Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- 88% of manufacturing companies use preventive maintenance

- Companies can save between 12% and 18% by using preventive maintenance over reactive maintenance, and each dollar spent on PM saves an average of $5 later on Upkeep

- Preventive maintenance costs can be reduced by up to 25% while increasing uptime by 10% to 20% Verdantis

- Teams using CMMS report dramatically reduced unplanned downtime and enhanced operational visibility

In today’s competitive industrial landscape, the difference between market leaders and those struggling to survive often comes down to one critical factor: how well they maintain their equipment.

Here’s the reality: In the automotive sector, downtime can cost over $2.3 million per hour, a twofold increase since 2019.

That’s not a typo. Every minute critical equipment sits idle costs thousands of dollars in lost productivity, delayed orders, and frustrated customers.

Yet despite these staggering numbers, 59% of facilities spend less than half their maintenance time on preventive maintenance. They’re essentially playing Russian roulette with their operations, waiting for equipment to fail rather than preventing failures before they happen.

The good news? The solution isn’t complicated. By implementing a preventive maintenance program, organizations can greatly reduce equipment downtime.

What Makes Preventive Maintenance Different?

Preventive maintenance shifts how organizations approach equipment reliability. Instead of always waiting for machinery to break down, PM takes a proactive approach to maintenance.

At its core, preventive maintenance involves regularly scheduled inspections, servicing, and repairs designed to prevent equipment failures before they occur.

Think of it like changing your car’s oil every 5,000 miles rather than waiting for the engine to seize up. The principle is simple, but the execution requires discipline, planning, and the right tools.

The modern approach to preventive maintenance goes beyond simple time-based schedules. Today’s maintenance professionals leverage multiple strategies:

- Time-based maintenance: Scheduled at fixed intervals regardless of equipment condition

- Usage-based maintenance: Triggered by operational metrics like runtime hours or production cycles

- Condition-based maintenance: Initiated when monitoring reveals parameters outside acceptable ranges

- Predictive maintenance: Using data analytics to forecast failures before they happen

Each approach serves specific purposes, and the most successful maintenance programs combine multiple strategies based on equipment criticality, failure patterns, and available resources.

8 Real-World Examples of Preventive Maintenance in Action

Let’s dive into eight powerful examples of preventive maintenance that are delivering measurable results across industries. These aren’t theoretical concepts—they’re proven strategies that maintenance teams implement daily to keep operations running smoothly.

1. HVAC System Optimization

Your HVAC system is the unsung hero of facility operations, quietly maintaining optimal environmental conditions 24/7.

When it fails, tenants complain, productivity plummets, product quality suffers, and in some industries, entire production lines shut down.

Effective HVAC preventive maintenance includes:

- Monthly filter replacements: Dirty filters force systems to work harder, consuming up to 15% more energy while reducing equipment lifespan

- Quarterly coil cleaning: Heat transfer efficiency drops dramatically with dirty coils, leading to higher energy costs and premature compressor failure

- Semi-annual belt inspections: A snapped belt can bring down an entire system, but visual inspection takes minutes

- Annual refrigerant level checks: Low refrigerant levels strain compressors and reduce cooling capacity by up to 20%

In one study, buildings can reduce maintenance costs by 20% through proactive, predictive maintenance and analytics.

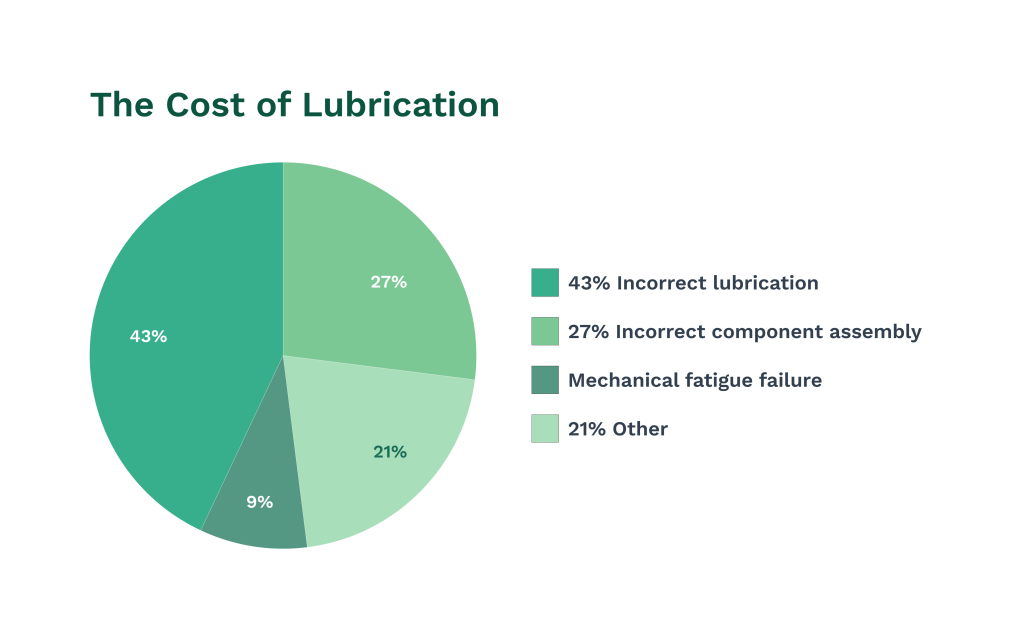

2. Manufacturing Equipment Lubrication Programs

In manufacturing environments, proper lubrication can mean the difference between smooth operations and catastrophic failure.

A single bearing failure can cascade through connected systems, causing production shutdowns that cost thousands per hour.

A comprehensive lubrication program encompasses:

- Automated lubrication systems: Deliver precise amounts of lubricant at optimal intervals, eliminating human error

- Vibration monitoring: Detect early signs of bearing wear before failure occurs

- Oil analysis programs: Identify contamination and degradation before they cause damage

- Temperature monitoring: Excessive heat indicates insufficient lubrication or impending failure

The impact can be substantial.

Organizations implementing a consistent lubrication program report a 50% reduction in bearing failures and a 35% decrease in maintenance costs.

Remember, dirt and dust can damage machinery, especially mechanical systems, leading to friction and premature wear.

3. Electrical Systems Inspection and Testing

Electrical failures don’t just cause downtime—they pose serious safety risks. From arc flash incidents to equipment damage from power surges, electrical problems can have devastating consequences.

Critical electrical preventive maintenance tasks include:

- Infrared thermography scans: Identify hot spots before they become fire hazards

- Circuit breaker testing: Ensure protective devices will function when needed

- Grounding system verification: Prevent equipment damage and protect personnel

- Power quality monitoring: Detect harmonics and voltage fluctuations that damage sensitive equipment

Manufacturing facilities implementing comprehensive electrical preventive maintenance programs report 70% fewer electrical-related incidents and significant reductions in equipment damage from power issues.

The investment in prevention pays for itself many times over in avoided catastrophes.

4. Fleet Vehicle Maintenance Scheduling

For organizations that manage fleets, breakdowns don’t just mean repair costs. It can result in missed deliveries, stranded drivers, and damaged customer relationships.

Whether managing delivery trucks, service vehicles, or heavy equipment, preventive maintenance keeps fleets rolling.

Modern fleet preventive maintenance leverages:

- Telematics-based monitoring: Real-time engine diagnostics and performance tracking

- Usage-based service intervals: Maintenance triggered by mileage, engine hours, or operating conditions

- Predictive analytics: Identify vehicles likely to fail based on historical patterns

- Mobile maintenance management: Technicians receive work orders and access service history on tablets

Companies implementing comprehensive fleet preventive maintenance programs see dramatic improvements: 45% reduction in roadside breakdowns, 30% lower maintenance costs per mile, and 25% extension in vehicle service life.

The key is moving from calendar-based service to data-driven maintenance decisions.

5. Production Line Conveyor Maintenance

Conveyors are the arteries of modern manufacturing. When they stop, everything stops.

A single conveyor failure can idle hundreds of workers and halt millions of dollars in production. That’s why leading manufacturers treat conveyor maintenance as mission-critical.

Effective conveyor preventive maintenance includes:

- Belt tension monitoring: Improper tension causes premature wear and tracking issues

- Roller bearing inspection: Failed bearings create friction, damaging belts and increasing energy consumption

- Alignment verification: Misaligned conveyors cause uneven wear and product damage

- Motor and gearbox servicing: Regular oil changes and vibration analysis prevent catastrophic failures

6. Critical Asset Vibration Analysis

Vibration tells a story about equipment health that visual inspection can’t reveal.

Rotating equipment like pumps, motors, and compressors can develop characteristic vibration signatures that change as components wear. By monitoring these changes, maintenance teams can schedule repairs before failure occurs.

Advanced vibration analysis programs incorporate:

- Baseline establishment: Document normal vibration levels for comparison

- Trend monitoring: Track changes over time to identify degradation patterns

- Spectrum analysis: Identify specific failure modes like imbalance, misalignment, or bearing wear

- Automated alerts: Notify technicians when vibration exceeds acceptable thresholds

40% of manufacturing companies employ predictive maintenance using analytics tools, with vibration analysis among the most widely adopted techniques.

Some maintenance organizations report detecting 90% of developing mechanical problems before they cause failures, dramatically reducing both downtime and repair costs.

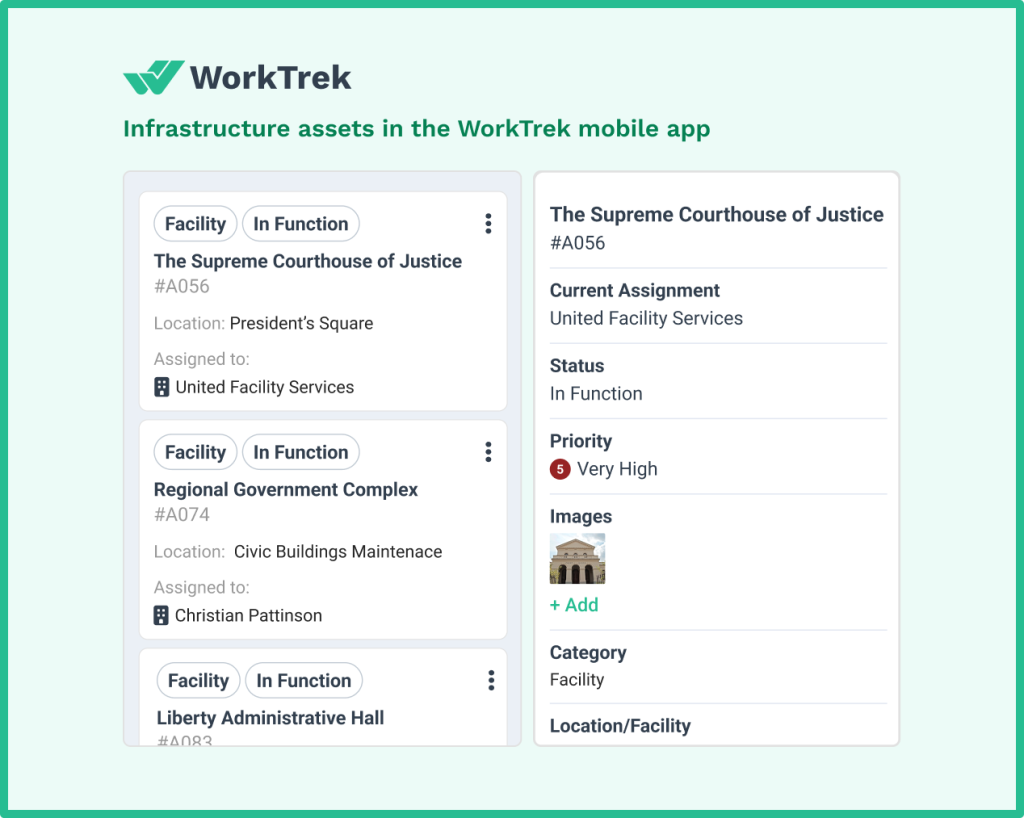

7. Building Infrastructure Maintenance

Buildings themselves require preventive maintenance to remain safe, functional, and efficient. Deferred maintenance on building systems doesn’t just create uncomfortable working conditions—it leads to exponentially higher repair costs and potential safety hazards.

Comprehensive building preventive maintenance addresses:

- Roof inspections: Identify and repair minor leaks before they cause structural damage

- Plumbing system maintenance: Prevent pipe failures that can flood facilities

- Structural inspections: Detect foundation issues, wall cracks, and other problems early

- Fire safety system testing: Ensure alarms, sprinklers, and suppression systems function properly

Industry studies show that every $1 in maintenance deferred due to budget cuts or delays can end up costing $4 in capital renewal down the line.

By proactively maintaining building infrastructure, organizations avoid emergency repairs, extend asset lifespans, and maintain safe working environments for employees.

8. Computerized Equipment Calibration

In industries where precision matters, such as pharmaceuticals, aerospace, and food processing, equipment calibration is critical.

Instruments drift over time, and uncalibrated equipment produces defective products, fails quality audits, and, in regulated industries, triggers costly compliance violations.

Modern calibration programs utilize:

- Automated scheduling: Never miss a calibration deadline

- Digital documentation: Maintain audit trails for regulatory compliance

- Predictive drift analysis: Identify instruments requiring more frequent calibration

- Mobile calibration management: Technicians complete calibrations and update records in real-time

Organizations with mature calibration programs report an 80% reduction in quality defects related to measurement errors, a 60% decrease in audit findings, and significant improvements in first-pass yield.

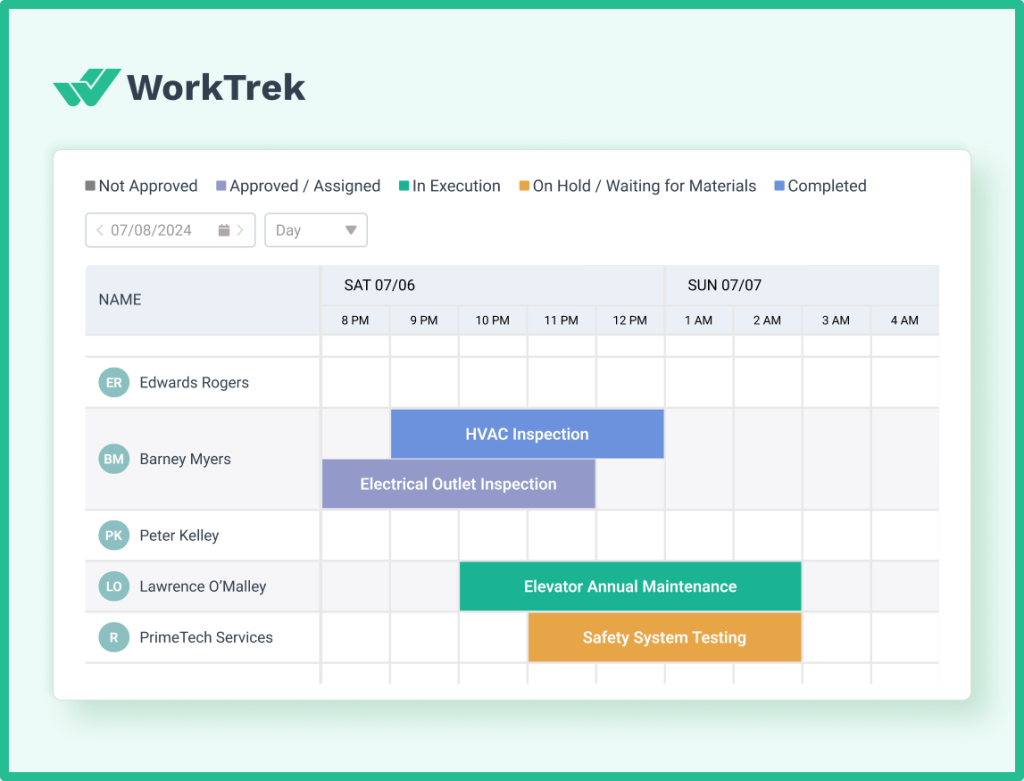

How CMMS Software Revolutionizes Preventive Maintenance Programs

The complexity of modern preventive maintenance programs demands preventive maintenance software.

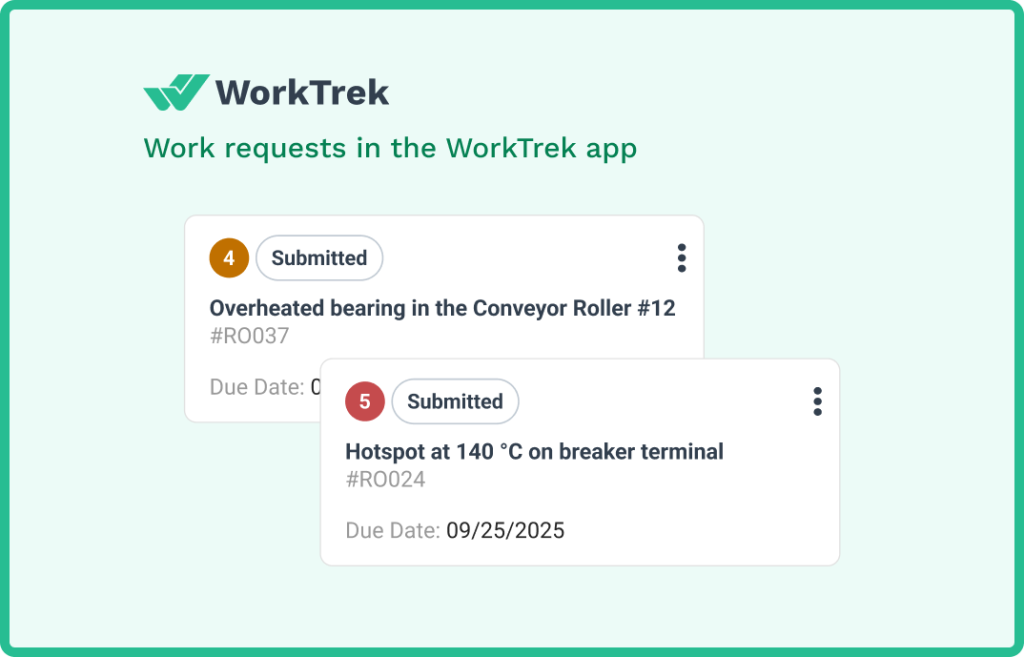

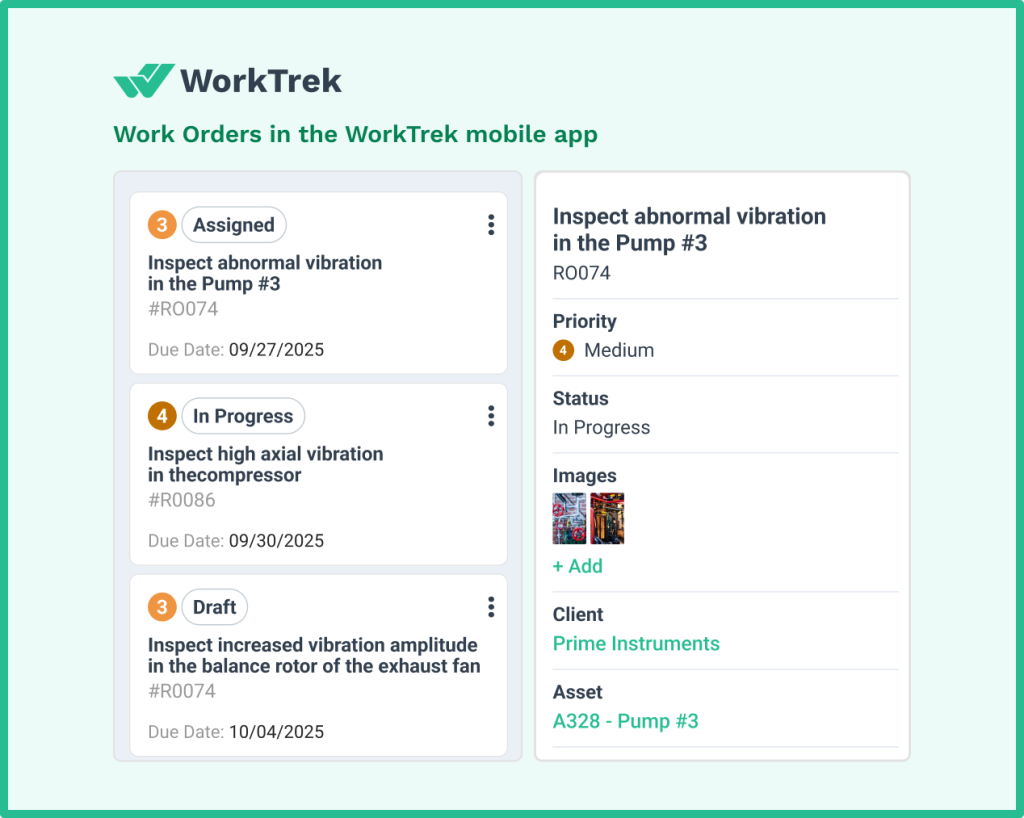

That’s where Computerized Maintenance Management Systems (CMMS) like WorkTrek become game-changers.

The CMMS Advantage

Modern CMMS platforms can transform preventive maintenance from a paper-based struggle to a streamlined, data-driven process.

Instead of juggling spreadsheets, sticky notes, and voice mails, maintenance teams gain complete visibility and control over their preventive maintenance programs.

Key capabilities that drive results:

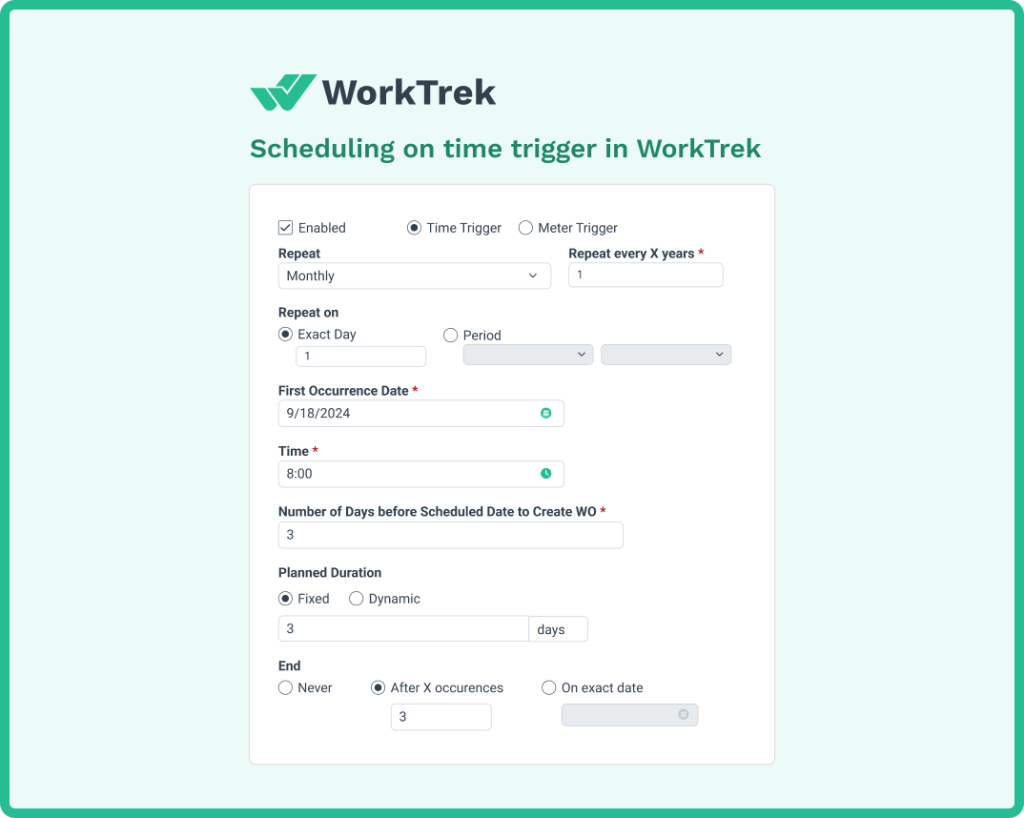

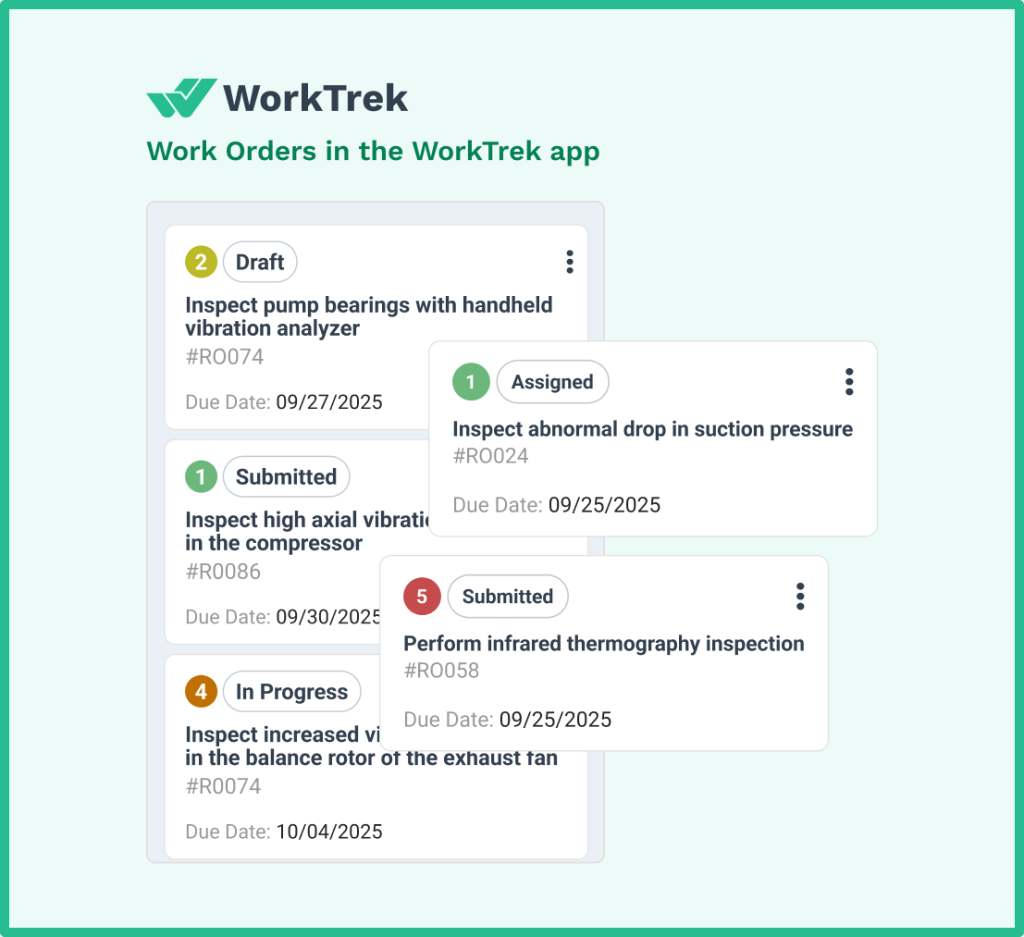

Automated Scheduling and Work Order Generation

- Eliminate missed maintenance with automatic work order creation

- Balance workloads across technicians

- Adjust schedules based on actual equipment availability

- Track compliance with regulatory requirements

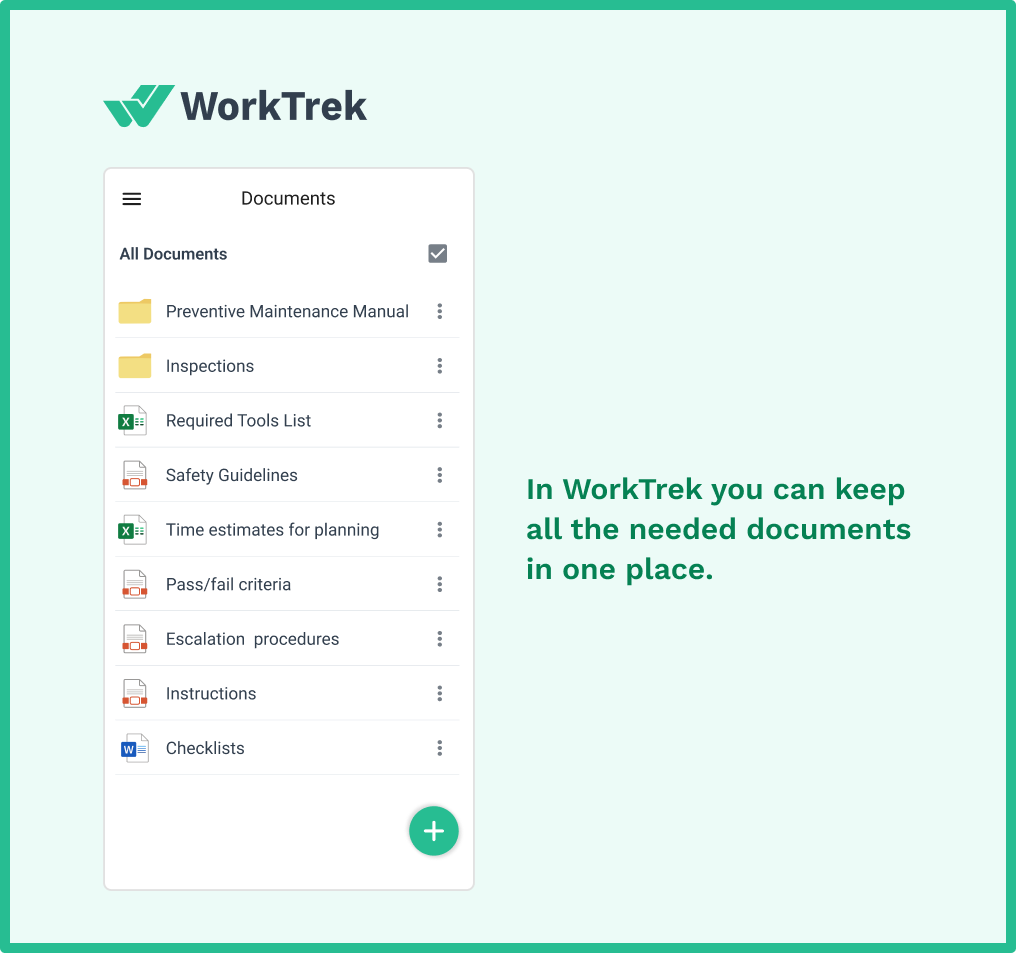

Real-Time Asset History and Documentation

- Access complete maintenance history instantly

- Review past repairs to identify recurring issues

- Store manuals, diagrams, and procedures digitally

- Track warranty information and service contracts

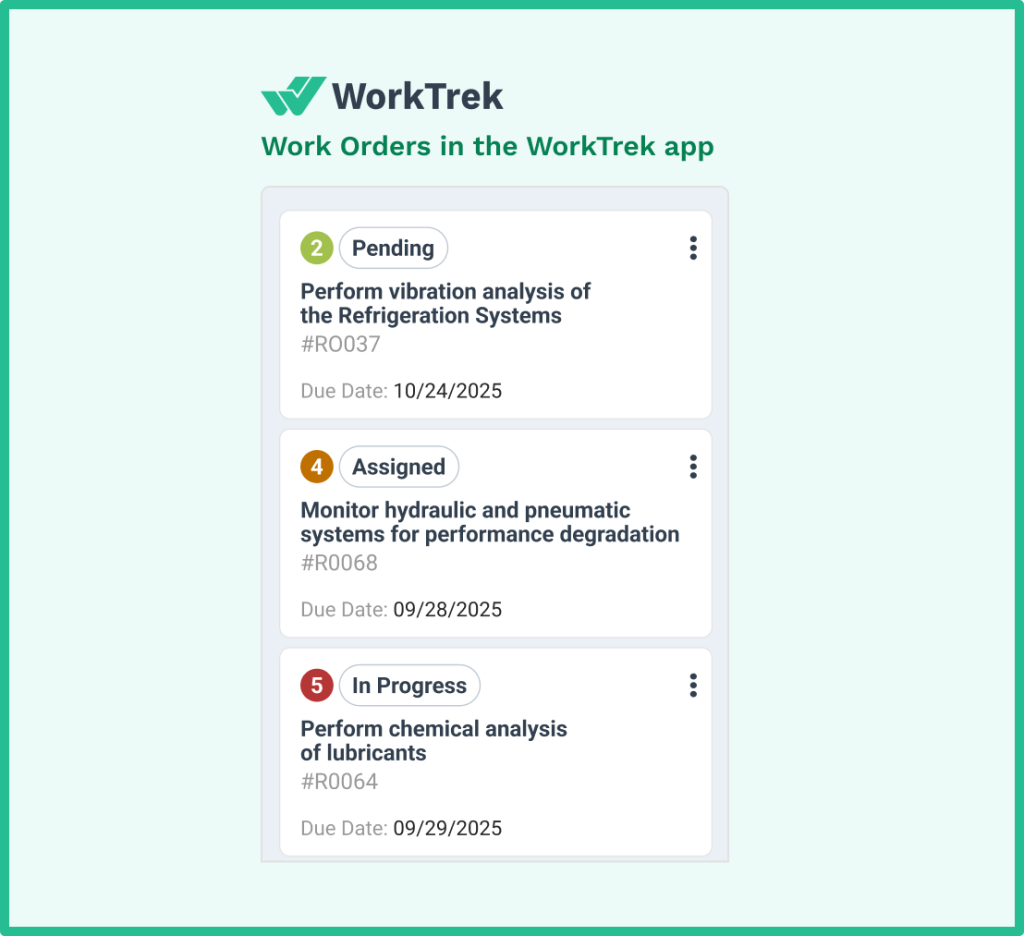

Mobile Accessibility

- Around 80% of maintenance techs now use mobile devices or tablets to receive and update work orders

- Complete work orders in the field

- Access procedures and documentation on-site

- Upload photos and notes in real-time

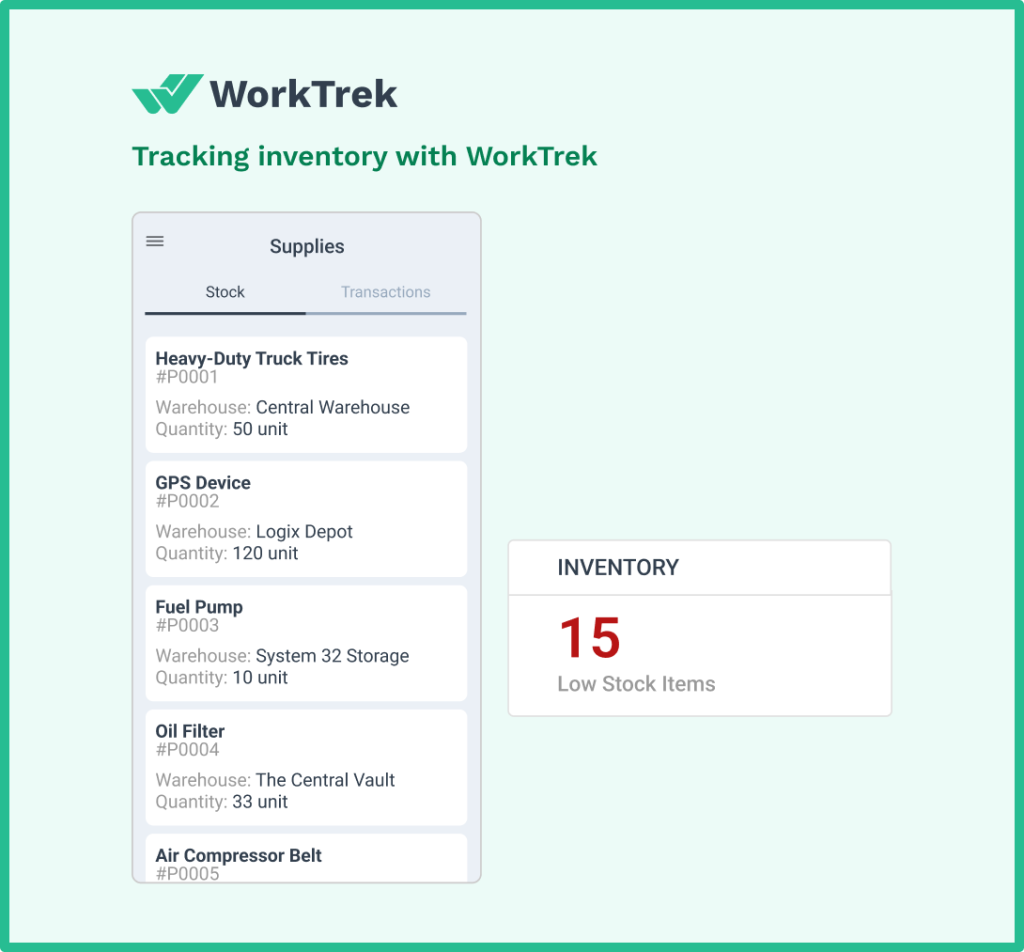

Inventory Management Integration

- Link parts to preventive maintenance tasks

- Automate reordering when stock levels drop

- Track part usage and costs by asset

- Prevent stockouts that delay maintenance

Why WorkTrek Stands Above the Rest

While many CMMS solutions exist, WorkTrek distinguishes itself through an unmatched combination of power, simplicity, and results. Built by maintenance professionals for maintenance professionals, WorkTrek understands the real-world challenges teams face daily.

Intuitive Design That Teams Actually Use

The best CMMS in the world is worthless if your team won’t use it. WorkTrek’s interface is so intuitive that technicians adopt it enthusiastically, not reluctantly. No more fighting with complicated software or reverting to paper—WorkTrek makes doing the job easier, not harder.

Comprehensive Preventive Maintenance Capabilities

WorkTrek handles every aspect of preventive maintenance programs:

- Multiple trigger types (time, usage, condition, or predictive)

- Sophisticated scheduling algorithms that prevent conflicts

- Automatic escalation for overdue tasks

- Complete regulatory compliance tracking

Powerful Analytics That Drive Improvement

Data without insight is just noise. WorkTrek transforms raw maintenance data into actionable intelligence:

- Track preventive maintenance compliance rates

- Identify assets consuming excessive resources

- Measure mean time between failures (MTBF)

- Calculate return on investment for PM programs

- Spot trends before they become problems

Seamless Integration Capabilities

WorkTrek doesn’t exist in isolation—it integrates with your existing systems:

- IoT sensors for condition monitoring

- ERP systems for financial tracking

- Building automation systems

- Telematics platforms for fleet management

Proven Results Across Industries

Organizations using WorkTrek report transformative results:

- 47% reduction in emergency maintenance

- 38% increase in equipment availability

- 52% improvement in preventive maintenance compliance

- 41% decrease in maintenance costs

- 3.2x return on investment within 12 months

Every feature, every update, every design decision focuses on one goal: making maintenance professionals more effective at protecting their organizations’ critical assets.

How to Implement a Preventive Maintenance Strategy

Successful preventive maintenance implementation requires more than good intentions—it demands systematic planning, stakeholder buy-in, and sustained execution. Here’s how leading organizations transform their maintenance operations.

Start with Asset Criticality Analysis

Not all equipment deserves equal attention. Focus initial efforts on assets where failure causes the most pain:

- Production bottlenecks

- Safety-critical equipment

- Assets with high repair costs

- Equipment lacking redundancy

By prioritizing critical assets, you demonstrate quick wins that build momentum for broader implementation.

Develop Comprehensive Maintenance Procedures

Vague instructions lead to inconsistent results. Effective preventive maintenance procedures include:

- Step-by-step task instructions

- Required tools and parts

- Safety precautions

- Acceptance criteria

- Time estimates

WorkTrek’s procedure templates accelerate this process, providing industry-standard procedures you can customize for your specific equipment.

Establish Realistic Schedules

Over-aggressive preventive maintenance schedules overwhelm teams and create backlash. Start conservatively, then optimize based on data:

- Begin with manufacturer recommendations

- Adjust based on operating conditions

- Monitor failure patterns

- Refine intervals using historical data

Train and Empower Your Team

Technology alone doesn’t solve problems—people do. Invest in comprehensive training:

- CMMS functionality and workflows

- Preventive maintenance principles

- Condition monitoring techniques

- Root cause analysis

- Safety procedures

When teams understand the “why” behind preventive maintenance, compliance and quality improve dramatically.

Measure and Optimize Continuously

Preventive maintenance programs aren’t set-and-forget. Continuous improvement drives long-term success:

- Track key performance indicators religiously

- Analyze failure data to identify gaps

- Adjust PM intervals based on results

- Celebrate successes publicly

- Learn from failures without blame

Organizations committed to continuous improvement see their preventive maintenance programs deliver increasing value year after year.

The Future of Preventive Maintenance

The preventive maintenance landscape continues evolving rapidly, driven by technological advances and changing business demands.

Artificial Intelligence and Machine Learning

39% of maintenance leaders say they see knowledge capture and sharing as the most valuable use case for AI in maintenance, followed by reducing unexpected equipment failure (36%). AI transforms preventive maintenance by:

- Optimizing PM schedules automatically

- Identifying patterns humans miss

- Predicting failures with unprecedented accuracy

- Recommending corrective actions

- Learning from every maintenance event

Internet of Things (IoT) Expansion

Industrial IoT is projected to generate $800 billion in economic value by 2024.

Falling sensor costs and improved connectivity enable:

- Real-time condition monitoring for all assets

- Automatic work order generation from sensor data

- Remote diagnosis and support

- Energy optimization

- Predictive analytics at scale

Augmented Reality Support

49% of businesses see maintenance automation as the top benefit of AR technology.

AR applications include:

- Visual work instructions overlaid on equipment

- Remote expert assistance

- Training simulations

- Digital twin visualization

- Safety hazard identification

Sustainability Integration

Environmental considerations increasingly drive maintenance decisions:

- Energy efficiency optimization

- Circular economy principles

- Carbon footprint reduction

- Sustainable material selection

- Waste minimization

Organizations leading in sustainable maintenance gain a competitive advantage through lower costs and an enhanced reputation.

Getting Started with Preventive Maintenance

Ready to transform your maintenance operations? Here’s your roadmap to success:

Week 1-2: Assessment and Planning

- Evaluate current maintenance practices

- Identify critical assets

- Calculate current downtime costs

- Define success metrics

- Secure stakeholder buy-in

Week 3-4: Technology Selection

- Evaluate CMMS options

- Request demonstrations

- Check references

- Calculate ROI

- Make selection decision

Month 2: Implementation Preparation

- Develop an implementation plan

- Create asset hierarchy

- Define PM procedures

- Establish schedules

- Train the core team

Month 3: Pilot Program

- Launch with critical assets

- Monitor closely

- Gather feedback

- Refine processes

- Document lessons learned

Month 4-6: Full Rollout

- Expand systematically

- Continue training

- Monitor KPIs

- Optimize continuously

- Celebrate successes

Conclusion

The evidence cannot be ignored: preventive maintenance transforms organizations.

With dramatic cost reductions to improved safety, extended asset life, and enhanced reputation, the benefits touch every aspect of operations.

Yet despite clear advantages, many organizations still struggle with implementation. They’re overwhelmed by complexity, constrained by resources, or stuck in reactive patterns.

Don’t wait for the next breakdown to convince you. Start your preventive maintenance transformation today with WorkTrek, and discover what it feels like to be in control of your maintenance operations rather than at their mercy.

The future belongs to organizations that proactively maintain their assets. Will yours be among them?