Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- A healthy backlog is essential for maximizing maintenance labor productivity, but it requires active management.

- Reactive maintenance rapidly inflates the maintenance backlog.

- 27 days of downtime per year are due to planned or unplanned maintenance activities.

- The cost of an hour of unplanned downtime has doubled in the last five years.

Is your team constantly pulled from planned maintenance to deal with urgent breakdowns?

This struggle is often a symptom of a growing and disorganized maintenance backlog.

While backlogs are unavoidable and often a necessary part of the job, leaving pending work unmanaged can directly jeopardize operations.

In this article, we’ll break down what a maintenance backlog is, why it grows, and some of the risks it poses if left unchecked.

What Is a Maintenance Backlog?

Let’s start by defining exactly what a maintenance backlog is.

Like any other backlog, a maintenance backlog is simply a list of all outstanding maintenance tasks.

It includes all necessary repair, preventive, and predictive work that has been identified but not yet completed.

Essentially, this is work you know about, but your team hasn’t started or perhaps hasn’t even scheduled it yet.

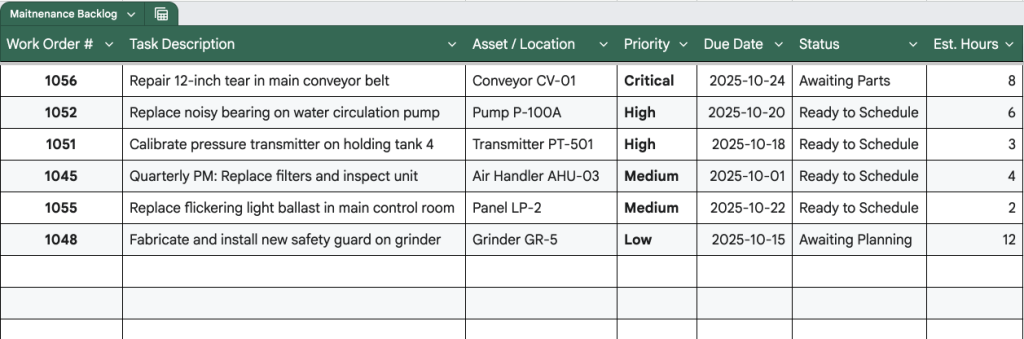

To visualize how these tasks can be organized, take a look at the example below.

Of course, the specific way a backlog is tracked can vary.

Some teams use simple spreadsheets like the one shown above, while others rely on modern computerized maintenance management systems (CMMS).

Regardless of the tool, the basics are the same.

A backlog is typically calculated in man-hours, the total estimated labor hours required to complete all listed tasks.

However, keep in mind that having a backlog is not automatically a bad thing.

A healthy, well-managed backlog is actually a useful tool, as it helps you prioritize important jobs and plan your team’s workload effectively.

But major issues can arise when this backlog becomes too large and grows uncontrollably.

What Causes Maintenance Backlogs?

Now, it’s time to dig into why maintenance backlogs tend to grow.

There are several common culprits, often working together to create an ever-increasing list of tasks.

Lack of Resources

Balancing the resources available for maintenance work is the biggest factor contributing to a growing backlog.

When a facility operates with limited staffing, it becomes difficult to address maintenance tasks as they arise.

This inevitably causes work to pile up, ultimately adding to the backlog.

Furthermore, a lack of physical resources, such as essential spare parts, or long delivery times for specialized components, can also stall planned work.

This forces teams to delay repairs even when labor is available.

Owe Forsberg, VP of consulting services at IDCON, a company specializing in reliability and maintenance consulting, emphasizes the challenge of effectively managing this aspect.

He elaborates that maintenance teams need to plan long-term resource demands meticulously.

This includes accurate time estimates for tasks, realistic staffing estimates, and proper scheduling.

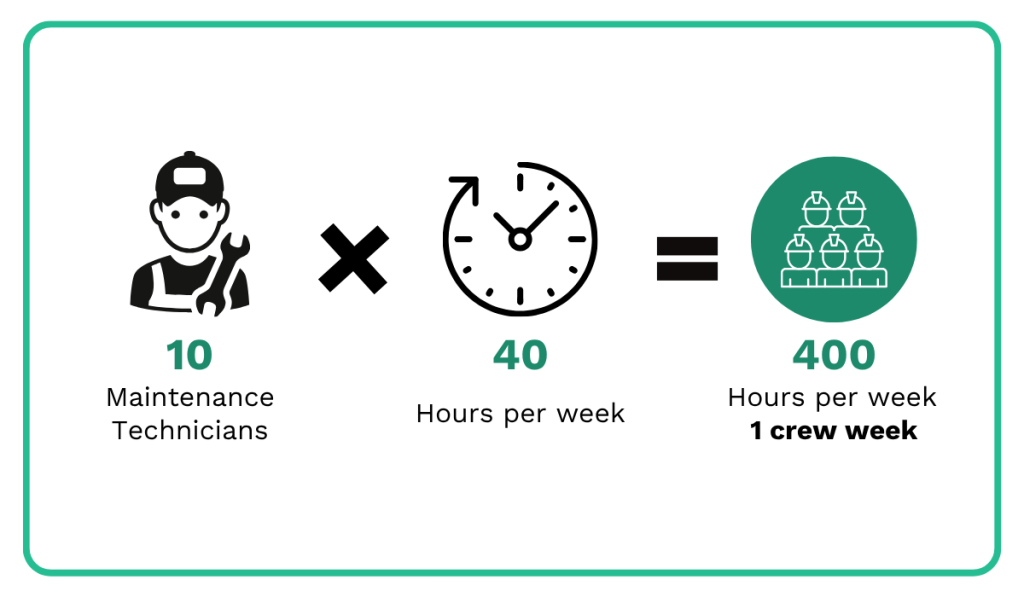

Calculating and planning are key here, even with simple metrics like crew weeks, i.e., the total available labor hours for maintenance in a given week.

For instance, a team of 10 workers, each working 40 hours a week, has 400 available hours, which equals one crew week of capacity.

In general, it’s recommended to maintain a backlog of about 2-4 crew weeks.

If your backlog consistently exceeds this range, it’s usually a clear indicator that resources are insufficient or poorly utilized, leading to an expanding list of overdue work.

Ultimately, addressing this can mean re-evaluating staffing, improving planning, or securing additional budget, but it’s essential for reducing backlogs.

Overly Reactive Approach to Maintenance

A persistent lack of resources, combined with poor planning, often forces maintenance teams to adopt an overly reactive approach.

This means less preventive work gets done, leaving teams constantly responding to failures as they happen.

This is commonly referred to as run-to-failure maintenance, in which equipment is used until it fails, and maintenance is performed only then.

The ideal, however, is to shift towards greater proactivity and less reactivity.

According to reliability expert Ricky Smith, the goal should be zero-backlog maintenance, where more than 80% of maintenance work is proactive.

He explains that the main focus should always be on preventing issues before they occur.

He goes on to explain that a proactive approach includes a mix of preventive, detective, and predictive technologies to spot problems before they become critical failures.

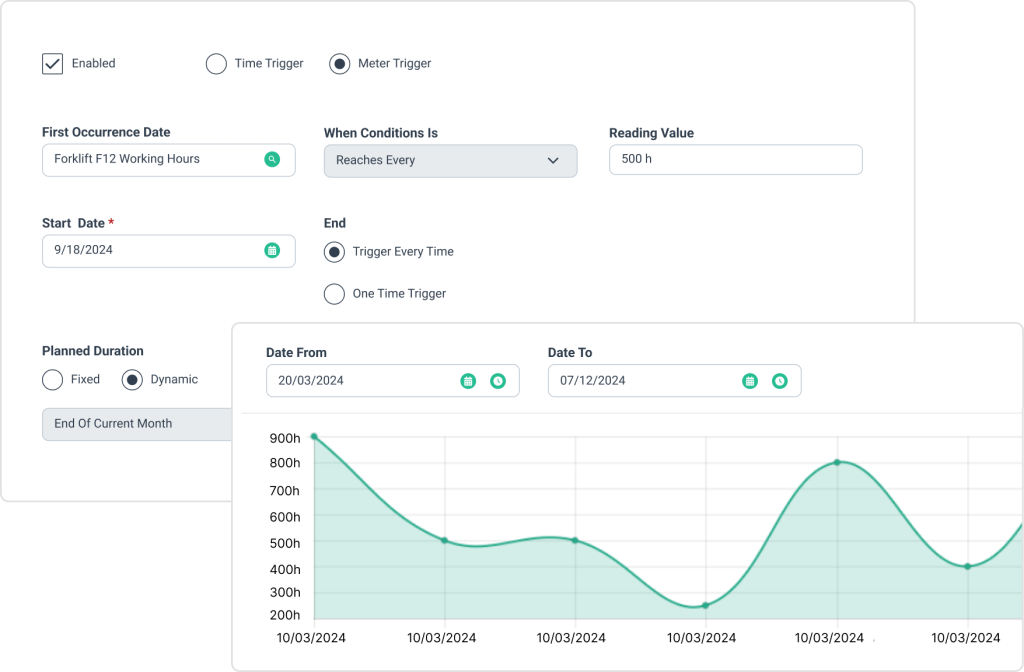

A major part of being proactive is basing maintenance work on actual equipment conditions, often using automated reminders facilitated by a software solution.

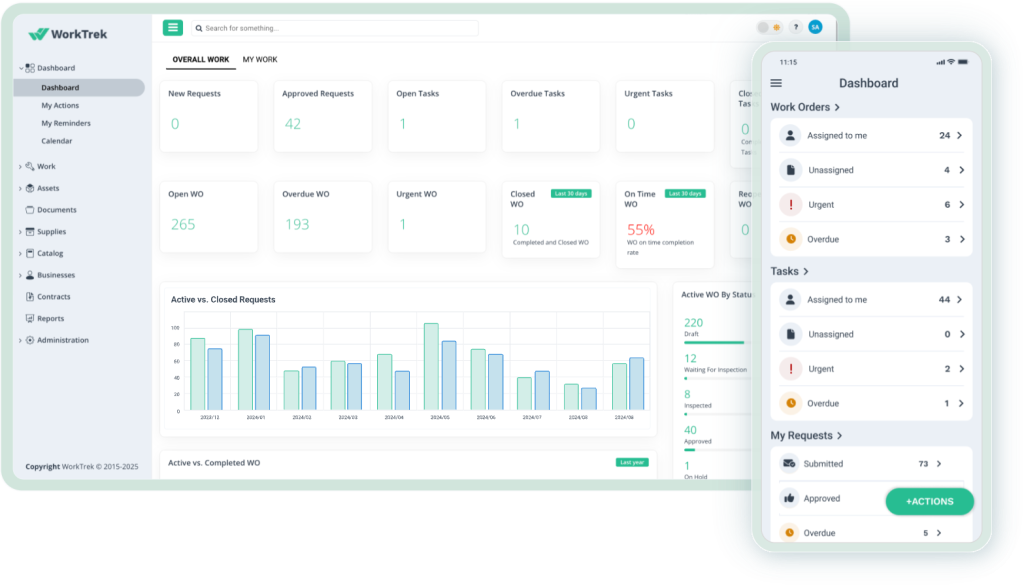

For instance, modern CMMS solutions like WorkTrek are designed specifically for this purpose.

Beyond its powerful functionalities for tracking and managing your maintenance backlog, you can set up automations and notifications to streamline your work.

These can be triggers that activate after a piece of equipment has run for a set number of hours, or for specific meter readings.

When a piece of equipment triggers its preset threshold, the system can automatically generate a work order and add it to the schedule.

This proactive approach saves significant resources by eliminating the need for constant manual checking.

Most importantly, it provides consistency and ensures critical maintenance is done before a failure occurs, directly preventing the emergency breakdowns that build up your backlog.

Aging Equipment

The causes of maintenance backlogs extend beyond just poor planning or reactive practices.

The physical equipment itself often plays a major role, especially when you are dealing with aging machinery that naturally depreciates over time.

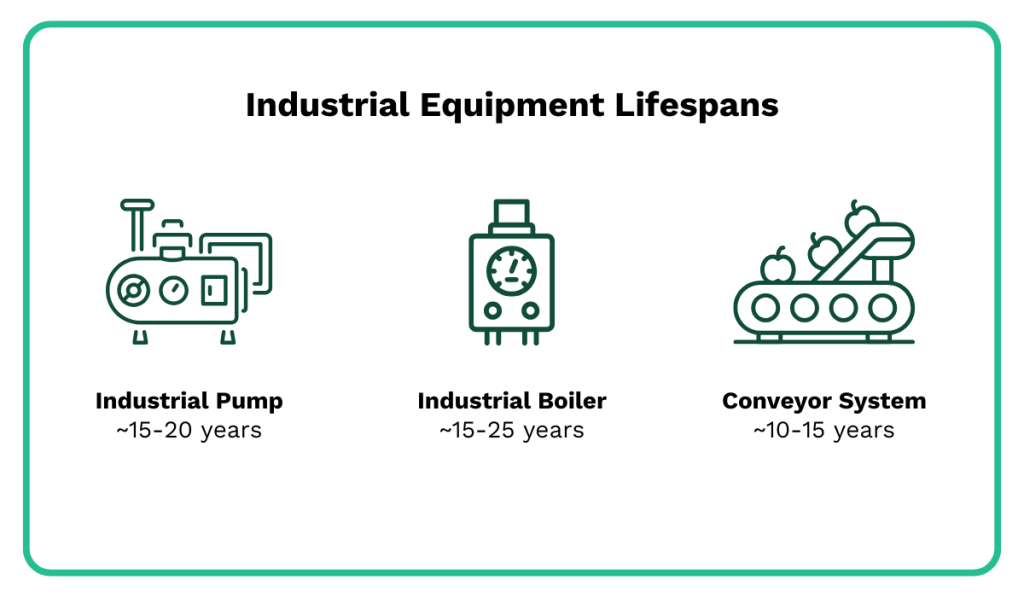

Different types of equipment have different operational lifespans.

While many machines can last for years or even decades, ensuring they remain at peak performance will require increasing maintenance as they age.

This is simply because components wear out, efficiency drops, and older designs may be less reliable or tolerant to stress.

And, as senior engineer Kevin Severin explains, simply finding replacement parts for older equipment can become a significant challenge.

He explains that this may be because the original manufacturer no longer exists, has stopped producing the specific parts, or the old components no longer meet new regulatory standards.

All of this contributes directly to backlog growth by slowing down repairs and extending downtime.

Ultimately, older equipment creates more work, more delays, and more complexity, making backlog growth almost inevitable without a plan in place.

While some of this increase in maintenance is inevitable, it can be mitigated through more proactive, strategic maintenance management.

Only by staying ahead of wear-and-tear can teams keep aging assets from overwhelming maintenance schedules and fueling the backlog.

Consequences of Unmanaged Backlogs

Now that we’ve seen why a backlog can grow, it’s critical to understand the consequences.

Think of an unmanaged backlog as a list of active operational risks.

When this list gets too long, it can lead to serious problems, starting with the most visible one: downtime.

Increased Downtime

With a large maintenance backlog, teams usually focus on the most urgent, high-priority tasks first.

This means less-critical repairs and preventive maintenance tasks get delayed.

While this prioritization makes sense in the short term, the problem is that as the backlog persists, non-critical tasks start to accumulate.

Each delayed task increases the risk of an unexpected equipment breakdown.

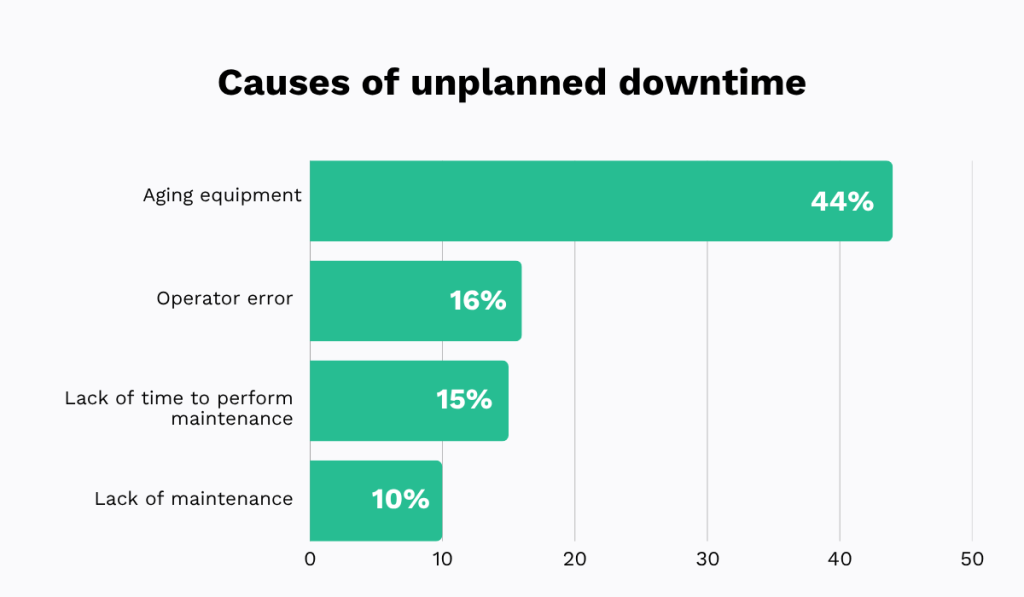

If we look at data from Plant Engineering, 15% of all unplanned downtime is caused by a lack of time to perform maintenance.

Plus, the single biggest cause of unplanned downtime, aging equipment, is also directly linked to this.

As we discussed earlier, older machines require more maintenance, and when that work is neglected, they fail more often.

These downtime occurrences are extremely costly.

They disrupt your operations, stalling production, wasting raw materials, and leaving labor idle.

To make matters worse, even planned maintenance can cause downtime.

Watco’s research shows that facilities can lose an average of 27 days per year to downtime due to maintenance activities alone.

When backlogs are unmanaged, maintenance becomes more reactive and chaotic, further increasing total downtime.

Ultimately, emergency downtime forces teams to focus all their resources on the immediate breakage, pushing all other planned tasks and preventive maintenance right back onto the backlog.

It becomes an infinite loop: the backlog causes downtime, and the downtime makes the backlog grow.

More Safety Risks

When maintenance backlogs are poorly managed, equipment can quickly become unsafe.

If essential preventive maintenance is constantly pushed back due to an overwhelming backlog, you are compromising the safety of your maintenance crews and equipment operators.

Why?

Because minor faults, leaks, or structural weaknesses that would have been found and fixed during a routine inspection go unnoticed and worsen until they turn into a serious safety hazard.

Plus, certain situations can arise that pose serious risks to the environment and surrounding communities.

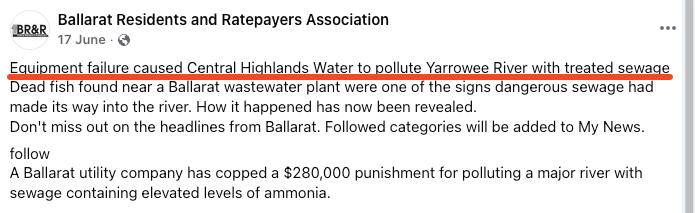

For example, neglected equipment that fails can cause serious environmental damage.

In one such case, unmaintained equipment failed, which resulted in significant water pollution near a Ballarat wastewater plant in Australia.

Source: Facebook

Along with the environmental danger, the resulting fines can be costly.

In this specific case, a utility company in Ballarat faced fines of over $280,000.

Because of scenarios like this, managing your backlog should be a primary safety and compliance concern, and not just an operational one.

Higher Costs

An unmanaged maintenance backlog is a guarantee of significantly higher operational costs.

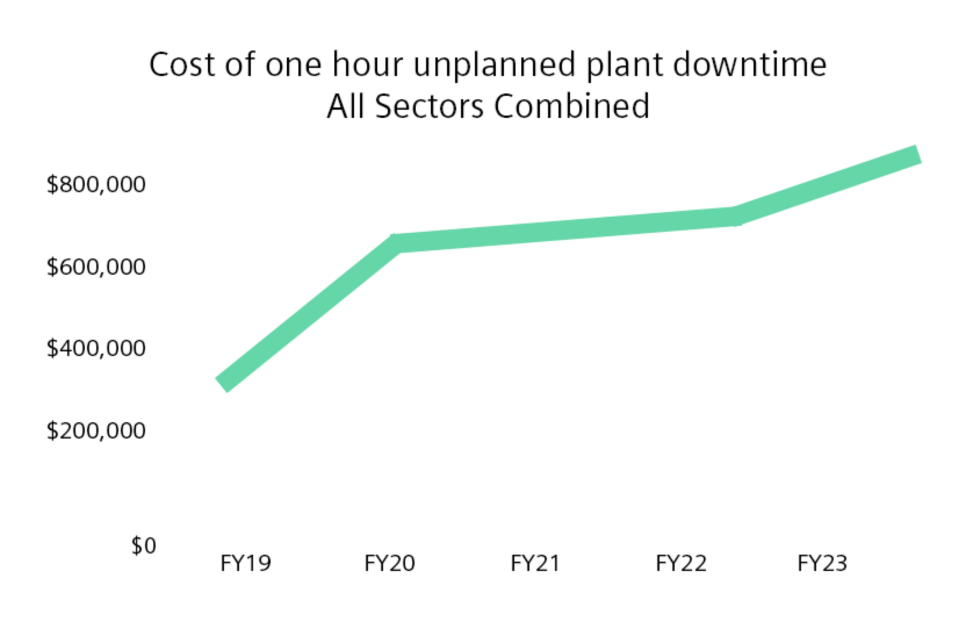

Simply put, increased and unplanned downtime caused by neglected tasks translates directly into massive financial losses.

In fact, according to a 2024 Siemens study, the cost of a single hour of unplanned downtime has doubled over the last five years, with the average cost surpassing $800,000.

Despite these crippling costs, another survey by ABB reports that 21% of organizations still primarily rely on run-to-failure maintenance.

This means they only fix equipment when serious failures occur, resulting in the greatest damage and the most expensive, disruptive repairs.

So, what can you do to avoid all this?

Erik Hupjé, founder and director of Reliability Academy, explains that certain practices can be implemented to mitigate costs and organize your backlog efficiently.

Interestingly, he argues that you actually want a managed backlog to exist to reduce costs:

“In most industrial plants, you can’t afford to have maintenance crews sitting around waiting for work to come through.”

The point here is clear: maintenance labor is a significant, high-value expense, and having a controlled backlog of planned work is the most efficient way to utilize your crews.

It ensures that, as soon as one job is finished, the next one is ready to go, thus maximizing work time and productivity.

Without this buffer of planned work, technicians would be idle, waiting for the next emergency or for new work orders to be created and scheduled.

So, the choice isn’t between having a maintenance backlog or not.

It’s between having a chaotic, expensive one and a controlled, cost-saving one.

Conclusion

We’ve now explored the core concept of a maintenance backlog, digging into what drives its accumulation and the operational and safety risks of letting it spiral out of control.

We hope that you now grasp the seriousness of unaddressed maintenance and recognize its signs.

Use this knowledge to get your team to start prioritizing and tackling those tasks today, and move from reactive emergency work to proactive, planned asset maintenance.