Blog

Operations & Maintenance

Top 8 Challenges of Maintenance Management

Key Takeaways Maintenance management faces an increasingly complex landscape. From aging equipment to skilled labor shortages, organizations struggle with multiple challenges that directly impact their operational efficiency and bottom line. Understanding these obstacles—and more importantly, knowing how to overcome them—can mean the difference between reactive firefighting and proactive excellence. Recent data shows that 67% of […]

Key Takeaways

Aging equipment is the #1 concern for 67% of maintenance managers, with 80% of manufacturing plants citing machinery breakdowns as their leading cause of operational inefficiencies

Fortune Global 500 companies lose $1.4 trillion annually due to unplanned downtime, with costs reaching $9,000 per minute for large organizations

Only 29% of facility managers believe their technicians are adequately prepared for modern maintenance challenges, highlighting a critical skills gap

Modern CMMS solutions can reduce emergency calls by 50% or more through preventive maintenance scheduling and real-time communication

Maintenance management faces an increasingly complex landscape.

From aging equipment to skilled labor shortages, organizations struggle with multiple challenges that directly impact their operational efficiency and bottom line.

Understanding these obstacles—and more importantly, knowing how to overcome them—can mean the difference between reactive firefighting and proactive excellence.

Recent data shows that 67% of managers believe aging equipment represents their main future challenge, while 34% cite lack of resources or staff as a critical concern.

These statistics paint a clear picture: maintenance teams need clear and strategic solutions now more than ever.

This article covers the eight most significant challenges facing maintenance management today, with practical suggestions on how to improve operations.

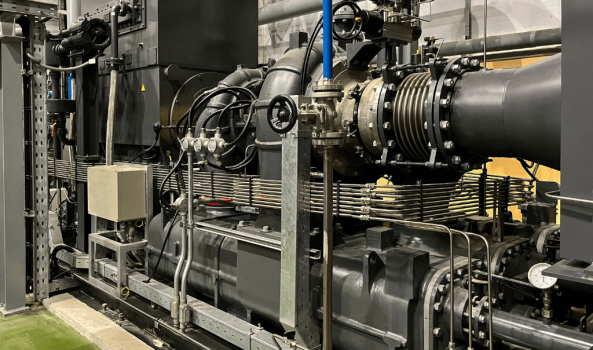

1. Managing Aging Equipment and Asset Deterioration

Aging equipment stands as the number one concern for maintenance managers worldwide.

A recent study found that 80% of manufacturing plants cite machinery breakdowns as their leading cause of operational inefficiencies.

Outdated equipment can greatly impacts maintenance.

As a facility manager, you already know that old equipment doesn't just break down more often, but it can create a cascading effect of maintenance issues.

Illustration: WorkTrek / Data: Advanced Technology Services

One issue faced by maintenance teams is that legacy systems require specialized knowledge that's increasingly hard to find.

Additionally, spare parts become scarce and expensive, and equipment failures happen with frustrating regularity.

The challenge can intensify when you consider that many facilities operate with equipment decades past its intended lifecycle.

The financial implications are staggering. Fortune Global 500 companies experience an annual total of $1.4 trillion in losses due to unplanned downtime disruptions—that's roughly equivalent to Spain's entire annual GDP.

For individual organizations, these frequent repairs and increased operational costs from aging assets can quickly spiral out of control.

There are a few strategies that innovative maintenance teams use to address this challenge:

Asset lifecycle management

Can becomes a critical cornerstone of your maintenance strategy. Rather than running equipment to failure, professional facility managers implement comprehensive tracking systems that monitor equipment health. They can also predict replacement needs and justify capital expenditures using complex systems and repair data.

Source: WorkTrek

This proactive maintenance approach helps minimize downtime while building a case for strategic equipment upgrades.

Predictive maintenance technologies

Predictive maintenance is another option. By implementing IoT sensors and data analysis tools, maintenance personnel can detect early warning signs of equipment failure.

Illustration: WorkTrek / Quote: Power MI

Anytime you move from reactive maintenance to predictive maintenance, you can extend equipment life while reducing the associated costs of emergency repairs.

Strategic replacement planning

Replacement planning helps facilities management teams balance financial constraints with operational needs.

Instead of replacing everything at once, create a phased approach that prioritizes critical assets first, ensuring continuous improvement without overwhelming your budget.

2. Skilled Labor Shortages and Knowledge Transfer

There is a quiet storm brewing in the maintenance industry: experienced technicians are retiring faster than new talent enters the field. This is creating a significant skills gap that threatens operational efficiency.

Only 29% of facility managers believe their technicians are "very prepared" for modern maintenance challenges, while 26% consider them "not at all prepared".

Illustration: WorkTrek / Source: Conger

The problem is multi-pronged - fewer people are getting into the industry, and training is limited in many organizations.

This perfect storm can undermine an organization's ability to maintain equipment properly, implement new technologies, and ensure safety procedures are followed.

Additionally, when experienced maintenance personnel leave, they take decades of institutional knowledge with them, leaving maintenance teams scrambling to fill the void.

These challenges become even more complex considering how the nature of maintenance work is evolving.

A maintenance manager today needs teams proficient not just in traditional mechanical skills but also in computerized maintenance management systems, data analysis, and increasingly sophisticated diagnostic tools.

Finding individuals who bridge this technical divide proves increasingly difficult.

Here are a few suggestions to help your organization navigate this complex landscape:

Develop a robust training program

Make this part of the foundation of any solution that you implement. Rather than hoping new hires arrive job-ready, successful maintenance teams invest in continuous skill development.

What should these programs covers? Any training program should encompass both technical competencies and soft skills like communication and problem-solving.

Don't forget to implement an organization-wide documentation process. Having easily accessible standard operating procedures ensures knowledge isn't lost when key personnel leave.

Illustration: WorkTrek / Data: Touchpoint

This can be greatly simplified by implementing a CMMS platform like WorkTrek.

Encourage mentorship

Illustration: WorkTrek / Data: Exploding Topics

Pair experienced technicians with newer team members, facilitating knowledge transfer before it's too late. This approach is invaluable in preserving institutional knowledge about specific equipment, unique facility challenges, and proven troubleshooting techniques. Some of this information might be hard to find in vendor manuals.

Adopt Technology

Implementing the right technology platforms can help bridge the gap. A modern maintenance software like WorkTrek can automate a lot of manual work order processes, centralize documentation, and provide detailed KPIs and reports. This ensures completed tasks meet quality standards even when expertise is limited. These systems also capture maintenance history and create a knowledge base that outlasts any individual employee.

3. Budget Constraints and Resource Allocation

Based on our experience, most maintenance organizations operate with limited resources and budgets. This forces facilities managers to do more with less while maintaining safety standards and operational efficiency.

According to recent surveys, 29% of facilities lack adequate budget for maintenance needs, creating a dangerous cycle of deferred maintenance and increased operational costs.

Illustration: WorkTrek / Data: Infraspeak Blog

The challenge isn't always about money, but also about efficient resource allocation.

Maintenance costs can spiral out of control when teams lack proper planning, leading to expensive emergency repairs, overtime labor, and expedited shipping for critical parts.

Without an effective maintenance strategy, organizations find themselves trapped in reactive maintenance cycles that drain budgets without improving reliability.

When dealing with competing priorities, budget pressures can intensify.

Facilities management teams always battle with balancing immediate repairs vs preventive maintenance tasks. This is all the while justifying expenditures to leadership who may not fully understand the long-term cost savings of proactive maintenance practices.

Below are a few tips on how to overcome budget challenges:

Data-driven justification

Illustration: WorkTrek / Data: PwC

Transforms maintenance from a cost center to a value driver. By tracking key performance indicators and demonstrating the value of preventive maintenance in reducing operational costs, maintenance managers can build compelling cases for budget increases. Show leadership how every dollar spent on proactive maintenance saves multiple dollars in avoided breakdowns and production losses.

Prioritization frameworks

Source: WorkTrek

Ensures that limited resources target critical tasks first. Not all maintenance activities should carry equal weight. The key is to focus on equipment that directly impacts production, safety, or customer satisfaction. This approach helps maintenance teams maximize impact even with constrained budgets.

Long-term cost savings strategies

In your discussions with management, shift the conversation from expense to investment. Implementing a preventive maintenance plan might require upfront costs, but the reduction in equipment failures, unplanned downtime, and emergency repairs delivers significant ROI.

4. Managing Unplanned Downtime and Emergency Repairs

Unplanned downtime and emergency maintenance affect 90% of European businesses, making it one of the most persistent maintenance challenges organizations face. The ripple effects can extend far beyond the immediate repair costs. It can result in production halts where customer relationships suffer, and maintenance teams scramble to address issues reactively.

Illustration: WorkTrek / Data: Traction

The actual cost of unplanned downtime often shocks leadership. For large organizations, downtime costs can reach as high as $9,000 per minute, with higher-risk industries like healthcare seeing costs soar beyond $5 million per hour. These staggering figures don't even account for the long-term damage to equipment, team morale, and customer satisfaction that frequent emergencies create.

Emergency maintenance can create a vicious cycle. When maintenance teams constantly fight fires, they lack time for preventive maintenance activities, which leads to more equipment failures and more emergencies.

This reactive approach can exhaust maintenance personnel, strain budgets, and prevent the implementation of improvement initiatives that could break the cycle.

Here are a few ideas on how to better handle emergency repairs:

Implement Preventive Maintenance

This forms the cornerstone of downtime reduction. By establishing regular inspection schedules, routine maintenance tasks, and proactive component replacement, organizations can identify and address issues before they cause failures.

This shift from reactive to preventive maintenance typically reduces emergency calls by 50% or more.

Root Cause Analysis

Source: WorkTrek

Helps prevent recurring failures. Instead of simply fixing problems, maintenance teams should take steps to understand the root causes of failures. Was it inadequate preventive maintenance? Operator error? Design flaws? By addressing root causes rather than symptoms, organizations can eliminate chronic issues that drive emergency maintenance.

Spare Parts Optimization

Source: WorkTrek

Having good visibility into your spare parts inventory can help reduce emergencies and costs. Implementing good inventory management means having critical components on hand without tying up excessive capital in unused parts. Modern maintenance software can predict parts needs based on maintenance history and the importance of equipment, which helps maintain the right balance.

5. Technology Integration and Digital Transformation

Despite the clear benefits of implementing a CMMS platform, many organizations struggle with technology adoption. Recent surveys show 88% of companies struggle with aging IT infrastructure and outdated technology, while 76% face challenges connecting modern assets and analyzing the resulting data.

This technology gap creates significant challenges for maintenance teams trying to improve efficiency.

Implementing technology alone is not enough. Consider integrating any maintenance software with your ERP or other enterprise applications. Facilities that operate with multiple systems without integration can create data silos that prevent comprehensive analysis.

Maintenance managers find themselves juggling disparate platforms for work orders, inventory management, asset tracking, and reporting. This can waste valuable time on manual processes that should be automated.

Legacy systems can compound the challenge. Older equipment often lacks the connectivity needed for modern monitoring solutions, while newer assets generate data volumes that overwhelm traditional maintenance management approaches.

This creates a two-speed maintenance environment where some assets benefit from predictive maintenance while others remain in reactive mode.

Below are a few tips to improve your digital transformation process:

Phased Implementation

Being strategic about implementation can reduce the load on teams. Start with core functionality like work order management, then gradually add features like predictive maintenance and advanced analytics. This approach allows maintenance personnel to adapt and see benefits before moving to the next phase.

Plan Integration Steps

This ensures new systems work with existing infrastructure. Before selecting a computerized maintenance management system, map current systems and identify integration points. Modern facility management software should connect with enterprise resource planning, production systems, and IoT sensors to create a unified maintenance ecosystem.

Change Management

Addresses the human side of technology adoption. Even the best maintenance software fails if teams don't embrace it. Invest in comprehensive training programs, identify champions within maintenance teams, and demonstrate early wins to build momentum for broader adoption.

6. Regulatory Compliance and Safety Management

It is becoming increasingly complex for maintenance organizations to manage regulatory compliance.

Safety procedures must be followed meticulously, regular safety inspections documented thoroughly, and compliance risks managed proactively—all while maintaining operational efficiency and managing daily maintenance activities.

Source: WorkTrek

The stakes couldn't be higher. Safety hazards in maintenance work can lead to serious injuries, hefty fines, and damaged reputations.

Yet many organizations struggle with fragmented safety training programs, inconsistent documentation processes, and difficulty tracking whether safety procedures are followed in the field.

The lack of maintenance history and inspection reports can make it difficult to get to the root cause of safety incidents.

Compliance gets even more complex as regulations evolve and enforcement increases. Facilities and maintenance managers must navigate federal, state, and local requirements while also meeting industry-specific standards.

This regulatory maze becomes even more challenging when managing multiple facilities across different jurisdictions, each with unique compliance requirements.

Below are a few things you can do to improve your organization's compliance:

Centralized Documentation Systems

Ensure all safety-related maintenance activities are properly recorded and easily accessible during audits. Digital maintenance software can automatically generate inspection reports, track safety training completion, and maintain comprehensive records that demonstrate compliance.

Source: WorkTrek

Using this centralized system, you can eliminate the risks associated with paper-based or fragmented documentation.

Standardize Safety Procedures

Implementing and standardizing safety procedures can reduce variation and ensure consistent compliance. Using a CMMS system, you can embed safety checks into work orders and require digital sign-offs. This can help maintenance managers verify that safety protocols are followed every time.

Proactive Safety Training

Illustration: WorkTrek / Data: DuraPlas

This goes beyond basic compliance and aims to create a culture of safety for your maintenance team. Regular training sessions, safety meetings, and refresher courses keep safety top-of-mind for maintenance personnel. Track training completion and certifications within your maintenance management system to ensure no one performs tasks they're not qualified for.

7. Poor Communication and Coordination

Communication breakdowns can plague maintenance operations. This can create inefficiencies that ripple throughout organizations.

When maintenance requests get lost, priorities aren't communicated, or teams work in silos, the result is is frustrated stakeholders. A significant 45% of maintenance professionals' working hours are spent managing physical work orders and documentation—time that could be better spent on actual maintenance tasks.

The challenge intensifies in larger organizations where maintenance teams must coordinate with operations, procurement, management, and external contractors. Without effective communication channels, addressing maintenance requests becomes a game of telephone where critical information gets lost or distorted.

This leads to wrong parts being ordered, technicians arriving unprepared for jobs, or critical maintenance being delayed because priorities weren't properly communicated.

Modern organizations overcome communication challenges through:

Unified Communication Platforms

A CMMS system like WorkTrek can integrate all maintenance-related communication into a single system. It can serve as the central hub where all stakeholders can submit requests, track progress, and access information.

Source: WorkTrek

This eliminates the confusion of emails, phone calls, and paper forms while ensuring nothing falls through the cracks.

Mobile Accessibility

A maintenance platform with a mature mobile platform can help teams stay connected regardless of location. Field technicians can receive work orders, update task status, and communicate issues in real-time through mobile devices.

Source: WorkTrek

Automated Workflows

Implementing automated workflows as part of your CMMS system can ensure proper procedures are followed. For example, when equipment failure is reported, the system can automatically notify relevant personnel. It can also create work orders and trigger parts ordering, all of which can be done without manual intervention.

8. Data Management and Performance Tracking

Despite living in a data-rich era, many maintenance teams struggle to harness information effectively.

Maintenance organizations collect vast amounts of data about equipment performance, maintenance activities, and costs, yet 40% struggle with obtaining and analyzing asset data.

Source: WorkTrek

Without proper data analysis capabilities, maintenance managers make decisions based on intuition rather than facts, missing opportunities for continuous improvement.

The challenge goes beyond simple data collection. Many organizations have data scattered across multiple systems, spreadsheets, and paper records, making comprehensive analysis nearly impossible.

Even when data is digitized, a lack of standardization means comparing performance across assets or facilities becomes a manual, error-prone process.

Key performance indicators often go untracked or unmeasured, leaving maintenance managers unable to answer critical questions: Are we improving? Where should we focus resources? What's our return on maintenance investment? Without these insights, it's impossible to optimize maintenance strategies or justify budget requests with concrete evidence.

Here are a few steps you can follow to improve data management:

Standardized Data Collection

This enables consistency across all maintenance activities. Define what data to collect, how to collect it, and where to store it. Modern maintenance software can enforce these standards through required fields and automated data capture, eliminating the variability that makes analysis difficult.

Real-time Dashboards

A good computerized maintenance management system can transform raw data into actionable insights. Instead of digging through reports, maintenance managers can see equipment availability, maintenance backlog, cost trends, and other key performance indicators at a glance.

These visual tools help identify problems quickly and track the effectiveness of improvement initiatives.

Predictive Analytics

Leverages historical maintenance data to forecast future needs. By analyzing patterns in equipment failures, maintenance costs, and resource utilization, organizations can optimize maintenance schedules, predict budget needs, and prevent failures before they occur. This data-driven approach transforms maintenance from reactive to strategic.

How WorkTrek CMMS Helps Organizations Overcome These Challenges

WorkTrek's computerized maintenance management system directly addresses all eight maintenance management challenges through an integrated, user-friendly platform designed for modern maintenance teams.

By combining powerful functionality with intuitive design, WorkTrek transforms how organizations approach maintenance management.

Source: WorkTrek

For aging equipment challenges, WorkTrek provides comprehensive asset management capabilities that track equipment lifecycle, maintenance history, and performance trends.

This data helps facility managers make informed decisions about repair versus replacement while maximizing asset lifespan through optimized preventive maintenance schedules.

Source: WorkTrek

Addressing workforce challenges, WorkTrek includes built-in training tracking, skill management, and knowledge base features that help organizations maintain competency even as team composition changes. The system's intuitive interface reduces training time for new technicians while standardized procedures ensure consistent quality regardless of who performs the work.

Budget optimization becomes achievable through WorkTrek's detailed cost tracking and reporting capabilities. By capturing all maintenance-related expenses and demonstrating preventive maintenance ROI through clear metrics, maintenance managers can justify budgets and allocate resources more effectively.

The system's predictive capabilities help prevent costly emergency repairs while optimizing inventory levels to reduce carrying costs.

WorkTrek's mobile-first design ensures seamless communication between office and field personnel.

Work orders, updates, and critical information flow instantly between team members, eliminating communication gaps that lead to delays and errors. Integration capabilities mean WorkTrek works with existing systems rather than creating another silo.

Most importantly, WorkTrek transforms data from a burden to an asset. Automated data collection, real-time analytics, and customizable dashboards provide the insights maintenance teams need to improve continuously.

Whether tracking safety compliance, measuring performance against KPIs, or predicting future maintenance needs, WorkTrek ensures decisions are based on facts rather than guesswork.

Conclusion: Turning Challenges into Opportunities

The challenges facing maintenance management are real and significant, but they're far from insurmountable. Organizations that acknowledge these obstacles and implement strategic solutions position themselves for operational excellence and competitive advantage.

Success requires more than just technology. It demands a commitment to continuous improvement, investment in people and processes, and a willingness to evolve from reactive to proactive maintenance practices.

By addressing these eight challenges systematically, maintenance teams can transform from cost centers to value drivers that directly contribute to organizational success.

The path forward is clear: embrace modern maintenance management approaches, invest in the right tools and training, and build a culture that values preventive over reactive maintenance. Organizations that make these investments today will reap the benefits of improved reliability, reduced costs, and enhanced operational efficiency for years to come.

Operations & Maintenance

Difference Between Maintenance Management and Facility Management

Key Takeaways:

Maintenance management focuses specifically on equipment upkeep and asset reliability, while facility management encompasses broader operational responsibilities

73% of facility managers report that equipment maintenance represents their most critical daily responsibility

Organizations with integrated maintenance and facility management approaches see 22% fewer operational disruptions

A lot of organizations struggle to distinguish between maintenance management and facility management, often treating them as interchangeable concepts.

This confusion can lead to inefficient resource allocation, unclear responsibilities, and missed opportunities for cost savings.

While there is a shared common ground between the two approaches, they each serve distinct purposes within modern organizations.

For maintenance managers, understanding their key differences can help you optimize operations, reduce maintenance costs, and ensure smooth business continuity.

If you're curious about how these two critical functions differ and how they can work together to enhance your operations, keep reading.

What is Maintenance Management?

Maintenance management is the systematic process that preserves and restores equipment, machinery, and physical assets to their optimal operating condition.

Based on studies, a lot of maintenance teams struggle with staffing. According to a study by JLL Technologies in 2024, nearly half (47%) of facility management teams are currently understaffed.

Illustration: WorkTrek / Data: Facilities Dive

The focus is specifically on the technical aspects of asset care, from routine inspections to complex repairs.

Simply, the objective of maintenance management is to maximize equipment reliability and keep maintenance costs down. Another goal is to reduce equipment downtime and operational disruptions.

This approach requires planning, scheduling, and execution of maintenance activities derived from data-driven insights.

According to the International Facility Management Association, good maintenance management can reduce equipment failures by up to 75% when properly implemented.

What are the components of Maintenance Management?

Preventive Maintenance: This is when scheduled tasks are performed at regular intervals to prevent equipment failures. PM includes routine inspections, lubrication, filter changes, and component replacements based on manufacturer recommendations or operating hours.

Source: WorkTrek

Corrective Maintenance: This is when repairs are only performed when an equipment fails. While reactive, corrective maintenance can be more strategic when integrated with proper maintenance planning.

Source: WorkTrek

Predictive Maintenance: This is the next generation of maintenance and is considered an advanced maintenance technique. Predictive maintenance works by using condition monitoring and data analytics to predict when equipment is likely to fail. Additionally, it can leverage sensors, vibration analysis, and thermal imaging to optimize maintenance timing.

Source: WorkTrek

Scheduled Maintenance: Time-based maintenance activities follow predetermined schedules, regardless of equipment condition. This approach ensures all equipment receives consistent maintenance regardless of condition.

Source: WorkTrek

What is Facility Management?

Facility management and maintenance aims to take a broader view. It covers the coordination of physical workplace environments to support business operations.

Maintenance is certainly a component of facility management. However, the discipline extends far beyond equipment upkeep.

Facility management services ensure that buildings, systems, and services are functioning properly. The role combines operational oversight with strategic planning to create environments where people and processes can thrive.

Scope of Facility Management Services

Facility maintenance involves:

Building Maintenance: This is the typical comprehensive care of building systems. Items include HVAC systems, electrical systems, plumbing, and structural elements. This ensures that office buildings and commercial buildings remain safe and functional.

Source: WorkTrek

Space Management: The goal is to optimize the use of physical space to support business objectives. This includes layout planning, space allocation, and ensuring efficient utilization of available square footage.

Safety Systems: Another part of the scope is managing safety systems like fire suppression and security systems. It also includes emergency procedures and ensuring compliance with safety regulations. Facility managers coordinate with specialized contractors to maintain these critical systems.

Source: WorkTrek

Vendor Management: Most facilities use external vendors for property maintenance. One of the primary tasks is coordinating with external service providers for specialized tasks such as HVAC maintenance, landscaping, cleaning services, and security. This includes managing service requests and ensuring quality delivery.

Illustration: WorkTrek / Data: Horizontal Insights

Strategic Planning: Long-term planning for facility needs, including capital project planning, real estate management, and ensuring alignment with organizational growth objectives.

Energy Management: All facility managers want to reduce energy use. This includes implementing energy-efficient practices, monitoring utility consumption, and managing air conditioning and heating systems.

Tools and Technology: How WorkTrek CMMS Supports Both Disciplines

To manage facilities and maintenance, you need a robust technology solution. One of the best solutions on the market is WorkTrek CMMS. It is a comprehensive platform that addresses the needs of both disciplines while enabling seamless collaboration.

Based on a recent study, CMMS can help organizations save between 5-15%of their maintenance budgets. Additionally, 65% of companies that use CMMS have better maintenance outcomes.

Maintenance Management Capabilities

WorkTrek streamlines core maintenance and asset management activities through automated scheduling, work order management, and comprehensive asset tracking.

Source: WorkTrek

This enables maintenance teams to efficiently plan preventive maintenance, track maintenance activities, and monitor equipment performance.

With WorkTrek's predictive maintenance features, maintenance professionals identify potential equipment failures before they occur.

This reduces unplanned downtime and maintenance costs.

Facility Management Integration

For facility managers, WorkTrek provides broader operational visibility and coordination capabilities.

It empowers you to implement efficient management of service requests, vendor coordination, and facility maintenance tasks across multiple building systems.

Source: WorkTrek

Facility managers can use WorkTrek's reporting and analytics features to track facility performance, monitor maintenance costs as a percentage of facility budgets, and make data-driven decisions about capital project planning and resource allocation.

Collaborative Features

With WorkTrek you can use shared dashboards that provide real-time visibility into facility operations. These integrated communication tools ensure that all stakeholders stay informed about critical activities.

With WorkTrek's mobile capabilities, maintenance technicians and facility managers can access information, update work orders, and coordinate activities easily.

Strategic Insights

With WorkTrek's extensive reporting capabilities provide valuable insights for both maintenance management and facility management decision-making.

Organizations can track key performance indicators, monitor cost trends, and identify opportunities for operational improvements.

These insights enable organizations to optimize their maintenance and facility management strategies, reduce operational costs, and ensure that facilities effectively support business objectives.

How Maintenance and Facility Management Work Together

While maintenance management and facility management have distinct roles, it is important for them to collaborate.

Organizations that can integrate these functions typically see significant improvements in operational efficiency and can reduce maintenance costs.

Coordinated Planning

Successful organizations align maintenance schedules with facility management priorities.

Source: WorkTrek

When facility managers understand maintenance requirements, they can better plan space utilization, coordinate vendor activities, and minimize disruptions to business operations.

For example, when major HVAC maintenance is scheduled, facility managers can coordinate temporary cooling solutions, adjust space assignments, and communicate with building occupants to ensure minimal impact on productivity.

Shared Resources

Maintenance teams and facility management teams often share resources, information, and expertise.

Maintenance technicians provide technical insights that aid facility managers in making informed decisions about equipment replacement, space modifications, and capital project planning.

Similarly, facility managers provide strategic context that helps maintenance teams prioritize their activities and align maintenance objectives with broader business goals.

Integrated Technology Solutions

Modern organizations increasingly use integrated technology platforms that support both maintenance management and facility management functions. These systems provide comprehensive visibility into facility operations and enable better coordination between teams.

A well-implemented CMMS can serve both maintenance management and facility management needs by tracking asset performance, managing work orders, and providing data for strategic decision-making.

Best Practices for Optimizing Both Functions

Below are industry best practices to help you manage maintenance and facility management.

Establish Clear Roles and Responsibilities

Clearly define the boundaries between maintenance management and facility management. This approach will help you prevent duplication of effort and ensure comprehensive coverage of all facility needs.

Illustration: WorkTrek / Quote: Peter Simoons

Also, focus on technical expertise and equipment reliability. Align the team's skills to the longer-term operational requirements.

Regular communication ensures alignment and prevents gaps in coverage.

Implement Integrated Planning Processes

This includes coordinating maintenance schedules with business operations. Also, focus on aligning preventive maintenance with the overall facility objectives.

Source: WorkTrek

Invest in Technology Integration

Implementing a modern CMMS and facility management platform can provide the technological foundation for your organization. Organizations should prioritize solutions that support both disciplines while enabling seamless data sharing and communication.

Focus on Preventive Approaches

Preventive maintenance is always cheaper in the long term than reactive maintenance. Additionally, it can reduce equipment failures and associated costs. All this while improving your overall operations.

Illustration: WorkTrek / Data: Oxmaint

Focus on routine maintenance, scheduled inspections, and preventive facility management practices that address potential issues before they become costly problems.

Develop Comprehensive Training Programs

Without an adequate training program, it is difficult to run an efficient maintenance and facility management program.

Illustration: WorkTrek / Data: whatfix

Facility managers require broader training on project management, vendor management, and strategic planning.

Maintenance managers need equipment-specific training along with safety and LOTO procedures.

Monitor Key Performance Indicators

It is always a good idea to track performance metrics for both maintenance management and facility management activities.

This includes equipment reliability metrics, maintenance costs, facility utilization rates, and customer satisfaction measures.

Regular performance monitoring empowers you to continuously improve your overall process.

Future Trends and Technology Integration

Technology, including machine learning and AI, is transforming management and facility management. This is increasingly characterized by technology integration, data analytics, and smart building systems.

IoT and Smart Buildings

Internet of Things (IoT) sensors and smart building systems are revolutionizing both maintenance management and facility management.

According to a recent study by Micromain, the smart building market is projected to grow from $96.9 billion in 2023 to $408.21 billion in 2030.

Illustration: WorkTrek / Data: MoldStud

These technologies provide real-time data on equipment performance, space utilization, and environmental conditions.

Smart systems enable more precise maintenance scheduling, automated facility management functions, and predictive approaches to both equipment maintenance and facility optimization.

Artificial Intelligence and Analytics

AI-powered analytics are quickly changing the maintenance industry. Machine learning algorithms can predict equipment failures, optimize maintenance schedules, and identify opportunities for facility management.

Mobile and Cloud Technologies

Mobile technologies are transforming how maintenance technicians and facility managers access information and coordinate activities.

Cloud-based platforms enable real-time collaboration and provide access to critical data from anywhere.

These technologies improve response times, enhance communication, and enable more flexible work arrangements for both maintenance and facility management teams.

Industry Applications and Considerations

Different industries have varying requirements for maintenance management and facility management. Below are a few examples.

Manufacturing and Industrial Facilities

Manufacturing environments typically focus on maintenance management due to the critical nature of production equipment.

Equipment failures can be costly and result in significant production losses. This makes preventive maintenance critical for the manufacturing sector.

Facility management, on the other hand, remains important for managing workspace safety and regulatory compliance.

They are also tasked with supporting manufacturing operations through effective space management and facility maintenance.

Commercial Buildings and Office Environments

Office buildings and commercial properties often prioritize facility management to improve the tenant and guest experience.

Illustration: WorkTrek / Data: Grand View Research

This includes maintaining comfortable environments through effective HVAC maintenance, managing building systems, and coordinating maintenance activities to minimize tenant disruption.

Maintenance management focuses on ensuring the reliable operation of building systems, including electrical systems, elevators, and safety equipment.

Healthcare and Critical Facilities

Healthcare facilities require integrated approaches to both maintenance management and facility management.

Equipment reliability is critical for patient safety, while facility management ensures regulatory compliance and supports healthcare delivery.

Specialized maintenance requirements include medical equipment maintenance, emergency power systems, and sterile environment maintenance.

Educational Institutions

Schools and universities balance facility management needs with specialized maintenance requirements.

Facility managers coordinate space utilization for educational activities while maintenance teams ensure safe, reliable operation of building systems and equipment.

Cost Considerations and ROI

Understanding the financial implications of maintenance management and facility management helps organizations make informed investment decisions and optimize their resource allocation.

Maintenance Management Costs

Maintenance management costs typically include labor, parts, tools, and technology.

While these are clearly significant investments, implementing an effective maintenance management generates substantial cost savings through reduced downtime, extended asset life, and improved safety.

Studies show that proactive maintenance approaches can reduce total maintenance costs by 12-18% compared to reactive maintenance strategies.

Illustration: WorkTrek / Quote: ATS

Facility Management Investment

Facility management requires broader investments in technology, personnel, and vendor management. However, effective facility management generates value through improved space utilization, energy management, and operational efficiency.

Organizations with comprehensive facility management programs typically see 15-25% improvements in operational efficiency and significant reductions in facility-related costs.

Integrated Approach Benefits

Organizations that effectively integrate maintenance management and facility management typically achieve superior ROI compared to those that manage these functions separately. This integration reduces redundancies, improves communication, and enables more strategic resource allocation.

Conclusion

As this article has described, understanding the difference between maintenance management and facility management is essential for organizations seeking to optimize their operations and reduce costs.

Both disciplines play important roles in modern organizations, and their effective integration can generate significant operational improvements.

Implementing appropriate technology solutions, like a CMMS application, establishing clear roles and responsibilities, and focusing on preventive approaches, organizations can maximize the value of both maintenance management and facility management.

Whether your organization prioritizes industrial maintenance or comprehensive facility management, investing in proper systems, training, and coordination will pay dividends in the future.

Operations & Maintenance

The Role of IoT in Predictive Maintenance for Manufacturing

Key Takeaways:

IoT sensors enable real-time monitoring, making early failure detection and proactive maintenance possible.

Common IoT sensors used in predictive maintenance include vibration, temperature, pressure, and oil quality sensors.

49 targeted cyberattacks per week hit the average manufacturing organization’s IoT devices.

Unplanned downtime can cost millions in modern manufacturing.

Maintenance strategies have, therefore, evolved from reactive fixes to smarter, data-driven approaches.

One of the most effective among these is predictive maintenance (PdM), and at its core lies the Internet of Things (IoT).

Together, they are transforming how manufacturers maintain equipment, plan interventions, and ensure operational continuity.

Read on to learn what role IoT plays in all of this.

What is Predictive Maintenance?

Predictive maintenance (PdM) is a proactive maintenance strategy.

Its purpose is to forecast equipment failures by analyzing data gathered from machines and their operating environments.

Unlike reactive maintenance, which addresses issues after they happen, or preventive maintenance, which schedules interventions regardless of actual wear, PdM relies on real-time condition monitoring.

In other words, it ensures that maintenance is carried out only when necessary, based on the actual health of the machine.

Today, predictive maintenance ranks as the fourth most widely used maintenance approach, following preventive and reactive methods.

Illustration: WorkTrek / Data: MaintainX

The continued dominance of traditional approaches is often attributed to their simplicity, familiarity, and lower upfront implementation costs.

However, these are increasingly being questioned as manufacturers seek greater efficiency, reliability, and cost control.

That’s precisely what PdM delivers.

Kevin Tucker, Advisory Practice Lead at Info-Tech Research Group, notes:

Illustration: WorkTrek / Quote: Facility Executive

Implementing predictive maintenance effectively depends heavily on high-quality, timely data.

And IoT plays a key role here.

How IoT Enables Predictive Maintenance

The Internet of Things (IoT) refers to the network of interconnected devices embedded with sensors, software, and connectivity, enabling them to collect and exchange data.

In manufacturing, IoT technology equips machinery with intelligent sensors that continuously monitor various operational and environmental parameters, including:

Vibration

Temperature

Humidity

Pressure

Energy consumption

This constant data flow creates a real-time overview of asset health.

IoT in the manufacturing sector is expanding rapidly.

In 2022, the market was valued at $53.7 billion and is projected to reach $152.8 billion by 2032, growing at a CAGR of 10.5%.

Illustration: WorkTrek / Data: GMI

This growth reflects the growing reliance on connected systems to drive smarter maintenance practices.

A wide range of sensors supports IoT-driven PdM, including temperature, humidity, gas, and pressure sensors.

Source: Google

Some advanced types—such as nanotechnology-powered sticker sensors—offer flexible, low-power options for environments with restricted space or exposure to harsh conditions.

The data these sensors collect is transmitted either wirelessly or via wired connections to centralized platforms.

Source: MDPI

In some cases, data is processed locally using edge computing —a technology that enables data analysis close to the source, rather than relying on remote cloud servers.

Edge computing reduces latency and enhances reliability, which is especially important in time-sensitive industrial applications.

Once collected, the sensor data is processed using artificial intelligence (AI) and machine learning (ML) algorithms.

They identify patterns, recognize early warning signs of failure, and recommend timely interventions.

Rakesh Prasad, Senior Vice President of Digital Business at Innover, summarizes the process:

“For PdM, IoT sensors are fitted in machines and equipment to monitor their health and surroundings, gathering data on factors such as vibration, temperature, and humidity. This data is then relayed to a central system that employs AI/ML algorithms to examine the data and give insights into the equipment or machinery’s well-being.”

The practical advantages of this approach are significant.

McKinsey reported as early as 2015 that the adoption of IoT technologies in maintenance could reduce costs by up to 25%, cut unplanned outages by 50%, and extend the lifespan of machines by several years.

Illustration: WorkTrek / Data: McKinsey

As manufacturers navigate tight margins and high production demands, these efficiencies yield substantial benefits.

Benefits of IoT-Based Predictive Maintenance

The most immediate benefit of IoT-based predictive maintenance is the ability to detect failures before they occur.

By monitoring subtle anomalies, such as vibration patterns, heat fluctuations, or shifts in energy usage, manufacturers can identify and address mechanical issues early, thereby avoiding costly breakdowns.

This reduces unplanned downtime, keeping production running smoothly.

According to a Deloitte report, predictive maintenance can increase productivity by an average of 25%.

Illustration: WorkTrek / Data: Deloitte

However, the true value becomes clear when examining how manufacturers apply these technologies in practice.

One global manufacturer partnered with Techseria, a Microsoft Solution Partner for Data & AI, to implement predictive maintenance across its production facilities.

IoT sensors were installed throughout the plant, feeding real-time data into Azure IoT Hub.

This information was processed using custom machine learning models trained to detect behavioral anomalies in equipment.

The result?

Early warnings are delivered weeks in advance through Power BI dashboards tailored to maintenance priorities.

Naturally, the transformation was measurable.

Source: Techseria

As you can see above, maintenance costs have been reduced by 25%, equipment uptime has improved by 30%, and repair resolution has been accelerated by 40%.

Most importantly, the system prevented 65% of critical failures and delivered an 18% improvement in energy efficiency.

As the Director of Operations reflected:

“The financial impact has been significant—not just the 25% cost reduction, but the additional production capacity from improved uptime. Most importantly, our teams now have the data they need to make smart decisions rather than educated guesses."

Beyond cost savings, predictive maintenance helps eliminate unnecessary servicing.

Traditional methods often rely on fixed schedules or reactive repair, both of which can result in excessive downtime or wasted resources.

IoT-based PdM changes this by aligning interventions with actual equipment condition, reducing wear-and-tear from over-maintenance, and preventing high-impact failures.

According to the same report by Deloitte, this can reduce maintenance expenses by as much as 25%.

Illustration: WorkTrek / Data: Deloitte

The financial argument strengthens further when considering the cost of unplanned downtime.

In the automotive sector, for instance, one hour of lost production can result in over $2.3 million in losses.

The ability to avoid even a few such interruptions each year has a substantial effect on profitability.

The story of magnetic components manufacturer TCT underscores the broader operational value of IoT-based PdM.

Working with Integral System and Advantech, TCT deployed a comprehensive solution across compressors and motors.

Redwan Kara, IoT Manager at Integral System, describes the sensor technology at the heart of the system:

“The sensor measures raw data along three axes. Inside the sensor, there's a chip with a controller that applies a Fourier transform to this data in real time. As a result, the sensor provides eight processed indicators per axis. What we send to the software isn't the raw vibration data, but the processed data after the Fourier transform.”

An AI engine, pre-trained on ISO standard 10816, then analyzed this data, delivering both a machine health score and a predictive forecast for the next seven days.

The infrastructure included the WISE-2410 LoRaWAN® Smart Vibration Sensor and the WISE-6610 V2 Gateway, which ensured secure, long-range communication across the plant.

Source: Advantech on YouTube

Additional sensors measured current consumption, allowing the system to estimate power usage and operation time.

When the team discovered that the compressor operated at varying speeds, they worked with Advantech’s R&D group to refine the AI algorithm.

This collaboration improved the system’s adaptability to a range of rotating equipment, making predictive alerts even more reliable.

Today, TCT benefits from 24/7 remote monitoring of its compressors, pumps, and motors.

Through Advantech’s IoTSuite dashboards, the team can oversee performance from any location, track key metrics, and receive alerts for abnormalities up to seven days in advance.

Source: Advantech on YouTube

These real-world examples illustrate how IoT-based predictive maintenance delivers more than just technical improvements.

It provides maintenance teams with foresight, enables data-driven planning, and helps safeguard production against costly surprises.

For manufacturers under pressure to optimize costs and output simultaneously, this should be the norm.

Challenges of IoT-Enabled Predictive Maintenance

While IoT-powered predictive maintenance offers impressive benefits, manufacturers face several key challenges in adopting and implementing it.

Here are the four most common ones.

Limited Resources and Skill Gaps

Many maintenance departments already operate with lean teams and tight budgets, making it difficult to absorb new systems without disrupting daily operations.

According to the State of Industrial Maintenance 2025 by MaintainX, 45% of maintenance leaders cite staffing and budget constraints as primary obstacles to better maintenance.

Illustration: WorkTrek / Data: MaintainX

IoT-based PdM requires upfront investment in sensors, connectivity, and analytics tools.

Additionally, nearly one-third of manufacturers struggle to find personnel with the necessary skills to interpret IoT data and act on predictive insights.

To help bridge this gap, some organizations are turning to integrated CMMS platforms such as WorkTrek.

While not a full predictive analytics solution, a modern CMMS can provide a practical foundation for teams looking to move toward smarter maintenance without overextending their resources.

With WorkTrek, maintenance managers can:

Set up meter-based maintenance schedules using inputs like mileage, hours of operation, or oil condition.

Track equipment performance over time through automated maintenance logs and failure histories.

Generate preventive maintenance work orders automatically once a predefined threshold is reached.

The latter is shown below.

Source: WorkTrek

When IoT sensors are integrated with the CMMS, condition data such as temperature, vibration, or load is monitored in real-time.

This enables even more precise failure predictions and proactive maintenance scheduling, without the need for a full-scale PdM system from day one.

For teams with limited resources, this incremental approach provides an affordable and scalable path away from reactive maintenance.

Aging Infrastructure and Integration Complexity

About one-third of maintenance professionals identify aging equipment as a barrier to better maintenance.

Illustration: WorkTrek / Data: MaintainX

On the one hand, older machines are more prone to failure and often require more frequent maintenance.

On the other hand, they typically lack the built-in connectivity required for IoT-enabled monitoring, making them difficult to include in modern PdM programs.

Legacy machines—such as hydraulic presses, gear-driven pumps, or older CNC systems—often don’t have standard ports or digital interfaces for sensor integration.

As a result, manufacturers must rely on external retrofitting, like mounting vibration sensors or temperature probes.

These installations can be technically demanding, with challenges such as:

Lack of physical mounting space or accessibility

Interference with existing control systems

Potential downtime for installation and testing

Inconsistent sensor data due to improper positioning or environmental noise

For example, retrofitting an older motor with a vibration sensor may require custom brackets and wiring through tight enclosures, followed by calibration and testing to ensure accurate readings.

In some cases, these retrofits introduce more complexity than value if not planned carefully.

Integration with existing industrial control systems, like PLCs or SCADA, is another hurdle.

Legacy systems may utilize outdated protocols or lack the necessary input/output (I/O) points, necessitating middleware or custom development.

Without a coordinated rollout, these upgrades can interrupt production and overwhelm IT or maintenance teams.

Cybersecurity Risks

With every additional IoT device comes an expanded attack surface, and manufacturing organizations face frequent and growing threats to connected assets.

According to Check Point research, 54% of companies experience attempted cyberattacks on IoT devices every week.

In manufacturing specifically, the average is 49 targeted attacks per organization per week.

Illustration: WorkTrek / Data: Check Point

The financial stakes are high, too.

IBM’s 2024 report revealed that the average cost of a data breach in the manufacturing sector exceeds $5.5 million.

Illustration: WorkTrek / Data: IBM

This includes damage to production, loss of intellectual property, and regulatory consequences.

Robust cybersecurity is, therefore, non-negotiable.

Manufacturers must adopt strong encryption protocols, secure authentication mechanisms, and continuous monitoring to protect their systems.

However, building such defenses requires both investment and internal expertise, which are often in short supply.

Data Reliability

Predictive maintenance relies on clean, consistent sensor data and stable connectivity.

Yet, in harsh industrial environments, sensors are often exposed to heat, vibration, dust, and moisture, all of which can degrade performance.

Inconsistent signals can result in false alarms or, worse, missed failure warnings.

As Karim Elbaz, Head of Growth at OCP MS, explains, installing a sensor on a critical asset essentially transfers the asset’s criticality to the sensor itself.

Illustration: WorkTrek / Quote: LinkedIn

In other words, improper sensor placement, mishandling during maintenance, or undetected faults can undermine the system’s reliability.

To address this, OCP MS invested in both AI-driven sensor diagnostics and training programs for technicians, emphasizing that success depends as much on people and processes as on technology.

Similarly, Carlos E. Torres, CEO of predictive maintenance platform Power-MI, observes that sensor-related issues, such as signal noise, outliers, calibration failures, and connection errors, are common during system commissioning.

“In my experience, issues like noise, outliers, missing values and calibration error failures are typically addressed during the commissioning phase of sensors and systems.”

He adds that many teams are unaware that the monitoring system itself needs monitoring.

In some cases, maintenance staff unknowingly reposition or misconfigure sensors during routine work, compromising the entire predictive system.

These examples illustrate a broader challenge.

The reliability of IoT-enabled PdM is only as strong as the reliability of the underlying data infrastructure.

Ultimately, ensuring data integrity requires rigorous setup, ongoing oversight, and a culture of accountability.

Conclusion

IoT plays an indispensable role in predictive maintenance.

Without sensors, there is no real-time data. And without data, there is no predictive insight.

IoT devices enable continuous monitoring of asset conditions, early detection of anomalies, and prompt action before failures occur.

While implementation comes with challenges, the value is clear: fewer breakdowns, lower costs, and smarter maintenance decisions.

For manufacturers aiming to stay competitive, IoT-powered predictive maintenance is the next logical step.

Operations & Maintenance

7 Common Maintenance Management Mistakes to Avoid

Key Takeaways:

Organizations using predominantly reactive maintenance practices experience 3.3 times more downtime compared to those using proactive strategies

A common mistake is poor documentation that can lead to 21.3% productivity loss, costing businesses approximately $19,732 per information worker annually

Companies can save $4 to $6 for every $1 invested in effective workplace safety and training programs

As a maintenance manager, you face an uphill battle every day. Yet according to recent research, even well-managed engineering enterprises are suffering opportunity costs equivalent to 30-50% of turnover due to maintenance and operating mistakes.

Between managing tight budgets, preventing equipment failures, and keeping operations running smoothly, there's little room for error.

Yet many organizations continue making the same costly maintenance management mistakes that drain resources and compromise equipment reliability.

Understanding these pitfalls and learning will help you avoid them. Let's explore the seven most critical maintenance management mistakes that organizations should avoid at all costs.

Mistake #1: Relying Too Heavily on Reactive Maintenance

One of the biggest mistakes maintenance managers make is falling into the reactive maintenance trap. When your maintenance team is constantly fighting fires instead of preventing them, you're setting yourself up for failure.

According to comprehensive research by Elara Digital, organizations that relied predominantly on reactive maintenance experienced significantly more operational disruptions; 3.3 times more downtime, to be exact.

Illustration: WorkTrek / Data: Comparesoft

On the surface, reactive maintenance might seem cost-effective. But the reality is that this approach is actually three times more expensive than preventive maintenance strategies.

When equipment fails unexpectedly, you're not just dealing with repair costs. You're also facing unplanned downtime, emergency parts procurement, overtime labor, and potential safety hazards.

The Hidden Costs of Reactive Maintenance

Unplanned downtime is particularly devastating for plant and maintenance managers.

According to Siemens' 2024 True Cost of Downtime report, an hour of downtime at a large automotive plant can cost up to $2.3 million—that's more than $600 per second. For other industries, while costs may be lower, they're still substantial, with the average cost reaching around $25,000 per hour in 2024.

According to another study by Vanson Bourne, unplanned downtime costs businesses an average of $260,000 per hour.

Illustration: WorkTrek / Data: ServiceChannel

This can create a stressful environment for employees and management, as every task is always urgent. Aberdeen Research found that companies with unplanned downtime experience a 20% decrease in worker productivity.

When your maintenance staff is constantly in crisis mode, it affects team morale and makes it difficult to attract and retain skilled maintenance technicians. Your maintenance team becomes demoralized, knowing they're always one step behind potential issues.

Research shows that companies can save between 12% and 18% by using preventive maintenance over reactive, and each dollar spent on preventive maintenance saves an average of $5 later on.

According to 2024 data from Limble, 67% of manufacturing companies now consider preventive maintenance the top strategy for preventing downtime.

What to do instead:

Develop a regular preventive maintenance schedule.

Prioritize assets based on criticality and failure history.

Use condition monitoring tools to spot early warning signs.

Mistake #2: Poor Documentation and Record Keeping

Not keeping documentation up to date is another mistake undermines maintenance management. Based.

Based on our experience, many maintenance departments still rely on paper-based systems or have limited digital records. This approach makes it impossible to track maintenance history effectively.

Illustration: WorkTrek / Data: Linkedin (Whale)

The impact of poor documentation is more severe than many realize. According to research on document management, document challenges are usually responsible for over 21% of organizational productivity loss.

More specifically, IDC reports that document challenges account for 21.3% of productivity loss, which costs businesses approximately $19,732 per information worker per year.

The Impact of Insufficient Documentation

When maintenance activities aren't properly documented, you lose valuable data that could help prevent future failures.

According to Iron Mountain research, more than half of professionals spend their time looking for information, and it takes them around 18 minutes to locate a document—almost 5 hours every week!

Poor documentation can create several problems for maintenance managers.

Some examples include:

Inability to identify patterns in equipment failures

Track spare parts usage

Identify pattern to help you make informed decisions

Reduce time wasted looking for documents by the maintenance teams

For example, if a pump fails repeatedly but the work orders only say "pump broke, fixed it," you'll never identify the root cause or implement a permanent solution.

This lack of information makes it difficult to improve equipment reliability or optimize maintenance schedules.

Building Better Documentation Practices

There are things you can do to improve your documentation practices.

The best approach is to implement a CMMS platform like WorkTrek that can digitize all of your work orders and streamline your operations.

Source: WorkTrek

Absent that, start by including details about the problem, the steps taken to resolve it, parts used, and time spent. This information becomes invaluable for future reference and analysis.

Research shows that employees from businesses of all sizes claim to spend as much as 25% of their workweek hunting down documents and information they need to do their jobs.

When technicians can quickly access equipment manuals, maintenance history, and standard procedures, they can work more efficiently and avoid repeating past mistakes.

Studies indicate that 75% of employees agree that their work would be easier if they could access documents on their mobile devices.

What to do instead:

Train technicians to log every completed task, repair, and inspection.

Store documentation in a centralized, digital system.

Track maintenance history by asset, location, and technician.

Implement a CMMS platform like WorkTrek to streamline documentation

Mistake #3: Neglecting Proper Training and Development

Lack of training programs is one of the most overlooked mistakes in maintenance management.

Organizations invest heavily in equipment but fail to train the people who use and maintain it adequately.

This creates a dangerous gap between the complexity of modern equipment and the skills of maintenance staff.

The cost implications of inadequate training are substantial.

Illustration: WorkTrek / Data: Touchpoint

According to research on workplace safety and training, the total cost of work injuries in 2023 was $176.5 billion, including wage and productivity losses of $53.1 billion and medical expenses of $36.8 billion.

The Cost of Inadequate Training

Without proper training, maintenance technicians are more likely to make mistakes that can damage equipment or create safety hazards. They may use incorrect procedures, fail to identify warning signs, or apply temporary fixes instead of addressing root causes.

OSHA research demonstrates that failure to comply with safety requirements can result in maximum penalties of up to $15,625 per serious violation or $156,259 for willful or repeated violations.

Illustration: WorkTrek / Data: EHS Insight

The average cost for workers' compensation claims for accidents in 2020-2021 was $41,757.

Poor training leads to several costly consequences.

Reduced equipment reliability

Increase in repair times

Increased safety risks

Longer times to fix issues

The Return on Investment of Training

However, research consistently shows that training investments pay significant dividends.

Studies show that companies can save $4 to $6 for every $1 invested in an effective workplace safety program.

Illustration: WorkTrek / Data: National Safety Council

A manufacturing company that implemented a robust training program focusing on hazard recognition, proper equipment use, and emergency procedures reported a 40% reduction in workplace accidents within a year and a significant decrease in downtime.

Lack of training also affects employee retention.

Skilled maintenance technicians want opportunities to learn and grow. When organizations don't invest in development, they risk having higher staff turnover.

Developing Comprehensive Training Programs

When developing a training program, focus on programs that cover both technical skills and safety procedures.

When a new maintenance technician joins the team, they will need a thorough orientation on equipment operation. This includes maintenance procedures and safety protocols.

Experienced staff, on the other hand, need ongoing training to keep up with new technologies and best practices.

llustration: WorkTrek / Data: Workable

Consider partnering with equipment manufacturers to provide specialized training on complex systems.

Most have developed full training courses for equipment that they market and sell.

Don't treat training as a one-time event.

Provide regular refresher courses, cross-training opportunities, and access to technical resources to help maintain high skill levels throughout your maintenance department.

What to do instead:

Provide regular training on safety procedures, software, and equipment.

Involve your team in developing SOPs and best practices.

Encourage cross-training to reduce dependency on individuals.

Mistake #4: Inadequate Spare Parts Management

If you are running a maintenance organization, you already know the importance of spare parts management.

You don't want too few parts on hand, since it can lead to extended downtime. You also don't want to tie up capital by overstocking your spare parts inventory.

Research indicates that 58.9% of facilities report a decline in downtime and costs with better parts inventory management.

Common Spare Parts Management Problems

Having access to the current inventory is always a struggle for maintenance departments.

Maintenance teams need to know what parts are available, how to locate them, and the total count on hand.

Illustration: WorkTrek / Data: Quality Digest

Most organizations also want to avoid emergency orders since they can be costly.

According to industry data, factories throughout the U.S. are estimated to be using about $40 billion worth of outdated equipment, which makes spare parts planning even more challenging.

Improving Spare Parts Management

There are ways you that you can improve your spare parts management program.

One way is to work with maintenance technicians and equipment manufacturers to determine which parts should be stocked and in what quantities.

Implement systematic approaches to inventory management, including regular cycle counts, reorder points, and lead time tracking.

Source: WorkTrek

Consider the criticality and importance of each equipment when determining stock levels.

Critical systems may justify higher inventory levels to minimize downtime risk.

One approach that many successful maintenance managers are using is to implement a modern CMMS platform to improve parts management.

These systems can greatly simplify spare parts management by tracking inventory levels, automating reorder processes, and providing visibility into parts usage patterns.

This data helps optimize inventory levels and ensures parts are available when needed.

What to do instead:

Build a parts database by using a CMMS platform like WorkTrek

Track part usage to forecast future demand.

Set reorder points and automate alerts to restock essentials.

Mistake #5: Failing to Communicate Effectively

Poor communication can undermine maintenance effectiveness in your organization.

When information doesn't flow properly between maintenance staff, operations teams, and management, it creates confusion, delays, and missed opportunities for improvement.

According to research from the University of Western Australia, maintenance management is often ineffective despite advances in instrumentation, computer capabilities, and integrated asset management software.

One key factor identified was the breakdown in communication between people, processes, and assets.

The Impact of Communication Breakdowns

Without effective internal communication, maintenance activities become disorganized and inefficient.

Technicians might end up wasting time working on low-priority tasks while critical issues go unaddressed.

Poor communication can also result in operations teams scheduling production activities without considering maintenance requirements. This can lead to conflicts and disruptions.

Research indicates that maintenance professionals spend approximately 45% of their working hours managing physical work orders and documentation.

This inefficiency can be significantly reduced through better communication systems that centralize information and make it easily accessible.

Safety can also be affected by poor communication. If, for instance, LOTO procedures or other safety information are not easily available, hazards may unknowingly expose themselves to risks.

Illustration: WorkTrek / Data: Brady

Building Better Communication Systems

You can establish an effective communication program with clear protocols and standardized procedures.

Start by establishing regular meetings between maintenance, operations, and management to discuss priorities, schedules, and issues.

Use standardized forms and procedures to ensure important information is captured and shared consistently.

Technology can significantly improve communication in maintenance operations.

For example, by implementing a modern CMMS system like WorkTrek, you can centralize all maintenance information in a single, easily accessible platform.

Source: WorkTrek

This gives technicians the power to easily access all information about a repair, including documentation, in a centralized place.

Another strategy is to consider implementing shift handoff procedures that ensure important information is transferred between teams.

Document these processes and train all staff on proper communication protocols.

What to do instead:

Hold regular check-ins between maintenance, operations, and plant managers.

Use a CMMS platform that integrates seamlessly with operations and production systems.

Make work orders, maintenance status, and reports easily accessible to all stakeholders.

Mistake #6: Ignoring Data and Analytics

Given the long work hours and the number of tasks, maintenance managers sometimes make decisions based on intuition rather than data.

This approach can lead to missing opportunities to optimize their operations. The key to success is to use and analyze this data to make better decisions.

Illustration: WorkTrek / Data: PwC

According to comprehensive research on maintenance management effectiveness, personnel attitude is a critical factor, contributing 12.59% to maintenance execution procedures.

This is while standard operating procedures contribute 15.64%, together accounting for 28.36% of overall maintenance performance.

The Value of Data-Driven Decision Making

Data analysis can reveal insights that aren't obvious from day-to-day operations.

For example, analyzing failure patterns might show that certain equipment fails more frequently during specific weather conditions or operational scenarios.

This information can be used to adjust maintenance schedules or operating procedures to prevent problems.

Performance metrics can help identify trends and measure the effectiveness of maintenance strategies.

Some key performance matrices to consider include:

Key performance indicators (KPIs)

Mean Time Between Failures (MTBF)

Mean Time to Repair (MTTR)

Overall equipment effectiveness (OEE)

Research from Deloitte shows that predictive maintenance systems can reduce maintenance planning time by up to 50% and improve uptime by as much as 20%.

Implementing Data-Driven Maintenance

How do you create a data-driven maintenance organization?

The first step is to identify the most important metrics for your operation and ensure you're collecting accurate data. Focus on metrics that directly relate to your maintenance objectives, such as equipment reliability, cost control, and safety performance.

Utilize this data to make informed decisions about maintenance strategies, resource allocation, and equipment investments.