What is Maintenance Scheduling?

Maintenance scheduling is systematically planning and organizing maintenance activities across facilities, equipment, and assets. It involves coordinating labor, parts, tools, and time to ensure regular upkeep while minimizing disruption to operations.

Think of it as creating a detailed roadmap that guides when and how maintenance tasks should be performed, much like how a doctor creates a treatment plan for preventive healthcare.

Benefits of Maintenance Scheduling

Maintenance scheduling delivers multiple advantages that ripple throughout an organization. Equipment reliability improves significantly because regular maintenance prevents small issues from growing into major problems.

This proactive approach typically reduces emergency repairs by 20-30%. Operating costs decrease as well-maintained equipment runs more efficiently, often leading to 12-18% energy savings. Worker safety improves because adequately maintained equipment is less likely to malfunction dangerously.

Additionally, asset lifespan extends considerably – well-maintained equipment can last 30-40% longer than poorly maintained alternatives. Most organizations report increased productivity since scheduled maintenance can be performed during planned downtimes rather than causing unexpected interruptions.

Best ways to create and Track Maintenance Schedules

The most effective tracking of maintenance schedules involves implementing a structured system combining clear documentation with regular reviews. Start by creating a comprehensive asset inventory that includes equipment specifications, maintenance requirements, and service histories.

Develop standardized procedures for each type of maintenance task, including step-by-step instructions and required resources. Establish a priority system based on equipment criticality and operational impact.

Regular schedule reviews should occur weekly or monthly, depending on your operation’s complexity. Consider implementing a feedback loop where technicians can report issues or suggest improvements to the scheduling system.

Tools for Managing Maintenance Schedules

Modern maintenance scheduling benefits from various sophisticated tools, ranging from basic to advanced solutions:

Computerized Maintenance Management Systems (CMMS)

These comprehensive platforms serve as the backbone of modern maintenance operations. Leading solutions like UpKeep or Maintenance Connection offer features including work order management, asset tracking, and automated scheduling. They can analyze maintenance patterns and suggest optimal scheduling based on equipment usage and history.

Enterprise Asset Management (EAM) Software

More robust than CMMS, EAM systems like IBM Maximo or SAP provide deeper analytical capabilities and better integration with other business systems. They’re particularly valuable for large organizations managing complex asset portfolios across multiple locations.

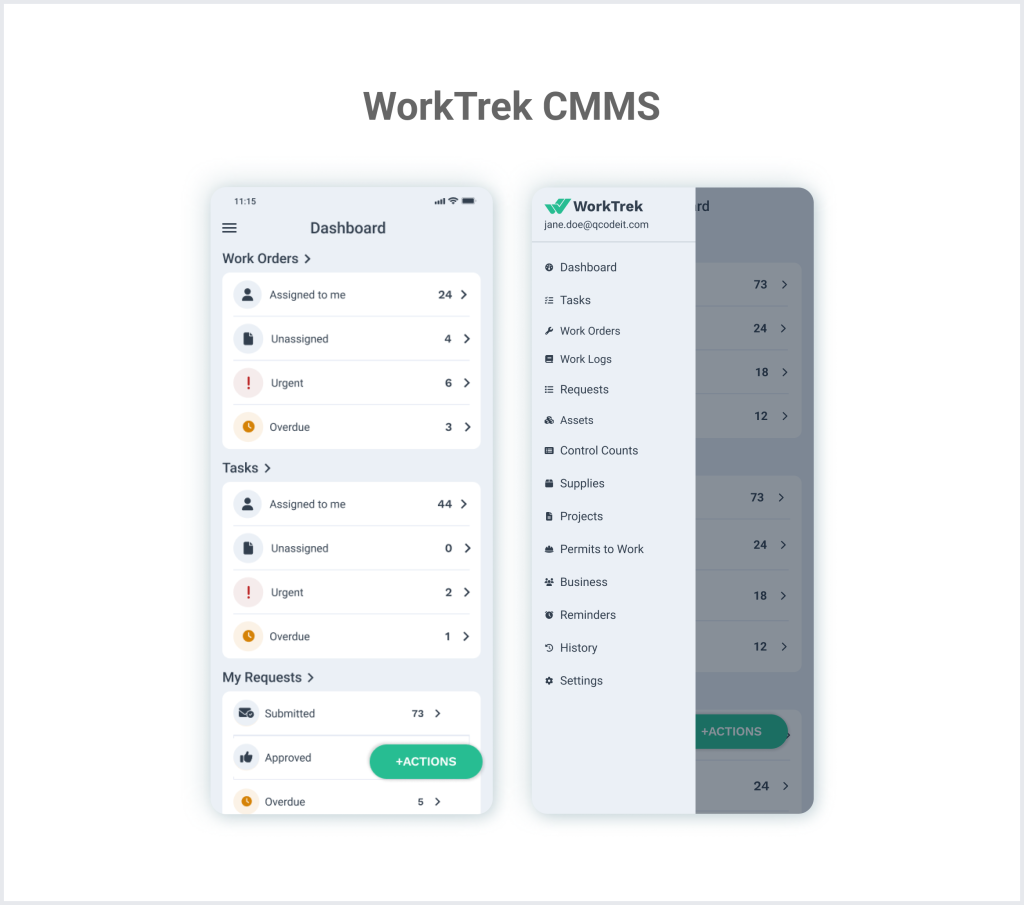

Mobile Maintenance Apps

Mobile solutions enable technicians to access maintenance schedules, document completion, and report issues in real-time from anywhere in the facility. This immediate documentation improves accuracy and reduces administrative overhead.

Simple Digital Tools

Even basic digital tools like Microsoft Excel or Google Calendar can be effective when properly structured for smaller operations. The key is maintaining consistent documentation and ensuring easy access for all relevant team members.

Paper-Based Systems

While not as efficient as digital solutions, traditional paper-based systems can still be effective for very small operations. The crucial element is maintaining organized documentation and establishing clear communication protocols.

Remember that the best tool for your operation depends on several factors: the size of your facility, the number of assets, the complexity of maintenance requirements, and available resources.

Starting with a simpler system and gradually expanding as needs grow often proves more successful than implementing an overly complex system.

Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for free