Blog

Operations & Maintenance

Maintenance Audit: Everything You Need to Know

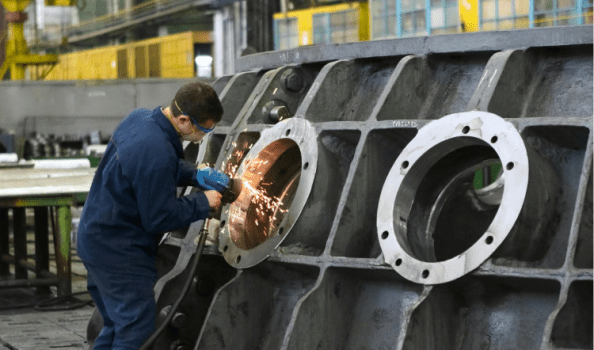

Keeping your company’s financial health demands strict controls, detailed records, and regular audits. The same goes for your physical assets. You likely know the frustration of unexpected equipment breakdowns, plant shutdowns, and rising maintenance costs. A thorough maintenance audit is the solution to prevent these issues. With a comprehensive audit, you’ll gain a clear picture […]

Keeping your company's financial health demands strict controls, detailed records, and regular audits.

The same goes for your physical assets.

You likely know the frustration of unexpected equipment breakdowns, plant shutdowns, and rising maintenance costs.

A thorough maintenance audit is the solution to prevent these issues.

With a comprehensive audit, you'll gain a clear picture of your assets' health, how well you plan and schedule maintenance, whether your technicians follow maintenance procedures, and much more.

Curious to learn more?

Keep reading to discover everything you need to know about maintenance audits and how the right tools can make them easier.

Maintenance Audit Basics

A maintenance audit is a thorough examination of your maintenance practices and procedures.

Think of it as a health check for your equipment and maintenance operations.

It identifies what’s working well and what needs improvement.

The primary purpose of a maintenance audit is to ensure you're doing the right things that make your equipment run efficiently and reliably, minimizing downtime and repair costs.

As per the latest statistics, unplanned downtime costs manufacturers more than $120,000 per hour.

Illustration: WorkTrek / Data: ABB

That’s a significant hit to the budget—and productivity.

A maintenance audit helps prevent these costly disruptions by identifying potential issues before they become real problems.

It ensures your maintenance teams follow best practices, keep detailed records, and adhere to safety standards.

This saves you money, prolongs your equipment’s lifespan, and improves overall efficiency.

Beyond cost savings and efficiency, maintenance audits also ensure regulatory compliance.

In different industries, various regulatory bodies conduct audits to make sure companies follow quality, health, and safety regulations.

Maintenance audits are an important part of these larger checks.

If you fail to comply with them, you face legal issues, damage to your company’s reputation, and hefty fines.

For instance, penalties from the US Occupational Safety and Health Administration (OSHA) currently range from $16,000 to over $160,000 per violation.

Source: OSHA

A maintenance audit helps you stay ahead of the industry requirements, ensuring you meet all necessary standards and avoid potential penalties.

How often these audits occur depends on who conducts them.

If the quality team within your organization does it, they have the authority to schedule them based on internal needs and goals.

And if we’re talking about external audits by regulatory bodies, their frequency may increase in response to past issues or compliance failures.

Extreme circumstances, like workplace injuries or product failures, might trigger immediate audits as part of an investigation.

The table below sums up maintenance audit basics:

Source: WorkTrek

All in all, getting a grasp of these basics is the first step towards conducting maintenance audits correctly.

Let’s now explore different types of maintenance audits.

Different Types of Maintenance Audits

Since maintenance audits come in several flavors, each serving a distinct purpose, let’s take a closer look at the main types of maintenance audits and how they can impact your operations.

Mandatory

These audits are non-negotiable and are conducted by government agencies to ensure you’re complying with industry regulations.

They are essential for maintaining operational standards and avoiding legal trouble.

For example, OSHA might show up for a safety audit.

Part of their examination could include how your maintenance team handles equipment repairs.

They could also check if there is a departmental safety program, including courses on topics like forklift safety, lockout/tagout, electrical hazards, and compressed gasses.

Similarly, the US Food and Drug Administration (FDA) audits the pharmaceutical industry to ensure adherence to Current Good Manufacturing Practices (CGMP).

Marie Getsug, an experienced maintenance and reliability subject matter expert, explains what exactly the FDA checks during these audits:

Well-documented asset logs of failures—with appropriate strategies implemented to prevent the failure in the future, a robust record of technician training—adding confidence that the implemented changes were executed appropriately, and lists of equipment specification, detailing the safety and efficacy of using such equipment, are areas of focus within this regulated industry that are fundamental to a successful maintenance program.

Overall, these mandatory audits often encompass a broad review of your company’s policies and procedures, including maintenance practices, as seen in the example below.

Source: AOL

To stay ahead of these audits, you should keep your maintenance records detailed and up-to-date.

This will prepare you for any inspection and avoid potential fines or compliance issues.

You can do this most easily with a good computerized maintenance management system, which we will discuss later on.

Voluntary

Voluntary audits usually happen when a company wants to evaluate the efficiency and compliance of its facilities and equipment.

They are your chance to showcase excellence and earn certifications for committing to high industry standards.

While these certifications (and, therefore, audits) aren’t required by law, they can boost your company’s credibility and competitiveness.

For instance, if you aim for ISO 55001 certification, which standardizes effective asset management practices, or LEED certification for sustainable building practices, you’ll undergo a series of self-audits to prove you meet these high standards.

Take a quick look at what obtaining an ISO 55001 certification looks like at the Bureau Veritas certification company.

Source: Bureau Veritas

The certification process usually starts with a pre-audit or gap analysis to assess your current practices against the standards.

This is followed by a two-stage certification audit:

Stage 1 assesses your readiness,

Stage 2 evaluates the effectiveness of your implementation.

Once you receive certification, you’ll undergo regular surveillance audits to ensure ongoing compliance.

Yes, these certifications can enhance your reputation.

However, maintaining them requires a consistent commitment to best practices.

So, regularly reviewing and refining your maintenance processes to stay compliant and keep the certification is all the more important.

And for that, you need the third type of maintenance audit: an internal one.

Internal

Internal audits are, essentially, your facility’s self-checkup.

They should be conducted by your team to ensure that maintenance processes align with your company’s standards and policies.

These audits help you identify and address issues before they escalate.

Paul Michalicka, former sales manager for maintenance products at SKF USA, advises conducting internal audits as soon as you notice any of the following signs:

Rising energy consumption

Frequent equipment failures

Rapid growth in your maintenance staff

Breakdowns in your work order system

A series of maintenance-related failures

An increase in overtime (10%+ of total maintenance hours)

Any of these issues can be a sign that you either don’t plan maintenance or your maintenance planning is not as it should be.

This can cost you a lot of money in the long run, as Gabriel Fagade, a maintenance advisor at ExxonMobil, rightly points out:

Illustration: WorkTrek / Quote: Linkedin

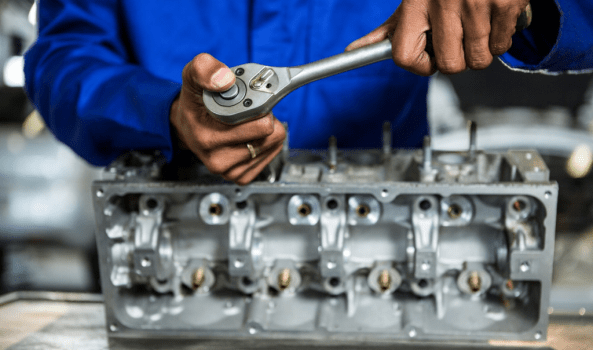

Conversely, internal audits can show whether your technicians follow procedures or have all the necessary tools.

Regular internal audits will pinpoint inefficiencies and help ensure that your maintenance planning, scheduling, and execution are as effective as possible.

This will ultimately prevent costly equipment breakdowns and downtime.

So, take it from the experts and make internal audits a regular part of your maintenance strategy.

What Does a Maintenance Audit Examine

Depending on your industry, the specifics of what’s examined can vary.

However, the core elements typically include safety practices, maintenance planning and scheduling, and adherence to documented procedures.

Here’s a quick overview of what maintenance audits commonly examine:

Policies and Procedures

Are technicians adhering to your maintenance policies and procedures?

Planning and Scheduling

Are your maintenance activities well planned and scheduled to avoid downtime?

Work Order Management

Is your work order system efficient? Do work orders include all necessary information?

Preventive Maintenance Programs

Review preventive maintenance schedules. Are maintenance intervals based on equipment specifications?

Shutdown Maintenance

Review procedures for planned shutdowns and overhauls.

Condition Monitoring

Check the use of predictive maintenance technologies.

Training and Skills

Is training provided to maintenance staff good? Are their skill levels adequate?

Safety Practices

Are safety protocols followed? Is equipment maintained to prevent accidents?

Documentation

Are maintenance records accurate? Do they match the equipment’s condition?

But these are not the only elements that audits examine.

Audits also check how you communicate with your maintenance team, how you budget and allocate resources for maintenance, and if you have emergency response plans for maintenance-related incidents.

To gather all this information, auditors observe maintenance processes, interview maintenance staff, and review all your documents or, ideally, go through your CMMS.

What’s The Role of CMMS In Maintenance Audits

A CMMS provides auditors with easy access to historical records for all maintenance activities.

This allows them to quickly verify maintenance tasks, check compliance with regulations, and review historical data without sifting through different spreadsheets.

For example, a key aspect of maintenance auditing involves reviewing past work orders.

It is a procedure done in almost every maintenance audit, and below is an example from the City of Denton’s facilities maintenance audit:

Source: The City of Denton

But if your work orders are scattered across several spreadsheets or printed out and put into various folders, the process becomes chaotic and inefficient.

Don’t you agree?

This Reddit user certainly does.

They describe struggling with siloed maintenance programs across multiple spreadsheets, making it hard and time-consuming to monitor and cross-reference tasks manually:

Source: Reddit

A CMMS, such as our WorkTrek, solves this problem by centralizing all asset and maintenance data in one place.

It features a robust work order management system that lets you assign tasks to technicians with step-by-step instructions.

Maintenance checklists are saved and linked to work orders, making it easy to see who completed each checklist and when.

Source: Reddit

Moreover, technicians can update task status and add details such as time spent and parts used. This creates a history showing what work was completed, by whom, and when.

WorkTrek also allows users to directly link OSHA rules and maintenance manuals to equipment records, ensuring that maintenance activities follow the required standards.

You can even specify which personal protective equipment (PPE) technicians should use, adding an extra layer of safety and compliance.

Source: WorkTrek

Also, WorkTrek replaces paper documentation with electronic signatures to track sign-offs, ensuring clear accountability for each task.

Source: WorkTrek

You can even enforce approval requirements before closing work orders.

Also, generating maintenance activity reports is quick and easy, so you’ll be well-prepared when auditors come knocking.

In summary, a robust CMMS like our WorkTrek simplifies maintenance audits by consolidating all your data and providing a clear, organized record of maintenance activities.

It’s a more efficient solution than managing various spreadsheets or keeping paper records, making your audit process much smoother.

Conclusion

Hopefully, we’ve clarified that maintenance audits are essential for keeping your plant or facility running smoothly and efficiently.

They help you identify areas for improvement, ensure compliance, and avoid costly downtime.

So, make sure your internal audits are regular and thorough—you have control over that.

For mandatory and external audits from regulatory bodies, you don’t need to worry if you follow the rules and use a reliable CMMS.

With all your data centralized, this tool will make your audits a breeze.

Operations & Maintenance

Preventive vs Breakdown Maintenance

Maintenance is crucial for keeping equipment and facilities running smoothly. Two main types of maintenance strategies are preventive and breakdown maintenance. These approaches differ in their timing and goals.

Preventive and predictive maintenance aims to prevent breakdowns before they happen, while breakdown maintenance addresses issues after they occur. Preventive maintenance involves regular checks and upkeep to keep things working well. It helps avoid sudden problems and keeps operations efficient.

Breakdown maintenance, on the other hand, is a reactive approach. It kicks in when something stops working. This method can lead to more downtime and higher costs. Both strategies have their place in a maintenance plan, depending on a business or facility’s needs.

[ez-toc]

Source: WorkTrek

Understanding Maintenance

Maintenance is vital for keeping equipment running smoothly and efficiently. It involves different approaches to caring for machinery and assets in a business.

https://youtu.be/21aY8-ifoo8

Definition of Maintenance

Maintenance refers to the actions taken to keep equipment and facilities in good working order. It includes fixing, replacing, and caring for machinery to prevent breakdowns. The goal is to extend equipment life and ensure it runs at peak performance.

Proper maintenance helps avoid costly repairs and unexpected downtime. It also improves workplace safety. Regular upkeep can spot potential issues before they become big problems.

Types of Maintenance

There are several types of maintenance strategies businesses can use:

Preventive or Preventative maintenance: Regular, planned care to prevent breakdowns

Breakdown maintenance: Fixing equipment after it fails

Corrective maintenance: Addressing issues as they arise

Predictive maintenance: Using data to predict when maintenance is needed

Planned maintenance: Scheduled upkeep based on time or usage

Run to failure maintenance: Allowing equipment to operate until it breaks down

Each type has its own benefits and best uses. The right mix depends on the business and its equipment needs.

Importance of Maintenance for Business Operation

Good maintenance practices are key to smooth business operations. They help:

Reduced unexpected downtime for critical equipment

Lower repair costs

Extend equipment life

Improve product quality

Boost productivity

Reduced emergency maintenance

Reduced Safety Risks

Reduced equipment failure

Reduce Maintenance Costs

Proper maintenance can lead to big savings over time. It cuts the risk of major breakdowns that can halt production. Well-maintained equipment also uses less energy, which saves money.

Maintenance is crucial for safety. It helps prevent accidents caused by faulty machinery, protects workers, and avoids legal issues.

What Is Preventive Maintenance?

https://youtu.be/TsDsE9fePLk

Preventive maintenance is a proactive approach to equipment upkeep. It aims to prevent breakdowns before they occur through planned inspections and repairs.

Core Principles of Preventive Maintenance

Preventive maintenance focuses on regular upkeep to avoid unexpected failures by employing preventive maintenance strategies. It involves scheduled inspections and maintenance activities to keep equipment running smoothly.

Key principles include:

Routine checks and cleaning

Timely replacement of worn parts

Regular lubrication of moving components

Adjustments to maintain optimal performance

A well-designed maintenance schedule is crucial. It ensures all equipment receives proper care at the right intervals.

Benefits of Preventive Maintenance Strategy

Implementing preventive maintenance offers several advantages:

Reduced downtime: Regular care helps avoid unexpected breakdowns.

Extended equipment life: Proper maintenance keeps machines running longer.

Improved safety: Well-maintained equipment is less likely to malfunction dangerously.

Cost savings: Preventing major repairs is often cheaper than fixing breakdowns.

Preventive maintenance can maintain efficiency and save time in the long run. It allows businesses to plan for maintenance costs rather than face surprise expenses.

Illustration: WorkTrek / Data: Plant Engineering

Challenges in Implementing Preventive Maintenance

Despite its benefits, preventive maintenance can face hurdles:

Initial investment: Setting up a program may require upfront costs.

Time commitment: Regular maintenance takes time away from production.

Overcoming resistance: Staff may resist changes to established routines.

Balancing maintenance needs with operational demands can be tricky. It requires careful planning and communication across teams.

Preventive Maintenance Techniques

Effective preventive maintenance strategy uses various techniques:

Visual inspections: Regular checks to spot early signs of wear or damage.

Vibration analysis: Detecting unusual vibrations that may indicate problems.

Oil analysis: Testing lubricants to assess equipment condition.

Thermography: Using infrared imaging to identify hot spots or thermal issues.

Preventive maintenance software can help manage these tasks. It tracks maintenance schedules, stores equipment data, and generates work orders.

Proper training ensures maintenance staff can effectively perform these techniques. This helps create a robust preventive maintenance system that keeps equipment running smoothly.

Illustration: WorkTrek / Data: FinancesOnline

What Is Breakdown Maintenance?

Breakdown maintenance strategy is a reactive approach to equipment upkeep. It involves fixing or replacing assets only after they fail or stop working properly. This strategy is used for certain types of equipment and situations.

Nature of Breakdown Maintenance

Unplanned breakdown maintenance is reactive and unplanned. It happens when equipment suddenly stops working, and teams rush to fix the problem quickly.

This type of maintenance often leads to unexpected downtime. It can disrupt normal operations and cause delays. Breakdown maintenance is also called emergency maintenance.

The main goal is to get equipment running again fast. This might mean quick fixes or total replacements.

When Breakdown Maintenance Is Applicable

Breakdown maintenance is best for non-critical equipment, which doesn't affect key operations if it fails. It's also suitable for short-life assets that are cheap to replace and generally not part of a scheduled maintenance strategy. This approach can reduce unnecessary maintenance.

Examples include:

Light bulbs

Fuses

Some office equipment

It's often cheaper to replace these items when they break than to check them regularly.

Ideal Scenarios for Breakdown Maintenance

Breakdown maintenance can work well when:

Failures won't cause safety issues

Downtime won't hurt production much

Repair costs are low

Downsides of Breakdown Maintenance

Relying too heavily on breakdown maintenance can cause problems. It often leads to more unplanned downtime, which hurts productivity and increases costs.

Other downsides include:

Higher repair costs due to sudden failures

Longer repair times

Shorter equipment life

Health and safety risks from unexpected breakdowns

Stress on maintenance teams

Unexpected failures can also damage other parts of a system. This can make repairs more complex and expensive.

Illustration: WorkTrek / Data: Unlocking Performance

Breakdown Maintenance Scenarios

Common breakdown scenarios include:

Flat tires on vehicles

Burnt-out light bulbs

Broken office printers

Failed computer hard drives

A non-critical machine might stop working in a factory. If this doesn't affect the main production line, breakdown maintenance could be used.

A retail store might use breakdown maintenance for its air conditioning. They'd fix it only when it stops working, not before.

Some examples of breakdown maintenance for home appliances like toasters or microwaves. They replace these items when they stop working.

Comparing Maintenance Strategies

Maintenance strategies are crucial in keeping equipment running smoothly. The right approach can save money and boost productivity. Let's compare preventive and breakdown maintenance.

Source: WorkTrek

Key Differences Between Preventive and Breakdown Maintenance

Preventive maintenance is planned and regular. It aims to stop problems before they start. Breakdown maintenance happens after equipment fails.

Schedules differ greatly. Preventive work follows a set plan. Breakdown fixes occur as needed.

Downtime varies too. Preventive tasks cause short, planned stops. Breakdowns lead to longer, unexpected halts.

The costs show a stark contrast. Preventive work spreads expenses over time, while breakdown repairs often cost more due to emergency repairs.

Equipment lifespan is affected. Regular care extends machine life. Waiting for failures can shorten it.

Source: WorkTrek

Evaluating Maintenance Approaches

Productivity impacts differ. Preventive maintenance keeps machines running well. Breakdowns disrupt workflow.

Quality of output varies. Well-maintained equipment produces better results. Failing machines may create defects.

Health and safety is a key factor. Regular checks catch hazards early. Breakdowns can pose sudden risks.

Costs over time show different patterns. Preventive care has steady, predictable expenses, while breakdown fixes have unpredictable, often higher costs.

Preventive: Planned, lower long-term costs

Breakdown: Reactive, higher emergency expenses

Choosing the Right Maintenance Strategy

The best strategy depends on several factors:

Equipment type and age

Production demands

Budget constraints

Available staff

Manufacturer Recommendations

Manufacturer recommendations guide preventive schedules. Critical machines need more care.

A mix of strategies often works best. Some items get regular checks. Others run until they fail.

Maintenance teams need proper training for each approach. They must know how to plan and respond.

The correct program balances costs and benefits. It keeps equipment running without excessive downtime or expense.

Advanced Maintenance Practices

Modern maintenance goes beyond simple prevention or repair. New methods use data and technology to predict issues and optimize maintenance tasks.

Predictive Maintenance and Its Advantages

Predictive maintenance uses data to forecast when equipment might fail. It relies on sensors and Internet of Things (IoT) devices to monitor machine health in real-time. This approach can spot problems before they cause breakdowns.

The main benefit is less downtime. Repairs happen only when needed, not on a fixed schedule. This cuts costs and extends equipment life.

Analytics play a big role in predictive maintenance. The software analyzes data from machines to find patterns. These patterns help predict future issues.

Illustration: WorkTrek / Data: McKinsey & Company

Implementing Computerized Maintenance Management Software

New tech tools make maintenance more efficient. Computerized Maintenance Management Systems (CMMS) help plan and track all maintenance tasks. They store equipment info, schedule work, and track parts.

Cloud-based systems let teams access data from anywhere. This improves communication and speeds up decision-making.

Benefits of CMMS

There are several benefits to implementing a CMMS solution. CMMS solutions offer several benefits:

Automate Work Orders

Get Real-time status updates

Spare parts management

Key Performance Indicators (KPIs)

Compliance & Control

Health and Safety Guidelines

Detailed Reporting

Maintenance Planning and Implementation

Planning and implementing maintenance strategies are key to keeping equipment running smoothly. Both preventive and breakdown maintenance require careful preparation and execution.

Developing a Maintenance Plan

A good maintenance plan starts with setting clear goals. These goals should focus on reducing downtime and costs while improving equipment life.

Next, create a maintenance schedule. This schedule lists when to check and fix equipment, helping prevent unexpected breakdowns.

The plan should also include a system for work orders. Work orders track tasks and who does them, ensuring nothing is missed.

Lastly, assign team roles. Each person should know their job in the maintenance process. Clear roles help avoid confusion and improve efficiency.

Implementing Maintenance Strategies

Train maintenance teams to put the plan into action. They need to know how to perform both preventive and breakdown maintenance.

Use tools to track maintenance tasks. The software can help schedule work and keep records, making it easier to see what's been done and what needs to be done.

Regular checks are important. They help catch minor issues before they become big problems. This is a key part of preventive maintenance.

Set up a system for quick responses to breakdowns. This might include having spare parts on hand or on-call technicians.

Keep good records of all maintenance work. These records help spot patterns, improve future planning, and minimize downtime.

Legal, Safety, and Economic Considerations

Maintenance strategies have big impacts on workplace safety and company finances. Rules and costs shape choices between preventive and breakdown approaches.

Compliance and Safety Standards

Preventive maintenance helps companies meet safety rules and regulatory compliance. It finds issues before they cause harm, and regular checks keep equipment safe for the maintenance team.

Safety groups often require preventive care, which reduces accident risks and lowers legal troubles from broken rules.

Breakdown fixes can be risky. Rush jobs may skip safety steps, and workers might use unsafe tools to get things running fast.

Some laws demand proof of upkeep. Preventive logs show a company takes care of its gear. This can help if there's an accident or inspection.

Source: secure frame

Cost Implications and Savings

Preventive care costs money upfront, but it saves cash over time. It prevents big, costly breakdowns and makes machines last longer, too.

Breakdown fixes cost more than prevention. Emergency parts and overtime pay add up fast, and stopped work loses income.

A mix of both types works best for many firms. They often do basic checks but let some less crucial items run until they break.

Smart maintenance planning stretches the maintenance budget, putting money where it helps most and boosting profits in the long run.

Replacing old gear on time saves money. New machines work better and use less power. The trick is knowing when to upgrade.

Operations & Maintenance

Run-To-Failure vs Breakdown Maintenance: What’s the Difference?

Maintenance strategies play a key role in keeping equipment running smoothly. Two common approaches are run-to-failure and breakdown maintenance. While they may seem similar, these methods have important differences.

This article will also compare run-to-failure and breakdown maintenance with other maintenance strategies, such as corrective maintenance.

Run-to-failure maintenance lets equipment operate until it stops working, while breakdown maintenance responds to unexpected failures as they happen. Run-to-failure is planned for non-critical assets that are cheap to replace.

Breakdown maintenance applies to both critical and non-critical equipment.

Understanding these strategies helps companies choose the best way to maintain their equipment. The right approach can save money and prevent unplanned downtime. Picking between run-to-failure and breakdown maintenance depends on each piece of equipment’s specific needs.

[ez-toc]

Understanding Maintenance Strategies

https://youtu.be/X3qkPJjfNwE

Maintenance strategies are key to keeping any piece of equipment running smoothly. Different approaches suit various situations and assets. Let's explore two common strategies and compare their uses.

Defining Run-to-Failure Maintenance

Run-to-failure maintenance is a strategy in which machines operate until there is an equipment break. This approach works best for non-critical assets with low repair costs.

For example, a non-critical stapling machine can be used in a cardboard box production factory under the run-to-failure approach. This method allows for continuous use without regular maintenance, addressing issues only after the machine fails, which is cost-effective and time-saving.

Companies use this method when:

Replacement parts are cheap and easy to get

Downtime won’t cause major issues

Regular checks cost more than letting it fail

Run-to-failure needs minimal planning. Managers wait for equipment to stop working before fixing it.

This strategy can save money on some items. But it’s risky for necessary machinery. Unexpected breakdowns may lead to longer downtimes and higher costs.

Defining Breakdown Maintenance

Breakdown maintenance is a reactive approach. It kicks in when equipment suddenly fails and needs urgent repair, with maintenance performed to address the unexpected malfunction.

Key points about breakdown maintenance:

It’s often unplanned and disruptive

Technicians respond quickly to fix issues

It applies to both critical and non-critical assets

This method is also called emergency or reactive maintenance. It aims to get broken equipment back up and running fast.

Breakdown maintenance can be costly. It may lead to:

Longer downtimes

Higher repair expenses

Lost production time

Unplanned failures

Yet, it remains common in many industries for certain types of equipment.

Source: WorkTrek

Comparing Maintenance Approaches

Run-to-failure and breakdown maintenance are both forms of corrective maintenance. They differ in key ways from preventive and predictive strategies.

Both run-to-failure and breakdown maintenance involve dealing with faulty equipment, but run-to-failure is a planned approach, while breakdown maintenance is reactive.

Differences between the two:

Run-to-failure is planned; breakdown maintenance is not

Run-to-failure suits low-priority items; breakdown applies to all equipment

Both strategies contrast with proactive methods like:

Preventive maintenance: Regular, scheduled upkeep

Predictive maintenance: Using data to forecast failures

Choosing the right approach depends on:

Equipment criticality

Failure consequences

Repair costs

Available resourcesSource: WorkTrek

Smart maintenance management often combines multiple strategies. This helps balance costs with equipment reliability and performance.

The Role of Maintenance in Operations

https://youtu.be/aiNDt3TLk4k

Maintenance choices shape how businesses run. They affect costs, productivity, and equipment life. In some scenarios, allowing equipment to break down is considered acceptable, mainly when safety risks are minimal. Smart maintenance helps companies succeed.

Operational Impact of Maintenance Choices

Run-to-failure maintenance can work for some equipment. It's used when replacing parts is cheaper than fixing them, and it saves money on routine checks.

But it has risks. Sudden breakdowns can halt work. This hurts productivity and profits.

Breakdown maintenance fixes things only when they stop working. It can lead to more downtime, and repairs may take longer and cost more.

Planned maintenance prevents many problems. It keeps machines running smoothly. This boosts efficiency and cuts long-term costs.

Businesses must balance these options. The right mix depends on equipment type and importance.

Downtime and Its Effects on Productivity

Equipment failure causes unplanned downtime. This stops work and wastes time. Workers sit idle while machines are fixed.

Even short delays add up. They can mean missed deadlines and unhappy customers.

Breakdown maintenance often leads to more downtime. Repairs take time to start, and parts may not be on hand.

Planned maintenance reduces surprises. It finds problems early. This means shorter, scheduled breaks instead of long, unexpected ones.

Less downtime means more output. Workers can focus on their jobs instead of waiting for repairs, boosting overall productivity and helping meet business goals.

Cost Considerations in Maintenance

Maintenance costs play a big role in asset management. Companies need to weigh repair expenses against equipment value. Smart planning can help reduce costs over time. It is also crucial to compare breakdown maintenance to other maintenance strategies, considering factors such as equipment criticality and cost implications.

Analyzing Maintenance Costs

Run-to-failure maintenance can seem cheaper at first, as it requires no ongoing upkeep. But sudden breakdowns may cost more in the long run.

Breakdown maintenance often leads to higher repair bills. Emergency fixes are pricey. They can also cause costly downtime.

To cut costs, companies should track repair history. This helps spot problem areas. It also shows which fixes work best.

A cost-benefit analysis compares different approaches. It looks at:

Parts costs

Labor fees

Downtime expenses

Equipment lifespan

This data helps pick the best maintenance plan for each asset.

Budgeting for Asset Maintenance

Good maintenance planning is key to controlling costs. It helps avoid surprise expenses.

Managers should set aside funds for regular upkeep. This includes money for:

Routine inspections

Minor repairs

Parts replacement

For critical equipment, extra budget may be needed. This covers potential breakdowns.

Companies can use past data to predict future costs. This helps create more accurate budgets.

Some firms use special software to track expenses. It can spot trends and suggest ways to save money.

Smart budgeting also includes staff training. Well-trained workers can spot issues early, preventing big problems later.

Safety and Risk Management

Safety is a key factor when choosing between run-to-failure and breakdown maintenance. Both strategies have different impacts on workplace safety and risk management.

Run-to-failure maintenance can pose higher safety risks. Equipment may fail unexpectedly, potentially causing accidents or injuries. This approach requires strong safety protocols to protect workers.

Breakdown maintenance also carries risks. Emergency repairs can be rushed, increasing the chance of mistakes. Workers may need to intervene in dangerous situations to fix critical equipment.

Source: ABB

What is the difference?

Risk management differs between the two approaches:

• Run-to-failure: Focuses on containing risks of sudden failures

• Breakdown maintenance: Emphasizes quick, safe responses to breakdowns

Both strategies need clear safety procedures. This includes:

Personal protective equipment requirements

Emergency shutdown protocols

Proper training for maintenance staff

Safety Audits

Regular safety audits help identify and address potential hazards. This is crucial for both maintenance approaches to minimize risks to workers and equipment.

Ultimately, the choice between run-to-failure and breakdown maintenance must prioritize safety. Companies must assess the risks associated with each strategy for their specific equipment and workplace.

Maintenance Execution and Tracking

Proper execution and tracking are key to successful maintenance programs. They help organizations manage repairs and keep equipment running smoothly.

Work Order Management and Execution

Work orders are essential for managing maintenance tasks. They outline what needs to be done, who should do it, and when. A good work order system helps prioritize tasks and allocate resources efficiently.

Many companies use CMMS software to manage work orders. This software makes creating, assigning, and tracking maintenance jobs easy and helps schedule preventive maintenance tasks.

CMMS tools often include mobile apps. These let technicians access work orders in the field. They can update job status and log completion in real time

Source: Keystone Industries

Importance of Maintenance Documentation

Good documentation is crucial for effective maintenance. It creates a record of all work done on equipment. This helps spot trends and plan future maintenance.

Maintenance reports should include details like:

Date and time of work

Equipment serviced

Problems found

Actions taken

Parts used

Time spent on the job

Well-kept records help with troubleshooting. They show what's been tried before when similar issues occur. This can speed up repairs and reduce downtime.

Documentation also aids in compliance. It provides proof of regular maintenance for safety inspections or audits.

Technological Integration in Maintenance

Modern maintenance strategies use advanced technologies to improve efficiency and reduce costs. These digital tools help predict failures, manage assets, and optimize operations.

Implementing CMMS Solutions

Computerized Maintenance Management Systems (CMMS) are key to effective asset management. CMMS software tracks equipment history, schedules maintenance, and manages inventory.

CMMS solutions offer several benefits:

Automated work order generation

Real-time asset status updates

Improved inventory control

Enhanced reporting capabilities

Key Performance Indicators (KPIs)

Compliance & Control

Health and Safety Guidelines

CMMS helps organizations make informed decisions about their equipment by centralizing maintenance data. It allows teams to shift from reactive to proactive maintenance strategies.

CMMS also supports continuous improvement efforts. Teams can analyze past maintenance activities to identify trends and optimize future work.

Data Analysis and Predictive Maintenance

Data analysis transforms maintenance practices. By examining equipment performance data, teams can predict failures before they occur.

Key aspects of data-driven maintenance include:

Collecting real-time equipment data

Using artificial intelligence to identify patterns

Developing predictive models for asset health

Predictive maintenance reduces downtime and extends equipment life. It allows teams to schedule repairs at optimal times, minimizing disruptions to operations.

This approach also helps with inventory management. Organizations can stock the right items at the right time by predicting part failures.

Illustration: WorkTrek / Data: Global Education Board

The Role of IoT in Maintenance Strategies

The Internet of Things (IoT) connects equipment to the digital world. Sensors on machines collect and transmit data in real time.

IoT devices in maintenance:

Monitor equipment performance constantly

Alert teams to potential issues quickly

Provide data for predictive analysis

Source: Q Services

Integrating IoT

IoT integration enhances both run-to-failure and preventive maintenance strategies. For run-to-failure, IoT sensors detect imminent failures, allowing for timely replacements.

In preventive maintenance, IoT data helps refine maintenance schedules. This ensures tasks are performed only when needed, saving time and resources.

Source: Softweb Solutions

Maintenance Strategy Optimization

Optimizing maintenance strategies is key for businesses to improve efficiency and cut costs. The goal is to find the right balance between different approaches.

A good maintenance strategy combines multiple methods. It may use run-to-failure for some equipment and preventive care for others.

Choosing the best strategy depends on several factors:

Equipment criticality

Failure patterns

Maintenance costs

Downtime impact

Preventive maintenance programs involving regular inspections and servicing can help extend equipment life and reduce unexpected breakdowns.

Data analysis plays a big role in optimization. Tracking repair history and failure rates helps identify trends. This information guides decision-making on when to repair or replace assets.

Continuous improvement is essential for maintenance strategy optimization. Regular reviews allow companies to adjust their approach as needs change. They can phase out ineffective practices and adopt new technologies.

Training staff is another important aspect. Well-trained technicians can spot issues early and perform maintenance more effectively.

Ultimately, the best maintenance strategy balances cost, reliability, and performance. It evolves to meet changing business needs and technological advances.

Advantages and Disadvantages

Both run-to-failure and breakdown maintenance have pros and cons. Each approach impacts asset conditions and repair costs differently.

Benefits of Run-to-Failure Maintenance

Run-to-failure maintenance can be cost-effective for certain assets. It requires minimal planning and upfront costs. This method works well for non-critical equipment with low replacement costs.

Companies save money on routine inspections and repairs. They can fully use an asset's lifespan. This strategy is simple to implement and manage.

Run-to-failure fits assets where:

Failure doesn't cause safety issues

Downtime has little impact

Replacement is cheaper than maintenance

Drawbacks of Breakdown Maintenance

Breakdown maintenance has significant downsides. It often leads to higher repair costs and longer downtime, and unexpected failures disrupt operations and production schedules.

This approach can shorten equipment lifespan. It may cause secondary damage to connected systems. Emergency repairs are usually more expensive than planned maintenance.

Disadvantages include:

Unpredictable failures and costs

Increased safety risks

Lower equipment reliability

Potential for more severe breakdowns

Breakdown maintenance makes it hard to budget for repairs. It can lead to rushed fixes and subpar work quality. This method is risky for critical assets or those with high replacement costs.

Communication and Training

Communication plays a key role in both run-to-failure and breakdown maintenance strategies. Clear channels help teams respond quickly when issues arise.

For run-to-failure, staff need to know which assets follow this approach. They should understand when to report problems and how to request replacements.

Breakdown maintenance relies on fast communication. Teams must quickly relay equipment failures to maintenance staff, allowing for rapid response and repair.

Training is vital for both methods. Employees should learn to spot signs of wear and impending failure. This helps even with run-to-failure, allowing time to order replacement parts.

Illustration: WorkTrek / Data: Pumble

Necessary skills

Maintenance teams require specific skills for each approach:

Run-to-failure: Focus on efficient replacement procedures

Breakdown maintenance: Emphasis on diagnostics and repair techniques

Regular refresher courses keep staff up-to-date on best practices. This ensures they can handle various maintenance scenarios effectively.

Communication

Proper communication and training lead to the following:

• Faster problem resolution

• Reduced downtime

• Improved safety

• Better resource management

By investing in these areas, companies can maximize the effectiveness of their chosen maintenance strategy.

Frequently Asked Questions

Run-to-failure and breakdown maintenance are complex topics with many nuances. These questions explore key aspects, strategies, and applications in industrial settings.

What are the examples of run-to-failure maintenance in industry?

Run-to-failure maintenance is used for non-critical equipment. Light bulbs in office buildings are a common example. They're left on until they burn out, then replaced.

Another example is disposable air filters in HVAC systems. These are used until they become clogged, then swapped out for new ones.

What are the potential advantages and disadvantages of run-to-failure maintenance?

Run-to-failure maintenance can save money on unnecessary preventive maintenance. It's simple to implement and requires minimal planning.

A big disadvantage is the risk of unexpected breakdowns. If critical equipment fails suddenly, this can lead to production delays, higher repair costs, and safety hazards.

How does run-to-failure maintenance compare to condition-based maintenance?

Run-to-failure maintenance allows equipment to operate until it breaks down. Condition-based maintenance uses sensors and data to predict when failures might occur.

Condition-based maintenance can prevent unexpected breakdowns. It's more complex and expensive to set up than run-to-failure, but it can save money long-term for critical assets.

What are the four primary types of maintenance strategies?

The four main maintenance strategies are:

Reactive maintenance

Preventive maintenance

Predictive maintenance

Reliability-centered maintenance

Each strategy has its benefits and drawbacks, depending on the equipment and industry.

Could you explain the concept of run-to-failure maintenance?

Run-to-failure maintenance involves using equipment until it stops working. Then, it's either repaired or replaced.

This approach is best for non-critical assets with low repair costs. It's also used when failure patterns are unpredictable or when equipment is near the end of its life cycle.

How is breakdown maintenance defined and when is it typically employed?

Breakdown maintenance is fixing equipment after it has already failed. It's often unplanned and requires immediate action.

This type of maintenance is used for both critical and non-critical equipment. It's common in industries where unexpected failures can occur despite preventive measures.

Operations & Maintenance

Importance of Maintenance Audits

Facility and plant managers often dread audits, especially when conducted by external auditors.

But why, when maintenance audits offer so many benefits?

Audits aren’t about pointing fingers, assigning blame, or highlighting mistakes.

They are valuable tools for reducing costs, improving maintenance procedures, and, most importantly, ensuring the safety of your team.

In this article, we’ll go deeper into these benefits.

We’ll also touch on what can happen when you don’t give them the attention they deserve.

Cuts Down Your Costs

You might be wondering how this works, so let’s break it down.

First, regular audits give you a chance to review everything about your maintenance practices.

This includes how you plan and schedule maintenance, the types of maintenance you use, and how much that costs you.

By doing this, you can pinpoint areas where better practices could save you money without compromising the quality of your work.

For example, imagine you discover that you’re frequently replacing a certain motor component. This part is expensive, and the cost of replacements across multiple facilities is adding up.

The audit reveals you’re replacing it every 4 months, although the wear and tear analysis shows it could last up to 9 months. There’s your savings opportunity.

Moreover, when you are on top of your maintenance regime, you keep equipment in good shape.

This means fewer breakdowns and, consequently, less need for expensive emergency repairs and costly downtime.

For example, in the oil and gas industry, downtime can cost as much as $500,000 per hour.

Illustration: WorkTrek / Data: Siemens

Imagine avoiding that kind of money loss.

Well, regular maintenance audits can help make that possible.

Good maintenance also means you won’t need to buy new equipment as frequently, which lowers your purchase costs.

Take, for example, a company that had issues with its limestone transport belt conveyor gearbox.

Initially, the problem seemed serious, but a detailed inspection revealed that the issue was a faulty drive drum bearing, not the gearbox itself.

By replacing the bearing for just $4,000, they avoided a costly $27,000 gearbox replacement and significant downtime.

Source: Reliable Plant

Another way to save money is to lower your energy bills. Well-kept equipment runs more efficiently and uses less power.

All these things reflect on labor costs. When your machinery runs smoothly, your workers can be more productive, and you spend less on maintenance technicians.

In short, maintenance audits, especially internal ones, are smart investments.

They help save money in the long run in more ways than one.

Helps Your Company Perform Better

Efficiency is where maintenance audits can make a significant difference.

Operational efficiency refers to how effectively your company uses its resources—like time, money, and equipment—to achieve results.

It’s about getting the best possible outcomes and doing more with less.

So, how do maintenance audits fit into this picture?

It’s simple.

By conducting a maintenance audit, you can detect areas where you waste too many resources.

This happened to Kaiser Aluminum’s extrusion plant in Sherman, Texas, a few years ago.

A maintenance audit conducted by the U.S. Department of Energy (DOE) revealed that simple fixes—like adjusting burner controls and repairing furnace door seals—could save them substantial energy.

So they fixed them.

The outcome?

They reduced their energy use by about 45,000 MMBtu annually and improved furnace efficiency by 11.1%.

This also resulted in big financial gains.

The company invested $28,000 in these improvements and saved $360,000 on energy costs, paying the investment off in less than a month.

Illustration: WorkTrek / Data: Reliable Plant

This success led Kaiser Aluminum to apply these findings across its other plants, showing that an effective audit can result in impressive savings and boost performance.

However, you don’t always need to wait for an external audit to find areas for improvement.

Sometimes, an in-house tool can do the job.

One such tool is a computerized maintenance management system (CMMS), like our WorkTrek.

Here’s how it helps.

First, with a CMMS like our WorkTrek, you can easily plan and schedule maintenance tasks in one place and assign work orders to your technicians.

Source: WorkTrek

You can also monitor your equipment conditions and identify patterns that point to maintenance inefficiencies.

Second, WorkTrek logs all maintenance activities, including work orders and changes.

This acts as an audit trail, showing exactly what was done, by whom, and when.

At the end of the day, this audit trail is crucial for passing audits and keeping everything transparent.

So it’s best when maintenance audits and a good CMMS work together. Their synergy can lead to improved performance and best use of resources.

Ensures You Comply with Regulations

Maintenance audits are crucial for keeping your business on the right side of the law and avoiding serious consequences.

Often, these audits are part of larger inspections, like health and safety audits, which are designed to ensure that your company is following all the necessary regulations.

Failing to comply with these regulations can have devastating consequences, both financially and operationally.

In the U.S., for instance, the Occupational Safety and Health Administration (OSHA) is the federal agency responsible for ensuring workplace safety.

Under the OSH Act of 1970, private companies are required to provide a safe and healthy work environment for their employees.

OSHA’s audits often focus on maintenance practices to determine whether safety regulations are being followed.

If your company is found lacking, the fines can be hefty.

Currently, penalties stand at $16,131 per violation, with willful or repeated violations costing up to $161,323 each.

Source: OSHA

Across the Atlantic in the U.K., the Health and Safety Executive (HSE) plays a similar role.

They also perform audits to check whether companies provide a safe and healthy environment for workers.

When accidents occur, the fines can reach millions.

A tragic example of what can happen when maintenance is neglected occurred in January 2019, involving Synergy Housing Limited and Orona Limited, a company responsible for lift maintenance.

A five-year-old girl lost her life after she put her head through a broken vision panel in her home’s lift, which was ascending.

Source: Google

The HSE investigation revealed critical failures by both companies, including a lack of inspections, failure to repair the broken panel, no risk assessments, missing safety mechanisms, and insufficient safety information for tenants.

As a result, Synergy Housing was fined £1 million plus £40,000 in costs, while Orona was fined £533,000 plus £40,000 in costs.

Another example is the 2009 fire at Lakanal House in Southwark, a borough in Greater London, which tragically claimed the lives of six people.

Poor maintenance, combined with inherent structural deficiencies, led to this disaster.

Southwark Council was fined £570,000 for safety failings, which included the absence of a proper fire risk assessment, breaches in fire-resistant structures, lack of compartmentation in ceilings, and missing fire door seals.

These issues could have been identified and addressed through regular maintenance audits.

As Dan Daly, London Fire Brigade’s assistant commissioner for fire safety, pointed out:

If buildings are built and maintained correctly, walls, floors and doors in flats and maisonettes give you protection from fire – a minimum of 30 to 60 minutes.

The lesson here is clear: preventive maintenance and regular audits are not just about staying compliant with regulations—they’re about saving lives.

Regular maintenance audits help you identify potential risks before they escalate, ensuring that your company stays within legal requirements, avoids hefty fines, and most importantly, keeps people safe.

Reduces Risky Situations

Even more, regular maintenance audits can prevent catastrophic incidents that lead to environmental harm.

This is especially crucial in high-risk industries like oil and gas, where even a small failure can have devastating consequences.

Take the Deepwater Horizon oil spill as a sobering example.

On April 20, 2010, this oil rig, operated by BP, a British multinational oil and gas company, suffered a blowout, causing one of the largest environmental disasters in history.

Source: Britannica

What went wrong?

A series of maintenance failures and safety oversights.

BP’s former Chief Executive, Tony Hayward, sums it up:

To put it simply, there was a bad cement job and a failure of the shoe track barrier at the bottom of the well, which let hydrocarbons from the reservoir into the production casing. The negative pressure test was accepted when it should not have been, there were failures in well control procedures and in the blowout preventer; and the rig’s fire and gas system did not prevent ignition.

The blowout resulted in the deaths of 11 workers and released millions of barrels of oil into the Gulf of Mexico, causing extensive environmental and economic damage.

The fallout from this disaster was immense, leading to major regulatory changes and significant fines for BP.

But more importantly, it is a powerful reminder of why regular maintenance audits are vital.

They help detect anomalies early, prevent escalation, and ensure that safety protocols are in place, thereby protecting lives, equipment, and the environment.

So, just as regular audits could have prevented the Lakanal House fire, they could have also prevented the Deepwater Horizon spill.

Enables You to Make Good Decisions

Maintenance audits don’t just keep your operations running smoothly but help you make smart, strategic decisions that benefit your company in the long run.

Take this real-world example: a tissue producer was dealing with repeated issues on their press suction roll cover, which was disrupting production.

Seeking a solution, they turned to an external auditor—Valmet.

The audit revealed several critical issues.

They discovered that the groove design on the roll was flawed, and the roll cover showed edge damage because of high temperature and nip pressure.

Based on this, Valmet recommended changes to the groove design and improvements in the chamfer design at the roll’s ends.

When these recommendations were implemented during the next scheduled maintenance, the results were clear: better performance without any extra costs.

Source: Valmet

This example shows how maintenance audits can guide you in making better decisions for your operations.

So, whether it’s upgrading outdated equipment, maintaining equipment more frequently, or investing in new technologies, the insights you gain from these audits help you steer your company in the right direction.

And if you’re using a CMMS, this process becomes even easier.

The software keeps all your maintenance data organized, making it simpler to analyze and turn into actionable plans.

In the end, maintenance audits, especially when paired with a CMMS, give you the knowledge and foresight to make decisions that truly benefit your business.

Conclusion

Maintenance audits are really nothing to fear.

In fact, they're incredibly valuable tools that can benefit your facility or plant in numerous ways.

They help improve efficiency, cut costs, prevent risks, and provide a safe working environment for your whole team.

So, make maintenance audits a regular part of your routine, and you'll quickly start seeing these benefits for yourself.

Operations & Maintenance

Breakdown Maintenance Planning Tips

If you are running a maintenance organization, you are likely dealing with breakdown maintenance.

Preventive maintenance can be resource-intensive but is ideally suited for critical equipment.

Based on our experience working with customers, most organizations prefer a breakdown maintenance approach to non-critical equipment.

Source: WorkTrek

This article provides several practical tips for improving your approach to breakdown maintenance.

If you are looking for a more detailed guide on breakdown maintenance, refer to our comprehensive guide on the topic.

Defining Breakdown Maintenance

Breakdown maintenance is a type of corrective maintenance. It happens when machines fail.

This also means that teams only take action after equipment stops working.

This method, also called reactive maintenance, is used for parts that are easy to replace or cannot be fixed. Some companies choose it for non-critical gear.

Breakdown maintenance can be quick and doesn’t require much planning. However, it can lead to extended downtimes and higher costs if not managed well.

Having defined maintenance procedures can help mitigate unexpected equipment failures.

Tips for Breakdown Maintenance

Below are a few practical tips for improving breakdown maintenance. We've learned these tips working with clients across a variety of industries.

Identify Critical Equipment and Areas

The first step in the process is to identify critical equipment. This involves assessing which machines or systems are vital to operations.

Illustration: WorkTrek / Data: PlanetEngineering

List all equipment and rank them based on importance. Use factors like production impact, repair costs, and safety risks to determine criticality.iiIt’s helpful to make a map of critical areas in the facility. This allows quick response when breakdowns occur. Teams should also gather technical information for each piece of equipment, including manuals and repair histories.

Safety Protocols and Risk Management

Regardless of the type of maintenance you are performing, safety is paramount. Teams must develop clear safety protocols for different types of equipment and situations.

Perform risk assessments for each critical piece of machinery. This helps identify potential hazards and necessary precautions.

Safety gear requirements should be clearly defined for each maintenance task. If you use Lock Out Tag Out (LOTO) products, ensure your staff is fully trained.

Training

Illustration: WorkTrek / Data: Infraspeak Blog

Proper safety procedure training is critical. This improves efficiency, improves safety, and saves the company resources.

Illustration: WorkTrek / Data: Linkedin Learning

An effective training strategy can also help with employee retention. According to a LinkedIn study,94% of workers will stay long with an employer if offered learning opportunities.

Parts Inventory

Good inventory management and low-quantity alerts are key to effective breakdown maintenance. It ensures teams have the right parts and tools when needed.

Maintenance departments should keep a detailed spare parts inventory in their maintenance report. This list should be updated regularly and include part numbers, quantities, and storage locations.

It's wise to keep essential spare parts on hand for critical equipment. This reduces downtime during breakdowns. Teams should set up a system to track part usage and reorder when stocks are low.

Tools and supplies needed for common repairs should also be readily available. This includes safety equipment, cleaning materials, and diagnostic tools. Regular inventory checks help ensure everything is in good condition and ready for use.

Communication and Reporting Procedures

Better communication can benefit all teams. This can include setting up daily standups, using chat software, or using group chat capabilities.

Illustration: WorkTrek / Data: Simon&Simone

Keep it simple. This could be an app or a phone hotline. Make it easy for workers to flag issues quickly.

Create detailed breakdown reports. Include what broke, why, and how it was fixed. Share these with all teams. This helps everyone learn from each event.

Hold brief meetings after major repairs to discuss what went well and what didn't. Use these talks to improve your handling of breakdowns.

Implementing Continuous Improvement

Always look for ways to improve. Review each breakdown afterward. Ask what went wrong and how to prevent it next time.

Track key stats like repair times and costs. Set goals to improve these numbers over time.

Get feedback from machine operators. They often notice small changes that can signal future problems.

Stay up to date on new maintenance tech. Tools like vibration sensors can catch issues early.

Share success stories and lessons learned across teams. This spreads good practices and builds a culture of improvement.

Implement CMMS Software

CMMS software is a vital tool for managing breakdown maintenance. It helps track equipment, schedule repairs, and manage work orders.

Illustration: WorkTrek / Data: GoodFirms

CMMS systems store each asset's information, including repair history and part details, and will reduce manual paper records.

This makes diagnosing issues easier and ordering parts quickly when breakdowns happen.

Illustration: WorkTrek / Data: Pumps&Systems

Teams can use CMMS to set up alerts for routine checks. This helps prevent minor problems from turning into big breakdowns. The software also tracks costs, assisting managers in seeing where money is spent on repairs.

The Role of Maintenance Data and Analytics

Data is crucial for smart breakdown maintenance planning. Good data helps teams spot trends and make better choices.

Maintenance software collects repair times, part usage, and equipment downtime. This data shows which machines break down most often and why.f

Analytics tools and SMART maintenance can predict when gear might fail. This lets teams fix things before they break. Managers can use data to decide if it's cheaper to keep fixing old equipment or buy new.

Charts and reports make it easy to see how well the maintenance team is doing. This helps improve processes over time.

Documentation and Knowledge Transfer

Good documentation is vital for sharing know-how. Teams should write down all repair steps and note any tricks they learn.

Creating a database of maintenance history is smart. This helps spot trends and prevent future issues. The database should include:

Problem details

Fix steps

Parts used

Time taken

Illustration: WorkTrek / Data: The Growth Blueprint

Older workers should teach newer ones. This passes on years of wisdom. Setting up mentor programs can help with this.

Regular team meetings help spread best practices. Workers can share what they've learned from recent jobs.

Condition Monitoring and Diagnostic Tools

Condition monitoring tools watch equipment while it runs. They can spot signs of wear before a breakdown happens.

Sensors check things like temperature, vibration, and oil quality. When something's wrong, they send alerts, giving teams time to plan repairs before a complete breakdown.

Illustration: WorkTrek / Data: icon

Diagnostic tools help find the exact cause of a problem. They can test electrical systems, check fluid levels, and analyze error codes.

Some tools use AI to learn what "normal" looks like for each machine. This makes it easier to spot when something's off. Mobile apps let workers check equipment status from anywhere.

Effective Utilization of Tools and Equipment

Proper tool use is vital in breakdown maintenance. Keep tools clean and ready for use. Store them in a set spot so workers can find them fast. Check tools often to make sure they work well.

Illustration: WorkTrek / Data: dynaway

Train staff on how to use tools correctly. This helps avoid equipment damage and keeps workers safe. Have a system to track who has which tools. This prevents tools from getting lost.

Keep spare parts for tools on hand. If a tool breaks, you can fix it fast. For non-critical gear, have backup options ready.

Materials and Replacement Parts Planning

Good parts planning helps fix breakdowns fast. Keep a stock of common parts like light bulbs, batteries, and fuses. Know which parts break most often and have extras.

Make a list of key suppliers for quick orders. Set up deals with them for fast delivery. The track part used to know when to order more.

For rare or costly parts, think about sharing with other sites. This can save money. Use software to track part levels and order history.

Plan for disposal of old parts. Some may need special handling. Set up a system to recycle when possible.

Performance Metrics and KPIs

Breakdown Maintenance planning relies on solid data. Teams should track:

Mean Time Between Failures (MTBF)

Mean Time To Repair (MTTR)

Overall Equipment Effectiveness (OEE)

Maintenance Costs vs. Equipment Value

Source: WorkTrek

These numbers show how well the maintenance plan works. Low MTBF or high MTTR may mean equipment needs more care.

Tracking these KPIs can help you better predict future breakdowns and help the team set clear goals for improvement.

Maintenance and Spare Parts Correlation

Match spare parts to your maintenance plan. Know which parts each machine needs. Keep those on hand.

Study equipment failure modes. Stock parts that often break or wear out. This helps prevent long downtimes.

Use maintenance data to spot trends. If a part fails often, keep more in stock. If it rarely breaks, stock less.

Link spare parts to work orders. This shows which parts are used most, helping plan future orders and stock levels.

Conclusion

Breakdown maintenance is an effective way to maintain non-critical equipment. Establish protocols for maintenance procedures, well-organized inventory, clear safety protocols, and effective communication.

These can help significantly improve your approach to breakdown maintenance.

Operations & Maintenance

When to Use Breakdown Maintenance

What situations are ideal for breakdown maintenance? Breakdown maintenance involves fixing equipment only after it fails. This approach can work well for non-critical systems where downtime isn’t a major issue.

A breakdown maintenance strategy is best used for low-priority assets that don’t significantly impact business operations if they stop working.

Companies often use this method for simple items like light bulbs or backup systems. It can save money on regular check-ups and repairs. But it’s not ideal for critical assets that keep a business running.

This article covers scenarios for when to use breakdown maintenance. Those scenarios depend on the importance of the equipment and the risk of failure. Waiting until they break is acceptable for some assets.

For others, it can lead to costly delays and safety issues.

Understanding Breakdown Maintenance

https://youtu.be/21aY8-ifoo8

Breakdown maintenance is a repair approach used when equipment fails unexpectedly. It involves fixing or replacing components after they stop working. This strategy has both pros and cons for businesses. Companies often need to perform breakdown maintenance due to budget constraints, which can impact other maintenance strategies like preventive maintenance.

Definition and Key Concepts

Breakdown maintenance occurs when equipment breaks and needs urgent repairs. Unlike planned upkeep, it's reactive. Teams fix issues as they arise, not before.

Key features of breakdown maintenance:

Repairs occur after failure

No planned schedules

It can be costly and disruptive

Sometimes called “run-to-failure” maintenance

Reduces unnecessary preventive maintenance

A breakdown maintenance workflow is a structured, step-by-step action plan for effectively managing equipment failures. This approach works for some less critical items, such as letting office light bulbs burn out before changing them.

Source: WorkTrek

Comparison with Other Maintenance Types

Breakdown maintenance differs from other upkeep methods in several ways.

Preventive maintenance involves regular, scheduled checks and repairs. It aims to stop breakdowns before they happen. This can save money in the long term but needs more upfront planning.

Predictive maintenance uses data to guess when parts might fail. It can be very effective but needs special tools and skills.

Corrective maintenance fixes minor issues before they become big problems. It’s less urgent than breakdown repairs but still reactive.

A strategic combination of preventive and breakdown maintenance is essential for efficiently managing high-value assets while saving costs on less critical components. This approach can also reduce downtime costs.

When to Apply Breakdown Maintenance

https://youtu.be/anTecYyb1a0

Breakdown maintenance is best used in specific situations that can be cost-effective and safe. It works well for non-critical equipment and items with short lifespans.

The key is knowing when this approach makes sense. A breakdown maintenance plan is essential to effectively manage equipment failures and differentiate between breakdown and preventive maintenance strategies to optimize maintenance costs.

Run-to-Failure Maintenance Scenarios

Run-to-failure maintenance is suitable for equipment that can fail without major consequences. This approach works for items that are cheap and easy to replace. Examples include:

• Light bulbs

• Fuses

• Batteries

These items often have predictable lifespans. Replacing them only when they fail can save time and resources. It’s more efficient than checking and replacing them regularly.

Spare Parts

Organizations can plan for eventual failures and keep spare parts on hand, minimizing downtime when replacements are needed.

Examples of breakdown maintenance show that while this strategy is cost-effective for noncritical parts, it is unsuitable for industries where safety is paramount, such as aviation and automotive.

Dealing with Non-Critical Equipment

Non-critical equipment is ideal for breakdown maintenance. These items don’t affect safety or core operations if they fail. Examples might include:

• Office printers

• Vending machines

• Backup systems

For these items, the cost of constant monitoring may outweigh the benefits. It’s often cheaper to fix them only when they break.

Companies should assess each piece of equipment. They need to determine its importance to operations.

This helps decide if breakdown maintenance is appropriate. Unplanned breakdown maintenance can occur with non-critical equipment, making it essential to have resources ready to address unexpected failures.

Considering Cost-Effectiveness and Safety

Cost and safety are critical factors in choosing a maintenance strategy. Breakdown maintenance can be cost-effective for certain items. It eliminates the expense of regular inspections and preventive work.

But safety must come first. Breakdown maintenance is not suitable for:

• Critical safety equipment

• Machinery that could cause injury if it fails

• Systems that would lead to costly downtime

Companies must weigh the risks and benefits. They should consider the potential costs of equipment failure. This includes repair expenses, lost productivity, and safety impacts.

In some cases, a mix of strategies works best. Critical systems receive preventive care, while less important items use the breakdown approach.

Source: IVC

Planning for Breakdown Maintenance

https://youtu.be/VvvnhlVv4-0

Planning for breakdown maintenance involves using systems, managing inventory, and optimizing workflows. These steps help companies respond quickly when equipment fails unexpectedly.

Effective asset management is crucial to minimize the occurrence of breakdowns and ensure efficient maintenance planning.

CMMS Software

Maintenance management systems, like CMMS software, are key for planning breakdown maintenance. These tools track equipment history, schedule repairs, and store important data about each machine.

CMMS software sends alerts when parts need replacing, helping prevent some breakdowns before they happen. The system can also track repair costs and downtime for each piece of equipment.

Good CMMS software is easy to use. It should work on mobile devices so technicians can access info anywhere. Look for systems that generate clear reports to help with planning.

Source: FinancesOnline

Inventory Management for Spare Parts

Keeping the right spare parts on hand is crucial for quick repairs. A good inventory system, generally part of most mature CMMS systems, tracks what parts are in stock.

It also shows where each part is stored. Implementing efficient inventory management procedures is essential for a successful breakdown maintenance program.

Set up automatic reordering for critical parts. This ensures you never run out when you need them most. Consider keeping extra stock of parts that are hard to get or have extended lead times.

Group similar parts together in storage. Label everything clearly. Use barcodes or RFID tags to track parts easily. Regular inventory checks help catch errors and prevent shortages.

Source: intelliarts

Workflow Optimization

Creating clear workflows helps teams respond faster to breakdowns. Start by listing all steps in the repair process. Then look for ways to streamline each step.