What is Corrective Maintenance?

Corrective maintenance involves repairing or restoring equipment after a fault or failure has been detected. It is a reactive maintenance approach initiated after equipment malfunctions to restore the asset to its proper working condition. While preventive and predictive maintenance strategies are designed to avoid breakdowns, corrective maintenance is triggered only when failures occur, meaning the equipment runs to failure before action is taken.

Corrective maintenance can involve repairs, part replacements, or recalibrations, depending on the nature of the failure. It is typically more urgent than preventive maintenance because unplanned downtime can disrupt operations and lead to additional costs.

However, in some cases, organizations deliberately allow non-critical assets to fail before performing corrective maintenance, as the cost of regular preventive maintenance may not be justified.

Corrective maintenance’s downside is that it can result in higher repair costs, longer downtime, and more significant damage to equipment if not addressed promptly.

However, it is most effective when combined with preventive and predictive maintenance strategies to reduce the likelihood of critical failures in high-priority assets.

How to effectively use corrective maintenance?

For maintenance organizations, effectively implementing corrective maintenance involves a balance of responsiveness, technical expertise, and strategic planning.

By refining their approach to corrective maintenance, organizations can minimize downtime, optimize resource use, and extend the lifespan of assets, all while maintaining operational efficiency.

1. Failure Detection and Response

Rapid detection and response to equipment failure is the cornerstone of corrective maintenance.

- Monitoring Systems: Use sensors, automated alarms, and condition-monitoring technology to identify issues immediately.

- Streamlined Reporting: Establish clear communication channels between operational and maintenance teams to report failures quickly and accurately.

- Documentation: Ensure detailed failure logs to provide technicians with the information needed for efficient diagnostics and repair.

2. Technical Expertise

Skilled personnel are vital for resolving issues efficiently and effectively.

- Training Programs: Regularly train technicians to handle a variety of equipment and systems, improving their versatility.

- Cross-Training: Enable technicians to gain skills across different areas, ensuring flexibility in addressing varied challenges.

- Access to Resources: Maintain up-to-date documentation, such as equipment manuals and schematics, to support informed troubleshooting.

3. Resource Management

Managing tools, spare parts, and personnel effectively minimize repair delays.

- Spare Parts Inventory: For high-value or frequently used equipment, keep critical components in stock. Inventory management software monitors usage and automatically reorders.

- Tool Availability: Ensure tools are well-maintained and accessible to technicians.

- Personnel Allocation: Schedule the right technicians, ensuring their expertise aligns with the specific issue.

4. Strategic Integration with Other Maintenance Types

Balance corrective maintenance with preventive and predictive approaches to optimize asset management.

- Analyze Failure Patterns: Use corrective maintenance data to identify recurring problems and implement preventive measures.

- Preventive Measures: Shift from reactive to proactive strategies by addressing the root causes of frequent failures.

- Data-Driven Improvements: Leverage insights from corrective maintenance to refine overall maintenance planning and reduce future issues.

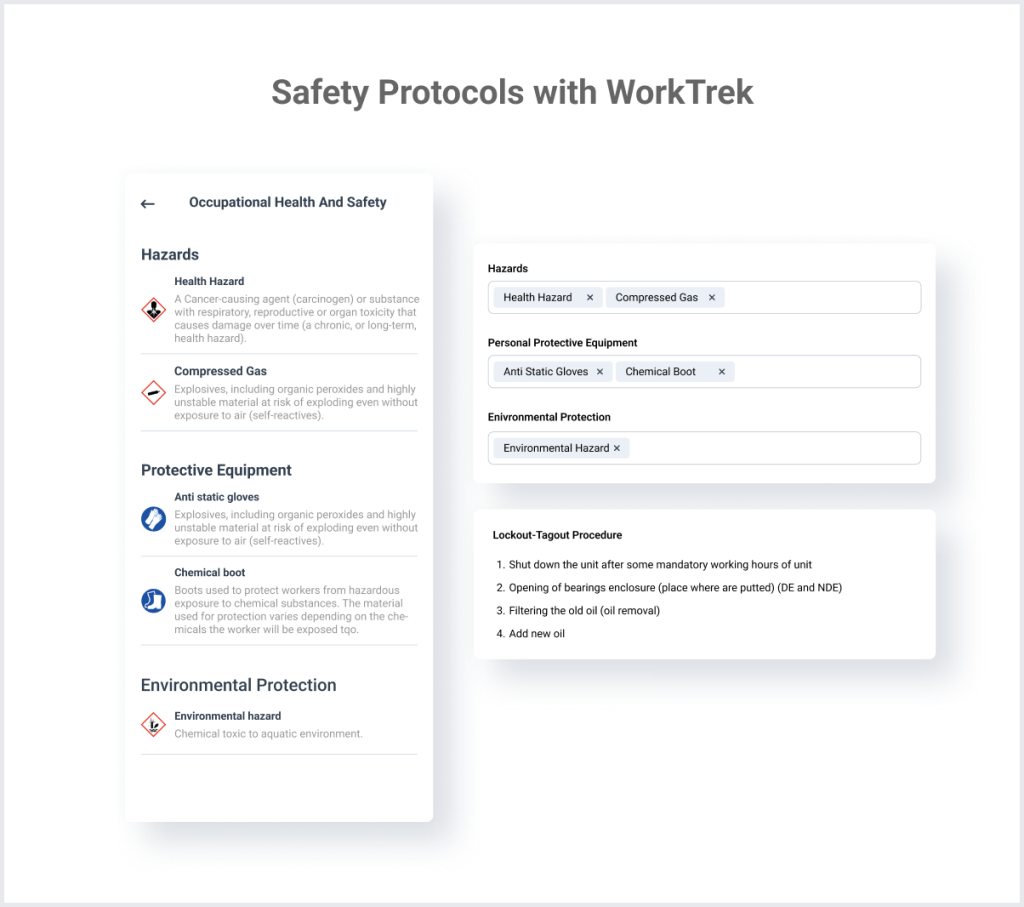

5. Safety Protocols

Urgent corrective tasks often pose safety risks, making robust protocols essential.

- Safety Training: Train technicians to follow safety best practices, even under time constraints.

- Provide PPE: Ensure personal protective equipment is available and enforced during all maintenance activities.

- Safety Culture: Foster an organizational mindset that prioritizes safety alongside efficiency.

6. Leveraging Technology

Technology can significantly improve the speed and effectiveness of corrective maintenance.

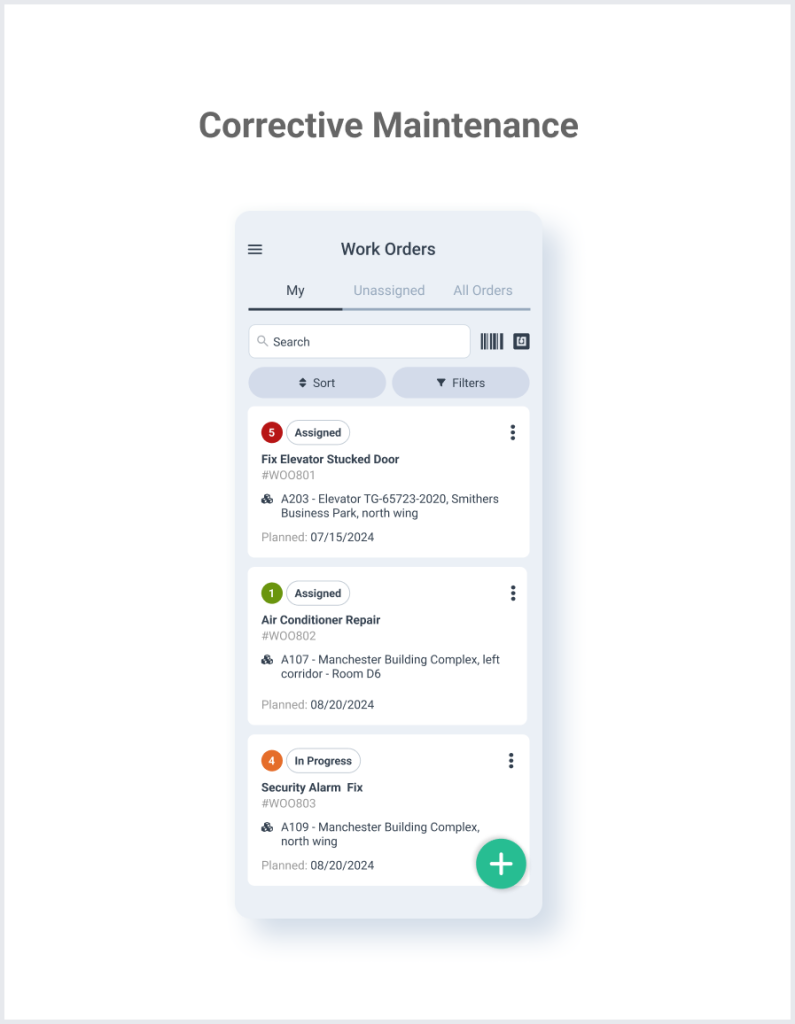

- CMMS Software: Use Computerized Maintenance Management Systems to track work orders, inventory, and technician assignments in real-time.

- Mobile Tools: Equip field technicians with mobile apps to access critical information and communicate quickly.

- Predictive Analytics: Adopt predictive tools to anticipate and mitigate failures, blurring the line between reactive and proactive strategies.

How can CMMS help with Corrective Maintenance?

Handling corrective maintenance can be challenging without the right tools. Corrective maintenance—repairing or replacing equipment after a failure—requires precise coordination, immediate action, and diligent tracking. This is where Computerized Maintenance Management System (CMMS) software comes into play, acting as an indispensable ally for maintenance teams.

CMMS software helps streamline the corrective maintenance process through the following features:

- Logging Issues Quickly

- When equipment fails or a problem is identified, CMMS ensures that a work request can be easily entered into the system. This work request includes details such as:

- Fault description

- Urgency level

- Impacted equipment

- Having all pertinent information readily accessible allows maintenance staff to respond more quickly.

- When equipment fails or a problem is identified, CMMS ensures that a work request can be easily entered into the system. This work request includes details such as:

- Prioritizing Repairs

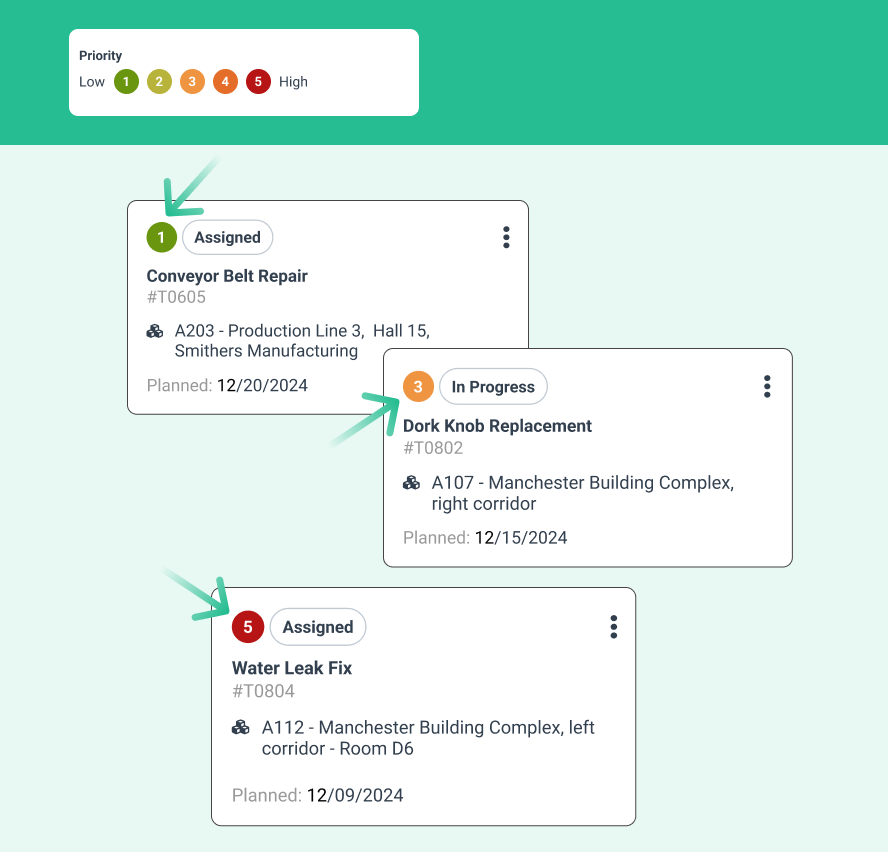

- One of the most crucial aspects of corrective maintenance is prioritizing repairs, and CMMS excels here by providing visibility into ongoing and pending tasks.

- Maintenance teams can view all corrective maintenance requests in real-time, allowing them to:

- Allocate resources effectively

- Prioritize jobs based on urgency and the potential impact on operations

- For instance, when critical equipment is down, a CMMS can highlight the repair’s significance and ensure it receives immediate attention.

- Tracking Progress of Repairs

- CMMS software allows maintenance managers to monitor work in real-time, from initial diagnosis to completion. Every step of the process is recorded, including:

- Assigning technicians

- Obtaining parts

- Actual repair

- This comprehensive digital trail ensures transparency and helps evaluate the efficiency of corrective actions.

- Historical records in the CMMS also allow for better decision-making, helping managers understand frequent failure causes and identify potential preventive measures.

- CMMS software allows maintenance managers to monitor work in real-time, from initial diagnosis to completion. Every step of the process is recorded, including:

- Data-Driven Insights and Analytics

- CMMS software provides valuable analytics by aggregating data on corrective maintenance activities. It helps identify:

- Trends in equipment failure

- Recurring issues that need attention

- These insights enable maintenance teams to make data-driven decisions, leading to:

- Reduced downtime

- Improved efficiency

- A more reliable maintenance operation overall

- CMMS software provides valuable analytics by aggregating data on corrective maintenance activities. It helps identify:

In short, CMMS makes the complex, often reactive world of corrective maintenance far more manageable by providing the tools needed for quick response, prioritization, tracking, and analytics.

Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for free