Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- TPM is a culture shift where everyone is responsible for equipment care and maintenance.

- Initial TPM costs for training and setup are offset by reductions in expensive unplanned downtime and defects.

- CMMS is a powerful tool that can support the implementation of TPM.

As you probably know first-hand, unexpected equipment breakdowns are incredibly expensive and frustrating for your operations.

The cause?

More often than not, machines aren’t getting consistent care from everyone, and maintenance crews wait for something to go wrong before they step in.

If this sounds familiar, this guide is for you.

In it, we’ll explore total productive maintenance (TPM): a team-based strategy that can help you work toward zero breakdowns and maximum efficiency.

What is Total Productive Maintenance (TPM)?

At its core, TPM is a strategy that gets everyone in a company, from the factory floor to the management office, involved in equipment maintenance.

It originated in Japan in the 1970s as a comprehensive way to improve manufacturing operations.

Seiichi Nakajima, the father of TPM, defines it in his foundational book, Introduction to TPM, in the following way:

Nakajima’s idea was so powerful because it used the established American preventive maintenance practices of fixing small problems before they turn into big, expensive breakdowns.

He then combined this with the Japanese philosophy that quality isn’t just one department’s job, and machine care isn’t just the maintenance crew’s job.

Instead, it is everyone’s responsibility, from the operator running the machine to the manager creating the schedule.

This team-based approach has a few specific goals, outlined below.

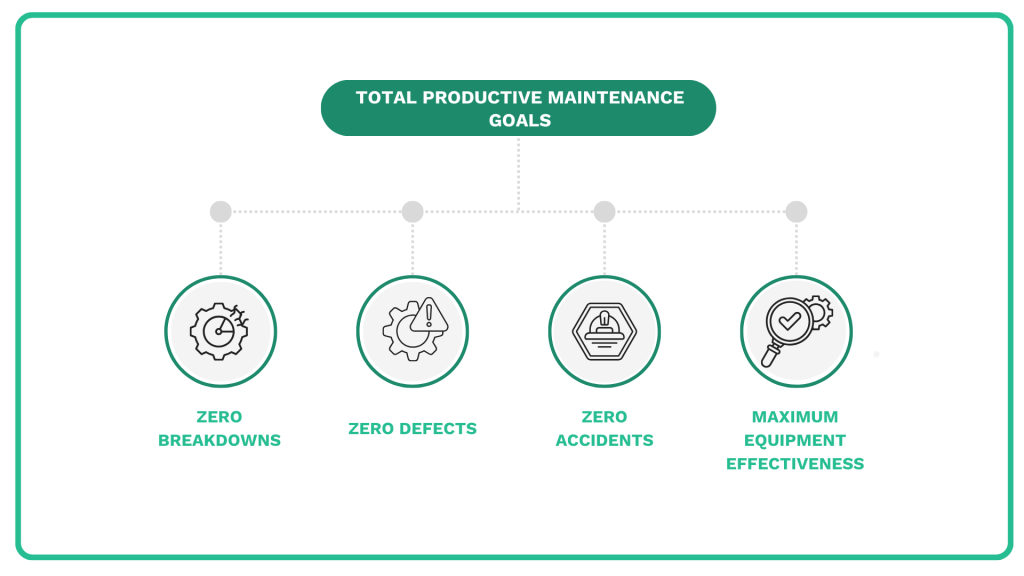

The central aim of TPM is to build an operation with zero unexpected breakdowns and machine-caused defects.

This is obviously a very ambitious target, and “zero” might not be 100% achievable all the time, but the TPM process is designed to get you incredibly close.

And it’s not just about the machines, either.

A critical part of the “total” concept is aiming for zero worker accidents, too.

After all, a clean, well-organized, and properly functioning machine is a much safer machine to be around.

And, when you successfully reduce breakdowns, defects, and safety incidents, the natural result is that your equipment is utilized to its maximum potential.

To summarize, the TPM philosophy aims to create a complete cultural shift where everyone in the organization takes ownership of equipment reliability.

The ultimate goal is achieving as close to perfect production as possible.

What Are the Pillars of TPM?

So, how do you actually achieve those big goals we just talked about?

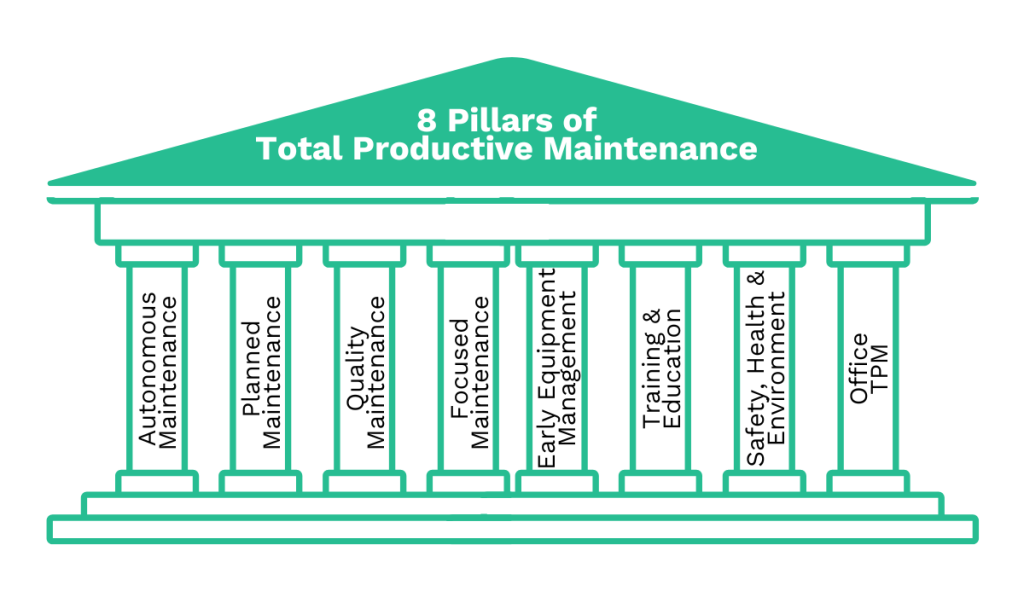

To explore that, we need to look at the eight foundational pillars of total productive maintenance.

The most well-known pillar is Autonomous Maintenance.

This is where you empower machine operators, not just maintenance teams, to handle daily cleaning, inspection, and lubrication for their own equipment.

As a result, maintenance teams have more time for Planned Maintenance instead of tackling routine tasks, and resources are saved for Focused Improvement, where cross-functional teams improve overall equipment operations.

To tackle product defects, the Quality Maintenance pillar embeds quality checks and error-proofing into the production process, aiming to stop defects.

TPM also looks to the future with Early Equipment Management, which uses all maintenance knowledge to help design and install new machines that are reliable and easy to maintain from the very first day.

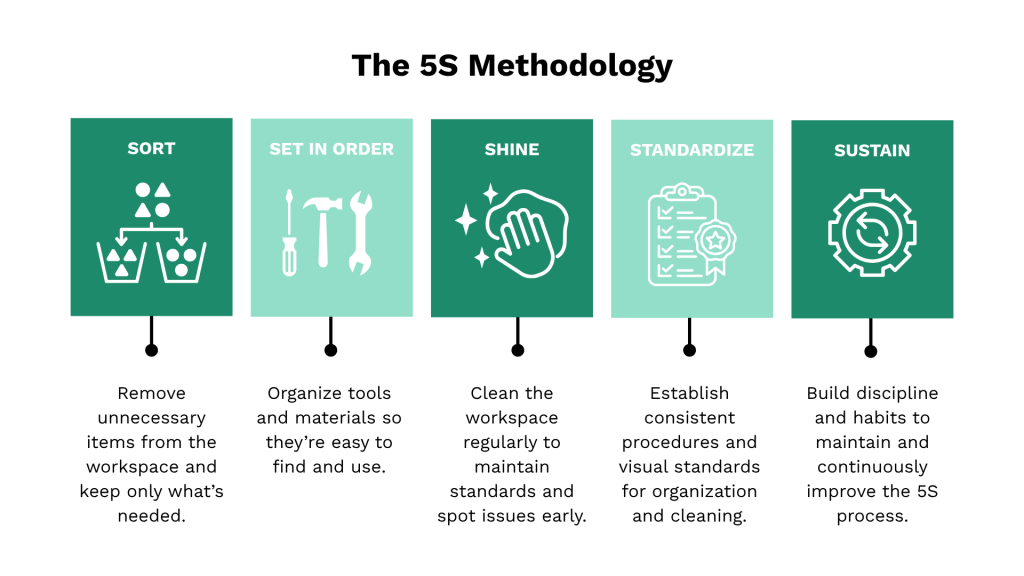

It’s important to note that the above activities can only be implemented with strong Training and Education, especially in the 5S methodology for organizing the work environment.

You can see the breakdown of the 5S steps in the image below.

Simply put, the goal of the 5S methodology is to create a decluttered, organized, and clean work environment, with a set of standardized rules that are followed consistently.

All the pillars, but especially the Autonomous Maintenance one, are built on this 5S foundation.

Of course, we can’t forget the Safety, Health, and Environment pillar, which ensures that all these TPM practices are performed in a way that protects both the workers and the planet.

Last but not least, the Administration pillar takes these same principles and applies them even to office and support functions for a truly unified approach.

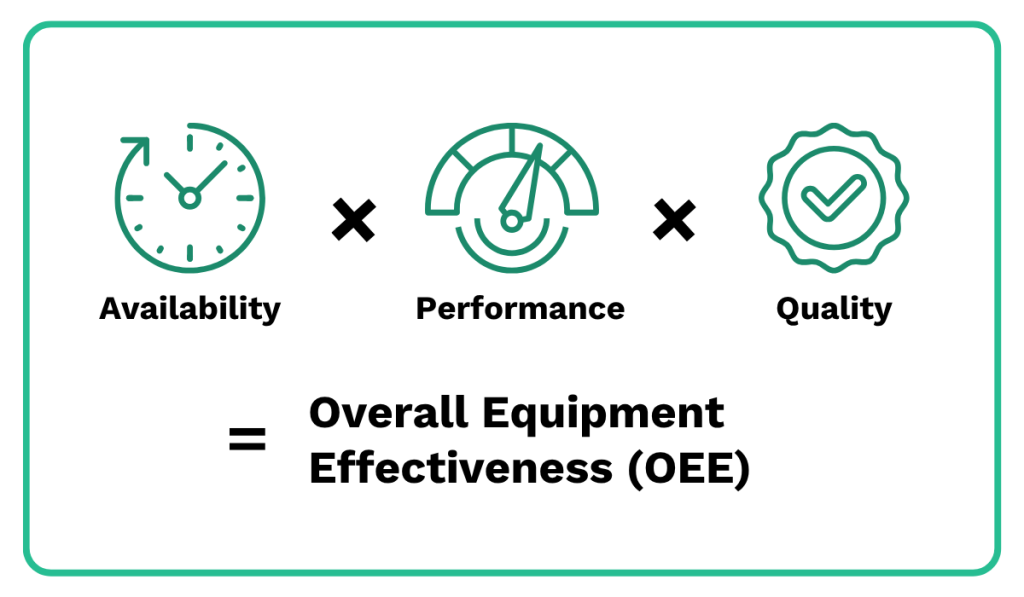

In essence, these eight pillars are all interconnected and work together to improve a very critical metric: Overall Equipment Effectiveness (OEE).

This is the gold standard for measuring manufacturing productivity, which is calculated by taking into consideration the equipment availability and performance, along with production quality.

While we won’t do a deep dive in this guide, the connection between TPM and this metric is clear.

For example, Autonomous Maintenance and Planned Maintenance directly address breakdowns, which boosts equipment availability and production quality.

On the other hand, the Focused Improvement pillar continuously improves equipment, which in turn improves all OEE elements.

In short, think of the pillars and the 5S steps as the action plan and OEE as the scorecard.

Together, they create a complete system for operational improvement.

Benefits of Total Productive Maintenance

Now that we’ve covered the “what” and the “how” of TPM, it’s time to get to the “why.”

Committing to what is essentially a culture shift can bring significant benefits to your facility, especially for your bottom line and your team’s engagement.

Let’s go over some of these key benefits of total productive maintenance.

Increased Equipment Uptime

One of the most immediate and impactful results you’ll see from implementing TPM is maximizing your equipment uptime.

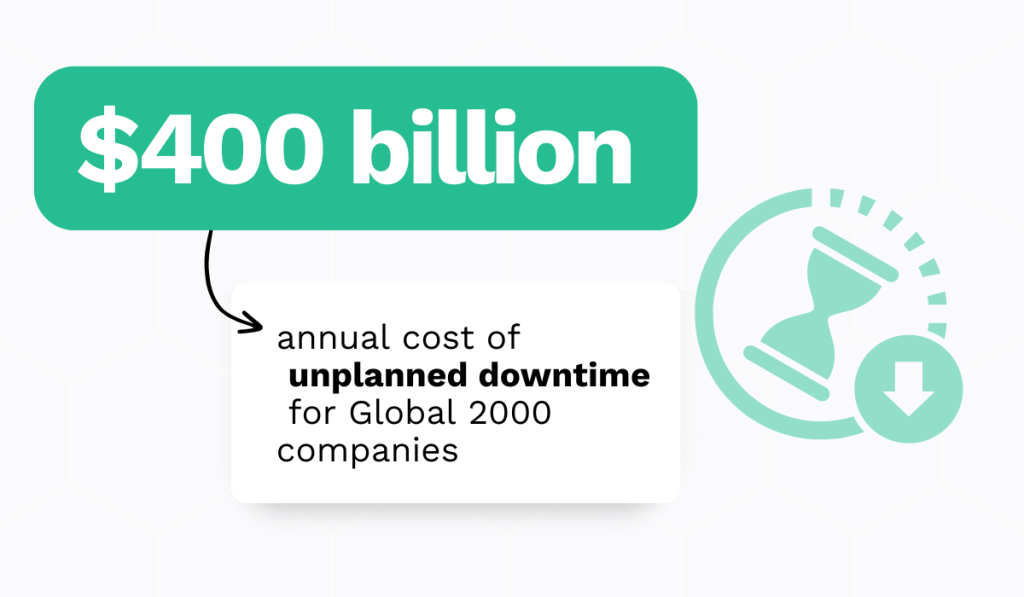

This is key, especially since unplanned downtime really hurts revenue.

A report from Splunk and Oxford Economics estimated that the annual cost of downtime for the Global 2000 companies is a staggering $400 billion.

This shouldn’t come as a surprise.

Just imagine what it costs major players like Toyota, Samsung Electronics, or General Electric when one of their massive production lines suddenly grinds to a halt for even an hour.

Even in smaller organizations, many still rely on the run-to-failure approach, which just means they wait for a machine to break down, and then scramble to fix it.

TPM stands in clear contrast, focusing on proactive and preventive maintenance.

Operators and maintenance teams work together to detect early signs of wear, contamination, or inefficiency before they can cause a breakdown.

By establishing routine inspections and general maintenance schedules, machines spend more time in productive use and less time waiting for repair.

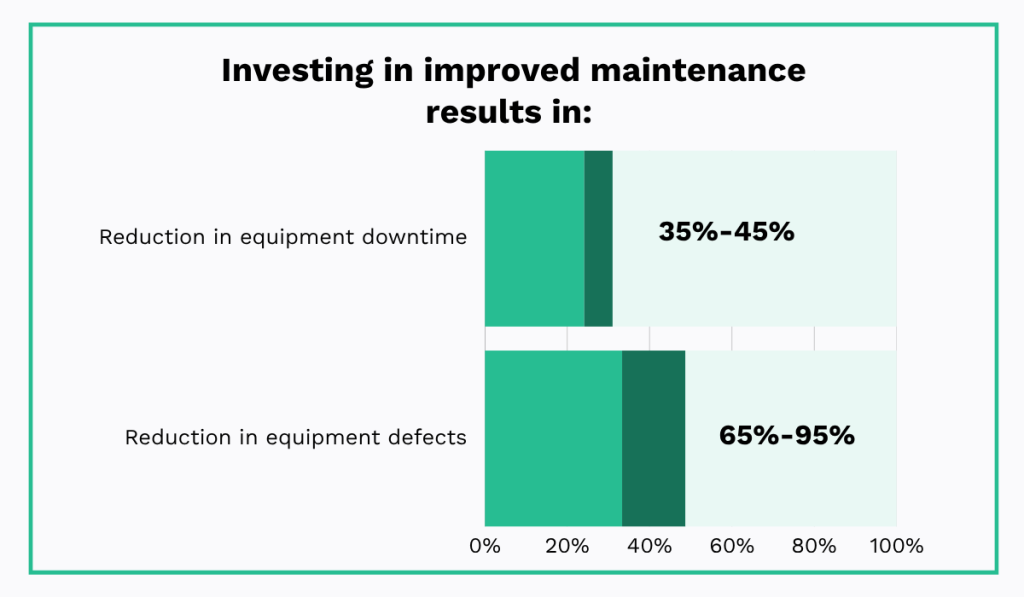

And there are some great numbers to back this up.

For instance, data from the National Institute of Standards and Technology shows that investing in maintenance improvements greatly reduces both downtime and product defects.

What’s important is that even if you just start small, the benefits from good TPM practices add up.

Over time, this leads to a measurable, significant reduction in unplanned downtime and frustrating production delays.

Reduced Maintenance Costs

With TPM, all employees share maintenance responsibilities and take more ownership over their equipment.

So it’s no surprise that this leads to healthier, more reliable machines.

Consequently, this can dramatically reduce maintenance costs, especially those that come with major breakages after it’s already too late.

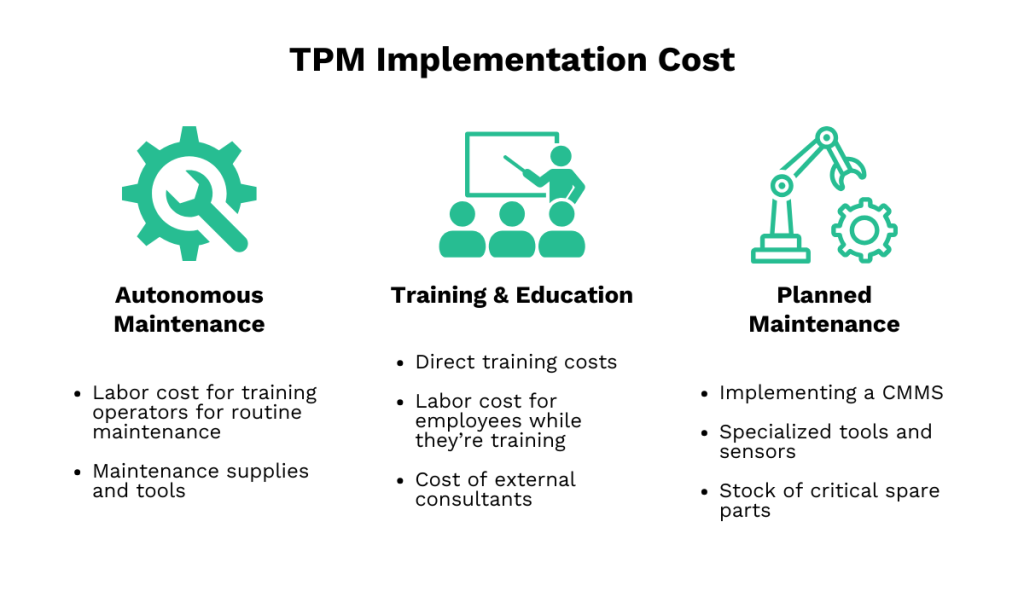

Now, that’s not to say that implementing TPM is free.

It definitely requires an initial investment, as illustrated in the image below.

While training your teams and establishing new systems and procedures represent the main costs, this investment delivers long-term returns.

For starters, the TPM approach can greatly reduce the frequency of expensive emergency repairs.

On top of that, with equipment condition more closely monitored and maintained, you can safely cut down on the need to keep a large, costly inventory of spare parts “just in case.”

Not to mention that efficient equipment also consumes less energy and has less wear, further reducing your operational expenses.

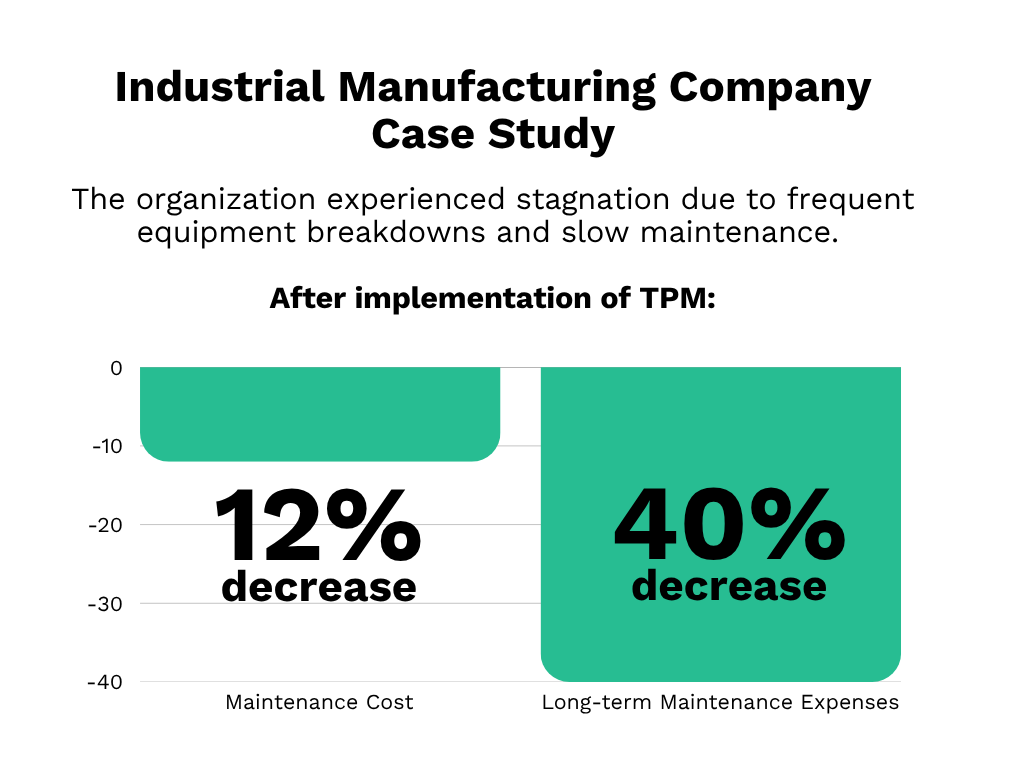

As the following case study of an industrial manufacturing company illustrates, these benefits and the cost savings add up.

As Flevy’s analysis highlights, the greatest cost savings come from the preventive and proactive nature of TPM.

This is especially true when it’s supported by modern predictive maintenance technologies that help catch issues before they escalate.

Overall, the money you save from fewer breakdowns and less wasted resources goes directly back to your bottom line.

Enhanced Employee Engagement

Another one of the biggest benefits of TPM is what it does for teams.

The entire philosophy is built on the idea that maintenance is everyone’s responsibility, not just a task for the maintenance department.

Now, you might see some resistance at first.

Operators may feel like they’re just being asked to do more work, or that they don’t have the necessary skills.

But with consistent training, employees gradually embrace their new roles, and the benefits soon become clear to everyone.

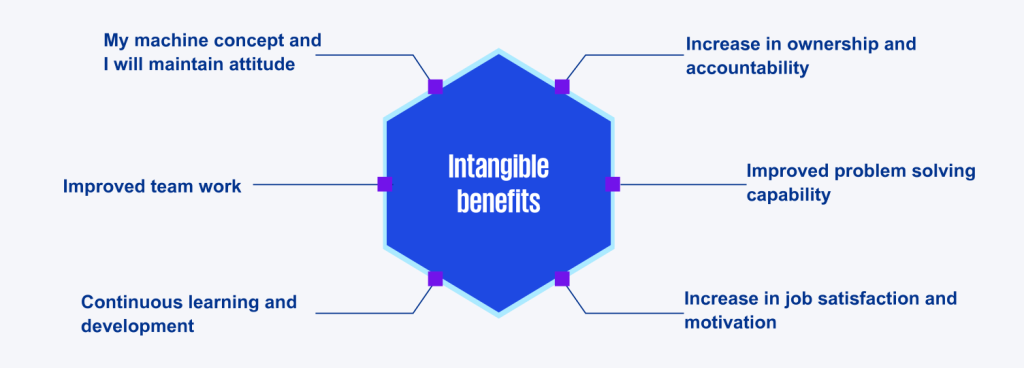

While we’ve talked about the concrete gains in terms of cost and downtime reduction, there are also some key intangible benefits that employees experience.

By involving operators in basic maintenance and continuous improvement projects, they gain a real sense of ownership over their equipment.

This inclusion naturally boosts accountability and gives operators more pride in their work.

Plus, the collaboration between production and maintenance teams improves dramatically.

Why?

Because they are finally working together toward the same goal—equipment reliability—instead of just blaming each other when a machine breaks down.

Becky Boleratz, a TPM Coordinator for Plastek’s Spectrum Molding Division, explains this shift in morale:

Instead of just being a manual laborer, the operator becomes a true partner in the machine’s health and performance.

This shift away from reactive maintenance crews to a proactive, team-based culture is one of the most valuable, long-lasting benefits of any TPM program.

How CMMS Enables TPM

The good news is that you don’t have to manage all of this using paper forms and spreadsheets.

There are plenty of tools and systems out there that can help your organization implement TPM quickly and effectively.

One of these, and arguably the most important, is a Computerized Maintenance Management System.

Tony Leombruno, a TPM champion at Ardagh Group, a global leader in metal and glass packaging, agrees.

He elaborates that for any modern maintenance strategy, a CMMS is a necessity.

It serves as the central hub for organizing all your maintenance information, scheduling tasks, and helping steer your efforts based on real data rather than guesswork.

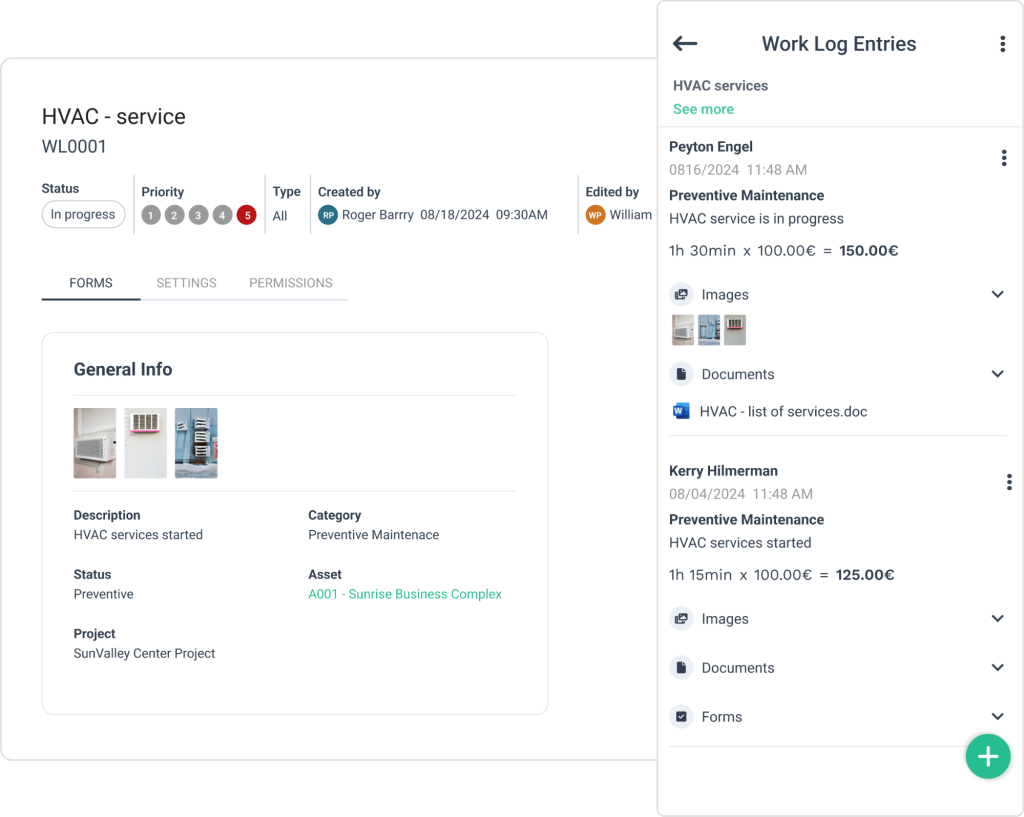

Take WorkTrek, for example.

WorkTrek is a CMMS platform designed to simplify maintenance workflows and make it easy for frontline teams to log and manage equipment issues directly from their mobile devices.

A tool like this is critical for enabling TPM, as it allows operators to instantly log inspection results or create a work order the moment they spot an issue.

This streamlines communication so nothing gets lost, and it gives maintenance teams a clear, prioritized to-do list.

Managers also gain real-time visibility into machine uptime, repair history, and downtime causes, making it that much easier to track OEE and identify chronic losses.

In short, with a CMMS like WorkTrek, you can bring the TPM philosophy to life through a digital platform that helps you plan, execute, and improve every part of your maintenance program.

Conclusion

That wraps up our quick guide to TPM.

We covered everything from the basic definitions and pillars to the real-world benefits, and even how CMMS systems can support your efforts.

Hopefully, you now see how TPM is a well-rounded system for improving your equipment reliability and overall maintenance operations.

If you’re still wondering whether TPM is the right fit for your organization, start simple: train a few operators on one machine and watch the benefits unfold.