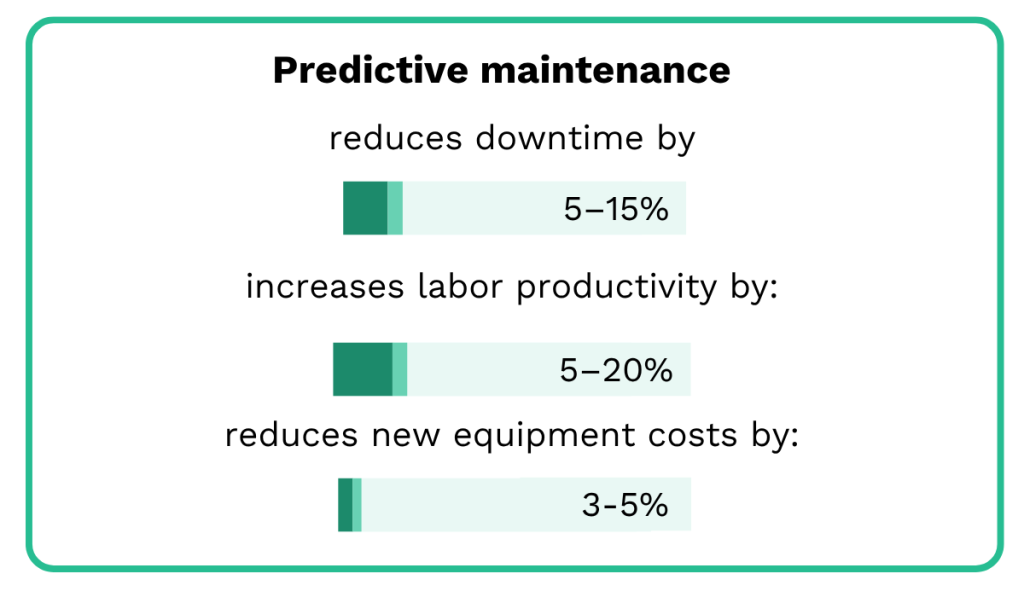

In fact, the 2022 Deloitte study has already confirmed that predictive maintenance can significantly reduce downtime and costs while increasing productivity.

Of course, not every maintenance supervisor will find this kind of system beneficial.

The upfront investment is considerable, so it’s mainly suited to industrial environments where equipment downtime comes at a high price.

That’s where predictive maintenance shines.

Take it from BlueScope, an Australia-based global leader in metal coatings and steel products.

In 2022, the company implemented a predictive maintenance system that monitors and analyzes data such as vibration and pressure to detect early warning signs of asset failure.

Within seven months, the results were clear.

In total, BlueScope avoided approximately 2,000 hours of downtime and prevented 53 full process interruptions worldwide, saving valuable time and materials.

Colin Robertson, Digital Transformation Manager at BlueScope, commented:

On top of that, the system made work safer by reducing risky manual interventions, like handling steel strips during unexpected stoppages.

The main takeaway is this: predictive analytics isn’t just the latest tech fad. It delivers real results.

In industries where every second counts and machinery is expensive, it’s an invaluable tool that keeps production running smoothly, costs down, and workers safe.

Employee Scheduling Tools

As the name suggests, employee scheduling tools automate workforce scheduling, track labor costs, and manage PTO, improving workforce planning and increasing overall productivity.

In industrial maintenance, these tools are more necessary than ever.

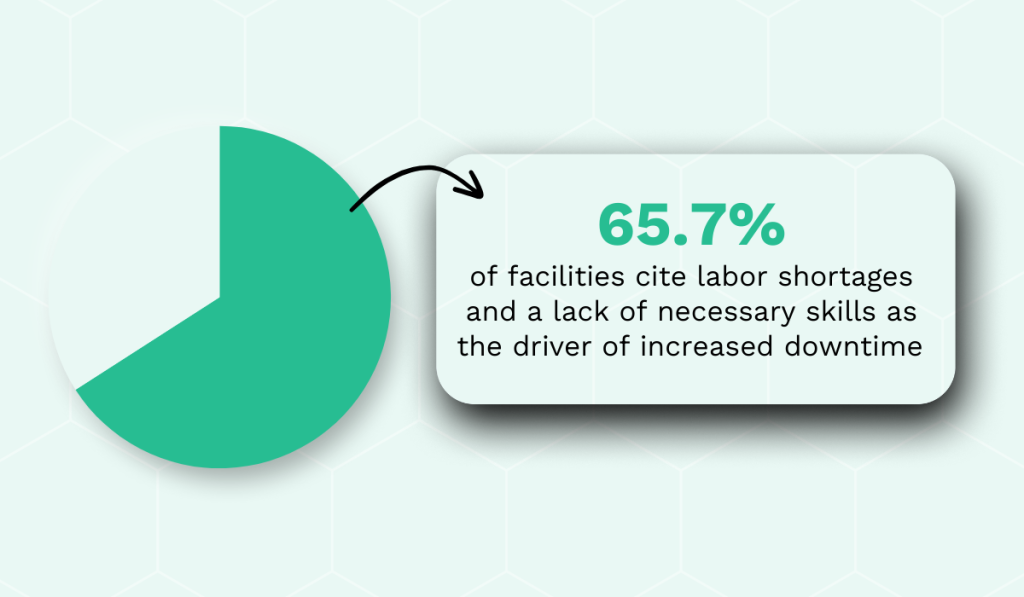

According to recent research, over half of facilities cite labor shortages and skill gaps as key drivers of increased downtime.

With experienced workers retiring and fewer new workers entering the field, maximizing the productivity of existing staff has become the number one priority in maintenance.

Scheduling tools help you do just that.

They ensure effective workforce allocation, thereby preventing budget overruns and reducing time theft.

You can think of them as the “control center” for managing people, just as a CMMS is the control center for managing assets and maintenance activities.

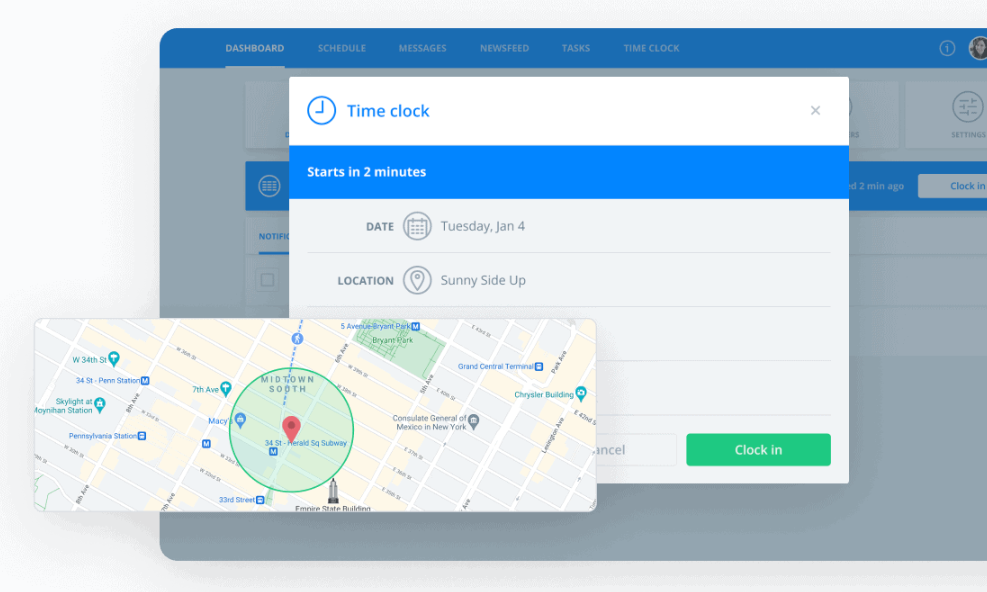

Nowadays, these solutions typically include mobile apps that allow technicians to clock in and out directly from their phones, often with a geofencing feature.

This means you can set up a parameter for where employees can clock in, ensuring they are always in the right place at the right time.

All of that makes it easier to monitor attendance across multiple workers and even various locations.

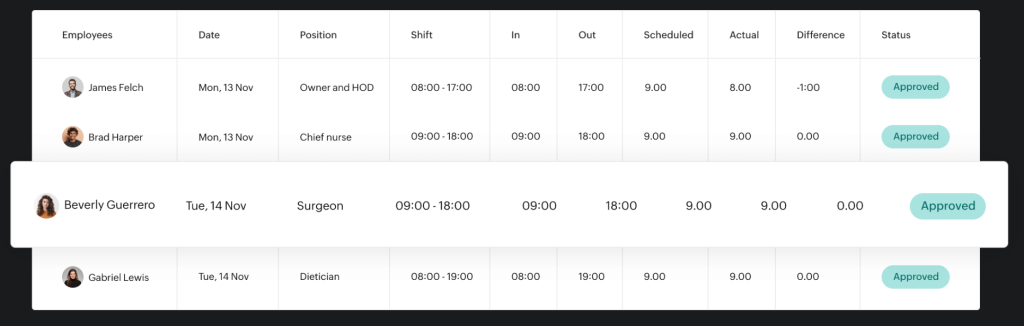

Scheduling itself becomes more streamlined as well.

You can view workforce availability across sites, plan shifts with intuitive drag-and-drop interfaces, use templates, and even copy schedules from prior weeks to save time.

Some tools allow staff to swap or offer shifts to more qualified coworkers, further boosting efficiency.

Additionally, these systems maintain accurate records of working hours in one centralized location, simplifying approvals for time off, overtime, and other requests.

At the end of the day, maintenance operations are only as effective as the technicians on the ground.

Experienced supervisors know this.

They also know that effective scheduling is a key factor in maximizing team performance, turning a team of individuals into a highly coordinated, productive unit.

With employee scheduling software, you can finally unlock your team’s full potential, while also saving time on repetitive, low-value administrative tasks.

Industrial Vending Machines

If you’ve been struggling with supply shortages or overordering, industrial vending machines could be the solution you need.

These automated dispensing units provide 24/7 access to tools, PPE, and consumables while helping control inventory and automatically reordering parts.

In short, they save time by automating stock management, ensuring technicians always have the tools they need, and preventing budget overruns caused by overordering.

A true win-win-win.

In the video below, you can learn more about how it all works from Kevin Wedge, Director of Metalworking at Würth Industry, a provider of such vending solutions.

Würth Industry’s solutions help manage everything, including ordering, delivery, storage, and point-of-use accessibility with a consumables program tailored to your facility.

Their vending machines even allow you to set employee usage restrictions by department, product, or machine, giving you complete control.

Simply put, these systems handle all inventory-related tasks, boosting productivity, lowering operating and administrative costs, and reducing product consumption.

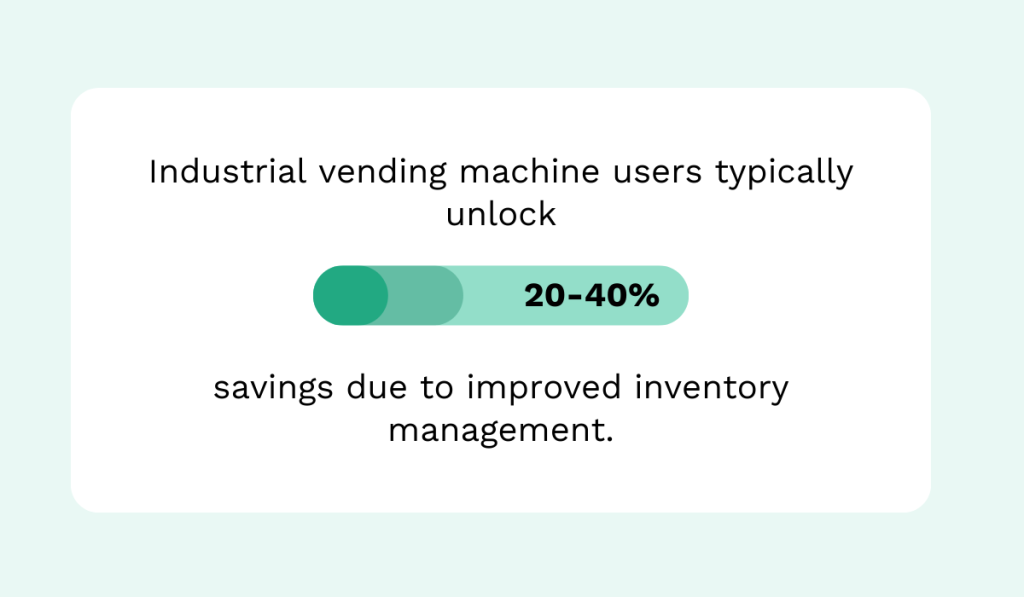

In fact, according to Wedge, new customers typically see 20–40% savings thanks to the inventory optimization these vending machines provide.

Yes, they can be that efficient.

So, if inventory and/or budget optimization are your priorities, consider industrial vending solutions.

They could be exactly what you were looking for.

Conclusion

While all these tools can greatly improve your maintenance operations, there’s no need to feel pressured to adopt them all.

Instead, start by analyzing your processes, talking with colleagues, and identifying the most urgent problem to solve.

Maybe you’re stuck in a reactive cycle, dealing with excessive unplanned downtime. Or perhaps you’re overspending on MRO supplies.

Once you clearly understand the core issue, you can focus on finding a solution that addresses it.

But before making any final decisions, be sure to test the solution thoroughly.

Read online reviews and take full advantage of free trials.

Remember, a tool that looks great on paper isn’t always the right fit for your specific needs.

Ultimately, this careful research will be well worth the effort.

You’ll end up with a solution that truly delivers, saving money, improving efficiency, and boosting productivity.