What is a Maintenance Manager?

A Maintenance Manager oversees all maintenance operations, equipment reliability, and facility upkeep within an organization. Think of them as orchestra conductors—they coordinate various teams and resources to ensure all machinery and facilities work harmoniously together.

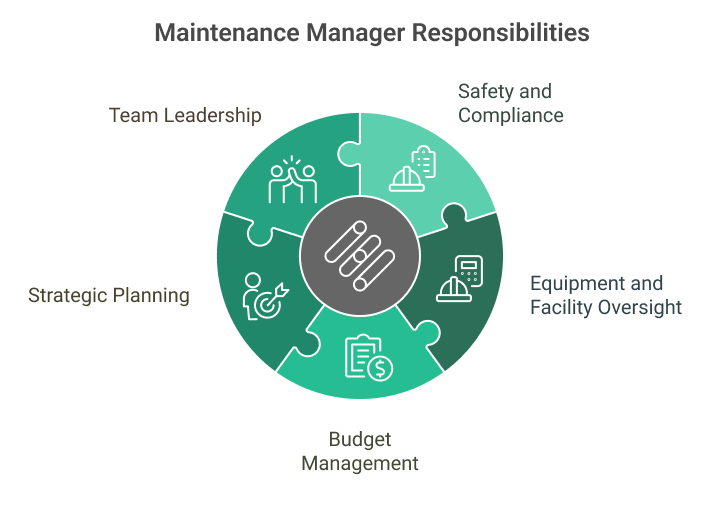

Responsibilities of Maintenance Managers

To understand the depth of a maintenance manager’s job description, let’s explore the core responsibilities that define a Maintenance Manager’s position:

Equipment and Facility Oversight

The Maintenance Manager ensures all machinery, equipment, and facilities remain in optimal working condition. They develop and implement maintenance strategies, from routine inspections to major repairs. This involves monitoring equipment performance, scheduling maintenance activities, and deciding about repairs versus replacements. Additionally, they must ensure that all maintenance activities comply with health and safety regulations to protect employees and maintain operational standards.

Team Leadership

Like a sports team coach, the Maintenance Manager directs maintenance staff, technicians, and contractors. A good maintenance manager handles staffing, training, work assignments, and performance evaluations.

A great maintenance manager possesses technical skills and demonstrates strong leadership and emotional intelligence to manage their team effectively. They must ensure their team has the right skills and resources to perform effectively while maintaining safety standards.

Strategic Planning

Maintenance Managers develop long-term maintenance strategies that align with organizational goals. They create maintenance schedules, establish preventive maintenance programs, and plan for equipment upgrades or replacements. This requires balancing immediate needs with long-term objectives while managing budgets effectively.

Budget Management

They oversee maintenance budgets, including labor costs, parts inventory, equipment purchases, and contractor services. This involves making strategic decisions about resource allocation and justifying maintenance investments to senior management.

Safety, Compliance, and Preventive Maintenance

A maintenance manager ensures that all activities comply with safety regulations and industry standards. They develop safety protocols, conduct training, and maintain required documentation for regulatory compliance.

Industries where Maintenance Managers play an important role

Industries that particularly value Maintenance Managers include:

- Manufacturing: Ensuring that machinery and equipment are running smoothly to avoid production delays.

- Healthcare: Maintaining medical equipment and ensuring facilities meet health and safety standards.

- Hospitality: Keeping hotel facilities in top condition to provide a pleasant experience for guests.

- Education: Ensuring that school facilities are safe and operational for students and staff.

- Real Estate: Managing the maintenance of buildings and ensuring that properties are well-kept.

Effective facility management goes beyond technical skills and highlights the importance of a maintenance manager’s ability to train and develop their team.

Manufacturing

In the manufacturing industry, maintenance managers are the backbone of production efficiency. They play a pivotal role in ensuring that production lines and equipment run smoothly, minimizing downtime, and reducing costs. These professionals oversee all maintenance operations, from routine inspections to emergency repairs, ensuring that every piece of machinery is in top working condition.

Manufacturing maintenance managers are also responsible for managing maintenance staff, including technicians and supervisors. They coordinate their team’s efforts and ensure everyone is well-trained and equipped to handle maintenance tasks.

By implementing robust preventive maintenance strategies, they can foresee and address potential issues before they escalate, thus maintaining uninterrupted production and safeguarding the company’s bottom line.

Manufacturing In manufacturing facilities

Maintenance Managers are essential for keeping production lines running smoothly. In the manufacturing industry, maintenance managers oversee all maintenance operations, from routine inspections to emergency repairs, ensuring that every piece of machinery is in top working condition. They prevent costly downtime and ensure product quality through proper equipment maintenance.

Healthcare

Healthcare Hospitals and medical facilities rely on Maintenance Managers to keep critical equipment functioning reliably. This includes everything from HVAC systems to sophisticated medical devices.

Property and Facilities Management

Large commercial properties, such as office buildings, shopping centers, and apartment complexes, need Maintenance Managers to oversee building systems, repairs, and renovations. They work closely with maintenance supervisors to delegate tasks and ensure efficient maintenance processes.

Logistics and Transportation

Airlines, railways, and shipping companies employ Maintenance Managers to maintain their fleets and facilities. This ensures vehicles and infrastructure remain safe and reliable. Understanding the responsibilities and skills necessary for a maintenance technician is crucial for effective team management in these industries.

Educational Facilities

Education Universities and large school districts need Maintenance Managers to oversee campus facilities, including buildings, grounds, and technical equipment.

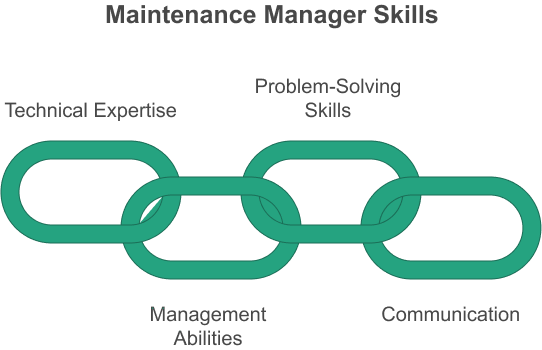

What skills do Maintenance Managers need?

Skills and Qualifications Needed:

Maintenance Managers need diverse skills to oversee a facility’s maintenance operations effectively. Technical skills are crucial, as they must understand the intricacies of the systems they manage, including HVAC, plumbing, and electrical systems.

Strong leadership and communication skills are also essential; they will lead a maintenance team and coordinate with other departments. Problem-solving skills are necessary to address and resolve issues that arise quickly.

While a high school diploma is often the minimum requirement, some employers may also consider post-secondary education or relevant work experience as alternatives.

Technical Expertise

A strong understanding of mechanical, electrical, and building systems is essential. This typically comes from formal education in engineering or related fields combined with extensive practical experience.

A strong understanding of the skills necessary for maintenance technicians is also essential for effective team management.

Management Abilities

This role requires strong leadership skills, including team management, project coordination, and budget administration.

Problem-Solving Skills

Maintenance Managers must quickly diagnose problems and develop effective solutions, often under pressure and with limited resources.

Communication

They must effectively communicate with various stakeholders, from maintenance staff to senior management, vendors, and contractors.

Education and Certifications

Educational Requirements

A solid educational foundation is crucial to starting a maintenance manager career, particularly in the manufacturing sector.

A bachelor’s degree in mechanical engineering, industrial engineering, or facilities management is typically required. These programs provide the technical knowledge and problem-solving skills necessary for the role.

In some cases, employers may prefer candidates with a master’s degree or specialized training in a specific trade, reflecting the increasing complexity and technological advancement in maintenance operations.

Relevant Certifications

Certifications can significantly enhance a maintenance manager’s credentials and career prospects. Notable certifications include the Certified Maintenance and Reliability Professional (CMRP) and the Certified Maintenance Manager (CMM).

These certifications validate a professional’s expertise in maintenance management, demonstrating their commitment to industry standards and best practices. Earning these certifications can open doors to advanced career opportunities and signal to employers a high level of competence and dedication to the field.

Career Path and Outlook

Career Advancement Opportunities

The career trajectory for maintenance managers is promising, with numerous opportunities for advancement. With experience and a proven track record, maintenance managers can ascend to senior leadership roles such as director of maintenance or vice president of operations.

These positions involve greater strategic oversight and influence over company-wide maintenance policies and procedures.

Additionally, maintenance managers can transition into related fields like facilities management or supply chain management, leveraging their expertise in maintenance processes and team leadership.

For those passionate about broader operational roles, positions such as plant manager or operations manager are attainable, especially with further education and professional development.

The diverse skill set acquired as a maintenance manager provides a strong foundation for various high-level organizational roles.

Impact of Technology on Maintenance Managers

Technology has transformed maintenance managers’ operations, shifting from reactive, paper-based systems to proactive, data-driven approaches.

The Impact of Technology on Maintenance Management

Digital transformation has revolutionized how maintenance managers work in several fundamental ways.

First, it has enabled real-time monitoring and decision-making. Instead of waiting for equipment to fail or relying on fixed maintenance schedules, managers can now access live data about asset performance and condition.

Think of this as having a continuous health monitoring system for equipment, similar to how modern smartwatches track vital signs 24/7.

Task Automation

Technology has also automated many routine tasks that previously required manual effort. Work order generation, parts inventory management, and maintenance scheduling can now be handled automatically based on predefined triggers.

This automation frees maintenance managers to focus on strategic planning and improvement initiatives rather than getting bogged down in day-to-day administrative tasks.

Improved Communication

Furthermore, technology has improved communication and collaboration across maintenance teams. Mobile devices and cloud-based systems allow technicians to access maintenance information, submit reports, and receive work orders from anywhere in the facility. This instant access to information helps reduce response times and improves work efficiency.

Tools for Modern Maintenance Managers

What are some of the tools that maintenance managers can use to improve their job performance:

CMMS Software

Computerized Maintenance Management Systems (CMMS) are the cornerstone of modern maintenance operations. These comprehensive platforms integrate various aspects of maintenance management, from work order tracking to asset history recording.

A good CMMS is like having a central nervous system for maintenance operations, coordinating all maintenance-related activities and information flow.

EAM

Enterprise Asset Management (EAM) systems provide broader functionality for managing assets’ entire lifecycle. These systems help maintenance managers make informed decisions about equipment replacement, upgrades, and retirement based on comprehensive historical data and predictive analytics.

IoT

Internet of Things (IoT) sensors and monitoring devices have become invaluable tools for maintenance managers. These devices continuously collect data about equipment performance, temperature, vibration, and other critical parameters.

This constant data stream enables predictive maintenance strategies by identifying potential issues before they cause failures. It’s similar to how modern cars use sensors to detect and warn about possible problems before they become serious.

Mobile Apps

Mobile maintenance applications have become essential tools for field technicians and managers alike. While working on-site, these apps allow real-time access to equipment information, maintenance procedures, and historical data.

They also enable immediate documentation of work performed, including photos and notes, ensuring accurate record-keeping.

AI and Machine Learning

Advanced Analytics and Artificial Intelligence tools are increasingly being used to process the vast amounts of data collected from various sources. These tools can identify patterns and trends that might not be apparent to human observers, helping predict equipment failures and optimize maintenance schedules.

Think of it as having a highly skilled analyst working 24/7 to spot potential issues and opportunities for improvement.

Digital Twins

Digital Twin technology is emerging as a powerful tool for maintenance managers. These virtual replicas of physical assets allow managers to simulate different scenarios and maintenance strategies without risking actual equipment. It’s like having a sophisticated simulator where you can test different approaches and see their potential outcomes before implementing them in reality.

Augmented Reality

Augmented Reality (AR) tools are beginning to transform how maintenance work is performed and supervised. Using AR devices, technicians can access step-by-step repair instructions overlaid directly on the equipment they’re working on, while managers can remotely observe and guide maintenance work in real time.

How to leverage new technology

To effectively leverage these tools, maintenance managers should:

Ensure proper integration between different systems to avoid data silos and duplicate efforts. Just as different organs in the body need to work together, maintenance technologies should communicate and share information seamlessly.

Invest in training for managers and technicians to fully utilize the capabilities of new tools. The best technology is only as effective as the people using it.

Regularly evaluate and update technological solutions to meet evolving needs and capabilities. Technology should grow with your organization, not constrain it.

Start with basic digital tools and gradually expand as your team becomes more comfortable with technology-enabled maintenance management. This approach helps ensure successful adoption and sustainable improvement.

Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for free