What is Fleet Maintenance?

Fleet maintenance refers to the systematic process of keeping a company’s vehicles (its “fleet”) in optimal working condition through regular inspection, servicing, repair, and asset management. This includes preventive and corrective maintenance activities designed to maximize vehicle reliability, extend operational lifespan, ensure safety compliance, and minimize downtime.

To better understand this concept, consider fleet maintenance similar to vehicle healthcare – just as humans need regular check-ups and occasional treatments, vehicles require consistent care to perform well. This maintenance encompasses several key areas:

The preventive aspect includes scheduled services like oil changes, tire rotations, brake inspections, and fluid level checks – all performed according to manufacturer specifications or usage patterns. This proactive approach helps prevent breakdowns before they occur.

The corrective component addresses issues during operation, from minor repairs to major mechanical overhauls. This reactive maintenance ensures vehicles can quickly return to service when problems occur.

Management involves tracking maintenance schedules, costs, vehicle history, and performance metrics through specialized software systems.

This data-driven approach helps organizations decide about vehicle replacement, resource allocation, and maintenance strategies.

Examples of Fleet Maintenance

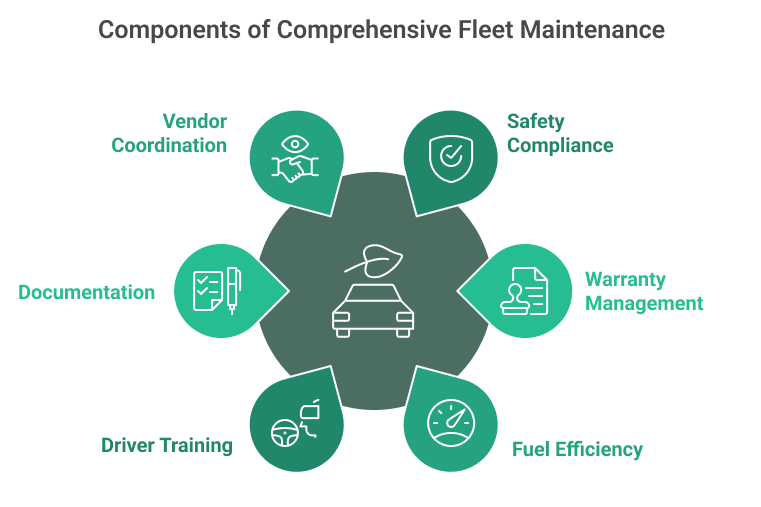

Significantly, fleet maintenance extends beyond just mechanical work. It includes:

- Ensuring compliance with safety regulations and industry standards

- Managing warranty claims and service contracts

- Monitoring fuel efficiency and environmental impact

- Training drivers on proper vehicle operation

- Maintaining detailed documentation for each vehicle

- Coordinating with various vendors and service providers

For example, a delivery company’s fleet maintenance program would track when each truck needs servicing, schedule repairs during off-peak hours to minimize disruption, monitor fuel consumption patterns, and ensure all vehicles meet safety standards – all while documenting every maintenance action for future reference.

Industry Examples of Fleet Maintenance?

Many industries rely heavily on fleet maintenance to keep their operations running smoothly. Let me walk you through the major sectors and explain why fleet maintenance is important.

1. Transportation and Logistics

Transportation and Logistics companies form the backbone of fleet-dependent industries. These businesses, like FedEx, UPS, and trucking companies, operate massive networks of delivery vehicles, from small vans to large semi-trucks. Their entire business model depends on vehicles being reliable and road-ready at all times. A single breakdown can disrupt carefully planned delivery schedules and disappoint countless customers.

Transportation Industry Examples

Companies like FedEx maintain diverse vehicle types, from vans to semi-trucks. Their maintenance programs must account for vehicles that travel long distances daily, often crossing multiple climate zones. A delivery van in Arizona faces different challenges than one in Maine, requiring maintenance schedules that adapt to these environmental factors. Think of how your own car might need different care in summer versus winter – now multiply that complexity across thousands of vehicles.

2. Construction

The construction and Mining industries operate specialized heavy equipment fleets. Consider how construction companies manage bulldozers, cranes, and dump trucks or how mining operations maintain massive haul trucks and excavators.

These vehicles often work in harsh conditions and require rigorous maintenance schedules because equipment failures can halt entire projects and cost thousands of dollars per hour in lost productivity.

Construction Industry Examples

Unlike logistics vehicles that primarily deal with road conditions, construction equipment faces extreme stress from constant heavy lifting, digging, and exposure to dust and debris. Consider a bulldozer working at a construction site: its maintenance program must account for hydraulic systems under immense pressure, tracks that experience intense wear, and engines that often run at maximum capacity for extended periods.

The maintenance schedule might require daily inspections of hydraulic lines and weekly cleaning of air filtration systems – tasks that would be unnecessary for a delivery van.

3. Public Services and Mass Transit

Public Transportation systems, including city bus services, school districts, and transit authorities, are another crucial fleet-dependent sector. These organizations transport thousands of people daily and must maintain exceptional safety standards.

Their maintenance programs must balance the need for regular service with the responsibility of keeping vehicles safe for public use.

Emergency and Public Service Industry Examples

Emergency services are perhaps the most demanding maintenance scenario. Their vehicles must maintain perfect reliability while experiencing unique stress patterns. Imagine an ambulance: it might idle for hours, then suddenly require maximum acceleration and braking.

This creates unusual wear patterns that standard maintenance schedules can’t address. Emergency vehicles often have redundant systems that require additional maintenance – backup power systems, specialized medical equipment, and communication systems all need regular checks and calibration.

4. Farming and Agriculture

Agriculture is another vital sector requiring fleet maintenance. Modern farms operate complex machinery like tractors, harvesters, and irrigation equipment. The seasonal nature of farming makes maintenance timing particularly critical—equipment must be perfectly reliable during narrow harvest windows when delays could result in crop losses.

Farming and Agriculture Industry Examples

The Agriculture sector demonstrates how seasonal operations influence maintenance timing. A combine harvester, for instance, might operate intensively for just a few weeks each year.

Unlike any other industry, this creates a maintenance pattern: comprehensive pre-season preparation, intensive mid-season support, and thorough post-season maintenance. Technicians must complete major repairs and upgrades during the off-season, ensuring zero failures during critical harvest periods.

5. Emergency Services

Emergency Services, including police departments, fire stations, and ambulance services, maintain specialized vehicle fleets that must be ready for deployment 24/7. Their maintenance programs are especially stringent because vehicle reliability can be a matter of life and death.

Industry Examples of Emergency Services

Utility Companies face unique challenges maintaining specialized equipment like bucket trucks and underground service vehicles. These vehicles often carry heavy equipment while operating in dangerous conditions near power lines or in confined spaces.

Their maintenance programs must integrate safety inspections for the vehicle and its specialized equipment – imagine checking the truck’s engine and the integrity of a 40-foot hydraulic lift system.

6. Utilities

Utility Companies operate fleets of service vehicles to maintain power lines, gas pipelines, and telecommunications infrastructure. These organizations need reliable vehicles to respond quickly to outages and emergencies, often in challenging weather conditions or terrain.

Industry Examples for Utilities

Utility Companies face unique challenges maintaining specialized equipment like bucket trucks and underground service vehicles. These vehicles often carry heavy equipment while operating in dangerous conditions near power lines or in confined spaces.

Their maintenance programs must integrate safety inspections for the vehicle and its specialized equipment – imagine checking the truck’s engine and the integrity of a 40-foot hydraulic lift system.

Retail and E-commerce

Retail and Service industries increasingly depend on fleet maintenance as more businesses offer delivery services. This includes everything from large retail chains managing their delivery fleets to food service companies maintaining refrigerated trucks for fresh food distribution.

Retail Industry Examples

The retail sector’s fleet maintenance needs have evolved dramatically with the rise of e-commerce and same-day delivery services. Modern retailers like Walmart, Amazon, and grocery chains operate complex delivery networks requiring different vehicle types, each with specific maintenance demands.

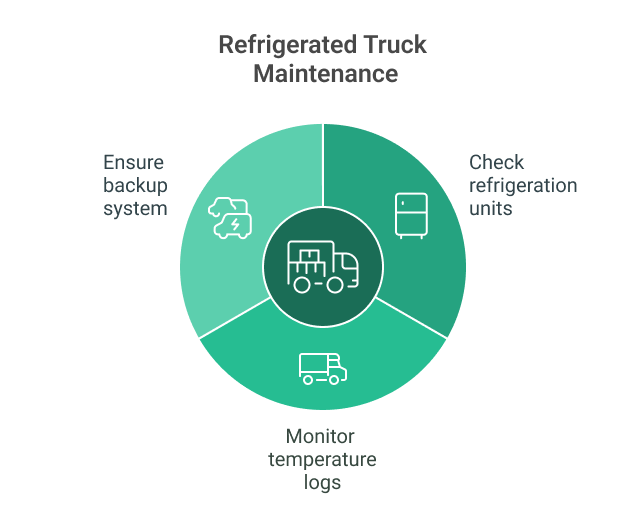

Consider a grocery chain’s fleet: They typically maintain three distinct vehicle categories, each with unique maintenance requirements. First, their refrigerated trucks require specialized cooling system maintenance beyond standard vehicle care. Technicians must regularly check refrigeration units, monitor temperature logs, and ensure backup systems are functional—because a cooling system failure could spoil thousands of dollars worth of perishable goods.

Waste Management and Recycling

Waste Management companies operate specialized garbage trucks and recycling vehicles that endure heavy daily use. These vehicles must be maintained meticulously to handle constant stops and starts while carrying heavy loads through urban environments.

Waste Management Industry Examples

Waste management fleets face some of any industry’s most punishing operating conditions. Their vehicles endure unique stresses that require specialized maintenance approaches. Let me break down the specific challenges and solutions.

Consider the mechanical stress on garbage trucks. These vehicles make hundreds of stops per day, each time operating hydraulic systems to lift and compact waste. A typical residential garbage truck might make 500-800 stops daily, meaning the hydraulic systems cycle thousands of times per week. This requires specialized maintenance schedules for hydraulic components, with daily fluid checks and weekly system inspections that wouldn’t be necessary in other industries.

Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for free