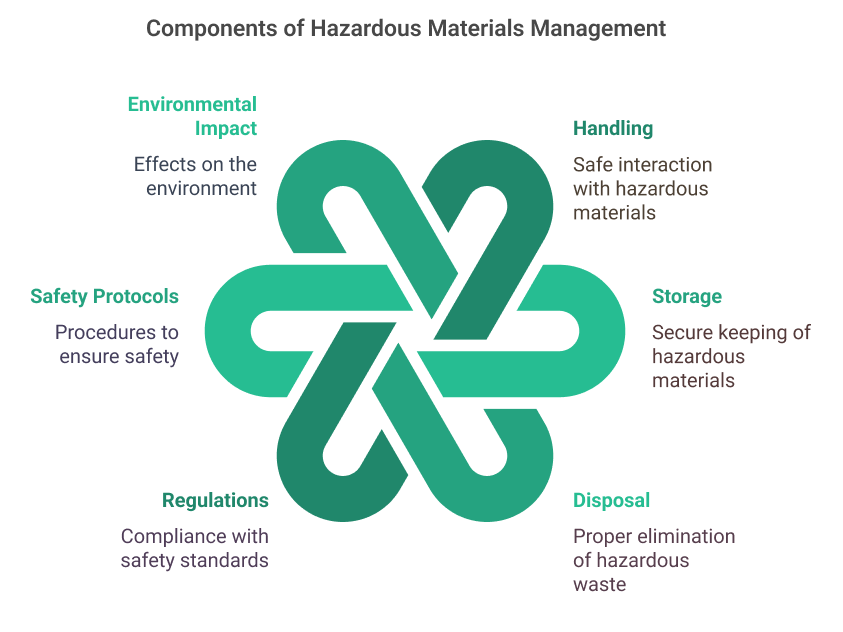

Hazardous materials management involves safely handling, storing, and disposing of substances that pose a risk to human health, safety, or the environment during maintenance activities. These materials can include chemicals, gases, flammable substances, corrosive liquids, and other dangerous goods that require special precautions to ensure safe working conditions.

Strict regulations govern the management of hazardous materials, such as OSHA’s Hazard Communication Standard (HazCom) in the United States. This standard mandates that employers provide employees with information about hazardous substances through safety data sheets (SDS), proper labeling, and training.

Organizations must also implement procedures to prevent exposure to hazardous materials, including using personal protective equipment (PPE), proper ventilation, and containment systems.

Technicians must follow safety protocols during maintenance tasks such as replacing chemical-based components, cleaning with industrial solvents, or disposing of contaminated materials to avoid spills, leaks, and exposure.

Hazardous waste generated during maintenance must be disposed of according to environmental regulations to prevent contamination of air, water, or soil.

Effective hazardous materials management is essential for protecting workers, ensuring compliance with health and safety regulations, and minimizing the organization’s environmental impact.

How can Maintenance Organizations manage Hazardous Waste?

Identification and Classification

The first critical step involves appropriately identifying and classifying all hazardous waste materials. Maintenance organizations must thoroughly examine their waste streams and categorize materials according to EPA classifications: ignitable, corrosive, reactive, or toxic.

For instance, solvents used to clean parts would be classified as ignitable waste, while battery acid would be classified as corrosive. This classification process requires detailed knowledge of the materials’ properties and careful documentation of their characteristics.

Storage and Containment

Once hazardous materials are identified, they must be stored properly to prevent spills, leaks, or environmental contamination. This involves using appropriate containers compatible with the waste materials – for example, corrosive materials must be stored in containers with special corrosion-resistant linings.

The storage area needs proper ventilation, temperature control, and secondary containment systems to prevent leaks. Organizations should establish clear protocols for labeling containers with content information, accumulation start dates, and hazard warnings.

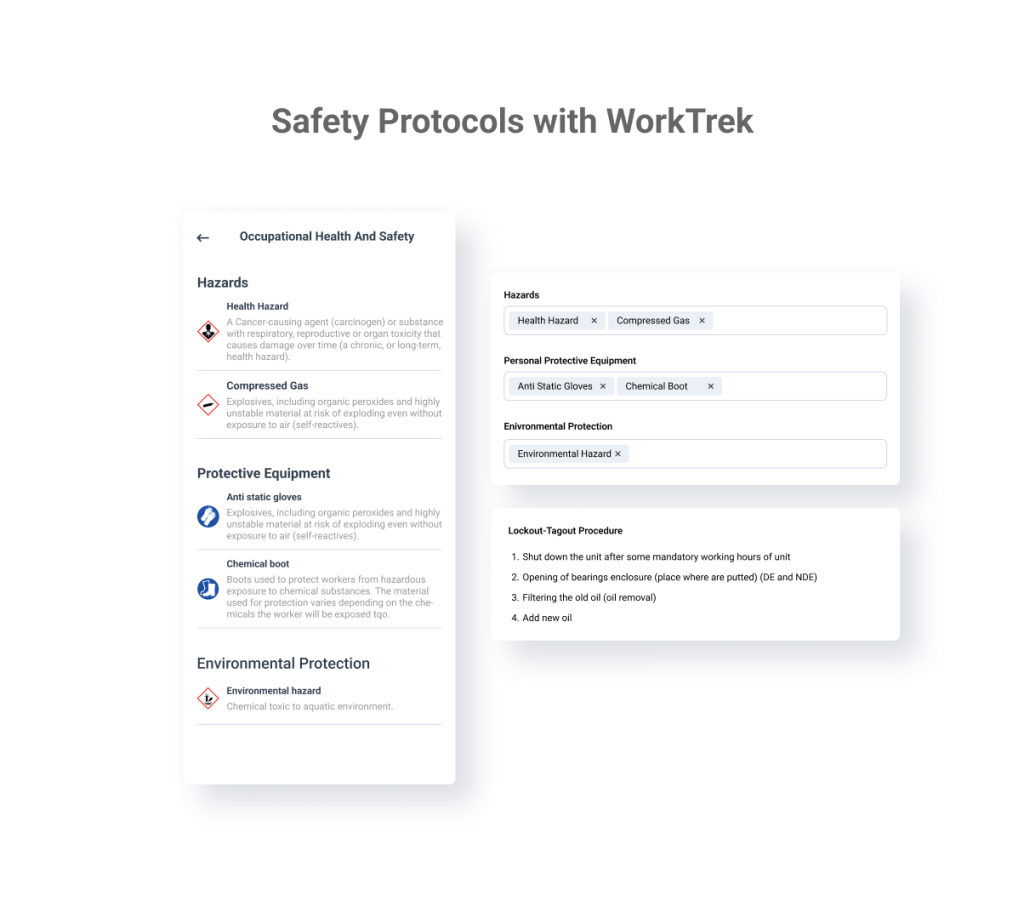

Training and Safety

Protocols Comprehensive training programs ensure all personnel understand proper handling procedures and emergency responses. This includes teaching workers about personal protective equipment requirements, proper lifting techniques for hazardous containers, spill response procedures, and evacuation protocols.

Regular safety meetings and refresher training sessions help maintain awareness and reinforce proper procedures. For instance, maintenance staff should know exactly what to do if they discover a chemical spill, including which emergency response team to contact and what immediate containment actions to take.

Documentation and Record-Keeping

Maintaining detailed records is crucial for compliance and safety. Organizations must track hazardous waste generation, movement, and disposal through a comprehensive manifest system. This includes documenting waste quantities, types, storage locations, transfer dates, and ultimate disposal information.

Modern maintenance management systems can help automate this process by generating electronic tracking records and maintaining all required documentation.

Transportation and Disposal

Working with certified hazardous waste transporters and disposal facilities is essential. Organizations must verify that their transport partners have proper Department of Transportation certifications and that disposal facilities have appropriate permits for handling specific types of waste.

The maintenance organization should maintain detailed records of all shipments, including manifest documents that track the waste from generation to final disposal.

Emergency Response

Planning and Developing comprehensive emergency response plans are crucial. These plans should outline specific emergency procedures, such as chemical spills, fires, or exposure incidents. The plans must include emergency contact information, evacuation routes, spill containment procedures, and coordination protocols with local emergency responders. Regular drills and simulations help ensure all personnel know their roles during emergencies.

Regular Audits and Inspections

Implementing a regular audit program helps identify potential problems before they become serious issues. These audits should examine storage areas, container conditions, documentation completeness, and compliance with safety procedures.

For example, weekly inspections might check for proper container labeling and signs of container deterioration, while monthly audits might review documentation completeness and training records.

Waste Minimization Strategies Organizations should develop strategies to reduce hazardous waste generation. This might involve:

- Substituting less hazardous materials when possible

- Implementing more efficient maintenance procedures that use fewer hazardous materials

- Recycling and reusing materials when safe and practical

- Modifying equipment or processes to reduce waste generation

Regulatory Compliance

Monitoring Staying current with changing regulations requires ongoing attention. Organizations should assign responsibility for monitoring regulatory changes and updating procedures accordingly. This includes maintaining relationships with regulatory agencies, participating in industry groups, and regularly reviewing compliance requirements.

Technology Integration

Modern technology can significantly improve hazardous waste management through:

- Electronic tracking systems for waste movement

- Automated documentation and reporting tools

- Real-time monitoring of storage conditions

- Digital training and certification tracking

- Mobile apps for conducting inspections and audits

Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for free