What is a maintenance engineer?

A Maintenance Engineer combines engineering expertise with hands-on technical knowledge to develop, oversee, and optimize industrial equipment, facilities, and systems maintenance strategies. They serve as the bridge between high-level engineering principles and practical maintenance execution.

Obtaining certifications, particularly the Certified Reliability Engineer (CRE) credential offered by the American Society for Quality, is significant as it validates an engineer’s expertise in maintenance and reliability engineering.

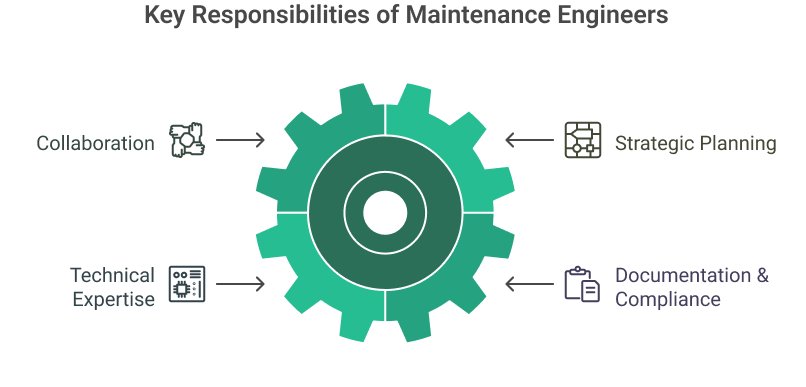

Job Responsibilities of a Maintenance Engineer

The role encompasses both strategic and technical aspects. At the strategic level, they develop comprehensive maintenance programs, analyze equipment performance data to predict potential failures and implement preventive measures.

Hiring maintenance engineers across various industries is crucial. They contribute to cost savings and efficiency by minimizing downtime and improving preventive maintenance strategies.

They create and maintain documentation for maintenance procedures, establish quality control standards, and ensure compliance with safety regulations and industry standards.

On the technical side, they investigate complex equipment failures, conduct root-cause analyses, and design solutions to prevent recurring issues. They often lead projects to improve system reliability and efficiency, working with vendors to evaluate and implement new technologies.

They also collaborate with other departments to optimize maintenance schedules that minimize production disruptions.

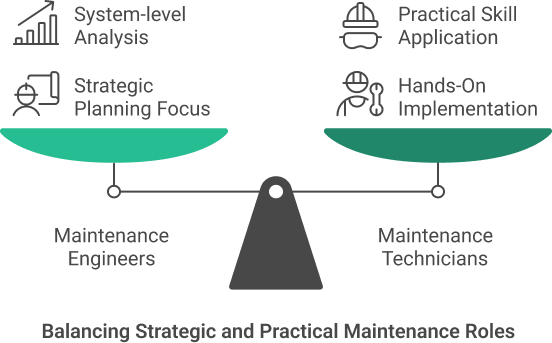

Key Differences from Maintenance Technicians

The primary distinction lies in their scope and approach to maintenance. While Maintenance Technicians focus on executing hands-on repairs and routine maintenance tasks, Maintenance Engineers take a more analytical and strategic role. Skilled maintenance workers are crucial in maintenance engineering jobs, as their expertise can significantly impact the efficiency and effectiveness of maintenance departments.

Think of it like the difference between a carpenter who builds and repairs structures (technician) and an architect who designs and plans them (engineer).

Maintenance Engineering Educational Requirements

Maintenance Engineers typically need a bachelor’s degree in engineering. They typically need technical skills to read engineering drawings and do advanced analytics.

Professional qualifications accredited by institutions such as the Institution of Mechanical Engineers (IMechE) are particularly beneficial for career progression and achieving chartered or incorporated engineer status. They focus on system-level thinking, using engineering principles to solve problems.

They develop maintenance strategies, analyze trends, and make data-driven decisions about equipment lifecycle management. Their work often involves complex calculations, technical documentation, and project management.

In contrast, Maintenance Technicians specialize in the practical implementation of maintenance tasks. They perform the actual repairs, preventive maintenance, and equipment inspections based on the procedures and schedules developed by Maintenance Engineers. Their expertise is more focused on specific trade skills and hands-on troubleshooting.

For example, a Maintenance Technician might repair a malfunctioning production line component in a manufacturing plant.

At the same time, the Maintenance Engineer would analyze the failure patterns across multiple components, design process improvements, and develop new maintenance protocols to prevent future failures.

Maintenance Engineer Certification Requirements

Below are a few types of maintenance engineer certificates:

Obtaining professional status, such as incorporated or chartered engineer, awarded by the Engineering Council, can significantly enhance your earning potential and career prospects.

Professional Engineer (PE)

Professional Engineering (PE) licensure is one of the most prestigious certifications. To become a PE, engineers must pass the Fundamentals of Engineering (FE) exam to become Engineers in Training (EIT).

They can take the PE exam after gaining several years of work experience under licensed engineers. This certification is particularly important for maintenance engineers who must sign off on critical system modifications or safety protocols.

The Society for Maintenance and Reliability Professionals (CMRP) offers a widely recognized certification tailored to maintenance and reliability.

This certification validates comprehensive knowledge of maintenance strategies, reliability principles, and business practices. It proves that you understand not just how to fix equipment but also how to prevent failures and optimize entire maintenance programs.

Specialized Certificates

Specialized certifications become important for those working with specific equipment or in particular industries. For instance, maintenance engineers in HVAC systems might pursue certification from ASHRAE (American Society of Heating, Refrigerating, and Air-Conditioning Engineers). Those working in manufacturing environments often benefit from Six Sigma or Lean Manufacturing certifications.

Safety Certification

Safety certifications play a crucial role as well. Many organizations require maintenance engineers to hold certifications from organizations like OSHA (Occupational Safety and Health Administration) or specialized safety credentials relevant to their industry. For example, a maintenance engineer working in a chemical plant might need Process Safety Management (PSM) certification.

Other Certificates

The International Organization for Standardization (ISO) offers several relevant certifications. ISO 55000 certification, which focuses on asset management, has become increasingly important for maintenance engineers who oversee large-scale equipment portfolios. This certification demonstrates an understanding of systematic approaches to maintaining and optimizing asset performance throughout their lifecycle.

It’s worth noting that certification requirements often vary by location and industry. Some jurisdictions might have specific legal requirements for maintenance engineers working on certain types of equipment.

For instance, working on boilers or pressure vessels might require special state or local certifications.

Continuous learning and certification renewal are also key aspects. Most professional certifications require ongoing education credits to maintain active status, ensuring maintenance engineers stay current with evolving technologies and best practices in their field.

Imagine a maintenance engineer working at a large manufacturing facility to give you a clearer picture. They might start with their PE license for general engineering authority, add a CMRP certification to demonstrate maintenance expertise, obtain Six Sigma certification to align with company quality initiatives and maintain various safety certifications specific to their facility’s equipment.

Skills and Qualities of a Maintenance Engineer

A successful maintenance engineer must possess diverse skills, combining technical expertise and strong interpersonal and management abilities.

At the core, they need a robust understanding of mechanical, electrical, and control systems to effectively diagnose and resolve equipment issues. Analytical and problem-solving skills are crucial for identifying the root causes of equipment failures and developing long-term solutions.

Communication and interpersonal skills are equally important, as maintenance engineers often collaborate with maintenance technicians, production staff, and other stakeholders. They must be able to convey complex technical information clearly and work as part of a team to ensure smooth operations.

Leadership and management skills are essential for leading maintenance teams, prioritizing tasks, and managing routine maintenance tasks and major repairs. Working under pressure and managing stress is also vital, especially when dealing with unexpected equipment failures or tight deadlines.

To ensure compliance and maintain safety, it is necessary to be familiar with maintenance procedures, industry-specific regulations, and standards, such as OSHA and ISO 9001.

Computerized maintenance management systems (CMMS) and other software tools helps streamline maintenance operations and optimize resource allocation.

Lastly, a strong business acumen is beneficial for managing maintenance costs and making data-driven decisions to enhance equipment maintenance and overall efficiency.

Career Benefits and Salary

A career as a maintenance engineer offers numerous benefits, including competitive salaries and opportunities for professional growth. Maintenance engineers can expect median salaries ranging from $60,000 to over $100,000 annually, depending on their experience, location, and industry.

There are ample opportunities for career advancement, with potential progression to senior leadership roles such as maintenance manager or technical expert. The diverse range of work environments and industries, from manufacturing to construction, ensures that maintenance engineers can find a niche that suits their interests and skills.

Professional growth and development are integral to this career, with various training and certification programs available to enhance expertise. Specialization in mechanical engineering, electrical engineering, or control systems can further boost career prospects and job satisfaction.

Moreover, maintenance engineers often find fulfillment in ensuring the smooth operation of complex equipment and systems, knowing their work directly impacts productivity and safety.

Job Outlook and Growth for Maintenance Engineering

The job outlook for maintenance engineers is promising, driven by the increasing complexity of industrial machinery and the growing need for specialized maintenance skills.

Efficient and effective maintenance strategies are crucial for minimizing downtime and optimizing resource allocation, making maintenance engineers indispensable in many industries.

The expanding use of computerized maintenance management systems (CMMS) and other software tools is transforming maintenance operations, requiring engineers to stay adept with the latest technologies.

Additionally, the focus on safety and regulatory compliance requires maintenance engineers to remain up-to-date with industry-specific regulations and standards.

Emerging industries, such as renewable energy and advanced manufacturing, also create new opportunities for maintenance engineers. According to the Bureau of Labor Statistics, employment in this field will grow by 4% from 2020 to 2030.

While this growth rate is slower than the average for all occupations, it varies by industry, with some sectors experiencing faster growth than others.

Overall, the demand for skilled maintenance engineers is expected to remain strong, ensuring a stable and rewarding career path for those in the field.

Types of Organizations that need Maintenance Engineers

Below are a few industry types that hire and depend on maintenance engineers:

Maintenance engineering jobs typically require a degree in engineering or a related field, and salary expectations can vary widely based on the organization’s size and the industry.

Additionally, many maintenance engineers work independently or as freelancers, offering their expertise through engineering consultancy services in power generation, oil and gas, or IT sectors.

Manufacturing

Manufacturing facilities are among the largest employers of maintenance engineers. These include automotive plants, food processing facilities, pharmaceutical manufacturing, and electronics production.

Maintenance engineers are vital in these settings because even minor equipment downtime can cost millions in lost production. Increasing expectations for manufacturing equipment highlight a demand for improved availability and reduced process variation.

For instance, a maintenance engineer might oversee the reliability of robotic welding systems, conveyor networks, and automated painting booths in an automotive assembly plant.

Heavy Industry

Heavy industry and resource extraction operations also depend heavily on maintenance engineers. This includes mining companies, oil refineries, steel mills, and power generation plants.

These facilities operate complex, high-value equipment under challenging conditions.

At a power plant, for example, maintenance engineers ensure the continuous operation of turbines, boilers, and cooling systems that cannot afford to fail.

Transportation

Transportation and logistics organizations form another key sector. Airlines employ maintenance engineers to develop maintenance programs for their aircraft fleets, while railway companies need them to maintain tracks, signals, and rolling stock.

Shipping companies rely on maintenance engineers to operate efficiently and safely. Consider a major airport where maintenance engineers must coordinate the maintenance of everything from jet bridges to baggage handling systems.

Industrial

Large commercial and institutional facilities like shopping malls, hospitals, universities, and data centers also require maintenance engineers.

These buildings have complex HVAC systems, electrical infrastructure, and other critical systems that need constant monitoring and maintenance.

For instance, a hospital’s maintenance engineer must ensure that operating rooms maintain precise environmental conditions and that backup power systems are always ready.

Government and Municipalities

Municipal infrastructure organizations, such as water treatment facilities, waste management systems, and public transportation networks, employ maintenance engineers to keep essential public services running smoothly.

Their work directly impacts public health and safety. For example, a city’s water treatment plant requires maintenance engineers to ensure that pumps, filters, and control systems operate reliably 24/7.

R&D

Research facilities and laboratories require specialized maintenance engineering. These include particle accelerators, wind tunnels, and clean rooms that require precise environmental control.

The maintenance engineers in these settings must understand the facility’s scientific requirements and the engineering systems that support them.

Concert and Entertainment

Entertainment venues and theme parks also employ maintenance engineers. These engineers maintain complex ride systems, show effects, and facility infrastructure. They must balance safety requirements with minimizing downtime during peak operating hours.

Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for free