What is Diagnosis for Maintenance Organizations?

In maintenance, diagnosis refers to identifying the root cause of a malfunction or failure in equipment or systems. When a problem arises, maintenance technicians perform diagnostic procedures to determine the underlying issue before deciding on the appropriate corrective action. Diagnosing problems accurately is essential to avoid unnecessary repairs and ensure the equipment is correctly restored to working order.

Diagnosis can involve various techniques, including visual inspections, sensor data analysis, and diagnostic tools like multimeters or vibration analyzers. In complex systems, diagnostic processes may also include reviewing maintenance logs, analyzing operational data, or conducting tests to isolate potential causes of failure. Once the root cause is identified, technicians can repair or replace the faulty components and prevent the problem from reoccurring.

Accurate diagnosis is critical for minimizing downtime and reducing the cost of repairs. It also plays an important role in preventive maintenance, where early detection of potential issues allows maintenance teams to address problems before they lead to more significant failures. Modern diagnostic tools and software, often integrated with CMMS platforms, make identifying issues easier and ensure that maintenance actions are targeted and effective.

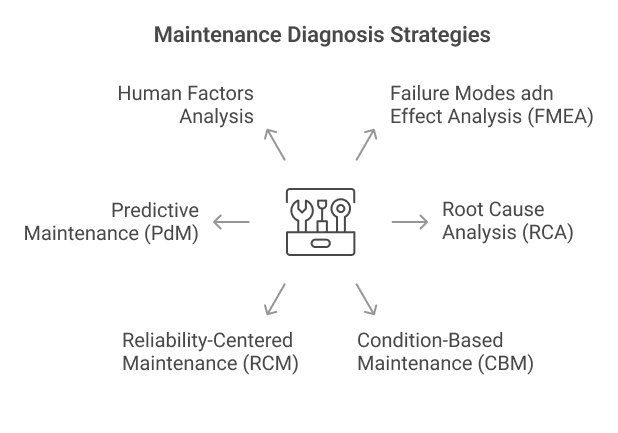

Diagnosis Strategies for Maintenance Organizations

Maintenance organizations can employ various diagnosis strategies to optimize their operations and improve overall equipment reliability and performance. These strategies focus on identifying and addressing the root causes of equipment failures and performance issues in a timely and effective manner. Some key diagnosis strategies that maintenance organizations should consider include:

- Failure Mode and Effects Analysis (FMEA): As discussed earlier, FMEA is a proactive approach to identifying potential failure modes and their effects on equipment performance. By conducting FMEAs on critical assets, maintenance teams can prioritize their diagnostic efforts and develop targeted strategies for preventing or mitigating the most impactful failures.

- Root Cause Analysis (RCA): RCA is a structured problem-solving methodology that identifies the underlying causes of equipment failures or performance issues. Common RCA techniques include:

- 5 Whys Analysis: Asking “why” repeatedly to drill down to the root cause of a problem.

- Fishbone (Ishikawa) Diagram: Visualizing the potential causes of a problem in categories such as man, machine, material, method, measurement, and environment.

- Fault Tree Analysis: Creating a logical diagram of the potential causes of a specific failure or event.

- Condition-Based Maintenance (CBM): CBM involves monitoring equipment performance and condition in real-time using various sensors and data collection technologies. By analyzing this data, maintenance teams can detect early signs of potential failures and take proactive steps to address them before they result in unplanned downtime. CBM techniques include:

- Vibration Analysis: Monitoring changes in equipment vibration patterns to detect issues such as imbalance, misalignment, or bearing wear.

- Thermography: Using infrared cameras to identify abnormal heat patterns that may indicate electrical or mechanical issues.

- Oil Analysis: Analyzing lubricant samples to detect contaminants, wear particles, or changes in oil properties that may indicate equipment degradation.

- Reliability-Centered Maintenance (RCM): RCM is a comprehensive approach to maintenance planning that focuses on identifying and prioritizing the maintenance tasks that are most effective in maintaining equipment reliability. RCM involves a systematic analysis of equipment functions, failure modes, and the consequences of failures, and the development of a tailored maintenance strategy based on this analysis. RCM helps maintenance teams optimize resources by focusing on the most critical tasks and eliminating unnecessary or ineffective maintenance activities.

- Predictive Maintenance (PdM): PdM takes CBM further by using advanced analytics and machine learning techniques to predict when equipment failures are likely. By analyzing historical data on equipment performance and condition, along with other relevant factors such as environmental conditions and production schedules, PdM models can provide early warnings of potential failures and help maintenance teams plan and schedule interventions before failures occur.

- Human Factors Analysis: Human errors can significantly contribute to equipment failures and performance issues. By analyzing the human factors that influence maintenance activities, such as training, communication, and work procedures, maintenance organizations can identify opportunities to improve the reliability and consistency of maintenance work. Techniques such as Task Analysis and Human Reliability Analysis (HRA) can be used to assess the potential for human errors and develop strategies for mitigating them.

To effectively implement these diagnosis strategies, maintenance organizations should:

- Develop a clear understanding of their critical assets and the failure modes most likely impacting their performance.

- Invest in the tools, technologies, and training to support the selected diagnosis strategies.

- Foster a culture of continuous improvement and data-driven decision-making, where diagnosis results are regularly reviewed and used to inform maintenance planning and optimization efforts.

- Collaborate closely with other stakeholders, such as operations, engineering, and reliability teams, to ensure that diagnosis strategies are aligned with overall business objectives and that learnings are shared across the organization.

Organizations can optimize their maintenance operations, reduce unplanned downtime, and improve overall asset reliability and performance by adopting a proactive and systematic approach to maintenance diagnosis. Effective diagnosis strategies are critical for driving the transition from reactive to predictive maintenance and ensuring that maintenance resources are allocated where they can deliver the greatest value to the organization.

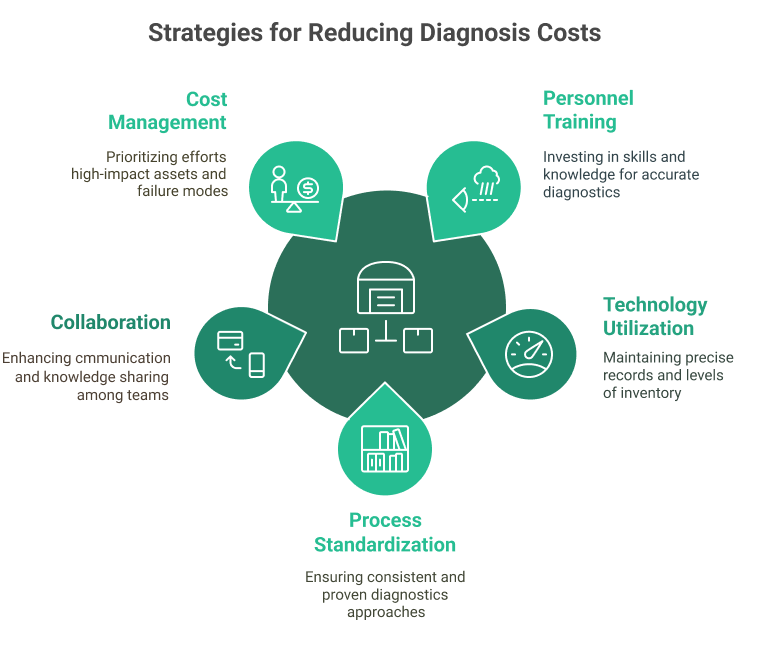

How to Reduce Diagnosis Costs for Maintenance Organizations

Maintenance organizations can reduce diagnosis costs by implementing various strategies that focus on optimizing the efficiency and effectiveness of their diagnostic processes.

Train and Develop Maintenance Personnel

One key approach is to invest in training and development for maintenance personnel, ensuring they have the necessary skills and knowledge to diagnose equipment issues accurately. This can involve providing in-depth training on specific diagnostic techniques, such as vibration analysis or thermography, and fostering a culture of continuous learning and knowledge sharing among team members.

Leverage Technology like CMMS

Another important strategy is to leverage technology to streamline diagnostic processes and reduce manual effort. This can include implementing condition monitoring systems that automatically collect and analyze data on equipment performance and alerting maintenance teams to potential issues before they escalate into costly failures. Predictive maintenance software can also identify patterns and trends in equipment behavior, enabling maintenance teams to proactively address potential problems and avoid unplanned downtime.

Standardize Processes

Standardizing diagnostic processes and procedures can also help reduce costs by ensuring maintenance personnel follow consistent, proven approaches to identifying and resolving equipment issues. This can involve developing standard operating procedures (SOPs) for common diagnostic tasks and establishing clear guidelines for when to escalate issues to higher levels of expertise. By reducing variability and improving the consistency of diagnostic work, organizations can minimize the time and resources required to identify and resolve problems.

Collaborate and Communicate

Collaboration and communication are also critical for reducing diagnosis costs. Maintenance teams should work closely with other stakeholders, such as operations and engineering personnel, to share knowledge and insights about equipment performance and potential issues. This can help identify problems early before they result in costly downtime or repairs. Regular meetings and forums for discussing diagnostic challenges and best practices can also help foster a culture of continuous improvement and knowledge sharing.

Focus on Critical Assets

Finally, organizations can reduce diagnosis costs by focusing on the most critical assets and failure modes. By prioritizing diagnostic efforts based on their potential impact on production and other essential business objectives, maintenance teams can ensure that they are allocating their resources where they will deliver the greatest value. This can involve conducting regular criticality assessments to identify the assets and failure modes that pose the most significant risk to the organization and developing targeted diagnostic strategies to address these priorities.

Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for free