What is Failure Modes?

A failure mode occurs when equipment, components, or systems stop working as intended. Think of it as the “how” and “why” behind equipment breaking down. Just as a car might fail with a dead battery, worn-out brakes, or a blown engine, every piece of equipment can fail in multiple ways.

Understanding failure modes is similar to how a doctor diagnoses illness – they need to understand that something is wrong and exactly what’s wrong and why. Each failure mode has its own “symptoms” and underlying causes. For example, a pump might fail because its bearings wear out (mechanical failure), its motor burns out (electrical failure), or its seals leak (containment failure).

These failures typically fall into several main categories. Physical failures involve material breakdowns, like metal parts wearing down, materials cracking from fatigue, or components corroding. Functional failures occur when equipment still works but doesn’t meet required performance standards, like a machine that runs but produces too many defects. Human-induced failures stem from mistakes in operation or maintenance.

The pattern of how equipment fails is also important. Some failures happen early in equipment life due to manufacturing defects (called infant mortality). Others occur randomly throughout the equipment’s life, while wear-out failures happen as equipment reaches the end of its expected lifespan.

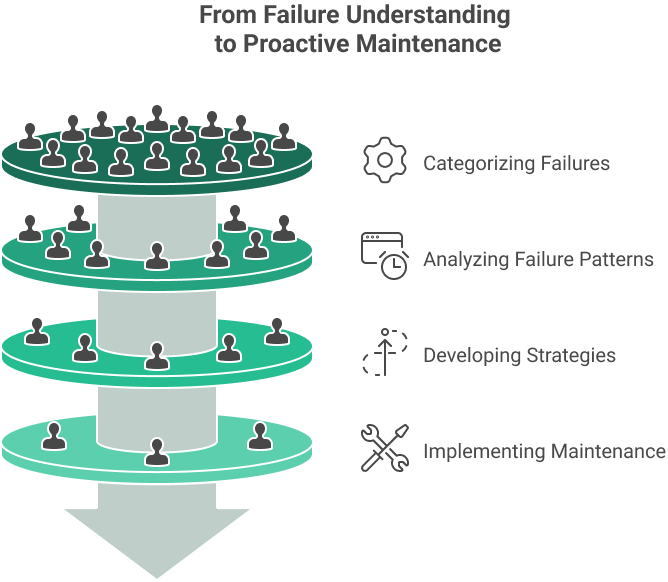

Understanding these patterns helps maintenance teams predict and prevent failures before they happen.

Maintenance teams use this knowledge to develop targeted strategies. By understanding how equipment typically fails, they can implement specific inspections, tests, and preventive maintenance tasks to catch problems early.

They can also prioritize their efforts by focusing on the most common or critical failure modes.

Think of it like preventive healthcare – just as regular check-ups look for specific health issues based on known risk factors, maintenance programs target known failure modes with specific preventive actions.

This systematic approach helps organizations move from reactive maintenance (fixing things after they break) to proactive maintenance (preventing breakdowns before they occur).

This understanding of failure modes forms the foundation of reliability engineering and modern maintenance practices. It allows organizations to optimize maintenance programs, reduce unexpected breakdowns, and ensure equipment operates reliably and efficiently throughout its life cycle.

Types of Failure Modes

Physical Failures

Physical failures form the foundation of failure modes, manifesting through wear, fatigue, corrosion, deformation, and fracture. Wear occurs through progressive material loss from surfaces in relative motion, while fatigue results from repeated stress cycles. Corrosion represents material degradation due to chemical or environmental factors, and deformation involves changes in component shape under stress.

Functional Failures

Functional failures present themselves differently, as performance degradation, calibration drift, control system malfunctions, and parameter deviations. These failures often develop gradually, making them more subtle but equally impactful. Software failures in modern equipment add another layer of complexity to functional failure modes.

Human-Caused Failures

Human-induced failures stem from operational, maintenance, installation, and design flaws. These failures highlight the importance of proper training, clear procedures, and robust quality control systems. The human element in failure modes necessitates comprehensive training programs and clear operational procedures.

Failure Mode Categories

Primary Categories of Failure Modes

- Physical Failures Wear: Progressive material loss from surfaces in relative motion Fatigue: Failure due to repeated stress cycles Corrosion: Material degradation due to chemical or environmental factors Deformation: Change in component shape under stress Fracture: Complete or partial separation of material

- Functional Failures Performance Degradation: Gradual decline in operational efficiency Calibration Drift: Loss of accuracy in measuring or control systems Control System Failures: Malfunctions in automated systems Parameter Deviation: Operation outside specified limits Software Failures: Issues with programmed control systems

- Human-Induced Failures Operational Errors: Incorrect equipment operation Maintenance Errors: Improper repair or service procedures Installation Errors: Incorrect assembly or setup Design Errors: Flaws in original equipment design Procedural Failures: Not following established protocols

Maintenance organizations utilize failure mode analysis through several methodologies:

Failure Mode and Effects Analysis (FMEA)

FMEA is a systematic approach to:

- Identify potential failure modes

- Assess their impact on system operation

- Determine failure causes

- Evaluate risk through occurrence and detection ratings

- Develop preventive measures

This analysis helps prioritize maintenance activities and allocate resources effectively.

Failure Mode, Effects, and Criticality Analysis (FMECA)

FMECA extends FMEA by adding:

- Criticality assessment of each failure mode

- Quantitative risk evaluation

- Priority ranking for corrective actions

- Cost-benefit analysis of solutions

Root Cause Analysis (RCA)

RCA investigates failure incidents to:

- Determine underlying causes

- Identify failure patterns

- Develop corrective actions

- Prevent recurrence

- Document lessons learned

Maintenance organizations employ various analytical tools to understand and address failure modes. Failure Mode and Effects Analysis (FMEA) systematically identifies potential failures and their impacts. This analysis extends to criticality assessment through FMECA, helping prioritize maintenance activities based on risk and importance.

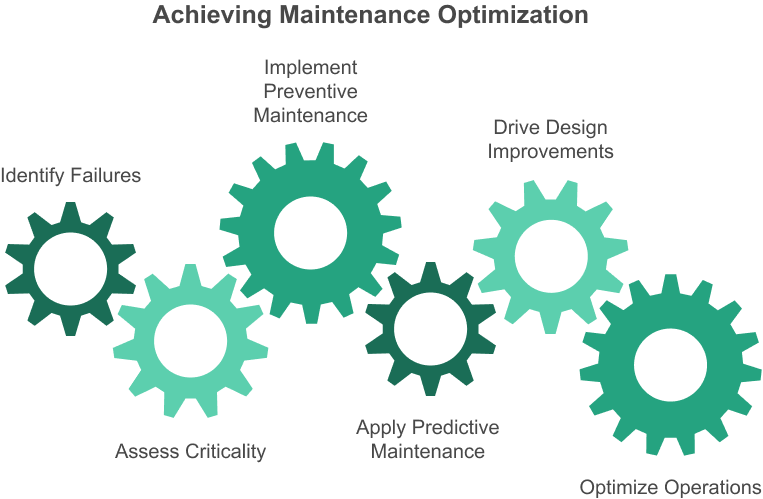

Quality Improvement Through Failure Mode Analysis Maintenance organizations leverage failure mode analysis to optimize operations through several approaches.

Preventive maintenance becomes more targeted by identifying critical failure modes and establishing appropriate inspection intervals, while predictive maintenance benefits from understanding failure indicators and establishing warning thresholds.

Analyzing failure modes drives design improvements by identifying weaknesses and implementing modifications. This process enhances overall reliability while optimizing maintenance planning and resource allocation.

The insights gained help organizations reduce costs, improve performance, and manage risks more effectively.

Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for free