What is Fault Tree Analysis?

Fault Tree Analysis (FTA) is a sophisticated, systematic approach to understanding and preventing equipment failures. At its core, FTA is a deductive reasoning tool that helps maintenance professionals understand complex system failures and their fundamental causes.

This analytical method uses Boolean logic to illustrate the relationships between various equipment failures, human errors, environmental conditions, and other events that could contribute to system malfunction.

The methodology behind FTA stems from reliability engineering principles developed in the 1960s by Bell Laboratories. Initially created for the U.S. Air Force to evaluate launch control systems for intercontinental ballistic missiles, FTA has evolved into an essential tool across various industries, from manufacturing to healthcare facilities maintenance.

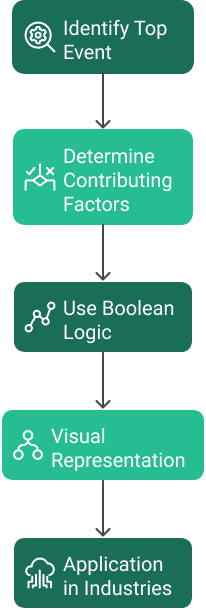

The process follows a structured approach that begins with identifying an undesired event, often called the “top event.” This could be anything from a complete system shutdown to a specific component failure.

From this starting point, maintenance analysts work backward, identifying all possible scenarios that could lead to this failure. The analysis creates a visual representation resembling an inverted tree, with the top event at the apex and contributing factors branching downward.

How does FTA Work?

Understanding how FTA works requires familiarity with its fundamental components. The analysis uses standardized symbols to represent different types of events and gates. Events might include basic events (fundamental failures that need no further development), intermediate events (failures that result from combinations of other events), and conditional events (conditions that must exist for failures to occur). Gates show how events combine to cause higher-level events, using logical operators like AND gates (all input events must occur) and OR gates (any input event can cause the output).

How can Maintenance Technicians use it?

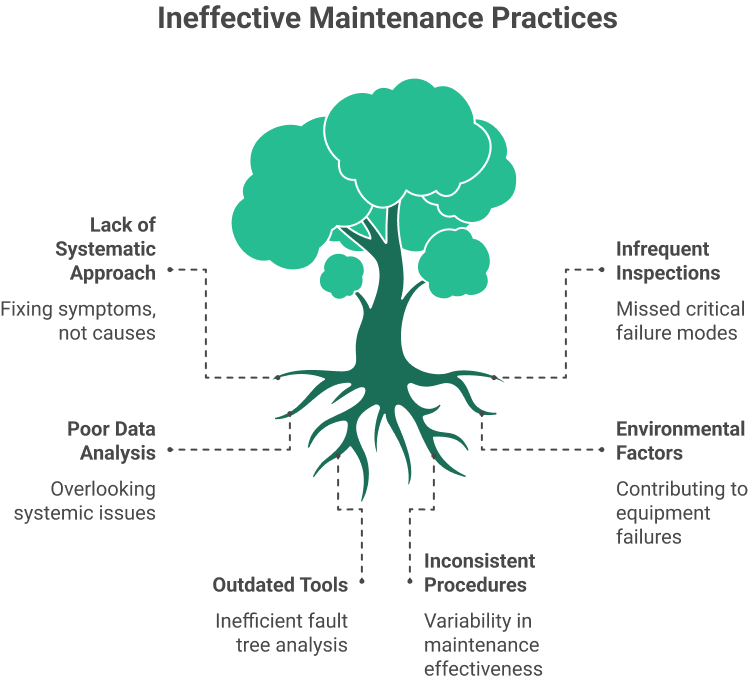

For maintenance technicians, FTA serves as both a diagnostic and preventive tool. When troubleshooting existing problems, technicians can use the fault tree as a roadmap, systematically checking each potential failure path until they identify the root cause. This structured approach prevents the common pitfall of fixing symptoms rather than underlying causes.

For instance, if a production line stops, the fault tree might reveal multiple potential paths to investigate, from power supply issues to mechanical failures, helping technicians prioritize their investigation based on probability and accessibility.

Source: WorkTrek

In preventive maintenance, FTA helps technicians identify critical components and failure modes that require regular monitoring or maintenance. By understanding the relationship between different failure modes, maintenance teams can develop more effective inspection schedules and preventive maintenance procedures.

For example, technicians might implement more frequent bearing inspections or vibration monitoring if the fault tree shows that bearing failure could lead to catastrophic equipment damage.

The practical application of FTA extends beyond individual equipment troubleshooting. Maintenance organizations use it to improve their overall reliability programs. By analyzing fault trees across multiple pieces of equipment, patterns often emerge that help identify systemic issues or opportunities for improvement.

This might include identifying common failure modes across similar equipment, recognizing environmental factors contributing to failures, or discovering maintenance practices needing modification.

Modern technology has significantly enhanced the implementation of FTA. Contemporary software tools have transformed what was once a paper-based process into a dynamic, digital analysis tool.

Advanced FTA software packages offer features like:

- Real-time collaboration capabilities allow multiple technicians to contribute to the analysis

- Integration with equipment sensors and monitoring systems to provide live data

- Probability calculations to help prioritize maintenance activities

- Simulation capabilities to test different scenarios and maintenance strategies

- Historical data integration to track failure patterns over time

- Mobile access for technicians to reference fault trees while working in the field

FTA Software and Tools

Many organizations are now integrating their FTA software with broader maintenance management systems. This integration allows maintenance teams to automatically generate work orders based on fault tree analysis, track the effectiveness of preventive maintenance programs, and maintain comprehensive equipment histories.

Some advanced systems even use artificial intelligence to predict potential failures based on patterns identified through fault tree analysis.

To maximize the effectiveness of FTA, maintenance organizations should establish clear procedures for its implementation. This includes training technicians in FTA methodology, standardizing symbols and terminology, and establishing processes for updating and maintaining fault trees as equipment and processes change.

Regular reviews of fault trees ensure they remain relevant and effective as maintenance strategies evolve.

FTA Financial Benefits

Implementing FTA can have substantial financial benefits. By helping prevent equipment failures and optimize maintenance activities, organizations often see reduced downtime, lower maintenance costs, and extended equipment life.

Additionally, the systematic nature of FTA helps organizations comply with safety regulations and industry standards by providing documented evidence of thorough failure analysis and prevention strategies.

Future of FTA

Looking to the future, FTA continues to evolve with technological advances. Integrating Internet of Things (IoT) sensors, machine learning algorithms, and augmented reality tools creates new possibilities for real-time fault analysis and predictive maintenance, making FTA an increasingly powerful tool for modern maintenance organizations.

Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for free