Blog

Operations & Maintenance

6 Myths About Manufacturing Equipment Maintenance

Want to avoid unnecessary breakdowns and maintenance expenses? These myth-busting tips will help you stay efficient.

Key Takeaways:

Unplanned downtime is the leading cause of lost productivity in plants.

BMW Group's plant avoids 500 minutes of production disruption annually due to PdM.

Teams using CMMS report fewer instances of unplanned downtime and increased team collaboration.

Understanding the distinction between fact and fiction in manufacturing maintenance can have a direct impact on your plant’s productivity, safety, and profitability.

So, to help you make informed, data-driven decisions, we’re debunking six common myths about maintaining manufacturing equipment.

Backed by recent data and expert insights, we’ll show you why these myths don’t hold up and what smart, high-performing teams are doing instead.

Maintenance Is Only Needed When Something Breaks

Unfortunately, some still cling to the old saying, “If it isn’t broken, don’t fix it.”

However, when it comes to manufacturing equipment, waiting for failure—known as reactive maintenance—can lead to costly disruptions, safety hazards, and avoidable damage.

It’s far from an ideal strategy.

A 2022 survey found that sudden equipment breakdowns causing unplanned downtime had the greatest negative impact on plant productivity.

Illustration: WorkTrek / Data: ATS

These unexpected failures are a result of the reactive mindset prevalent in manufacturing plants.

Therefore, to avoid asset reliability issues and maintain plant efficiency, manufacturers should adopt a more proactive strategy, such as preventive maintenance.

Instead of waiting for assets to break, preventive maintenance prioritizes regular inspections and smaller repairs to keep valuable machinery and tools operational and reliable.

Zach Williams, Engineering Manager at Kito Crosby Australia, an industrial equipment supplier specializing in custom hoists and lifting solutions, explains the benefits:

Illustration: WorkTrek / Quote: Manufacturers’ Monthly

Williams adds that proactive maintenance doesn’t just help prevent breakdowns and keep plants running efficiently.

It’s also nearly three times more cost-effective than reactive maintenance.

Perhaps that’s why 66% of manufacturing businesses are moving away from reactive maintenance and express a willingness to embrace a more proactive mindset.

Illustration: WorkTrek / Data: Limble

Slowly but surely, companies are realizing that fixing assets only when they break simply doesn’t cut it anymore.

It’s inefficient, expensive, and damaging to both equipment and overall productivity.

Preventive Maintenance Stops All Failures

Of course, preventive maintenance isn't a perfect solution that guarantees protection from all future breakdowns.

While it significantly reduces risk, it can’t eliminate every potential issue.

Unexpected failures may still occur due to wear and tear, human error, or various external factors.

Adding to the challenge, manufacturing equipment is becoming increasingly complex, as are its upkeep needs.

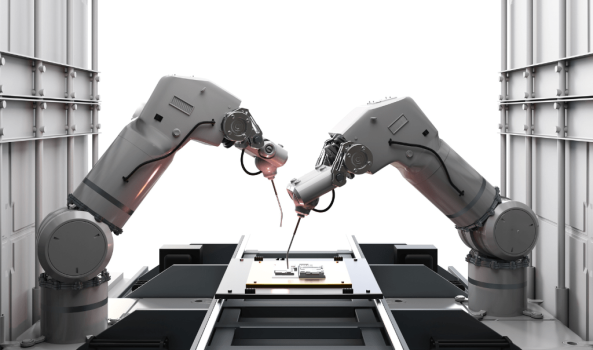

Nilam Ruparelia, an AI Segment Leader at semiconductor maker Microchip Technology, points to robotic systems as an example:

Illustration: WorkTrek / Quote: BizTech Magazine

In other words, advanced equipment requires an advanced maintenance strategy, such as predictive maintenance (PdM).

Rather than relying on rigid time-based schedules that can lead to overmaintaining or undermaintaining assets, PdM uses historical and real-time data to predict when failures are likely to occur.

This enables more precise and effective maintenance planning.

According to a 2023 Siemens survey, the benefits of PdM can be enormous.

Respondents reported improvements in downtime forecasting accuracy, a reduction in unplanned downtime, an increase in staff productivity, and a reduction in maintenance costs.

Illustration: WorkTrek / Data: Siemens

Unsurprisingly, many large manufacturers are adopting predictive maintenance because of these significant advantages.

Take BMW’s Regensburg plant, for example.

They utilize an AI-powered system to monitor conveyor systems during vehicle assembly, enabling them to detect potential faults proactively.

Project manager Oliver Mrasek explains:

Illustration: WorkTrek / Quote: BMW Group

As a result, the plant avoids an average of around 500 minutes of production disruption per year.

Achieving this level of precision would be challenging without relying on preventive maintenance alone.

That’s why we’ll likely see manufacturing maintenance focus more on prediction rather than prevention in the future.

New Equipment Doesn’t Need Maintenance

It’s a common misconception that new manufacturing equipment doesn’t require regular maintenance.

In reality, even the latest assets need proper care from day one to stay efficient, safe, and compliant with warranty requirements.

Jaime Miller, SQF Consultant at Kellerman Consulting, which specializes in food safety, quality & ISO, agrees:

Illustration: WorkTrek / Quote: Kellerman Consulting on YouTube

That’s right: to ensure long-term reliability, maintenance should begin before the asset even arrives on-site.

Some tasks to complete during this early stage include:

Creating an asset number and entering the equipment into the CMMS

Identifying all recommended maintenance tasks (inspections, measurements, adjustments, etc.)

Scheduling maintenance according to the manufacturer’s guidelines

Assessing necessary resources, such as training and tools

Assigning personnel or teams to handle required maintenance

Performing recommended maintenance during start-up to establish baseline data

Following the manufacturer’s recommendations is particularly important.

Miller advises speaking to the manufacturer directly when possible and documenting all their advice and suggestions:

“If it is a large enough piece of equipment, the manufacturer may send a representative to help with installation and training. If so, make sure to document preventive maintenance and sanitation recommendations during that visit.”

Remember, your equipment is a major investment.

Taking the right steps from day one helps ensure its longevity and reliability. So, don’t let the “it’s new, it’s fine” mindset shorten its lifespan.

Any Spare Part Will Do the Job

Using aftermarket parts instead of OEM ones might save you some money upfront, but it’s not always the wisest choice.

While the lower price may be tempting, it often comes with trade-offs in quality, compatibility, reliability, and performance.

In some cases, opting for aftermarket components can even void equipment warranties.

Jorge Abelho, Director of Technical Support at Pilot Crushtec International, a manufacturer of mobile and static crushing solutions, shares an OEM perspective on the matter:

Illustration: WorkTrek / Quote: Engineering News

In general, when you choose an OEM part, you’re not just purchasing a part. You’re also purchasing long-term support.

That means expert installation instructions, usage recommendations, technical advice, and peace of mind during the part’s entire lifecycle.

In some cases, OEMs are also directly involved in the maintenance process.

Fernando Mejia, Former Aftermarket Director at Automated Handling Solutions (AHS), shared how his team approached it:

Illustration: WorkTrek / Quote: Processing Magazine

Overall, when comparing OEM and aftermarket parts side by side, the advantages of OEM options become clear.

Therefore, next time you purchase replacement parts, especially for critical assets, consider not just the price tag but also the long-term value and reliability that OEM components offer.

Cutting corners now will cut into your productivity later.

The Manual Is Optional

Maintenance technicians, especially those with years of experience, can sometimes fall into the trap of thinking they can handle equipment upkeep without ever opening a manual.

However, that assumption can be a costly mistake.

Jaime Miller from Kellerman Consulting, whom we mentioned earlier, explains why:

“User manuals for the equipment typically specify upkeep activities for the equipment, and it is recommended to perform all manufacturer-specified maintenance items to maintain any warranties and comply with best practices.”

In other words, the manufacturer is best equipped to understand the equipment, and their guidelines are in place for a reason.

Take Haas Automation, a U.S.-based machine tool manufacturer, as an example.

Their lathe manuals include detailed upkeep schedules, outlining the upkeep frequency and specific tasks required for each component:

Source: Haas Automation

This type of information is crucial for effective preventive maintenance, enabling you to deliver the right care at the right time.

No need for guesswork or relying on your intuition.

But manuals offer more than just schedule recommendations.

For instance, ABB’s frequency converter manuals provide detailed lists of possible faults, their potential causes, and troubleshooting steps:

Source: ABB

They even include flowcharts with step-by-step repair instructions to ensure issues are fixed correctly, minimizing the risk of accidental damage:

Source: ABB

In short, equipment manuals are a goldmine of information: from safety procedures and troubleshooting guides to recommended spare parts.

Ignoring them puts your assets, workers, and operations at unnecessary risk.

Digital Maintenance Systems Are Just a Waste of Money

CMMS solutions and other digital maintenance systems have repeatedly proven their value; yet, some still view them as an unnecessary expense.

They are certainly missing out.

A recent survey found that teams using CMMS platforms report significant improvements, including better visibility into completed work, reduced unplanned downtime, and enhanced team communication.

Illustration: WorkTrek / Data: UpKeep

In manufacturing, where inefficiencies are costly, these benefits can have a major impact on your bottom line.

For instance, according to a 2024 Siemens survey, automotive plants incur approximately $695 million in annual losses due to unplanned downtime.

Illustration: WorkTrek / Data: Siemens

So, doesn’t it make sense to invest in a tool specifically designed to reduce that?

CMMS solutions streamline a significant portion of time-consuming, error-prone tasks and log vital maintenance data, providing you with greater transparency and control over your operations.

Take our CMMS platform, WorkTrek, for example.

It automates tasks like:

Preventive maintenance scheduling

Routine work order creation

Task management

Inventory tracking

Invoicing

As such, it significantly reduces errors, increases data accuracy, and ensures your maintenance program is data-driven and well-executed.

Technicians can easily access their upcoming tasks, step-by-step instructions, issue descriptions, and more, which allows them to walk into any job with confidence:

Source: WorkTrek

At the same time, supervisors can monitor their progress, planned/unplanned costs, inventory levels, and the overall effectiveness of the maintenance efforts to identify inefficiencies proactively:

Source: WorkTrek

In short, WorkTrek makes every part of maintenance easier, more accurate, and more efficient.

No more miscommunication, wasted time fixing errors, or chasing down missing information.

Instead, your team can focus on doing maintenance the right way, on time, and with the right resources.

And over time, that efficiency turns into real savings: fewer maintenance issues, longer asset life, and dramatically reduced downtime.

Conclusion

Now that you have all the facts, it’s time to apply what you’ve learned in the real world.

Leverage digital tools, adopt a proactive mindset, trust the guidance of OEM recommendations, and watch your maintenance program transform.

When maintenance is done right, your equipment pays you back with increased reliability, safer operations, and minimal unexpected downtime.

It’s the most efficient way to unlock your manufacturing plant’s full potential.

Announcements

WorkTrek Monthly Updates: July 2025

July has been an exciting month at WorkTrek, with powerful updates aimed at making your maintenance and fieldwork operations even smoother and more secure. Here’s what’s new:

1. Multi-Factor Authentication (MFA) – Flexible Configuration

Security remains a top priority, and we’ve enhanced MFA to give you more control:

Tenant-level settings: Administrators can now decide whether MFA via email is mandatory for all users or optional per user.

Cross-platform support: The new MFA settings work seamlessly on both the WorkTrek web and mobile applications.

Source: WorkTrek

2. Documents Module Now on Mobile

The Documents module, previously available only on the web, is now fully integrated into the WorkTrek mobile app.

Organize with folders: Easily manage and structure your documents into folders, just like on the web..

Mobile-first workflow: Access, view, and upload documents while on the go, enabling your team to stay productive from anywhere.

Source: WorkTrek

3. Request for Quote (RFQ) – Simplified and Enhanced

The RFQ module has been improved for a more streamlined experience:

Optional email notifications: You can now create and manage RFQs without sending email notifications to vendors.

Upload on behalf of vendors: Save time by uploading vendor quotes directly, allowing for a faster decision-making process.

Source: WorkTrek

Looking to take your maintenance to the next level?

These features are now available for all WorkTrek users. Sign in to check them out, or just reply if you’d like a quick demo from our team.

Operations & Maintenance

6 Building Maintenance Procedures That Benefit from Automation

Key Takeaways:

Automation improves accuracy and efficiency in building maintenance tasks.

HVAC monitoring benefits from remote control and predictive alerts.

Leak detection sensors reduce water damage and waste.

Drones enable faster and safer roof and façade inspections.

By 2025, 84% of businesses plan to expand their use of robotic automation.

Many building maintenance tasks are repetitive, time-sensitive, and resource-intensive.

However, automating them can significantly reduce manual workload, improve task accuracy, and ensure timely intervention.

From HVAC upkeep to floor cleaning, automation is transforming how facility teams operate.

It improves consistency, minimizes delays, and enables staff to focus on more complex responsibilities.

This article outlines six key building maintenance procedures that benefit most from automation.

It also highlights how modern tools, ranging from cloud-based software to robotics, are delivering measurable results in building maintenance.

HVAC Systems Monitoring

Heating, ventilation, and air conditioning (HVAC) systems are among the most critical and energy-demanding components of any building.

When they malfunction, issues such as uneven airflow, unexpected noise, or unstable temperatures can affect comfort and productivity almost immediately.

Traditionally, HVAC maintenance involves:

The staff adjusting controls manually

Visiting multiple locations to troubleshoot

Relying on multi-step inspections

Delays in part orders, unclear fault origins, and a lack of consumption data often prolong resolution times and drive up costs.

These challenges were familiar to the maintenance team at Rockpool Songbird Oxley, an aged care facility managed by Rockpool Residential Care.

To improve HVAC control and response times, they partnered with NRG Services to implement a smart automation system.

Using CoolAutomation’s smart gateways, NRG connected the facility’s entire HVAC network to a centralized, cloud-based Predictive Maintenance Suite.

The new system enables staff to remotely control HVAC units via desktop or mobile devices, and malfunctions now trigger automatic alerts, allowing for faster interventions.

The suite’s energy monitoring tools also provide insights down to the level of individual indoor units.

Facility managers receive routine reports on inefficiencies, which helps them identify wasteful usage patterns and set operational rules based on actual needs.

Below is a summary of the benefits Rockpool Songbird Oxley now experiences:

Source: Cool Automation

In other facilities, automation may begin with less complex tools.

Computerized Maintenance Management Systems (CMMS) are often the first choice.

These platforms automate routine maintenance scheduling, track service history, and centralize task assignment.

With a CMMS like WorkTrek, teams can automate time-based or meter-based maintenance, assign tasks to technicians, and maintain full maintenance records in one place.

Source: WorkTrek

On the other hand, residents or building users can also submit maintenance requests via a mobile app, a request portal, or a branded mobile platform, like in the example below.

Source: WorkTrek

This ensures issues like poor airflow or inconsistent heating are reported and resolved faster.

Tomislav Matković, Maintenance Manager at TRIUS, an organization focused on leasing and managing its own and rented properties, uses WorkTrek precisely for this:

“We use WorkTrek to help us maintain our building. Before the app, our staff would often be overwhelmed with calls and messages from our tenants, often leading to missed work.”

Now, maintenance requests are submitted through the app and immediately converted into structured work orders.

Managers can attach instructions, assign tasks, and set priorities.

Source: WorkTrek

Meanwhile, technicians access everything through their phones, clock in, follow directions, and close work orders upon completion.

By combining automated system monitoring with streamlined communication, maintenance teams can improve HVAC reliability, reduce downtime, and extend equipment lifespan, all while enhancing tenant satisfaction.

Plumbing and Water Leak Detection

Leaks and water damage can escalate quickly and often go unnoticed until significant damage has already occurred.

According to Moen, water damage in buildings is eight times more common than fire, underscoring the importance of early detection and rapid response.

Source: Moen

Automated leak detection systems address this by using smart sensors placed near high-risk areas such as pipes, water heaters, and mechanical rooms.

These sensors track changes in moisture or water flow and trigger instant alerts when anomalies are detected.

Some systems, like Phyn, take it a step further by using high-definition pressure sensors and AI-driven analysis to monitor water usage patterns and automatically shut off the main water valve in the event of a serious leak.

As Ryan Kim, CEO and Lead Engineer of Phyn, explains:

“What makes me proudest about Phyn Plus is its ability to go beyond just detection—it learns and automatically takes action when it matters most. In the event of a catastrophic leak, it can shut off the water in seconds, preventing costly damage before it starts.”

While primarily marketed to homeowners, the underlying technology—real-time detection, automated response, and remote control—is also increasingly relevant for larger residential and commercial properties.

For facility managers, these systems offer more than just damage prevention.

Real-time alerts sent via mobile apps enable faster response, while collected usage data helps teams detect inefficiencies, reduce waste, and plan maintenance proactively.

Even simple setups can make a meaningful difference.

One Reddit user described how placing leak sensors on the floor near air handlers in mechanical rooms helped their team prevent two major floods.

Source: Reddit

In another example, maintenance staff were notified via email when moisture was detected in a vacant unit, enabling a timely intervention before further damage occurred.

Source: Reddit

It’s clear that incorporating automated leak detection into plumbing maintenance procedures protects properties.

But beyond that, it supports sustainable maintenance by minimizing water waste and reducing the need for emergency repairs.

Fire Safety System Testing

Fire protection systems, including sprinklers, alarms, extinguishers, and emergency lighting, must be regularly inspected and maintained to remain effective.

However, many failures are caused by avoidable oversights.

According to the National Fire Protection Association (NFPA), 59% of sprinkler systems that failed during fires had simply been turned off.

Illustration: WorkTrek / Data: NFPA

Automation helps eliminate these risks by ensuring systems are continuously monitored, properly maintained, and operational.

Smart fire safety platforms, such as Honeywell’s Connected Life Safety Services (CLSS), integrate IoT sensors and smart control panels to track system health in real time.

These platforms can run self-diagnostics, detect low batteries or faults, and generate alerts when systems fall out of compliance.

They also maintain digital logs of inspections, which improves documentation and reduces the risk of human error during manual checks.

As one technician noted on Reddit, CLSS can also assist less experienced staff during inspections by enabling remote supervisors to verify their work in real time and provide immediate guidance:

Illustration: WorkTrek / Quote: Reddit

AI can also flag overdue maintenance, detect blocked exits, or recommend service based on usage patterns, thereby reducing manual error and improving safety.

By automating key aspects of fire safety maintenance, facility teams can ensure greater compliance, reduce the risk of oversight, and maintain higher levels of occupant safety.

Elevator and Escalator Checks

Elevators and escalators are mission-critical assets in most buildings, especially in high-rises, hospitals, and public facilities.

When maintenance is neglected, the consequences can be severe.

In one tragic example from 2011, a woman died in a New York elevator accident after the system abruptly moved with its doors still open.

Source: The Guardian

An investigation found that maintenance workers had bypassed the door safety circuit using a jumper wire and failed to follow basic safety protocols, including alerting the city to a reinspection before putting the elevator back into service.

The incident underscored how poor or rushed maintenance can lead to fatal outcomes.

Unfortunately, this case is not an isolated incident.

Across industries and geographies, elevator accidents often stem from skipped inspections, overdue part replacements, or overlooked system faults—all of which can be prevented with proper monitoring and maintenance.

Source: Google

Traditionally, elevator maintenance has been conducted according to fixed schedules based on calendar intervals, regardless of actual usage.

However, this approach can lead to both over-servicing and missed failure risks.

Today, automation is enabling a smarter, usage-based model.

IoT sensors installed in elevator systems now track metrics like door cycles, vibration levels, motor current, and braking patterns.

These data points are analyzed in real time by AI-powered platforms to detect unusual wear or performance degradation.

As a result, teams can identify components approaching failure and schedule maintenance proactively.

One example is N2 Infotech, which recently launched an AI-driven predictive maintenance system explicitly designed for elevators.

Boeun Nam, CTO of N2 Infotech, explains:

“In the past, there was no way to measure elevator usage quantitatively, so maintenance schedules mostly relied on engineer experience and intuition. With our system, we overcome these limitations using sensors and AI analysis to enable more systematic and precise maintenance.”

This shift from intuition to data-backed decision-making leads to fewer unnecessary service visits, lower maintenance costs, and, most importantly, enhanced passenger safety.

These predictive platforms can also integrate with CMMS software, automatically generating tasks based on actual usage data and eliminating the need for manual tracking or paper logs.

As a result, maintenance teams gain clearer visibility into asset health and can prioritize their work based on actual risk, rather than just routine.

Ultimately, automated elevator and escalator monitoring creates more efficient workflows, helps prevent downtime, and ensures that safety standards are consistently met.

Roof and Facade Inspections

Inspecting roofs, gutters, and building facades is a vital part of building maintenance.

These checks help identify early signs of wear—such as cracks, clogged drainage, water damage, or material degradation—before they escalate into costly repairs or structural issues.

Traditionally, however, these inspections are time-consuming, expensive, and often risky.

They typically require scaffolding, aerial lifts, or rope-access technicians, especially for high-rise or complex structures.

Depending on the building’s size and layout, a full inspection might take several days.

The cost of equipment is high, and the safety risk is even higher, as working at height remains one of the leading causes of injuries and fatalities across industries.

In construction, for example, 50% of work-related fatalities in 2023 and 2024 were caused by falls from height.

Illustration: WorkTrek / Data: HSE

Automated drone inspections are changing that.

Equipped with high-resolution cameras and thermal imaging, drones can capture detailed visuals of rooftops and facades quickly, safely, and without disrupting daily operations.

This reduces both the time and risk associated with traditional inspections, while delivering more comprehensive data.

For example, in Chesterfield County, Virginia, a drone was used to inspect the roof of a fire station.

It captured 268 images in a single session and identified seven significant defects that had gone unnoticed in prior inspections.

With this information, the maintenance team was able to intervene early, potentially extending the roof’s lifespan by up to 10 years.

In another case from Australia, a large commercial building’s facade was inspected via drone in just 1.5 days, a task that would have taken up to two weeks with rope-access teams.

Illustration: WorkTrek / Data: Avian

Obstacle avoidance sensors helped the drone maintain a consistent flight path, capturing each square meter in 3–4 images.

The result was not only higher image clarity, but also a faster and more efficient desktop review process.

Source: Avian

By automating roof and facade inspections, facilities teams gain quicker access to actionable insights, reduce downtime, and eliminate many of the risks associated with working at height.

The data also supports more accurate reporting, long-term planning, and capital budgeting, making drones an increasingly valuable asset in modern maintenance strategies.

Floor Cleaning and Disinfection

Cleaning may not be the most glamorous aspect of building maintenance, but it’s essential for safety, hygiene, and occupant satisfaction, particularly in large commercial, healthcare, or educational facilities.

Traditionally handled by janitorial staff, cleaning is a time-consuming and labor-intensive task, often scheduled after hours to avoid disrupting operations.

As staff shortages and cost pressures grow, automating this routine task has become a priority.

According to ABB’s 2025 survey, 84% of businesses plan to expand robotic automation, and floor cleaning is one of the clearest areas of opportunity.

Illustration: WorkTrek / Data: ABB

Autonomous cleaning robots such as the Avidbots Neo and SoftBank Robotics’ Whiz are already being used in offices, airports, hospitals, and schools.

They can map and navigate large spaces, avoid obstacles, disinfect high-touch surfaces, and record when and where cleaning took place, improving both efficiency and accountability.

For the Thief River Falls School District in Minnesota, automation became a necessity.

Ongoing labor shortages had reduced a once 30-person janitorial team to less than half its original size.

Naturally, that affected the quality of work, as Building and Grounds Supervisor Jason Hruby explains:

Illustration: WorkTrek / Quote: Avidbots

Administrators began to notice the decline, and extracurricular events turned into “all hands on deck” cleanups involving maintenance staff, teachers, and even students.

The tipping point was when only two staff members were available to clean 200,000 square feet overnight.

That’s when the district adopted the Avidbots Neo.

Source: Avidbots

With support from Avidbots technicians, the facilities team configured Neo to suit the school’s layout and needs, mapping cleaning paths, setting no-go zones, and adjusting water flow and brush pressure for different floor types.

During the evening shift, Neo now handles surface disinfection and cleaning around lockers, trash bins, water fountains, and railings.

By automating routine cleaning and disinfection, the district regained control over hygiene standards and freed up limited staff to focus on more specialized tasks.

For facilities teams facing similar pressures, robotic floor cleaners offer a scalable, consistent, and data-driven solution to one of maintenance’s most foundational challenges.

Conclusion

Maintenance automation is transforming the way buildings are managed, enabling easier problem prevention, enhanced safety, and increased productivity with fewer resources.

From leak sensors to cleaning robots, today’s tools help facility teams stay ahead of issues instead of constantly reacting to them.

As buildings get smarter, so should maintenance.

Now’s the time to invest in technologies that make everyday tasks faster, safer, and more reliable.

A CMMS solution is the ideal starting point.

Operations & Maintenance

Key Services for Commercial Property Maintenance

Commercial property owners face a constant challenge in maintaining their buildings to protect their investment and keep tenants satisfied. From HVAC systems breaking down unexpectedly to parking lots needing repairs, the demands never stop. The seven key services for commercial property maintenance include HVAC system care, electrical maintenance, plumbing services, structural repairs, exterior upkeep, cleaning services, and emergency response capabilities.

Commercial property maintenance services cover critical building systems, including electrical, plumbing, and HVAC components that require regular attention to prevent costly breakdowns. Property managers who understand these essential services can reduce emergency repair costs by up to 40% while extending the lifespan of their building systems.

Illustration: WorkTrek / Data: 99firms

So at this point, you might be asking, what exactly is the difference between reactive and proactive maintenance?

This guide examines each service area in detail, providing property owners with a comprehensive approach to developing a maintenance strategy that safeguards their investment while ensuring tenant satisfaction and regulatory compliance.

Key Takeaways

Regular maintenance of building systems prevents costly emergency repairs and extends the life of equipment.

Professional services, including cleaning, landscaping, and structural care, maintain property value and tenant satisfaction.

Proactive maintenance task planning reduces costs while ensuring safety compliance and operational efficiency.

Understanding Commercial Property Maintenance

Commercial property maintenance is the care and upkeep of building systems, structures, and grounds. It is performed to ensure safety, functionality, and visual appeal.

Source: WorkTrek

Property managers coordinate these activities with the commercial property maintenance teams to protect investments and maintain tenant satisfaction.

Core Components of Maintenance

Typically, professional property maintenance covers HVAC systems, electrical systems, plumbing, building exteriors, and parking lots. These components work together to create a safe and functional environment for tenants and visitors.

Source: WorkTrek

HVAC maintenance involves filter replacement, coil cleaning, and system monitoring.

Regular servicing prevents breakdowns during peak seasons and significantly reduces energy costs.

Electrical Systems

Includes panel inspections, wiring checks, and equipment updates. Licensed professionals identify potential fire hazards and ensure compliance with relevant codes.

Plumbing

Plumbing maintenance encompasses leak repairs, pipe winterization, and the upkeep of drainage systems. Preventive care prevents water damage and costly emergency repairs.

Exterior maintenance

Can include roofing inspections, parking lot repairs, and facade cleaning. These tasks preserve property value and create positive first impressions.

Illustration: WorkTrek / Data: zipdo

Safety systems

Regularly test fire detectors, security equipment, and emergency exits. Property managers must maintain first aid supplies and ensure that clear evacuation routes are available.

Role in Property Management

A commercial property maintenance strategy relies on regular maintenance to preserve asset value and ensure tenant retention. Regular preventative maintenance reduces emergency repair risks and enhances tenant satisfaction.

Property managers schedule routine inspections to identify issues before they escalate and become more severe.

This proactive approach minimizes downtime and maintains consistent rental income streams.

Tenant satisfaction improves when maintenance issues are addressed quickly. Happy tenants provide positive reviews and referrals, attracting new renters to the property.

Property values remain stable through consistent upkeep of building systems and appearance. Well-maintained properties command higher rental rates and resale values.

Regulatory compliance requires knowledge of local building codes and safety requirements. Professional maintenance providers ensure properties meet all legal standards and avoid costly violations.

Commercial property maintenance has a direct impact on operational efficiency and long-term profitability for property owners and managers.

Routine Maintenance and Upkeep

The backbone of facility management is regular maintenance.

The goal of routine maintenance tasks is to prevent costly repairs while maintaining the safety and functionality of buildings.

Scheduled Inspections

Using a preventive maintenance checklist and schedule can help you organize and catch problems early.

Source: WorkTrek

HVAC servicing and plumbing inspections should occur quarterly, while electrical systems need annual reviews.

Maintenance technicians check key systems during these visits:

HVAC maintenance: Filter replacement, coil cleaning, and control monitoring

Plumbing: Leak detection, pipe winterization, and drain maintenance

Electrical: Panel inspections, wiring checks, and connection repairs

Safety equipment: Fire detectors, extinguishers, and emergency exits

Regular inspections can identify minor issues.

Additionally, professional technicians use specialized equipment to test system performance. They document findings and create repair schedules based on priority levels.

General Repairs

Routine repairs address wear and tear before systems fail.

Common repair tasks include:

Interior systems: Fixing leaks, replacing worn components, and updating outdated equipment

Exterior work: Roof repairs, facade maintenance, and parking lot crack filling

Emergency responses: Burst pipes, gas leaks, and power outages

Preventative maintenance reduces the risk of expensive emergency repairs. Maintenance technicians can schedule these fixes during convenient times.

Quick response times minimize tenant disruption. Professional crews have the tools and expertise to complete repairs efficiently.

Daily Facility Tasks

You need daily maintenance to keep buildings clean and operational. These tasks support tenant satisfaction and property value.

Cleaning and sanitation

Includes shared area maintenance and pest control. Regular cleaning helps prevent health issues and maintains a professional appearance.

Groundskeeping

Involves lawn care, hedge trimming, pruning, and leaf removal. Well-maintained exteriors create positive first impressions for visitors and tenants.

Security and safety

Checks ensure door locks function properly and emergency equipment remains accessible. Daily monitoring prevents security gaps.

Cleaning, pest control, and groundskeeping should be scheduled biweekly or more frequently. This frequency maintains consistent building standards throughout the year.

Preventive Maintenance and Planning

If you want an efficient building, consider implementing a preventive maintenance plan.

Preventive maintenance can reduce the need for emergency repairs and extend the lifespan of their assets.

Developing a Maintenance Plan

Start by creating a comprehensive asset inventory. This process involves documenting all equipment, systems, and components that require regular attention.

Utilizing a Computerized Maintenance Management System (CMMS) like WorkTrek can automate this process.

Illustration: WorkTrek / Data: repairist

Key Asset Categories:

HVAC systems and components

Electrical panels and wiring

Plumbing fixtures and pipes

Fire safety equipment

Elevators and mechanical systems

Start with manufacturer guidelines to better understand requirements and schedules.

Following these specifications helps maintain warranties and prevents premature equipment failure.

A good commercial property maintenance checklist prioritizes assets based on their criticality to operations.

Maintenance Strategy and Scheduling

Effective maintenance scheduling requires determining specific tasks and frequencies for each asset. Property owners must balance manufacturer recommendations with operational demands.

Preventative maintenance schedules can help commercial properties remain in good condition and run smoothly. Having a structured plan determines what needs to be done and when.

Common Maintenance Frequencies:

Daily: Basic inspections and cleaning

Weekly: HVAC filter checks and system monitoring

Monthly: Deep cleaning and minor repairs

Quarterly: Comprehensive system testing

Annually: Major inspections and equipment overhauls

Maintenance team task assignment can be time-consuming. Using a CMMS system, you can automate a lot of that process.

Long-Term Cost Savings

All maintenance teams want to save money. What is the easiest way to do this?

Implement a preventive maintenance plan.

Regular maintenance extends the lifespan of equipment and reduces the need for emergency service calls.

Illustration: WorkTrek / Data: ResearchGate

Some studies show that property owners typically save 12-18% on maintenance costs through preventive programs.

These savings come from reduced emergency repairs, less overtime hours, extended equipment life, and improved energy efficiency.

Cost Reduction Benefits:

Lower emergency repair expenses

Reduced equipment replacement costs

Improved energy efficiency

Decreased business disruption

Extended warranty coverage

Lower labor costs

Your tenants also appreciate a well-maintained building. Well-maintained buildings attract quality tenants and command higher rental rates.

Emergency Repairs and Rapid Response

As a maintenance professional, you want to reduce instances of emergency repairs. While this is not always avoidable, there are strategies you can implement to improve the process.

Types of Emergency Services

Emergency repairs are when a critical system in your building fails.

24/7 emergency repairs can include HVAC, plumbing, and electrical systems that require immediate attention.

Below

Plumbing Emergencies

Burst pipes and major water leaks

Sewage backups and drainage failures

Water heater malfunctions

Flooding incidents

Electrical Failures

Power outages and circuit breaker issues

Exposed wiring and sparking outlets

Emergency lighting system failures

Fire alarm system malfunctions

Security systems

HVAC System Breakdowns

Complete heating or cooling system failures

Gas leaks and ventilation problems

Refrigeration unit breakdowns in commercial kitchens

Air quality emergencies

Structural Damages

Roof leaks during severe weather

Broken windows and security breaches

Foundation issues and water intrusion

Elevator and escalator failures

24/7 Response Protocols

Professional emergency response services monitor operations continuously to handle urgent situations promptly. Response protocols ensure quick resolution while maintaining safety standards.

Immediate Response Steps

Emergency assessment and safety evaluation

Temporary containment measures

Contractor dispatch and coordination

Progress monitoring and updates

Most emergency services are time-sensitive.

Depending on your internal response policies and Service Level Agreements (SLAs), critical safety issues receive responses within one to two hours.

Non-critical emergencies typically get addressed within 4-6 hours.

Communication Protocols

Develop clear communication channels for reporting emergencies. Give tenants visibility through a customer portal which is usually part of a CMMS system.

Vendor Coordination

Depending on the emergency, you might have to use an outside service provider.

Establish clear service level response times to ensure repairs are completed within agreed-upon timeframes while maintaining quality standards.

Risk Mitigation Strategies

As a maintenance manager, your goal is to reduce risks. Here are a few ways to do that:

Proactive Inspection Programs

Monthly system checks for critical equipment

Seasonal weatherproofing assessments

Regular safety equipment testing, including lighting maintenance

Documentation of potential problem areas

Emergency Preparedness Plans

Property managers should develop a comprehensive action plan for different emergency scenarios that is shared with the entire team.

These plans include contact information for emergency services, utility providers, and specialized contractors.

Technology Integration

Modern emergency management uses digital tools for faster response coordination. Centralized maintenance platforms streamline emergency processes and improve overall efficiency.

Staff Training

On-site personnel receive training to safely handle initial emergency responses. They learn to assess situations, implement temporary safety measures, and coordinate effectively with emergency services.

Illustration: WorkTrek / Data: Sockeye Technologies

Vendor Relationships

It is really important to build strong relationships with reliable contractors. You never know when you need them for specific tasks.

Exterior and Grounds Maintenance

The exterior and grounds are what your visitors first see. Regular maintenance can keep buildings safe, attractive, and valuable through landscaping care, parking lot maintenance, clean windows, and overall structural upkeep.

Landscaping Solutions

Well-maintained landscapes boost property value, can attract quality tenants, and improve curb appeal.

Professional grounds maintenance encompasses essential services that maintain the health and appeal of outdoor spaces.

Lawn Care

This forms the foundation of landscape maintenance - keeping the grass looking good. Keep a consistent schedule to keep up a professional appearance.

Seasonal plantings

Keep the property's look fresh and up to date all year. Spring flowers, summer annuals, and fall decorations create visual interest.

Tree and shrub care

Keep trees and shrubs pruned and remove any dead branches to reduce safety hazards. Implementing a regular trimming process also prevents overgrowth.

Irrigation systems

Regularly check the irrigation system to ensure plants receive adequate water without waste.

Structural Repairs and Renovations

Building exteriors require ongoing maintenance to prevent small problems from becoming expensive repairs.

Concrete and masonry

Repairs fix cracks, chips, and weathering damage. Water can cause a lot of damage, so make sure to stay on top of these issues.

Roofing maintenance

Regularly inspect major roof areas like gutters and shingles. Hire a professional annually to do a thorough inspection.

Exterior painting

Inspect, repaint, and repair areas as necessary. Depending on the weather conditions, you might need to repaint buildings every 5-7 years.

Pressure washing

Can removes built-up dirt, mold, and mildew from building surfaces. Schedule annual pressure washing for critical areas.

Conclusion

Commercial property maintenance necessitates a comprehensive approach that strikes a balance between proactive planning and responsive emergency services.

Illustration: WorkTrek / Data: Kentley Insights

The seven key service areas—HVAC systems, electrical maintenance, plumbing, structural repairs, exterior upkeep, cleaning, and emergency response—work together to protect your investment while ensuring tenant satisfaction.

Implementing a preventive maintenance strategy can deliver measurable returns through reduced emergency repair costs, extended equipment lifespan, and improved energy efficiency.

Studies consistently show that property owners can achieve 12-18% cost savings while reducing emergency repairs by up to 40%.

Operations & Maintenance

How To Measure Maintenance Costs

Key Takeaways:

Maintenance costs must include both direct and indirect expenses for accurate analysis.

Downtime, safety risks, and lost productivity represent major hidden costs.

A CMMS standardizes the recording of labor, parts, and service costs.

Comparing planned vs. actual costs improves budgeting and forecasting.

Maintenance costs are more than the numbers in the budget.

They are a direct reflection of how efficiently your facility runs and how effectively your assets are managed.

Yet, many maintenance teams still struggle to measure these costs in a consistent, actionable way.

What should be included as a maintenance expense? How do you track and categorize it? And how can you use that data to improve operational performance?

This guide is here to help you answer these questions and more.

From defining your cost categories to leveraging a CMMS and analyzing asset-level spending, you’ll learn how to measure maintenance costs in a way that strengthens budgeting, reporting, and long-term planning.

1. Define the Scope of Your Maintenance Costs

The first step in measuring maintenance costs is to define exactly what will be included.

Without clear boundaries, your analysis can quickly become inconsistent or misleading.

Begin by separating costs into two categories: direct and indirect.

Direct maintenance costs are linked to maintenance work.

They typically include:

Technician labor

Replacement parts

Contractor fees

Tools and consumables

These are relatively straightforward to track since they appear in work orders, invoices, time sheets, and purchase records.

As Eric Woltz, Garage Management System Liaison at Holman, notes, these costs may seem simple when viewed individually, but can be substantial when aggregated across all activities.

Illustration: WorkTrek / Quote: Fleet Owner

If some of your maintenance work is outsourced, be sure to include external vendor costs, service agreements, and support contracts in your direct cost calculations.

These services directly support your maintenance program and must be accounted for.

Indirect maintenance costs are less visible but equally important.

They include:

Lost production due to unplanned downtime

Health and safety incidents

Emergency part shipments

Reputational damage due to delays

These costs may not be immediately apparent in a maintenance report, but they impact overall business performance and increase your total cost of ownership.

And the scale of indirect costs is growing.

In 2024, 31% of companies reported increasing downtime costs, highlighting how much is at stake when equipment reliability is compromised.

Illustration: WorkTrek / Data: MaintainX

Including both direct and indirect costs in cost calculations gives you a more accurate view of your maintenance spending.

Without that, you risk underestimating the value of preventive maintenance or missing the true cost of system failures.

2. Capture Maintenance Data Consistently With a CMMS

The next critical step in measuring maintenance costs is to capture maintenance data in a consistent, structured format.

The most effective way to do this is by using a computerized maintenance management system (CMMS).

According to recent industry data, 72% of maintenance professionals use a CMMS primarily to organize maintenance activities and data in one place.

Illustration: WorkTrek / Data: UpKeep

But its value goes far beyond maintenance planning and scheduling.

It plays a central role in accurately measuring costs.

A modern CMMS records the key data needed to analyze maintenance expenses, including:

Technician labor hours

Parts and materials used

Contractor or vendor services

Additional task-related expenses

Each work order becomes a structured record of time, materials, and effort, enabling maintenance managers to see where resources are going.

Source: WorkTrek

However, a CMMS is only as reliable as the data entered into it.

That’s why it’s essential to build strong habits across your team.

Technicians must:

Open and close work orders systematically

Log time spent on tasks

Select parts used from the inventory

Attach receipts or notes for any non-standard costs

A CMMS like WorkTrek streamlines this process.

Technicians can clock in and out of tasks on their phones, upload photos, leave comments, and sign off on completed work, creating a full digital trail of each job:

Source: WorkTrek

You can also link parts and labor to each job, enabling the CMMS to automatically calculate the labor cost based on technician rates and the time spent.

Source: WorkTrek

Each inventory item is assigned a cost, making the financial impact of every work order visible in real-time.

The result is a centralized, reliable dataset that eliminates the guesswork.

In other words, there’s no need to dig through spreadsheets or manually cross-reference invoices.

Your cost data is clean, complete, and ready to use for planning, reporting, and financial control.

Once this data is in place, WorkTrek allows you to generate detailed reports that go beyond raw numbers.

You can filter expenses by project, asset, or site, and visualize spending trends across the organization:

Source: WorkTrek

With structured reports, it becomes much easier to identify cost drivers, monitor performance, and support data-driven maintenance decisions.

3. Calculate Total and Asset-Level Maintenance Costs

When you have cost information gathered and organized in your CMMS, calculating maintenance costs is relatively easy.

Start with the total maintenance cost.

That’s the sum of all direct and indirect expenses over a defined period, as seen in this simple formula:

“Total Maintenance Cost = Labor + Materials + External Services + Other Expenses”

Labor costs are calculated by multiplying technician work hours by their respective hourly rates.

Materials and parts are tracked through usage logs and inventory data.

External services include vendor invoices, service contracts, and specialist repairs.

Other expenses may include permits, rentals, or one-time vendor charges.

By calculating these totals on a monthly, quarterly, or annual basis, you can track how maintenance spending evolves and compare it across sites or departments.

Understanding total costs is undoubtedly important.

But asset-level cost data is what reveals how individual machines or systems contribute to your overall maintenance spending.

This allows you to answer key questions:

Which assets require the most maintenance resources?

Are certain machines repeatedly exceeding the budget?

Does the maintenance cost justify continued operation, or is replacement a more cost-effective option?

To answer these, use your CMMS to break down expenses by asset.

This illustrates the amount of labor, materials, and vendor support required by each machine over time.

Some platforms even allow you to set estimated costs at the work order level and then compare them to actual costs once work is complete:

Source: WorkTrek

These comparisons help identify recurring cost overruns, inefficiencies, and misaligned estimates.

They also support more accurate forecasting and long-term financial planning.

With complete cost data in place, you can calculate key performance indicators such as:

Maintenance cost per unit of production

Maintenance cost as a percentage of asset replacement value

These KPIs—especially when combined with reliability metrics like MTTR or MTBF—provide a more comprehensive view of asset performance and effectiveness of your maintenance strategy.

You should also quantify less obvious costs, like the cost of unplanned downtime, the number of emergency repairs, or the costs of expedited shipping.

These calculations reveal the full financial impact of delays and supply chain gaps—insights that are often missed in high-level budgeting.

4. Turn Cost Data Into Actionable Improvements

Collecting maintenance cost data is only valuable if it leads to better decisions.

With accurate cost reports, maintenance managers can identify trends and inefficiencies that are often obscured in day-to-day operations.

For example, if reactive tasks are consuming a growing share of the budget, it may indicate that preventive work has been missed or that scheduled maintenance has been delayed.

If one asset repeatedly requires more labor and parts than similar equipment, it may indicate poor condition, excessive wear, or even incorrect technician assignments.

By surfacing these patterns, cost data allows teams to take corrective action, such as:

Adjusting preventive maintenance schedules

Rebalancing workloads across teams

Improving spare parts availability

Renegotiating vendor rates

This level of financial visibility also supports broader planning.

Comparing actual spending to budgeted forecasts helps refine future budgets, set realistic performance targets, and justify investment in training, inventory, or new equipment.

These improvements are significant because maintenance is a major operational expense in most facilities.

A recent report found that 64.4% of plants allocate between 5% and 20% of their annual operating budget to maintenance, and nearly 1 in 5 facilities dedicate over 20% of their total budget to it.

Illustration: WorkTrek / Data: MaintainX

Even small improvements in cost control can translate into a significant financial impact.

For example, if frequent equipment failures lead to costly emergency part shipments, it may be more economical to stock critical spares.

If certain repairs consistently go over budget, it may be time to revisit supplier agreements or retrain staff.

On top of that, cost reports improve communication with leadership.

Instead of requesting additional resources based on assumptions, you can demonstrate precisely where funds are allocated, where overruns occur, and what return is anticipated from improvements.

WorkTrek simplifies this with dashboards and reports that break down costs by asset, location, project, or period.

Below is a report that highlights the top five projects by asset-level expenses:

Source: WorkTrek

This level of clarity strengthens internal discussions, performance reviews, and audit preparation.

Ultimately, the goal isn’t just to track maintenance costs, but to gain control over them too.

With reliable data and clear reports, your team can move from reactive budgeting to proactive cost management.

This leads to smarter scheduling, fewer breakdowns, and more efficient use of labor and materials, building a stronger foundation for long-term reliability and lower total cost of ownership.

Conclusion

Labor hours, spare parts, and lost production time all contribute to maintenance costs.

Measuring these costs accurately requires clear definitions, appropriate categories, and consistent tracking methods.

A CMMS provides the necessary tools to record detailed data, analyze spending by asset, and convert numbers into actionable insights.

Rather than viewing maintenance as a fixed monthly expense, it should be understood as a strategic investment in uptime, reliability, and the long-term performance of assets.

When maintenance costs are accurately measured and used to inform decisions, maintenance becomes a source of operational improvement and business value, rather than merely a line item on the budget.

Operations & Maintenance

7 Trends in Maintenance Automation Happening Right Now

Key Takeaways:

CMMS adoption increases every year.

84% of businesses plan to introduce or expand the usage of robots.

IoT allows companies to shift from time-based to condition-based maintenance.

Maintenance isn’t the first thing that comes to mind when most people think of cutting-edge technology.

It’s often seen as routine, behind-the-scenes, and firmly rooted in the physical world of tools, checklists, and elbow grease.

Nevertheless, maintenance is undergoing a quiet revolution, full of exciting new technologies and upkeep strategies.

In this article, we will explore seven trends that are redefining what maintenance looks like in the age of automation and why each of these advancements matters.

Smarter CMMS Solutions

Computerized Maintenance Management Systems (CMMS) have existed for decades, but their capabilities have advanced significantly.

Today’s CMMS platforms differ significantly from the early systems of the 1960s, which lacked screens and relied on punch cards processed by IBM mainframes.

Now, they automate nearly every aspect of maintenance, including:

Work order management

Inventory tracking

Preventive maintenance scheduling

Invoicing

Purchase order analytics

This shift helps explain why 62% of organizations reported using a CMMS in 2024, up from 49% the previous year.

Illustration: WorkTrek / Data: Institution of Mechanical Engineers

The increase is expected.

CMMS solutions have become essential due to the efficiency they bring to maintenance operations.

Consider our platform, WorkTrek.

It not only streamlines work order processes but also functions as a maintenance command center.

Every time a work request is submitted, a WO is completed, a spare part is used, or a task is scheduled, WorkTrek records the activity automatically in one centralized system accessible from any location.

It doesn’t matter if you’re on a laptop in the office or out in the field using a mobile phone.

The result is improved visibility across all operations.

With WorkTrek’s intuitive dashboard, you can monitor everything from outstanding tasks to unexpected expenses:

Source: WorkTrek

When deeper analysis is needed, our analytics feature offers over 50 pre-built reports and more than 20 KPIs, giving you the insights you need to plan and coordinate more effectively.

The benefits are measurable:

Source: WorkTrek

At InterEnergo, an international energy company based in Ljubljana, the team experienced the advantages of WorkTrek directly.

Matjaž Valenčič, Operations and Maintenance Manager, explains:

Source: WorkTrek

At the end of the day, the future of maintenance is undeniably data-driven.

That’s why CMMS solutions aren’t just a trend but mission-critical tools for maintenance teams of all sizes and industries.

Their capabilities will continue to expand.

Digital Twins for Real-Time Insights

A digital twin is a virtual replica of a physical asset or system.

It uses real-time data from sensors and operational systems to simulate, monitor, and analyze asset behavior.

This provides a comprehensive view of an asset’s condition, enabling the early detection of anomalies or potential issues.

According to a 2023 report by ABB, the value of digital twin technology is already widely acknowledged.

When asked which trends would influence their future maintenance strategies, 47% of respondents chose digital twins.

Illustration: WorkTrek / Data: ABB

One organization that has adopted this technology is ConocoPhillips Canada, the Canadian division of the global exploration and production company.

The company implemented digital twin systems at two key facilities: Surmont’s Central Processing Facility 2, and Montney’s C-11-K central processing plant.

The impact was significant.

According to Rune Tufta, their Operations Support and Optimization Manager, the technology is driving improvements in safety, cost, efficiency, and production performance:

Illustration: WorkTrek / Quote: ConocoPhillips

One of the strengths of digital twin technology lies in its versatility.

As the team at ConocoPhillips Canada notes, the range of potential applications continues to expand. New use cases are still being discovered.

Their technicians now use the system to locate misplaced equipment, leave maintenance notes (as shown below), plan scaffolding, and estimate heights and distances for crane operations.

Source: ConocoPhillips

In practice, digital twins place a detailed virtual model of the facility at the user’s fingertips.

This level of visibility enables faster decision-making, supports proactive maintenance, and improves resource management across all levels of operation.

Remote Monitoring with IoT

The Internet of Things (IoT), particularly IoT sensors, complements digital twin technology by enabling continuous, real-time monitoring of equipment.

When installed on assets, these sensors track key performance indicators and equipment health without requiring manual checks.

Below are some practical examples of how sensors support condition monitoring:

Vibration AnalysisDetect abnormal vibrations in rotating machinery, indicating issues like misalignment, imbalance, or worn-out components.Temperature MonitoringTrack temperature fluctuations that may signal overheating or impending mechanical failures in motors, pumps, and similar equipment.Pressure/Flow MonitoringIdentify leaks, blockages, or wear by monitoring pressure and flow rates in systems involving pumps, compressors, or hydraulics.

Access to these insights without manual inspection supports quicker responses and helps shift maintenance strategies from reactive to proactive.

Andrew Kunzmann, Chief of Technology at Tracsis US, a leading provider of technology solutions to the world’s railroad industry, agrees:

Illustration: WorkTrek / Quote: Railway-News

This technology enables early detection of wear, damage, or system failures, forming the basis for condition-based maintenance (CBM).

Unlike traditional time-based maintenance, where service is performed at regular intervals regardless of an asset’s condition, CBM allows intervention only when it is needed.

This targeted and data-driven approach reduces downtime, increases asset longevity, and improves cost-efficiency across operations.

Predictive Maintenance Powered by AI

Combining IoT sensors with artificial intelligence creates a maintenance approach more advanced than condition-based maintenance: predictive maintenance (PdM).

PdM applies machine learning and AI algorithms to predict when equipment is likely to fail, allowing maintenance to be performed just in time.

According to Siemens' 2023 report, predictive maintenance is rapidly becoming mainstream among global manufacturers.

Interest in PdM has increased by 275% over the past seven years.

Illustration: WorkTrek / Data: Siemens

This growth reflects the clear benefits of PdM.

A 2022 study by Deloitte highlights measurable results.

Companies that utilize predictive maintenance report a 5–15% reduction in facility downtime, a 5–20% increase in labor productivity, and a 3–5% decrease in new equipment costs.

Illustration: WorkTrek / Data: Deloitte

These improvements represent a significant competitive advantage.

Sachsenmilch, one of Europe’s largest dairy producers, experienced these benefits firsthand.

The company recently implemented AI-driven predictive maintenance to monitor its complex production infrastructure.

The result has been higher equipment availability, reduced maintenance effort, and considerable cost savings.

Roland Ziepel, Head of Engineering and Project Execution at Sachsenmilch's Leppersdorf site, shares a concrete example:

Illustration: WorkTrek / Quote: Siemens

By identifying the end of a pump’s service life in advance, the company saved a low six-figure sum, according to Ziepel.

Looking at all the data and real-world results, it’s easy to see why predictive maintenance is gaining significant momentum.

It removes the guesswork of fixed maintenance schedules, replacing them with intelligent, condition-based insights that help prevent failures before they occur.

No other maintenance strategy can match this level of efficiency.

Augmented Reality for Real-Time Guidance

Augmented Reality (AR) overlays digital information onto the physical environment using smartphones, tablets, or AR glasses.

To illustrate this, consider the popular 2016 game Pokémon Go.

However, AR is not limited to gaming. It also has practical applications in maintenance.

As shown in the video below, AR enables technicians to view asset schematics during work and receive real-time support from remote experts.

https://www.youtube.com/watch?v=kjhnB-UmOaY&t=29s

Source: AVL on YouTube

This significantly speeds up repairs and reduces the risk of errors.

For example, five U.S. Navy ships recently adopted AR technology for this purpose.

Sailors now wear a simplified AR headset that allows remote experts to see and hear from their point of view.

While wearing the headset, sailors can also access technical manual excerpts, maintenance requirement cards, 3D images, design models, or schematics—all while receiving live guidance from SMEs.

NSWC PHD Commanding Officer Capt. Anthony Holmes praised the innovation:

Illustration: WorkTrek / Quote: US Navy

Remote assistance of this kind enables sailors to resolve issues more quickly and independently, saving time and resources.

There’s no more need for SME travel. Technicians can connect with anyone, anywhere in the world, almost instantly.

AR—and its closely related counterpart, virtual reality—are unlocking new frontiers in maintenance that were once unimaginable.

They make maintenance faster, smarter, and safer.

It will be interesting to observe how this technology develops further.

Virtual Reality for More Efficient Training

Unlike AR, which overlays digital elements onto the real world, virtual reality (VR) creates a fully immersive digital environment that completely engages the human senses.

In the field of maintenance, this opens up many opportunities, especially in training.

In these interactive virtual environments, technicians can practice various procedures without needing physical equipment, minimizing the risks of safety incidents and asset damage.

The video below demonstrates a VR training program for conducting a pre-flight inspection.

https://www.youtube.com/watch?v=D-3Vapzl5yw

Source: The DiSTI Corporation on YouTube

This technology can be applied across many other scenarios, especially those involving high safety risks.

For FL Technics, a Lithuanian company specializing in aircraft maintenance, repair, and overhaul, the safety gains are the most valuable benefits of VR.

Ramunas Paškevičius, IT Project Manager at FL Technics, says they use VR to prepare mechanics for potentially dangerous tasks:

Illustration: WorkTrek / Quote: Flight Safety Australia

At best, incidents cause financial loss. At worst, they can seriously injure the mechanic or others nearby.

That’s why proper training is essential.

According to Paškevičius:

“Virtual reality can show mechanics that event—and even allow them to feel it.”

That is the real power of VR in maintenance.

It provides a safe and cost-effective environment where technicians can make mistakes, learn, and improve without incurring risk.

This ultimately prepares them to walk into real-life tasks with confidence and all the necessary knowledge.

Increased Use of Cobots

Collaborative robots, also known as cobots, are designed to work safely alongside humans, assisting with repetitive, hazardous, or precision-driven tasks.

This technology improves maintenance efficiency, reduces physical strain on workers, and increases overall safety.

ABB’s 2025 survey shows that robots are no longer just science fiction.

84% of businesses plan to introduce or expand the use of robotic automation across their operations in the coming decade.

Illustration: WorkTrek / Data: ABB

Maintenance is no exception.

Although cobots have traditionally been used in production, their use in maintenance is growing quickly.

For example, Lam Research’s Dextro™ is the first collaborative robot built specifically for maintaining semiconductor manufacturing equipment:

https://www.youtube.com/watch?v=XkmLamh5ZX8

Source: Lam Research on YouTube

Dextro is mobile and works alongside engineers and technicians in fabrication facilities, taking on tasks that are time-consuming, prone to error, or dangerous.

Russell Dover, General Manager, Service Product Line at Lam Research, explains Dextro’s potential impact:

“A single application could take up to 30 minutes, including docking and undocking time. Done manually, it can typically take two to four times longer.”

He adds that a single Dextro unit can service up to 100 Lam Flex chambers at a maintenance frequency of once per month.

Cobots like Dextro are just the beginning.

With their precision, efficiency, and ability to improve safety and uptime, collaborative robots will likely become even more prevalent within maintenance operations across all industries.

Conclusion

Now that you know what technologies are available, you can explore each trend further.

You don’t have to rush to implement everything immediately, but knowing what’s happening and what’s possible will give you an advantage.

Undoubtedly, these tools will become increasingly integrated into maintenance practices.

However, only maintenance experts who are prepared will be able to use them effectively.

Operations & Maintenance

8 Types of Corrective Maintenance Explained

No matter how well equipment is maintained, breakdowns are inevitable. Corrective maintenance addresses these failures directly, enabling teams to restore operations quickly and minimize disruptions.

Understanding the eight types of corrective maintenance can improve response times, reduce costs, and keep systems running smoothly.

Key Takeaways

There are different types of corrective maintenance for different situations.

Knowing each type helps improve repair decisions and resource use.

Choosing the right approach can lead to better equipment performance.

Understanding Corrective Maintenance

Corrective maintenance refers to any action taken after equipment exhibits signs of failure or ceases to function properly.

Illustration: WorkTrek / Data: Camcode

Unlike preventive maintenance, which is performed on a schedule, the corrective maintenance process is inherently reactive.

But they’re not always unplanned. Some are scheduled once an issue is identified, but it isn’t urgent.

Role in Maintenance Strategies

Corrective maintenance stands out as a distinct type of maintenance. Some people refer to it as "breakdown" or "reactive" maintenance.

Maintenance teams often mix corrective work with preventive and predictive tasks. That way, they save money and limit disruptions.

Planned corrective maintenance refers to teams addressing non-urgent issues identified during inspections.

Unplanned corrective maintenance kicks in when something breaks unexpectedly and requires emergency repairs.

Using both allows teams to react quickly while still keeping things organized.

On its own, corrective maintenance isn't always the most cost-effective option or the best maintenance strategy, but it helps round out a comprehensive maintenance plan.

Comparison With Preventive And Predictive Maintenance

Corrective maintenance isn't the same as preventive maintenance or predictive maintenance.

Preventive maintenance involves performing tasks at regular intervals to prevent problems before they occur. Predictive maintenance utilizes IoT sensors and data to identify issues before they become significant.

Illustration: WorkTrek / Data: IndustryWeek

What is the main benefit of corrective maintenance? You only act when something breaks, so you skip a lot of extra work.

However, waiting for things to fail can result in larger repair bills and more downtime compared to the other two options.

Preventive maintenance reduces the risk of breakdowns by addressing issues early, although it may require additional labor and parts.

Predictive maintenance tries to fix stuff only when the data says it’s needed, but you do have to invest in tech.

Combining these methods enables companies to achieve improved reliability and more effective maintenance management.

1. Planned Corrective Maintenance

Planned corrective maintenance involves fixing equipment or assets according to a schedule, rather than waiting for a total breakdown.

Teams follow clear steps and use the right tools to complete repairs at the optimal time and in the most effective manner.

Process and Procedures

Planned corrective maintenance begins when teams identify signs of trouble before a complete failure occurs.

They use inspections, sensors, or reports to catch problems early and then plan repairs for a time that causes the least hassle.

Standard operating procedures (SOPs) keep the work safe and effective. Teams document every step, from the first sign of trouble to the final repair check.

Illustration: WorkTrek / Data: Touchpoint

Maintenance management software, like a computerized maintenance management system (CMMS), helps track work orders and schedules.

The software organizes tasks, assigns work, and stores repair history for later.

Good documentation, which can be electronically managed within a CMMS platform, also helps new team members learn the ropes and prevents mistakes.

Benefits and Limitations

Planned corrective maintenance reduces the likelihood of unexpected breakdowns and machine failure.

Repairs are scheduled during slow periods, so operations are not disrupted.

SOPs and a CMMS make the whole thing smoother and save time.

Teams can identify which assets fail most frequently and adjust their plans accordingly.

However, this method still responds to problems after they occur, not before.

If teams miss early warning signs, breakdowns can still sneak up. Compared to preventive maintenance, planned corrective maintenance may allow some issues to grow before they are detected.

2. Unplanned Corrective Maintenance

Unplanned corrective maintenance is all about responding to unexpected equipment failures or breakdowns.

This type of maintenance is crucial for keeping systems running smoothly and minimizing downtime.

Illustration: WorkTrek / Data: EZO CMMS

Typical Scenarios

Unplanned corrective maintenance, also known as unscheduled maintenance, occurs when equipment fails unexpectedly. Teams need to move fast to fix the issue and get things back online.