Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- Organizations implementing preventive maintenance can save 12-18% compared to reactive approaches

- Companies prioritizing preventive maintenance achieve a 90% compliance audit pass rate versus 68% for those who don’t

- Preventive maintenance programs can reduce unplanned equipment downtime by 25-30%

Preventive maintenance audits are the most effective tools maintenance managers have for optimizing operations, reducing costs, and extending equipment lifespan.

Yet many organizations overlook this critical evaluation process, missing opportunities to identify inefficiencies, improve compliance, and strengthen their overall maintenance strategy.

Understanding the benefits of conducting a preventive maintenance audit can transform how you approach equipment maintenance and asset management.

In this comprehensive guide, we’ll explore eight compelling benefits that demonstrate why preventive maintenance audits should be a cornerstone of your maintenance program.

Understanding Preventive Maintenance Audits

Let’s start with a definition.

A preventive maintenance audit is a systematic evaluation of your preventive maintenance processes, procedures, and outcomes.

This structured assessment reviews maintenance records, equipment performance metrics, work order completion rates, and adherence to established maintenance protocols.

The primary goal is to assess whether your preventive maintenance program is good at preventing equipment failures, complies with safety regulations, and supports organizational objectives.

According to FieldCircle, a preventive maintenance audit evaluates effectiveness (are PMs actually preventing failures?), efficiency (are we optimizing resources?), and compliance (are we following safety and regulatory maintenance requirements).

Unlike regulatory audits conducted by external agencies, preventive maintenance audits serve as internal tools for continuous improvement.

They help maintenance teams identify gaps between planned and actual maintenance activities, uncover hidden inefficiencies, and benchmark performance against industry best practices.

1. Significant Cost Savings

The financial benefits of conducting preventive maintenance audits are substantial and well-documented across industries.

Organizations that implement structured preventive maintenance programs based on audit findings consistently demonstrate remarkable cost reductions compared to reactive maintenance approaches.

Research from Jones Lang LaSalle reveals that businesses can achieve savings of 12-18% by adopting preventive maintenance over reactive counterparts.

These cost savings come from multiple sources.

Preventive maintenance audits help identify unnecessary maintenance tasks that drain budgets without providing proportional value.

The National Institute of Standards and Technology found that reactive approaches can incur costs 2 to 5 times higher than preventive strategies.

When you conduct regular preventive maintenance audits, you create opportunities to eliminate wasteful spending on over-maintenance while ensuring critical assets receive adequate attention.

UpKeep research demonstrates that every dollar spent on preventive maintenance saves an average of $5 in future repair costs.

Moreover, preventive maintenance audits reduce maintenance costs by optimizing inventory management, preventing costly emergency repairs, and extending equipment lifespan through proper maintenance timing.

Organizations also avoid the substantial indirect costs associated with equipment failures, including lost production time, expedited shipping fees for emergency parts, and overtime labor expenses.

2. Reduced Unplanned Downtime

Equipment downtime represents the most significant operational challenge facing organizations today.

When equipment fails unexpectedly, production stops, deadlines are missed, and costs skyrocket.

Studies show that preventive maintenance programs can reduce unplanned equipment downtime by 25-30%, keeping facilities running smoothly and minimizing disruptions.

Preventive maintenance audits identify patterns in equipment failures, revealing which assets require more frequent inspections and which maintenance tasks prevent the most critical failures.

By analyzing maintenance history and equipment performance data during audits, maintenance teams can predict potential failures and schedule corrective maintenance before breakdowns occur.

This staggering figure underscores the financial impact that effective preventive maintenance audits can help organizations avoid.

Regular preventive maintenance audits ensure your preventive maintenance schedule aligns with actual equipment needs rather than arbitrary time intervals.

This optimization prevents both under-maintenance (which leads to failures) and over-maintenance (which wastes resources), striking the right balance to minimize unexpected downtime.

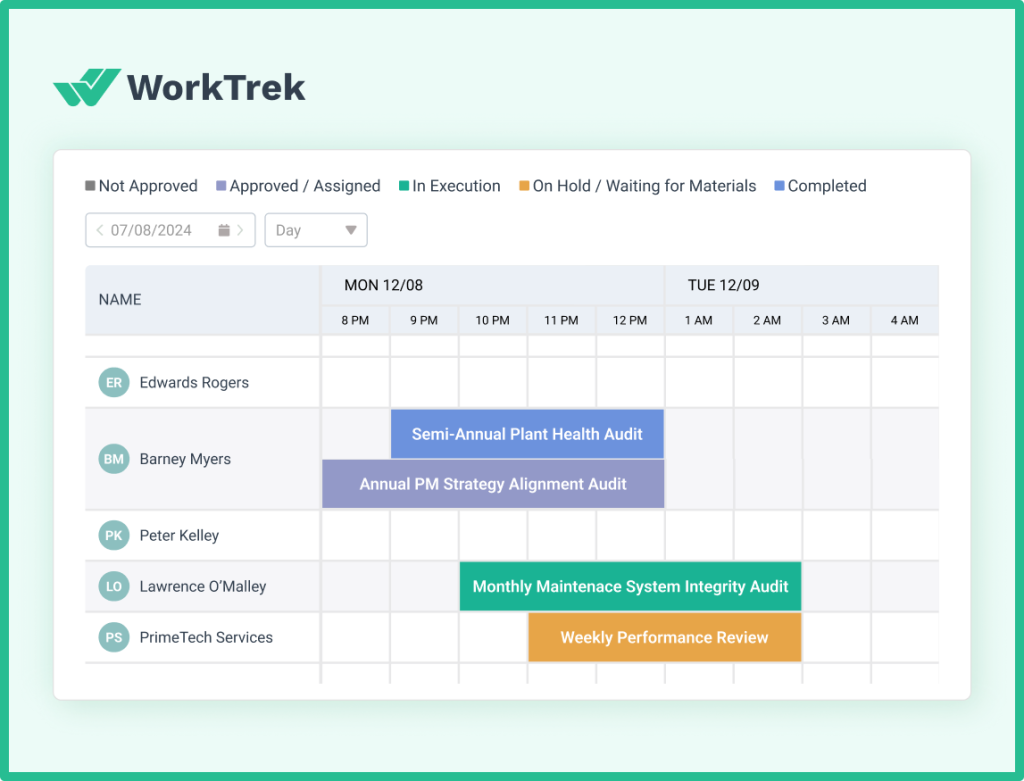

Maintenance teams using insights from preventive maintenance audits can transition from reactive to proactive maintenance, addressing issues during planned maintenance windows rather than responding to emergency breakdowns.

3. Enhanced Equipment Reliability

The one factor that impacts production capacity, product quality, and customer satisfaction is equipment reliability.

When you conduct thorough preventive maintenance audits, you systematically evaluate which maintenance activities most effectively prevent equipment failures and which require adjustment.

Preventive maintenance audits examine maintenance procedures against manufacturer recommendations and industry best practices to ensure your team performs the right preventive maintenance tasks at optimal intervals.

This alignment between maintenance activities and equipment needs significantly improves asset reliability.

Research indicates that routine maintenance and inspections minimize unexpected equipment failures, extend asset life expectancy, and reduce the risk of out-of-hours breakdowns.

During preventive maintenance audits, maintenance managers review maintenance data to identify recurring equipment issues that standard preventive maintenance might miss.

These insights enable teams to implement targeted corrective maintenance strategies that address root causes rather than symptoms.

By analyzing equipment performance metrics during audits, organizations can establish baseline performance standards and track improvements over time.

4. Improved Regulatory Compliance and Safety

Safety regulations and industry standards impose strict requirements on organizations across virtually all sectors, making compliance a non-negotiable aspect of operations.

Preventive maintenance audits play a crucial role in ensuring adherence to these safety protocols and regulatory requirements.

According to the Aberdeen Group, businesses that prioritize preventive maintenance achieve a 90% compliance audit pass rate, compared to just 68% for organizations that don’t emphasize preventive maintenance.

This significant difference highlights how preventive maintenance audits strengthen compliance postures.

When maintenance teams conduct preventive maintenance audits, they verify that all required safety inspections are performed on schedule, that documentation meets regulatory standards, and that maintenance procedures align with safety regulations.

These comprehensive reviews identify compliance gaps before external regulators discover them, helping organizations avoid hefty fines, legal actions, and potential business shutdowns.

Preventive maintenance audits also enhance workplace safety by ensuring critical safety equipment receives proper attention through the preventive maintenance program.

5. Optimized Maintenance Schedules

One of the most valuable benefits of preventive maintenance audits is the ability to optimize maintenance schedules based on actual equipment performance rather than assumptions.

Many organizations implement preventive maintenance programs based on manufacturer recommendations or industry standards without considering their specific operating conditions, usage patterns, or environmental factors.

Preventive maintenance audits assess whether scheduled maintenance is performed at frequencies that truly prevent failures without creating unnecessary work.

Fiix Software notes that preventive maintenance scheduled too close together drains budgets while teams perform unnecessary work, whereas scheduling PMs too far apart increases breakdowns and reduces production.

During audits, maintenance managers analyze maintenance history to identify equipment that consistently operates without issues between scheduled preventive maintenance tasks.

This analysis reveals opportunities to extend maintenance intervals for reliable equipment, freeing up maintenance resources for critical assets that require more attention.

Conversely, preventive maintenance audits identify equipment that is failing before scheduled maintenance tasks, indicating the need for more frequent preventive maintenance.

Organizations using computerized maintenance management systems can leverage maintenance data analytics during audits to make evidence-based decisions about optimal maintenance frequencies.

This data-driven approach to preventive maintenance planning ensures that maintenance teams focus their efforts where they deliver the greatest impact on equipment reliability and operational efficiency.

6. Better Resource Allocation

Effective resource management represents a critical challenge for maintenance departments facing budget constraints, staffing limitations, and competing priorities.

Preventive maintenance audits provide the visibility needed to allocate maintenance resources more effectively across people, parts, and time.

When maintenance managers conduct preventive maintenance audits, they identify which preventive maintenance tasks consume disproportionate resources relative to their value in preventing equipment failures.

This analysis reveals opportunities to streamline maintenance procedures, eliminate redundant preventive maintenance activities, and redirect resources toward higher-priority maintenance tasks.

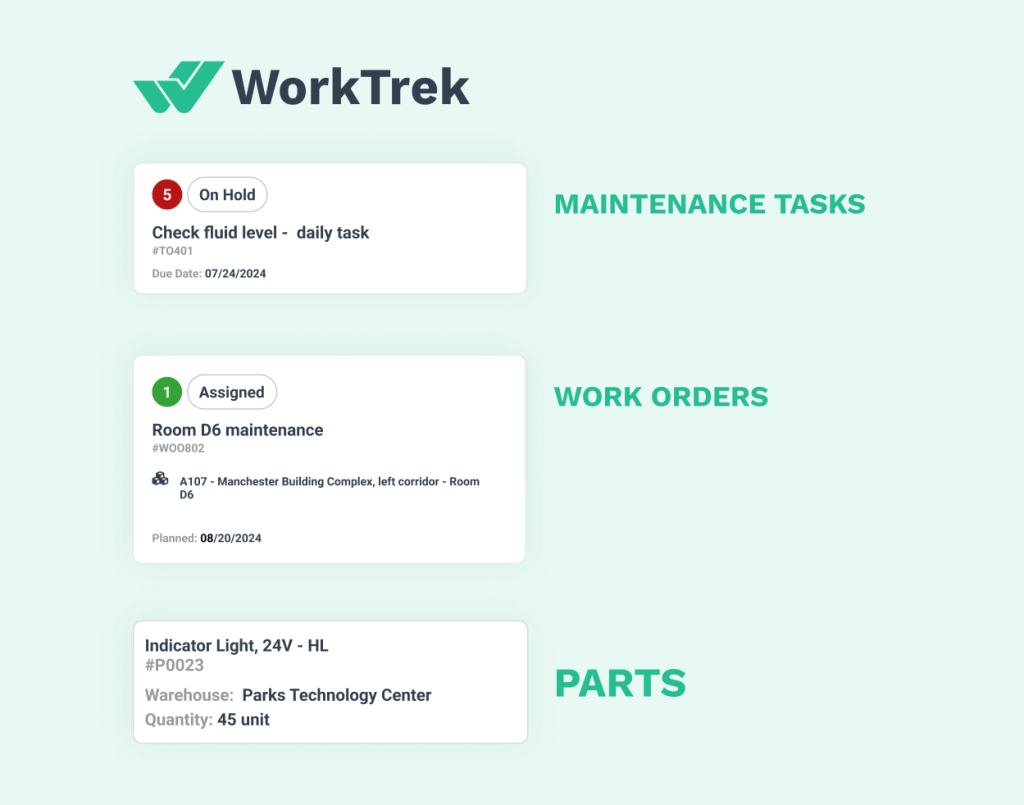

Preventive maintenance audits also evaluate spare parts inventory against actual usage patterns documented in maintenance records and work orders.

Organizations frequently discover they’re stockpiling parts that rarely see use while experiencing shortages of often-needed components.

These inventory optimization insights reduce carrying costs while ensuring maintenance technicians have the materials they need for preventive maintenance.

Labor allocation also improves significantly through preventive maintenance audits.

By analyzing work order completion times and maintenance activities, managers can better estimate staffing requirements for scheduled maintenance and identify skill gaps requiring training or additional hires.

MaintWiz emphasizes that optimizing the utilization of maintenance resources and materials is essential for controlling costs and maximizing efficiency.

Preventive maintenance audits help organizations optimize their programs by evaluating how resources support them.

The insights gained from regular preventive maintenance audits enable maintenance managers to make strategic decisions about resource investments.

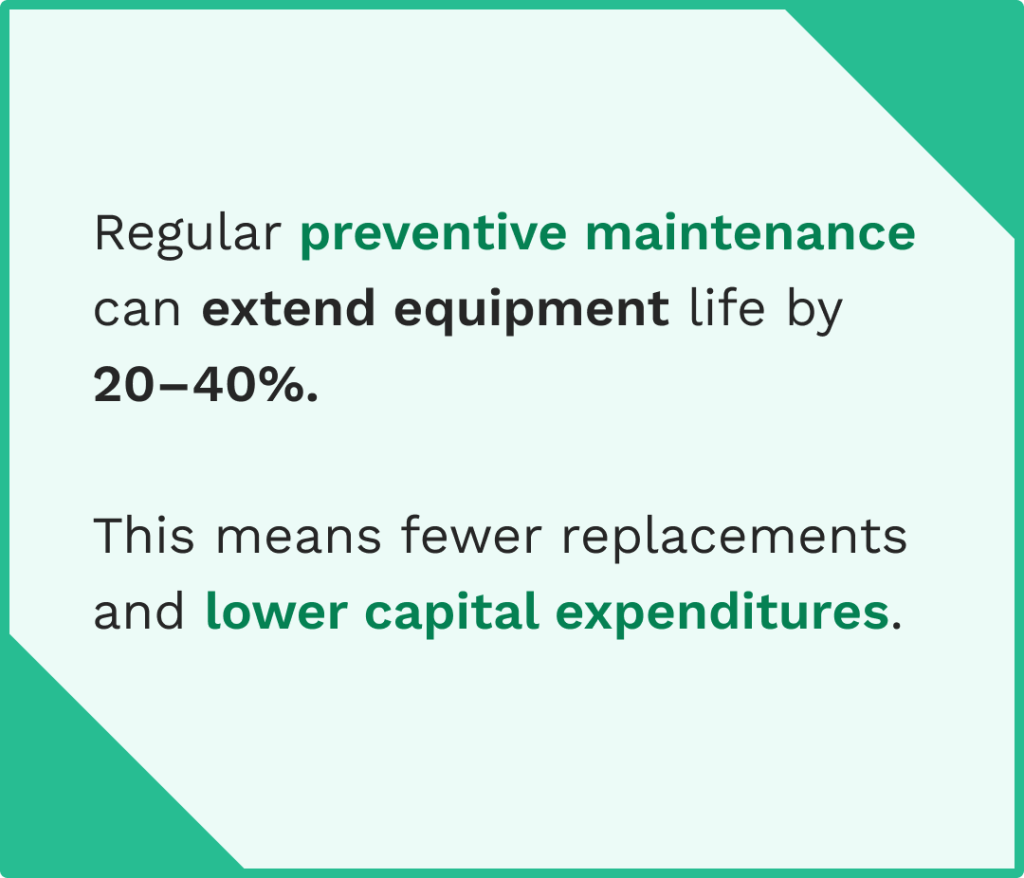

7. Extended Equipment Lifespan

Capital equipment represents substantial organizational investments, making asset longevity a key financial consideration.

Preventive maintenance audits significantly contribute to extending equipment lifespan by ensuring assets receive appropriate care throughout their operational life.

Regular preventive maintenance audits verify that maintenance teams follow manufacturer-recommended maintenance procedures and intervals designed to preserve equipment integrity.

These audits identify instances where deviations from recommended practices might accelerate wear and reduce equipment lifespan.

By analyzing maintenance history during audits, organizations can track equipment degradation patterns and implement preventive measures before minor issues escalate into major failures requiring premature replacement.

Research shows that running equipment to the point of failure can cost up to 10 times as much as regular preventive maintenance would have cost.

Preventive maintenance audits help organizations avoid this costly outcome by ensuring consistent execution of preventive maintenance tasks that prevent catastrophic failures.

Equipment that receives regular, properly executed preventive maintenance operates more efficiently and experiences less stress, directly contributing to longer operational life.

Preventive maintenance audits verify that lubrication, calibration, cleaning, and inspection activities occur as planned, protecting critical assets from premature deterioration.

The cost savings from extended equipment lifespan compound over time, as organizations delay major capital expenditures while maintaining productive capacity.

When preventive maintenance audits reveal opportunities to improve maintenance practices, the resulting changes can add years to equipment service life.

Moreover, well-maintained equipment typically commands higher resale values when organizations eventually upgrade or replace assets, further enhancing the financial benefits of effective preventive maintenance programs.

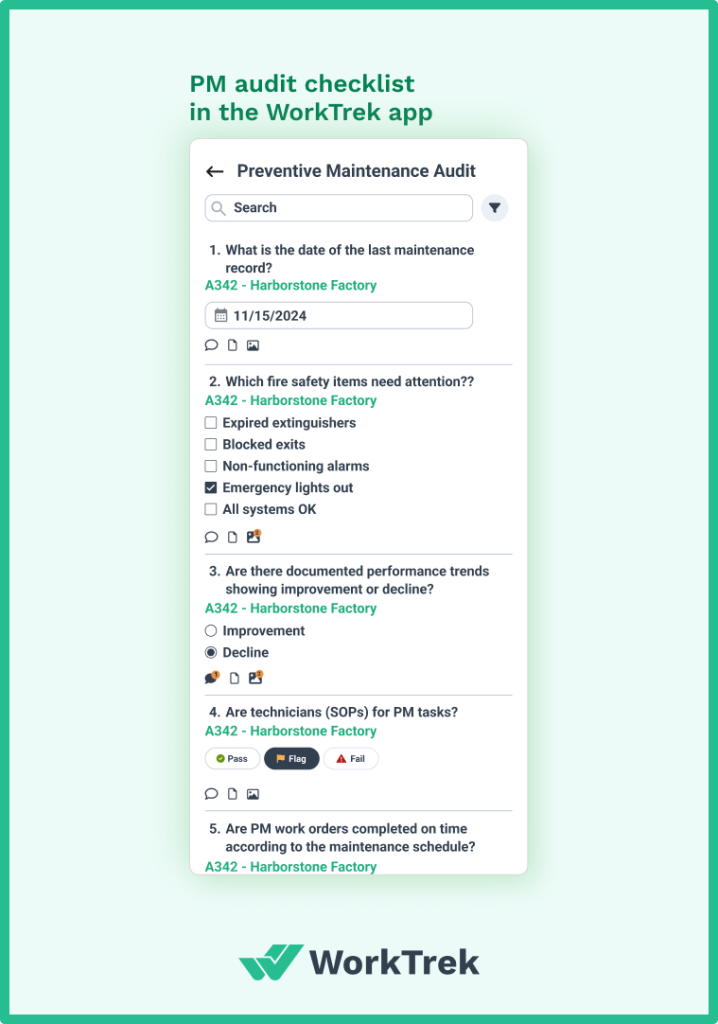

8. Enhanced Maintenance Performance Monitoring

Continuous improvement requires accurate performance measurement, making enhanced monitoring capabilities a valuable benefit of preventive maintenance audits.

These systematic evaluations establish baseline metrics and track progress toward maintenance excellence over time.

Preventive maintenance audits examine key performance indicators, including preventive maintenance completion rates, mean time between failures, and the ratio of planned to unplanned maintenance.

By regularly measuring these metrics, organizations gain visibility into whether their preventive maintenance program delivers expected results.

When maintenance teams conduct preventive maintenance audits, they compare current performance against historical data to identify trends indicating improvement or decline.

This trend analysis helps maintenance managers assess whether recent changes to the preventive maintenance strategy have improved equipment reliability and maintenance operations.

Preventive maintenance audits also facilitate benchmarking against industry best practices and standards.

MaintWiz notes that maintenance audits provide opportunities to compare processes, metrics, and performance against industry standards, helping organizations identify areas for improvement and adopt proven strategies.

The documentation and record-keeping requirements of preventive maintenance audits create comprehensive maintenance histories that support data-driven decision-making.

When considering equipment replacement, process improvements, or resource allocation, maintenance managers can reference audit findings to justify recommendations with concrete evidence.

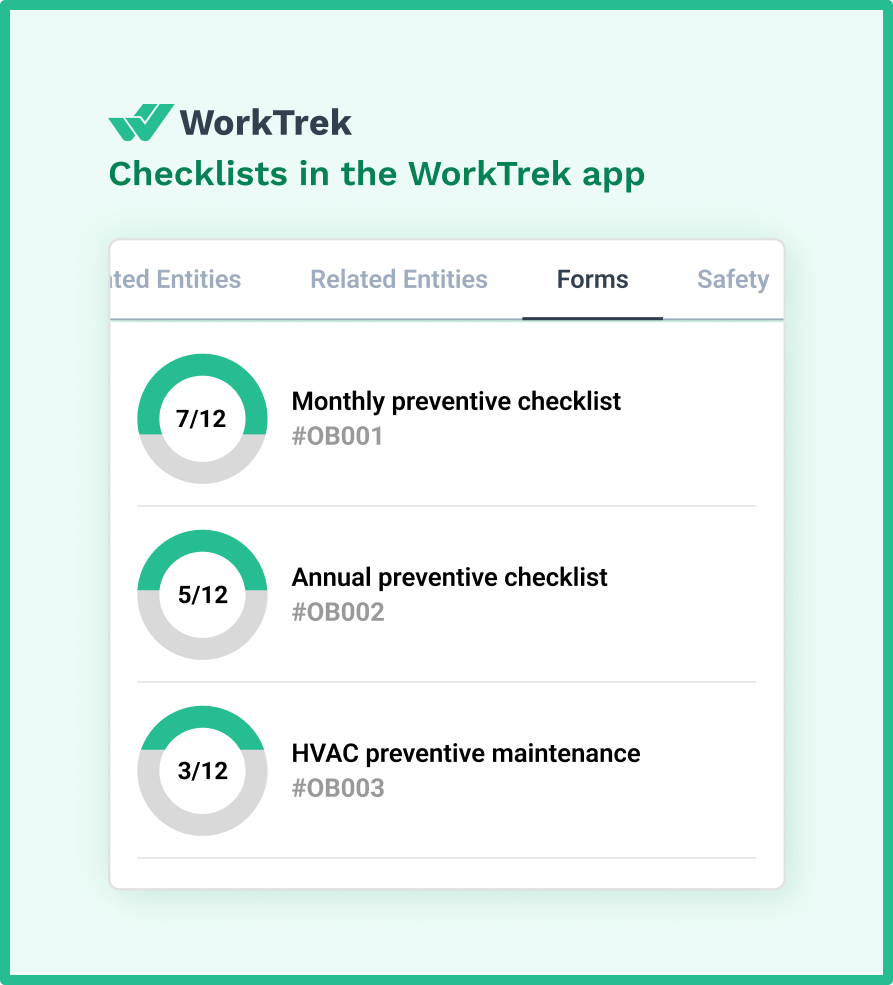

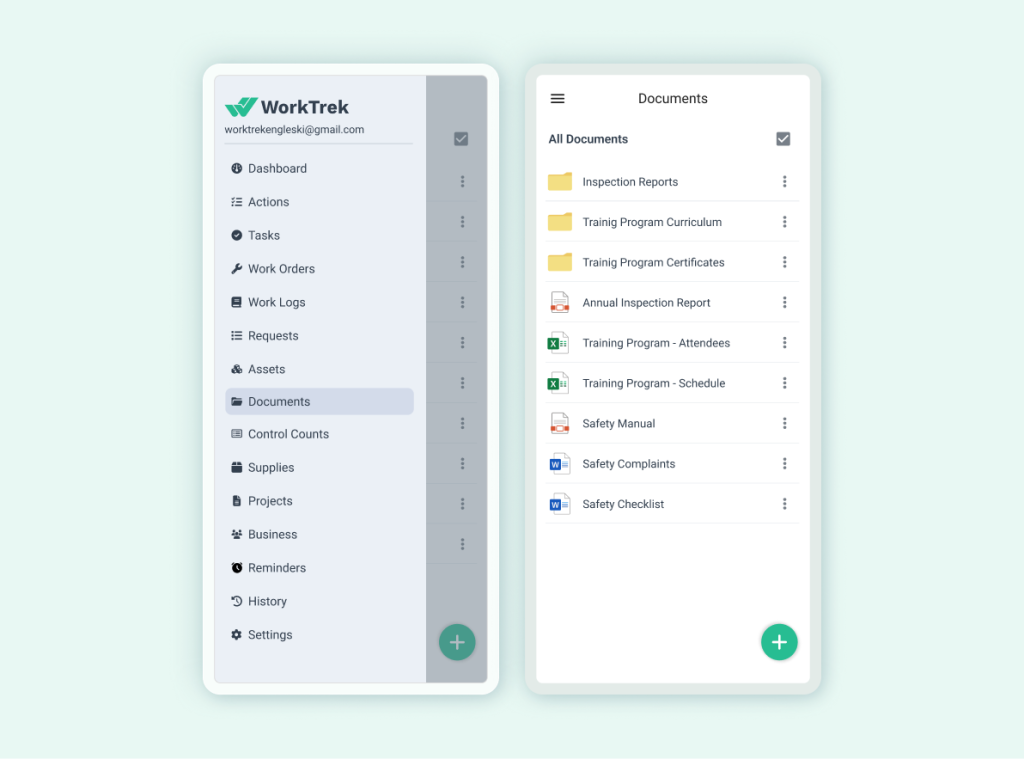

Organizations implementing preventive maintenance software benefit from automated performance tracking, which simplifies audits and provides real-time visibility into maintenance performance.

These systems generate reports showing work order completion rates, maintenance costs, equipment downtime, and other critical metrics that audits evaluate.

By establishing regular preventive maintenance audit schedules, organizations create accountability mechanisms that ensure the preventive maintenance program remains aligned with operational goals and continues to deliver value.

Conclusion

The benefits of conducting preventive maintenance audits extend far beyond simple compliance checks or cost reduction exercises.

It represents a significant opportunity to transform maintenance operations, enhance equipment reliability, and drive continuous improvement across organizations.

From the significant cost savings and reduced downtime to improved compliance, optimized schedules, and better resource allocation, preventive maintenance audits deliver measurable value that directly impacts organizational success.

Modern CMMS platforms like WorkTrek make implementing comprehensive preventive maintenance programs easier than ever, providing the digital infrastructure necessary to support data-driven maintenance strategies.

Start conducting preventive maintenance audits today to unlock these benefits and transform your maintenance operations from reactive firefighting to proactive asset management.