Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- Wind turbines require maintenance 2-3 times per year, with proper preventive maintenance reducing operational costs by up to 18%.

- Blade damage accounts for the leading cause of turbine failure, with leading-edge erosion threatening structural integrity and energy production.

- Companies using CMMS for wind turbine maintenance report a 25-50% reduction in unplanned downtime and a 200-400% improvement in ROI.

Wind energy has become a cornerstone of the global transition to clean energy, with wind turbines transforming how we generate power across residential, commercial, and utility-scale operations.

However, maintaining these sophisticated machines requires more than just occasional check-ups.

From horizontal-axis wind turbines dominating commercial wind farms to vertical-axis wind turbines serving specialized applications, proper maintenance is the difference between optimal performance and costly failures.

In this guide, we’ll explore eight essential tips for wind turbine maintenance that wind farm operators and wind technicians use to maximize efficiency, prevent costly repairs, and ensure their assets deliver peak performance year after year.

1. Establish a Comprehensive Preventive Maintenance Schedule

Reactive maintenance might seem like a cost-saving strategy, but when it comes to wind turbines, waiting for parts to fail is a recipe for disaster.

Preventive maintenance is the foundation of any successful wind energy operation.

According to the U.S. Department of Energy, small wind systems should undergo annual maintenance at a minimum. At the same time, larger commercial turbines typically follow maintenance schedules at predetermined intervals of 4, 6, 12, 24, and 48 months.

Wind turbine maintenance procedures should cover essential maintenance tasks including:

- Routine inspections of turbine blades, tower structure, and nacelle components

- Lubrication schedules for bearings, gearbox, and yaw system

- Electrical systems checks, including control panels and SCADA systems

- Structural integrity assessments ofthe tower and foundation

The maintenance frequency depends on several factors: turbine age, operating conditions, and whether you’re managing onshore or offshore installations.

Carsten Andersen, CEO of the Danish Wind Power Academy, emphasizes the importance of timing:

“Preplanning and organization can result in significant benefits. Servicing should not just be about fixing a machine – it should be about looking after it so that you can achieve maximum uptime and efficiency.”

By scheduling maintenance during low-wind periods, you avoid losing valuable energy production during peak performance times.

This proactive approach helps wind farm operators control maintenance costs while ensuring turbines operate correctly throughout their operational life.

2. Prioritize Turbine Blade Maintenance and Inspection

Rotor blades are among the most critical components of any wind turbine, directly impacting aerodynamic efficiency and power generation.

These massive structures face constant assault from extreme weather conditions, lightning strikes, and environmental wear.

Research published in the National Center for Biotechnology Information identifies blade damage as a leading cause of turbine failure, with several failure modes requiring close attention:

- Leading edge erosion: Constant exposure to rain, hail, and airborne debris weakens blade surfaces, creating cracks and compromising structural integrity

- Blade tip damage: High-speed operation makes tips vulnerable to erosion, cracking, and lightning strike damage

- Trailing edge failures: Debonding and buckling from stress loads can lead to premature failure

Wind turbine technicians should regularly inspect blades for these issues, focusing on visual inspections to catch problems before they escalate.

Small cracks may seem minor, but they can quickly progress to major damage that requires expensive repairs or complete blade replacement.

When you clean blades regularly—removing dirt, debris, and biological growth—you maintain the aerodynamic efficiency that drives energy production.

Even seemingly insignificant buildup can alter blade performance, reducing the turbine’s ability to capture wind energy effectively—a challenge best addressed with robust maintenance management software solutions.

For wind techs working hundreds of feet in the air, blade inspections also represent a critical safety concern.

Damaged blades operating at high speeds pose risks not just to equipment but to personnel and nearby structures.

3. Monitor and Maintain Critical Components

Beyond the blades, wind turbines contain numerous turbine components that require regular attention to prevent costly breakdowns.

The gearbox, generator, and bearings form the heart of wind turbine operation, converting mechanical energy from rotating blades into electrical power.

According to Enerpac’s analysis of wind turbine maintenance, at least 62.9% of all failure causes are internal engineering-related failure modes, making component monitoring essential.

Key components requiring regular inspection include:

Gearbox maintenance

Check oil levels, monitor for leaks, and watch for signs of wear. Gearbox failures can cause weeks of downtime and cost $200,000-$500,000 to replace.

Generator maintenance

Inspect electrical connections, test insulation, and ensure proper cooling system function. Generator issues can halt power generation entirely.

Bearing inspection

Proper lubrication reduces friction and prevents overheating. Bearings support massive loads and high rotational speeds, making them vulnerable to failure without adequate care.

Yaw system

This mechanism keeps turbines aligned with the wind direction. Regular checks ensure smooth operation and prevent misalignment that reduces efficiency.

Wind turbine parts fail at different rates depending on operating conditions and maintenance quality.

The more proactive your approach to monitoring these critical elements, the better you can prevent unexpected breakdowns that lead to costly failures and lost revenue.

Condition monitoring systems using sensors provide real-time data on vibration, temperature, and other performance indicators, allowing maintenance scheduling based on actual equipment condition rather than arbitrary timelines.

4. Implement Predictive Maintenance Technology

While preventive maintenance follows fixed schedules, predictive maintenance takes a smarter approach by using data to anticipate when wind turbine parts fail before catastrophic breakdowns occur.

This strategy represents the future of wind turbine maintenance and is increasingly becoming standard practice at advanced wind farms.

Predictive maintenance leverages SCADA systems, IoT sensors, and advanced analytics to monitor turbine performance in real-time.

According to Deloitte’s research on predictive maintenance, this approach can:

- Increase equipment uptime by 10-20%

- Reduce overall maintenance costs by 5-10%

- Decrease maintenance planning time by up to 50%

How does it work in practice?

Sensors placed on key components continuously collect data on:

- Vibration levels in bearings and gearboxes

- Temperature fluctuations in electrical systems

- Lubrication levels and oil quality

- Foundation displacement and structural stress

- Wind speed and turbine performance correlation

This monitoring data flows into maintenance management software that uses machine learning algorithms to identify patterns indicating impending failure.

When the system detects anomalies—such as unusual vibration signatures in a bearing or temperature spikes in the generator—it triggers alerts allowing wind techs to schedule maintenance before complete failure occurs.

The BMW Group’s Regensburg plant provides a compelling example from industrial maintenance that applies equally to wind energy operations.

Their AI-powered predictive system prevents approximately 500 minutes of production disruption annually by catching potential failures early.

For wind farm operators, this translates to fewer emergency repairs, better parts inventory management, and significantly improved turbine availability during high-wind periods when revenue potential is greatest.

5. Maintain Proper Lubrication Throughout the System

Proper lubrication might sound basic, but it’s one of the most critical and most commonly neglected aspects of wind turbine maintenance.

Moving parts operating under extreme loads and high speeds generate tremendous friction and heat, highlighting the importance of maintenance strategies.

Without adequate lubrication, components wear rapidly, leading to minor repairs escalating into major component failures.

The lubrication requirements for wind turbines are extensive:

Gearbox oil

Maintains smooth gear operation and heat dissipation. Regular oil changes prevent contamination and degradation that accelerates wear, and are a fundamental aspect of predictive maintenance strategies.

Bearing grease

Applied to main shaft bearings, pitch bearings, and yaw bearings. These components support massive loads and require high-quality lubricants formulated for extreme conditions, making predictive maintenance an increasingly valuable approach.

Pitch system lubrication

Ensures blade angle adjustments occur smoothly, optimizing turbine performance across varying wind speeds.

Yaw drive grease

Keeps the turbine rotation mechanism functioning correctly, allowing the nacelle to track wind direction efficiently.

Wind turbine manufacturers provide specific lubrication schedules and specifications in their maintenance manuals.

Following these guidelines isn’t optional. It’s essential for maintaining warranty coverage and preventing premature wear.

According to wind farm management best practices, inadequate lubrication accounts for a significant share of bearing failures, one of the most common and costly turbine problems.

Modern turbines may incorporate automated lubrication systems that deliver grease at scheduled intervals, reducing manual labor and ensuring consistent application.

For turbines without automated systems, wind technicians must manually apply lubricants during routine maintenance visits, verify proper distribution, and identify any components showing signs of inadequate lubrication.

Temperature monitoring helps identify lubrication issues. When that happens, components running hotter than normal often indicate lubrication problems requiring immediate attention.

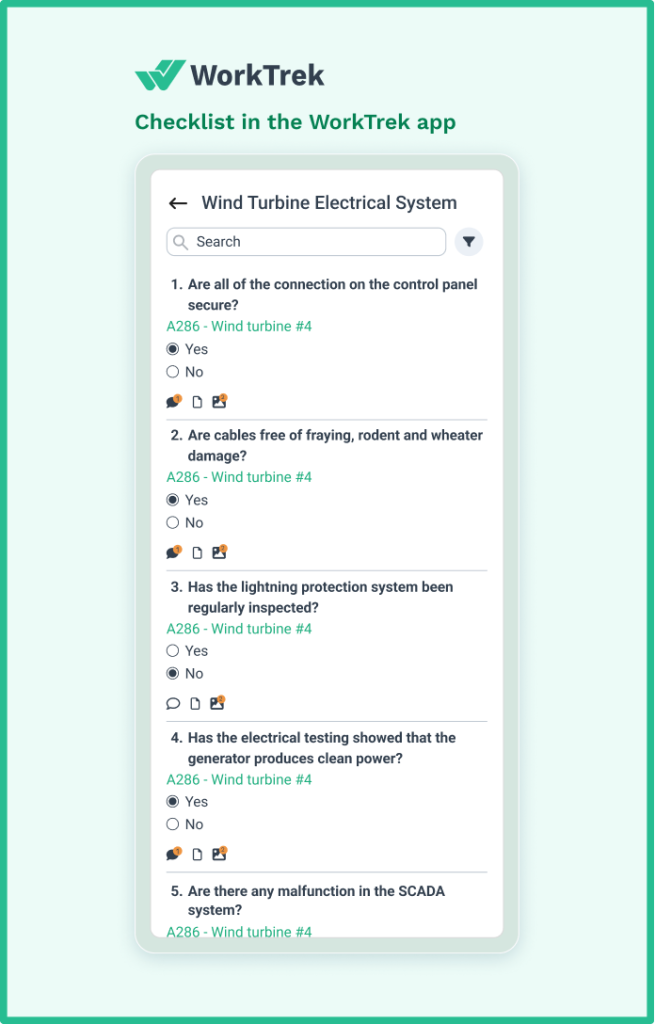

6. Conduct Regular Electrical Systems Inspection

While mechanical components often get the most attention, electrical systems are equally critical to wind turbine operation and maintenance.

From the generator that converts mechanical energy into electricity to the control panels that manage turbine operation, electrical components require systematic inspection and maintenance.

Essential electrical maintenance tasks include:

Control panel inspection

Verify all connections are secure, check for signs of corrosion or overheating, and ensure proper grounding. Control panels coordinate all turbine functions and must operate flawlessly.

Wiring assessment

Examine cables for fraying, rodent or weather damage, and proper insulation. Wind turbines operate in harsh environments where electrical systems are constantly exposed to moisture, extreme temperatures, and physical stress.

Lightning protection verification

Wind turbines are prime targets for lightning strikes. Regular inspection of lightning protection systems prevents catastrophic damage from electrical surges.

Generator testing

Beyond mechanical inspection, electrical testing ensures the generator produces clean power at the proper voltage and frequency.

SCADA system verification

These monitoring tools provide the data essential for both immediate operational control and long-term predictive maintenance. Any malfunction in SCADA systems leaves operators blind to turbine performance issues.

According to the U.S. Department of Energy, electrical system failures contribute significantly to unplanned downtime, making regular inspection a priority for maintaining turbine availability.

For offshore wind installations, electrical system maintenance becomes even more critical due to the additional challenges posed by saltwater corrosion and limited access during severe weather.

Wind technicians working on electrical systems must follow strict safety protocols, as the combination of high voltage, elevated work environments, and potentially explosive conditions in the nacelle creates significant hazards.

7. Address Environmental and Weather-Related Challenges

Wind turbines operate 24/7 in some of the harshest environmental conditions imaginable. This obviously means that the environment takes a toll on every component.

From coastal installations battling salt spray and humidity to inland turbines enduring temperature extremes and dust storms, environmental factors significantly impact maintenance requirements and turbine lifespan.

Strong winds and extreme weather conditions

While wind is obviously essential for power generation, excessive wind speeds force turbines into shutdown mode to prevent damage. Regular inspection after extreme weather events helps identify stress damage before it becomes critical.

Salt corrosion for offshore and coastal turbines

Marine environments accelerate corrosion of metal components, requiring more frequent inspections and protective coating applications. Offshore wind turbines face particularly aggressive corrosive conditions.

Temperature extremes

Both intense heat and extreme cold affect lubrication viscosity, material expansion/contraction, and component stress. Maintenance scheduling should account for seasonal variations in operating conditions.

Ice accumulation

In cold climates, ice buildup on blades disrupts aerodynamic efficiency and adds dangerous weight loads. Some advanced turbines include heating systems to prevent ice formation, but these require their own maintenance.

UV degradation

Constant sun exposure, especially on composite blade materials, can weaken structural integrity over time. Regular blade coating inspection and maintenance help prevent this gradual degradation.

Debris and biological fouling

Birds, insects, and airborne debris can accumulate on blades and in nacelle ventilation systems, reducing efficiency and potentially causing component damage.

Industry data shows that external weather-related effects account for approximately 37.1% of failure causes, underscoring the importance of environmental considerations in maintenance planning.

Effective maintenance schedules account for local environmental conditions, increasing inspection frequency, and adjusting maintenance tasks based on the specific challenges each wind farm faces.

Wind farm operators in harsh environments may need more frequent blade cleaning, more aggressive corrosion prevention measures, and specialized equipment to handle region-specific challenges.

8. Train and Equip Your Maintenance Team Properly

Even the best maintenance schedule means nothing without skilled wind technicians who can execute it safely and effectively.

The wind energy industry faces a growing need for qualified professionals who understand both the mechanical complexity of modern turbines and the safety requirements of working at extreme heights in challenging conditions.

According to Universal Technical Institute’s wind turbine maintenance guide, professional wind technicians, often called “wind techs”, require specialized training covering:

- Mechanical systems, including gearboxes, bearings, and hydraulic components

- Electrical systems and power generation equipment

- Climb and rescue procedures for working safely at heights exceeding 300 feet

- Confined space safety for nacelle work

- First aid and emergency response

- Equipment-specific knowledge for various turbine models and manufacturers

The complexity of modern wind turbines means general mechanical knowledge isn’t sufficient.

As Carsten Andersen of the Danish Wind Power Academy notes:

“You have to be realistic about what your service engineers can achieve. While they may be specialized in one area or understand one platform well, there are very different approaches to different technologies. Many engineers simply don’t receive the additional training they need for new platforms.”

Beyond training, proper equipment is essential.

Advanced tools for wind turbine maintenance now include:

- Drone inspections: Unmanned aerial systems with thermal imaging and high-resolution cameras can inspect blades and tower structures without requiring technicians to climb, improving both safety and efficiency

- Vibration analysis equipment: Portable devices that detect bearing problems and other mechanical issues through vibration signature analysis

- Thermographic cameras: Identify electrical hot spots and insulation problems before they cause failures

- Torque tools: Ensure bolts are properly tightened to manufacturer specifications—critical given that turbines may contain up to 25,000 bolts

Investing in continuous training and modern diagnostic tools pays dividends through improved turbine performance, reduced safety incidents, and lower long-term maintenance costs.

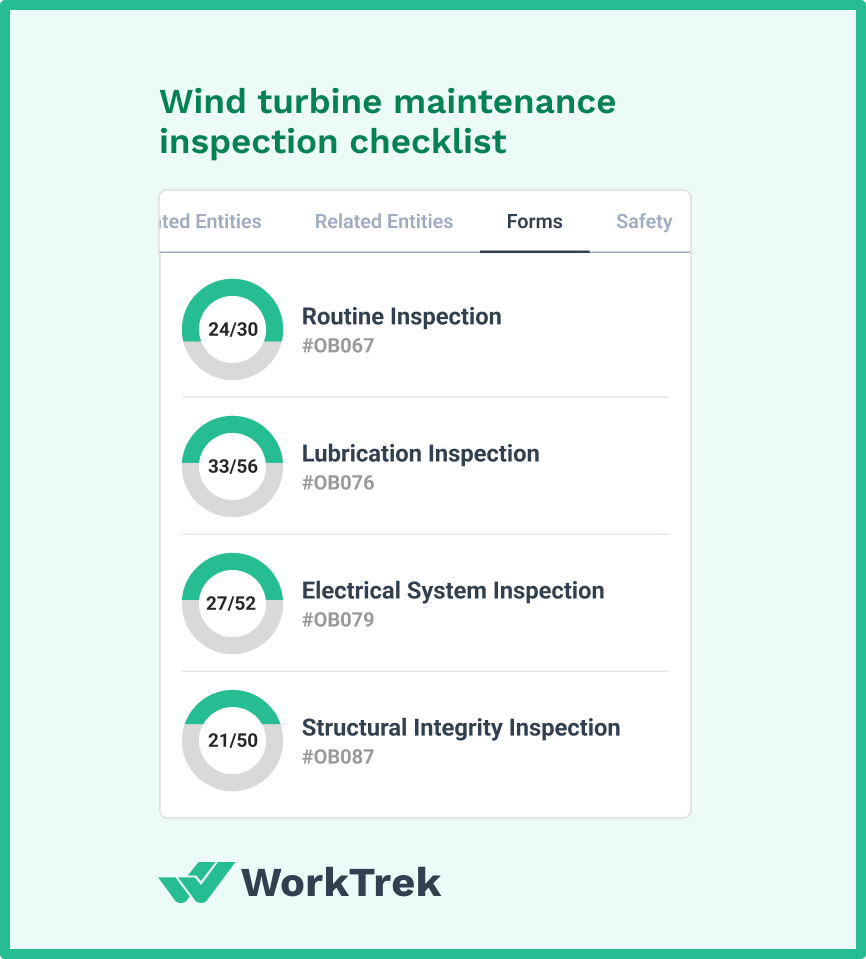

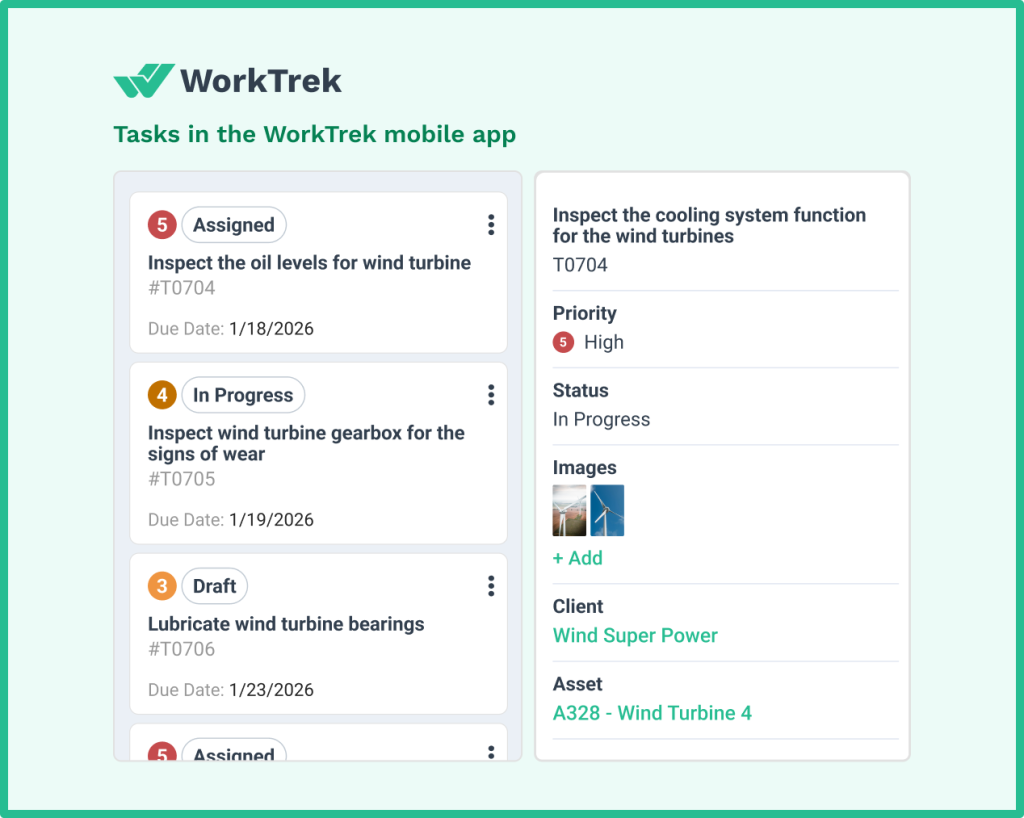

How CMMS Can Transform Wind Turbine Maintenance

Modern wind energy operations require more than just skilled technicians and proper tools—they need intelligent systems that coordinate, track, and optimize every aspect of turbine maintenance.

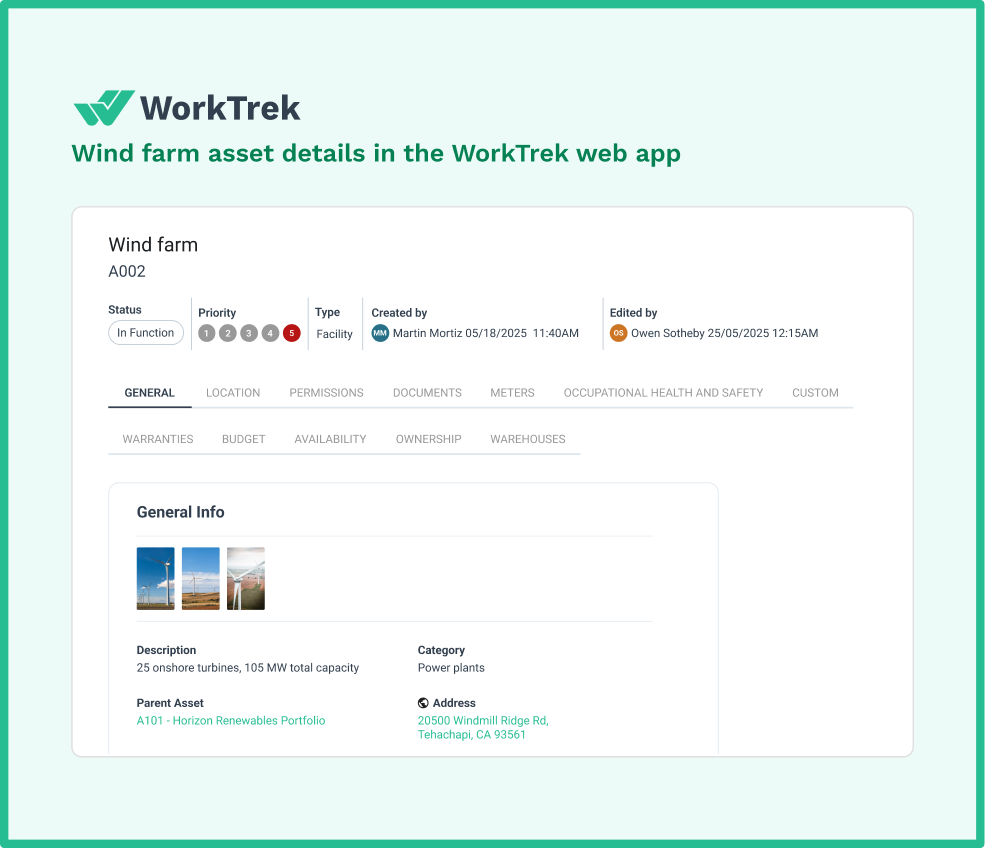

This is where Computerized Maintenance Management System (CMMS) software like WorkTrek becomes invaluable for wind farm operators seeking maximum efficiency and uptime.

According to UpKeep’s State of Maintenance Report, organizations using CMMS platforms report significant improvements including:

- Better visibility into completed work and overall maintenance operations

- 25-50% reduction in unplanned downtime

- Enhanced team communication and collaboration

- Improved resource allocation and parts inventory management

These benefits directly address the most pressing challenges in wind turbine maintenance, where downtime costs can reach $695 million annually at large automotive-scale operations, according to Siemens’ research.

The WorkTrek Advantage in Wind Energy

While many CMMS platforms exist, WorkTrek’s combination of user-friendly design, powerful automation, and industry-specific features makes it the ideal choice for wind energy operations.

The platform scales effortlessly from small wind installations to large commercial wind farms, managing hundreds of turbines across multiple locations.

Wind farm operators report dramatic improvements after implementing WorkTrek:

- 200-400% return on investment through reduced downtime and optimized maintenance costs

- Elimination of missed preventive maintenance tasks

- Faster emergency response through better parts availability and technician coordination

- Improved turbine reliability and energy production

- Reduced administrative burden through automation

Whether you’re managing a single wind turbine or an entire wind farm, WorkTrek provides the tools, insights, and automation necessary to achieve optimal performance, minimize maintenance costs, and ensure your wind energy operations deliver maximum value throughout their operational life.

Conclusion

Wind turbine maintenance is more than just preventing breakdowns. It’s about maximizing the return on your clean energy investment while ensuring safe, reliable operation over decades of service.

The eight tips covered in this guide represent the foundation of successful wind energy operations, from establishing comprehensive preventive maintenance schedules to investing in skilled technicians and modern diagnostic tools.

As wind energy continues expanding globally, the importance of proactive maintenance only grows.

The difference between reactive and preventive approaches can mean millions in avoided downtime costs, extended equipment life, and consistent energy production, making wind power economically viable.

Modern CMMS platforms like WorkTrek transform wind turbine maintenance from a reactive scramble into a strategic, data-driven operation that consistently delivers peak performance.

Whether you’re managing horizontal-axis wind turbines at a utility-scale wind farm or maintaining small vertical-axis wind turbines for distributed generation, the principles remain the same: prevent problems before they occur, monitor critical components continuously, and leverage technology to work smarter rather than harder.

Your wind turbines represent a significant investment in renewable energy infrastructure. maintenance operations

Give them the maintenance they deserve, and they’ll deliver clean, sustainable power for decades to come.