Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeWant to improve your maintenance team’s performance? This guide covers the 10 best practices for an excellent maintenance team, including hiring, defining roles, using technology, and ensuring safety. Learn how to build and sustain an efficient and reliable team.

This article will provide you with a detailed guide on how to create an excellent maintenance team.

1. Hire the Right Maintenance Technicians

Hiring the right employees can be challenging for any organization. It is sometimes impossible to gauge a person’s ability to do the job without working with them for a set period. The technicians’ skills, experience, and dedication are the foundation of your maintenance department’s success.

One of the first steps during an interview process is evaluating technical prowess and character traits. Neglecting either aspect can increase operational costs through overtime and outsourcing, ultimately impacting your facility’s overall performance.

Creative Recruiting

Employing creative recruiting methods like social media advertising, referrals from your existing employees, and industry trade shows are just a few methods for attracting top talent.

Some of these web platforms can help you reach a wider audience of potential candidates, increasing your chances of finding the perfect fit for your team.

Additionally, offering attractive incentives like 401(k) matching, training, childcare reimbursement, gym memberships, and office snacks can make your job openings more appealing to skilled professionals.

Remember, investing in the right people from the start can save you time and resources, minimize downtime, improve asset performance, and improve the organization’s performance.

Source: WorkTrek

Evaluate Technical Skills

When evaluating candidates’ technical abilities, don’t just look at their resumes. Develop and put potential candidates through practical assessments and tests to gauge their hands-on skills.

These evaluations will offer insight into a candidate’s competence with different hand and power tools, essential skills for any maintenance technician.

Another tip is to include scenario-based questions that present real-world challenges applicants might face on the job. This strategy enables you to discern applicants who possess the required knowledge and can apply it effectively within your facility’s operations.

Cultural Fit

A cultural fit is as important as technical skills when selecting the ideal maintenance technician in many situations. When assembling your maintenance team, weigh cultural fit as heavily as technical abilities. Conducting in-person interviews during recruitment events can help gauge an applicant’s character and potential compatibility with the current team dynamic.

Additionally, have the candidate meet as many team members as possible. The ability of any candidate to work well with others is more important than technical skills.

Finding the right person with the correct cultural fit can sometimes be more important than technical skills. If the candidate has the aptitude, ability, and cultural fit, they can be trained with the correct technical skill set.

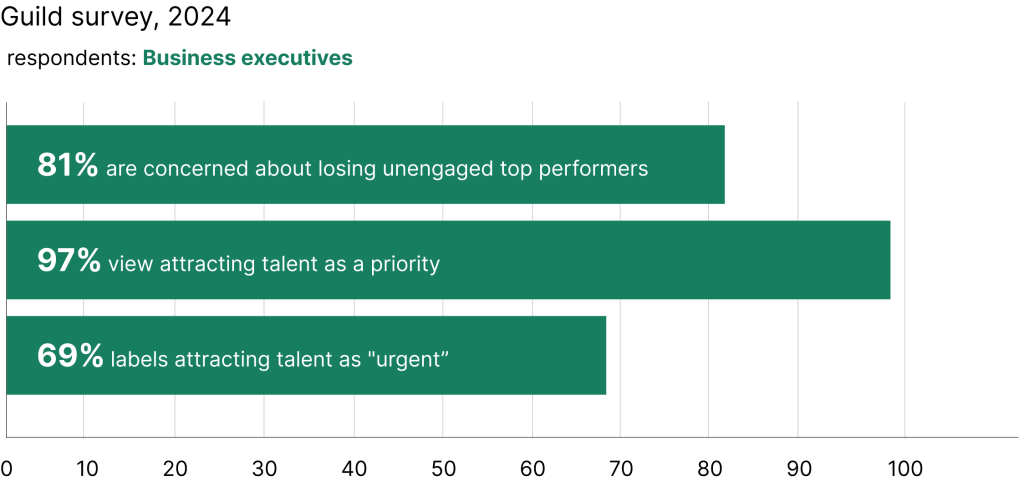

Illustration: WorkTrek / Data: Forbes

2. Establish Clear Roles and Responsibilities

Once you have assembled your ideal maintenance team members, defining their precise roles and responsibilities is the next critical step.

This process is important for maintaining an orderly maintenance department and elevating operational efficiency.

When all maintenance team members clearly understand their tasks and contribute to the collective objective, confusion can be reduced, and maintenance efforts can be optimized.

Role Clarity

Define each team member’s role as clearly as possible. This requires developing comprehensive job descriptions that reflect and support your company’s objectives.

These detailed outlines should clearly define each team member’s duties and demonstrate how their functions interrelate with others in their department.

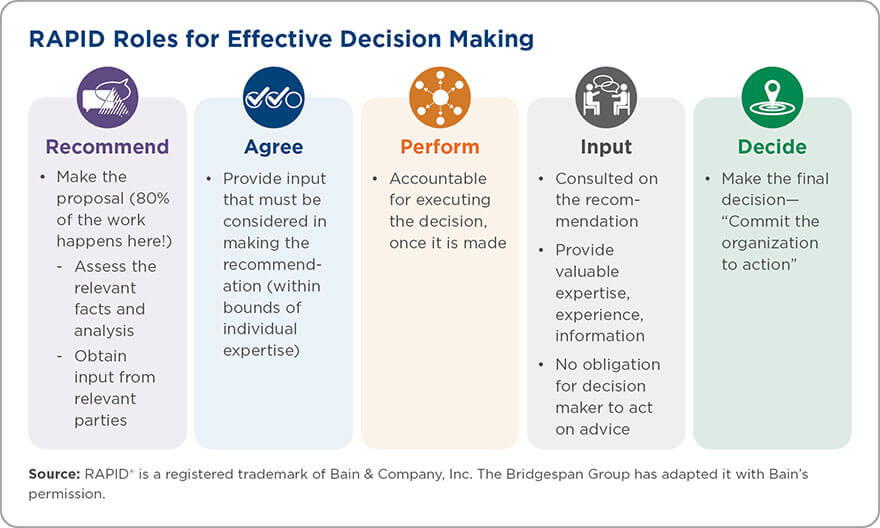

Adopting mechanisms such as RAPID (Recommend, Agree, Perform, Input, Decide)can significantly help clarify each person’s role during decision-making. This method allows every member to gain a clearer insight into their unique contributions and how they connect with those around them, leading to improved unity and productivity.

Source: The Bridgespan Group

When all members are conscious of their contribution to the collective goal, pinpointing areas needing enhancement is simplified while allowing for agility amidst evolving requirements in maintenance tasks.

Accountability

Defining clear roles establishes the foundation for accountability, a pivotal component of an excellent maintenance team.

Implementing robust accountability measures ensures tasks are assigned and executed correctly and on time. This involves tracking completed assignments and responsibilities, which can be facilitated using a Computerized Maintenance Management System (CMMS), as discussed in more detail later.

An important metric is the maintenance backlog, which represents the labor required to complete all pending maintenance tasks.

By regularly monitoring this backlog and holding team members accountable for their assigned duties, you can improve overall team performance, reduce delays, and enhance the efficiency of your maintenance operations.

3. Implement a Computerized Maintenance Management System (CMMS)

As more companies go through digital transformation, implementing a CMMS system for your maintenance organization can significantly enhance productivity, improve routine maintenance management, and increase overall efficiency and equipment health.

CMMS can be the primary hub for upkeep activities, boost coordination, enhance communication, and significantly increase operations’ overall efficiency.

Advantages of CMMS

Implementing a CMMS can provide several benefits and advantages to any maintenance organization. It can reduce operational bottlenecks, improve asset performance, implement preventive maintenance tasks, and give maintenance managers a centralized view of all work activity.

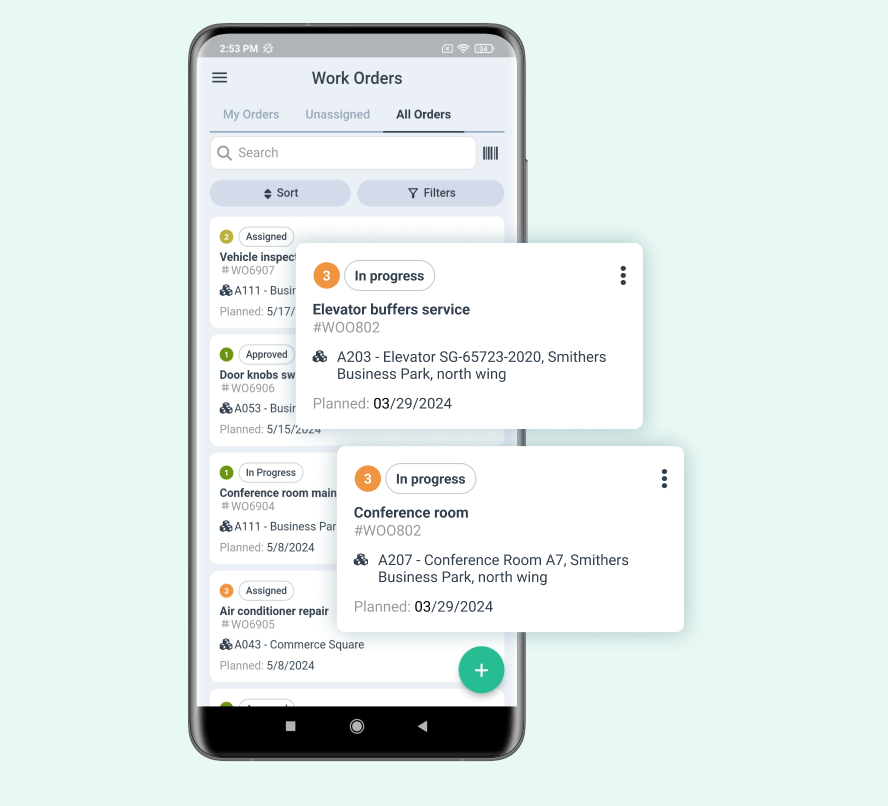

Automate Work Orders

For instance, CMMS can autonomously set in motion service orders preemptively upon particular triggers like machine usage counts or through condition monitoring sensor inputs. This approach and key performance indicators, viewed in CMMS apps, can improve routine maintenance, reduce equipment failures, and organize all maintenance work.

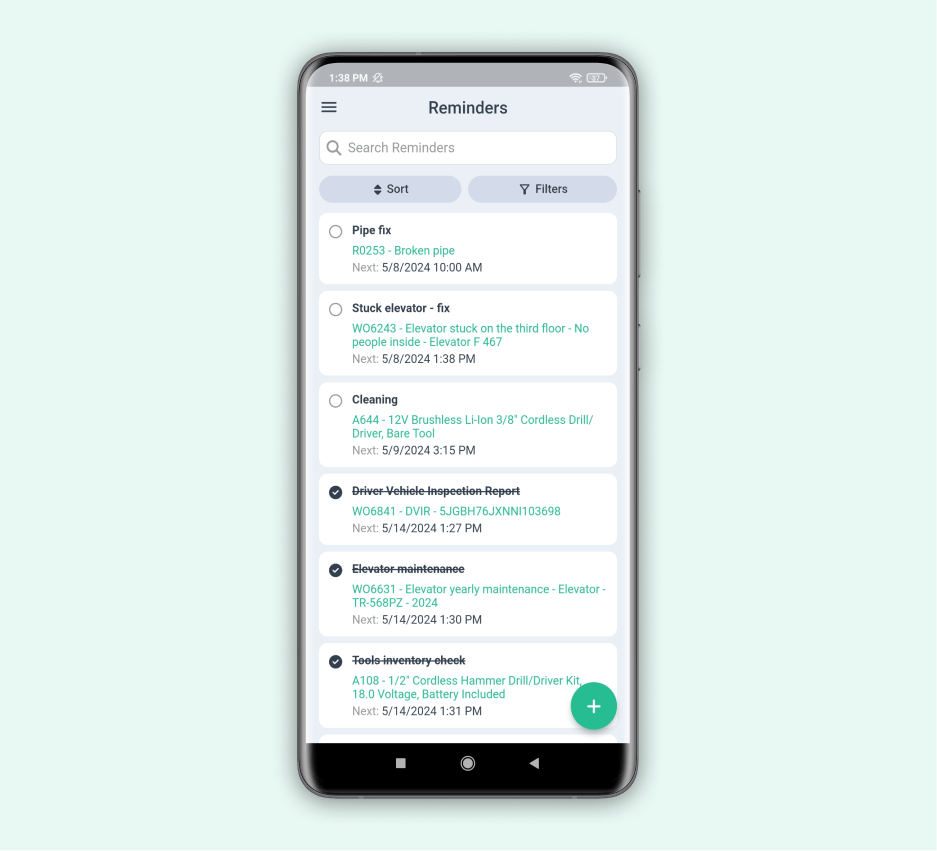

Source: WorkTrek

Alerts

Alerts about upcoming routine services or notifications signaling the need to replenish stock can ensure that maintenance operations run smoothly.

CMMS can also provide alerts through mobile devices or email and SMS to everyone involved in the maintenance process.

Source: WorkTrek

Work Order Management

One of the top benefits of CMMS is its ability to enhance and automate work order management. Some of the benefits include:

- Organizing and monitoring maintenance requests

- Streamlining work order assignments to maintenance technicians

- Improve equipment health and asset performance

- Define custom workflows to meet every business requirement

- Develop and employ industry best practices to work orders

- Reduce manual maintenance efforts

Suppose you are still using paper-based or manual work orders. In that case, a CMMS can greatly improve your maintenance operations, reduce errors and equipment failure, and give the maintenance manager and maintenance supervisor full visibility to all tasks.

Additional CMMS benefits

There are a lot of other benefits to implementing a CMMS. Some of those benefits include:

- Removing inefficiencies in document management since all work orders, manuals, and safety documents are stored online

- Automating duplicate checkers for work orders can reduce team member error

- Organizing various tasks in one place while automating routine procedures conserves time, bolsters precision, and holds your maintenance team more accountable.

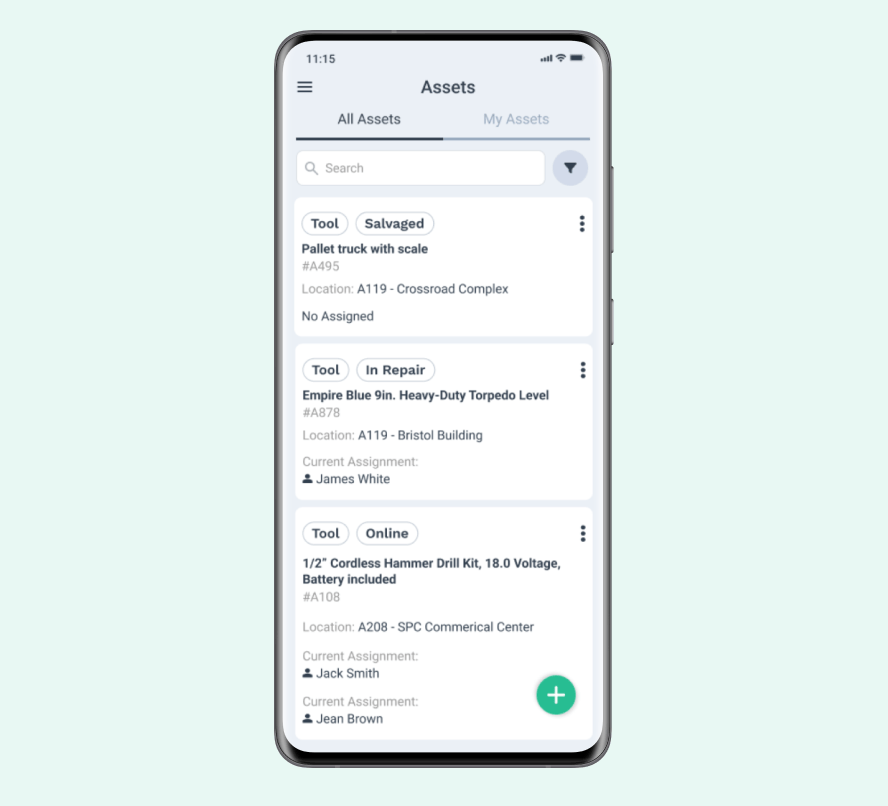

Asset Tracking

A CMMS excels by delivering instantaneous insights into the condition and performance of an organization’s assets.

IoT devices, QR Codes, or even bar codes can simplify tracking critical assets. Paired with a CMMS mobile app, maintenance technicians can scan and obtain critical information about each piece of equipment.

Source: WorkTrek

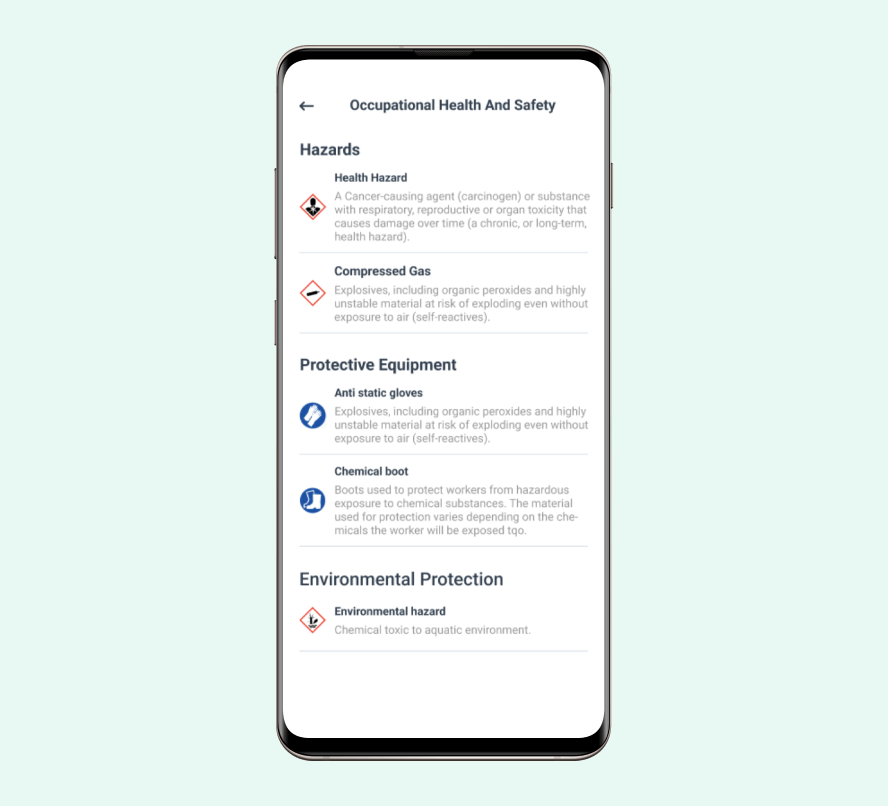

Health and Safety

This information can include health and safety protocols, equipment manuals, and product diagrams. There is no longer a need to manage.

With its asset tracking features, your team can take informed steps when determining what demands priority attention regarding upkeep activities, allocating resources wisely, and planning strategies for long-term asset care.

Source: WorkTrek

4. Prioritize Preventive Maintenance

Most successful maintenance strategies are anchored in an effective preventive maintenance process. Commitment to regular preventive care reduces the likelihood of equipment failure, minimizes unexpected shutdowns, and amplifies the durability of your assets. This method involves routine activities such as:

- Examinations

- Cleansing operations

- Lubrication tasks

- Filter and other consumable replacements

- Spare parts management

Benefits of Preventive Maintenance

It is always advisable to perform preventive maintenance before the system breaks down. This approach will reduce operating costs, minimizing downtime, and can lead to operational success.

Implementing a robust preventive maintenance program requires deliberate planning and reasonable allocation of resources.

One of the first steps in any preventive maintenance strategy is identifying the company’s most important assets and critical components.

Directing your preventative efforts towards key equipment crucial to operations (“critical assets”), you can enhance the effectiveness of any provided services under these protocols while ensuring optimal utilization outcomes from investing funds into it. Yielding better investment returns considering what’s at stake here: those integral parts themselves!

Schedule Regular Inspections

Regularly scheduled inspections are effective preventive maintenance for the maintenance team. These programs can:

- Prevent minor issues from developing into more significant, costly problems through early detection, ultimately conserving time and financial resources.

- Analyzing historical data can enhance the scheduling of future inspections, helping to discern patterns regarding equipment reliability and breakdown frequencies.

- Facilitate a strategic approach for establishing optimal preventative maintenance intervals that can lead to notable cost reductions.

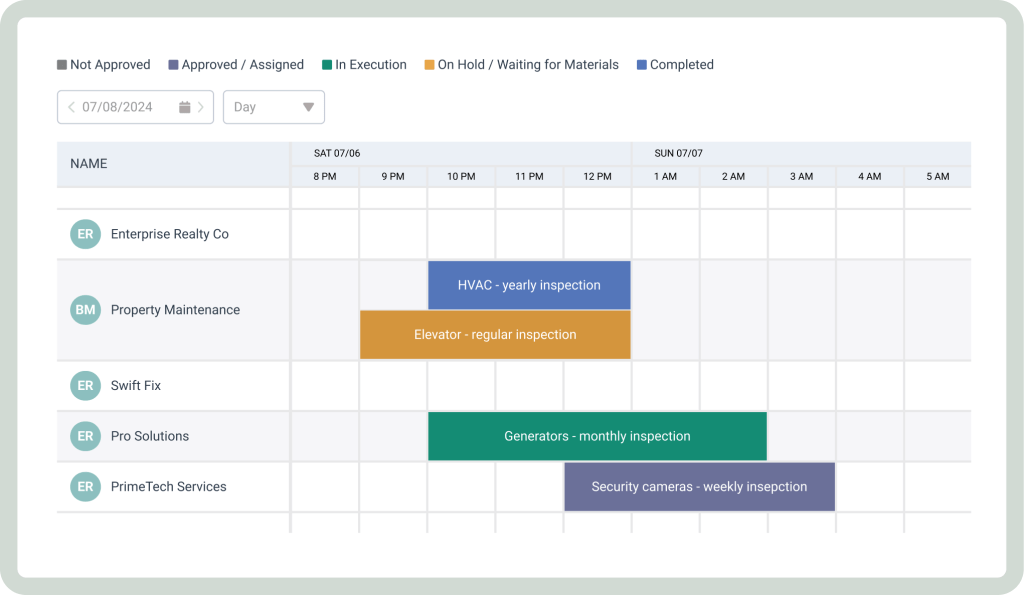

With a Computerized Maintenance Management System (CMMS) you can precisely monitor equipment usage patterns and accurately determine when preventive maintenance is necessary. You can also easily create PM checklists that can optimize your maintenance process.

These standardized procedures guarantee uniformity among different technicians and locations, thus safeguarding quality control and efficiency within your organization’s preventive maintenance endeavors.

Source: WorkTrek

Failure Mode Analysis

Incorporating Failure Mode Analysis (FMA) is a fundamental part of an effective preventive maintenance plan. This systematic process aids in detecting potential root causes behind equipment malfunctions, enabling your maintenance team to take anticipatory action.

With FMA as part of their approach, teams can prevent recurring machinery issues and significantly enhance asset dependability.

The practice requires an in-depth analysis of each item’s operation, examining every imaginable scenario for malfunction and its subsequent impact. By pinpointing vulnerabilities in how the equipment operates or is designed, FMA shapes more precise and beneficial maintenance approaches.

When you weave FMA into your regular maintenance activities, you mitigate the risk of unforeseen failures and maximize efficiency across all maintenance work by ensuring that resources are invested wisely where they will have the most significant effect.

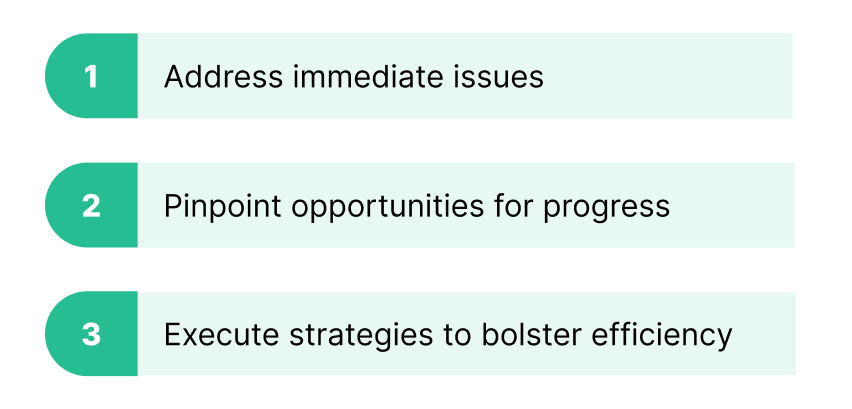

5. Foster Continuous Improvement

Implementing a continuous improvement culture and process can greatly enhance your maintenance team.

This approach constantly looks for avenues to refine the various facets and overall functioning of maintenance processes and strategies. By adopting cutting-edge technologies, like CMMS software, and best practices, your maintenance department can stay at the forefront of industry changes and needs.

Beyond Continuous Improvement

Source: WorkTrek

Continuous improvement extends beyond just addressing immediate issues. It involves preemptively pinpointing opportunities for progress and executing strategies that bolster efficiency and productivity.

Involving all team members to evaluate current methods can help continuous improvement. Their hands-on experience provides valuable insights that can streamline processes and address ongoing challenges.

Here are a few things you can do to improve communication between team members:

- Empower staff members to put forward their suggestions for enhancements

- Establish mechanisms through which employees can relay grievances or reservations

- Promote transparent dialogue by encouraging everyone’s input

Benefits of Open Communication

Not only does such open communication help spot inefficiencies, but it also heightens employee engagement and satisfaction levels.

Concentrating on core processes or items where focused attention could substantially benefit your augmentation endeavors.

Training and Development

Fostering a culture of continuous improvement within the maintenance team requires a commitment to ongoing training and skill development.

Regular instruction keeps your technicians up-to-date with industry best practices, equipping them for the dynamic nature of maintenance tasks.

Crafting bespoke educational initiatives to plug specific proficiency or knowledge gaps can ensure optimum impact. These initiatives could be vendor-specific training or generalized training offered by local educational institutions.

Training Options

Provide additional training incentives to reward exceptional work performance, which can boost motivation and keep staff updated with industry advancements. There are several avenues for enhancing learning, including:

- Accredited certification paths

- Interactive workshops and symposiums

- Web-based instructional courses

- Structured mentorship arrangements

By providing employees with pathways for professional growth, you can build a team that constantly learns, tackles any problem, and champions ongoing improvement across operational procedures.

Source: WorkTrek

Embrace New Technologies

As the facilities management landscape continues to evolve, staying abreast of emerging technologies is crucial for maintaining a competitive edge in the industry. Leveraging the latest technological advancements, such as CMMS software, can significantly enhance your maintenance team’s effectiveness, optimize efficiency, and reduce costs.

For example, adopting project management software offers a streamlined method for enhancing communication and overseeing maintenance tasks.

These platforms typically offer a centralized hub that allows team members to collaborate effortlessly, share timely updates, and collectively address challenges in real time.

Modern Tools

Whether you’re considering sophisticated diagnostic equipment, IoT sensors geared towards predictive maintenance, or even AI-infused systems designed for orchestrating maintenance schedules, selecting appropriate technology can revolutionize your organization’s approach to upkeep procedures.

Successfully introducing new tools relies heavily on comprehensive training and effective change management. This ensures that your staff can fully utilize these innovations in their roles.

By continuously supporting new technical solutions and integrating them into daily practices, you guarantee that your facility’s management efforts align with recognized best practices in this ever-evolving field.

6. Promote Open Communication

Effective communication channels are essential for maintaining a top-tier maintenance team. Such an environment enhances collaboration, improves problem-solving capabilities, and fosters a more cohesive workforce.

When team members are encouraged to share ideas, raise concerns, and voice any apprehensions, it creates a proactive mindset where emerging issues can be identified and addressed quickly before they escalate. Ensuring this seamless exchange of information is crucial for maintaining equipment reliability and operational efficiency.

Open Accessible Policy

Establishing an accessible policy where workers feel at ease discussing their perspectives with management is key to championing open dialogue among staff members. This strategy nurtures confidence between colleagues at all levels, indicating that contributions from every member are respected.

Having direct avenues for conveying messages enables prompt identification of concerns or complications, leading to quicker actions and significantly reducing system idle time.

Creating an environment that prizes attentive listening is as important as speaking out. This leads to enhanced outcomes regarding machinery upkeep, amplified employee morale, and greater satisfaction in their professional roles.

Team Meetings

Consistent and clear communication within a maintenance department is essential, typically achieved through scheduled team meetings.

These meetings can help evaluate task progress, set future goals, discuss key performance indicators (KPIs), and provide a collaborative problem-solving and innovation platform.

These sessions should be used to achieve several objectives.

- Update everyone on the status of current assignments

- Look ahead at upcoming plans for equipment care routines

- Communicate shifts in approaches related to managing facilities

- Urge members of your crew to convey their struggles, triumphs, or unique insights

- Detect issues promptly, which permits faster response times with more resourceful resolutions

To maximize efficiency during these discussions, consider adopting methods that best align with your team’s dynamics and available resources. Visualizing progress or incorporating educational segments into your regular meeting agenda might be helpful. The goal is to ensure these meetings are informative and engaging for everyone involved.

Feedback Mechanisms

Establishing a dynamic and responsive maintenance team depends on robust feedback mechanisms. These channels enable personnel to raise concerns, propose enhancements, and participate in continuously improving their maintenance processes and methods.

Cultivate an atmosphere of open communication so that everyone feels empowered to provide frank and constructive opinions. This could be facilitated through various means, such as confidential suggestion boxes, systematic private meetings between supervisors and employees, or online forums for sharing and debating ideas.

7. Develop a Comprehensive Maintenance Plan

Creating a comprehensive maintenance schedule helps steer your team toward effective maintenance management.

This plan is a proactive strategy to prevent malfunctions, reduce costs, and enhance overall equipment efficiency.

By identifying assets, determining maintenance needs, and designing preventive maintenance schedules that align with your organization’s specific requirements, you create a structured approach to maintenance that supports your infrastructure’s goals and operational demands.

Below are a few suggestions for creating a comprehensive maintenance plan:

- Assess current maintenance practices to identify strengths and areas for improvement.

- Establish maintenance goals centered around equipment reliability, cost reduction, and adherence to industry standards.

- Choose appropriate maintenance strategies for various assets by considering their criticality and likelihood of failure. This might involve a combination of preventive, predictive, and reactive maintenance approaches.

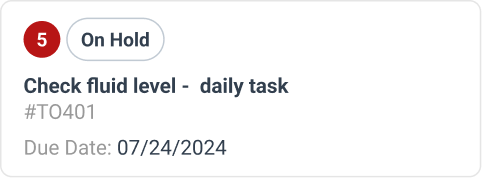

Short-Term Maintenance Tasks

You must incorporate short-term maintenance tasks into your routine schedule to ensure operational efficiency.

These tasks focus on keeping equipment in good working order and include daily inspections and routine checks to catch and resolve minor issues before they become significant problems.

Daily maintenance might involve monitoring fluid levels in machinery, checking for wear or damage, and performing basic cleaning operations.

Source: WorkTrek

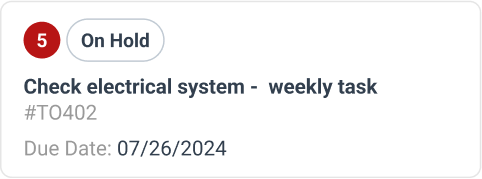

Weekly Tasks

These tasks may be expanded weekly with more thorough assessments, such as verifying electrical systems’ performance, lubricating parts to prevent frictional deterioration, and adjusting settings to hinder excess wear.

By executing these preventative maintenance actions frequently each week, you can substantially lower the incidence rate of sudden equipment failures while increasing the longevity of your machinery.

Ongoing scrutiny provides valuable insights that can shape broader maintenance strategies, leading to more efficient use of management resources.

Teams must understand that preventive maintenance activities shouldn’t be considered mundane chores. Instead, they are critical elements of a proactive approach that ensures continuous reliability and efficiency in the facility’s operations.

Source: WorkTrek

Long-Term Goals

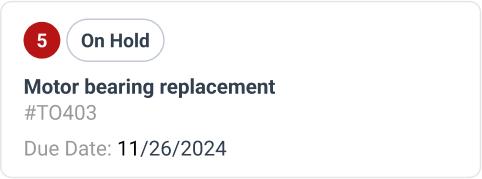

While short-term tasks ensure daily operations run smoothly, setting long-term maintenance goals to maintain your facility’s assets’ sustained efficiency and longevity.

These goals typically focus on increasing equipment lifespan and maintaining high production efficiency over extended periods.

Long-term objectives might include implementing advanced predictive maintenance techniques, upgrading critical equipment to more efficient models, or developing comprehensive staff training programs to enhance overall maintenance capabilities.

Another key element of long-term planning is scheduling major equipment overhauls and replacements, which are crucial for sustaining operational efficiency.

Replacing critical assets can be costly and requires careful planning, budgeting, and collaboration among all team members.

Remember, aligning these long-term maintenance goals with your organization’s broader business objectives ensures that your maintenance efforts contribute directly to the company’s success.

Source: WorkTrek

8. Monitor Key Performance Indicators (KPIs)

Key Performance Indicators (KPIs) help guide and sustain continuous improvement in your maintenance organization. KPIs provide tangible data points that facilitate evaluating how well you meet maintenance objectives and pinpoint areas requiring enhancement.

Critical metrics for gauging the efficiency of maintenance teams include Mean Time Between Failures (MTBF), Mean Time To Repair (MTTR), and Planned Maintenance Percentage. These metrics offer insight into equipment reliability, effectiveness in carrying out repairs, and the current approach to conducting maintenance activities’ proactive versus reactive nature.

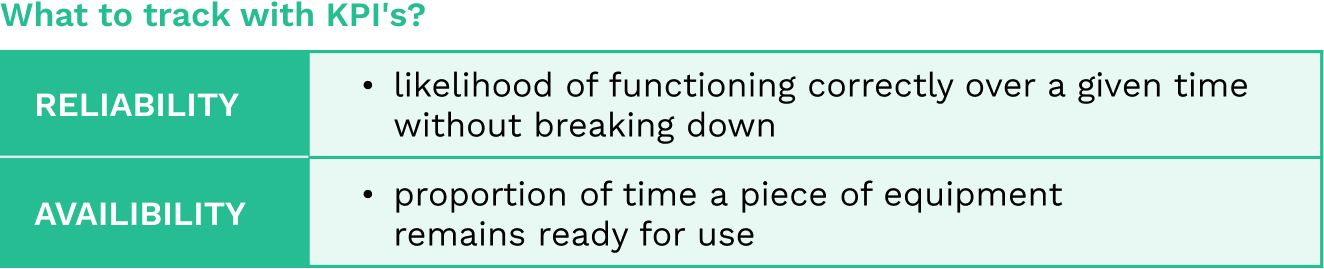

Measure KPIs

Two important things to track with KPI’s are reliability and availability matrix. The former assesses an item’s likelihood of functioning correctly over a given duration without breaking down.

Conversely, availability calculates the proportion of time a piece of equipment remains ready for use, thus reflecting operational readiness levels.

Tracking machine downtime is also essential, as it illuminates just how much production efficiency can be influenced by diligent or negligent execution of upkeep tasks.

Source: WorkTrek

Estimated Replacement Value Percentage

Finally, yet important, is analyzing Maintenance Costs against the Estimated Replacement Value percentage (MC/ERV). This specific ratio aids in making more grounded judgments about whether it’s financially smarter to maintain or replace assets.

Regularly reviewing these indicators during meetings keeps everyone aligned with collective goals and enhances overall maintenance performance.

This data should be collected and strategically applied in decision-making, fostering continuous improvements within the scope of operations managed under your care.

Equipment Uptime

Tracking equipment uptime helps monitor maintenance performance and enhance operational efficiency.

Using a Computerized Maintenance Management System (CMMS), facilities can significantly reduce downtime caused by equipment failure or poor maintenance planning.

This proactive approach allows for more accurate scheduling of maintenance activities and helps prevent unexpected breakdowns.

Implementing condition-based maintenance strategies can further boost equipment uptime by addressing potential issues before they lead to failures.

Every minute of downtime translates to lost production and potential revenue, making equipment uptime a crucial metric for assessing the effectiveness of your maintenance program.

Regularly analyze your uptime data to:

- Identify patterns or recurring issues that might be affecting equipment reliability

- Focus on improving equipment uptime

- Enhance operational efficiency

- Contribute directly to your organization’s bottom line through reduced repair costs and increased productivity.

Cost Savings

Identifying and monitoring cost savings are vital components of maintenance management, and they have direct consequences on your organization’s financial health.

An effective maintenance program can enhance machinery longevity and diminish cumulative upkeep expenditures.

Monitoring Maintenance Costs as a percentage of estimated replacement value (MC/ERV) is crucial for assessing whether persisting with an asset’s maintenance or procuring its replacement is more economically viable.

CMMS for Expense Tracking

Employing a Computerized Maintenance Management System (CMMS) can track expenses associated with various aspects, such as labor and parts involved in maintenance processes.

This can help unearth potential efficiencies and areas where spending could be optimized.

Creating tailor-made reports can identify areas that can hinder production schedules.

![]()

Source: WorkTrek

9. Maintain a Positive Work Environment

Creating and maintaining a positive work environment can improve the performance of your maintenance team.

This approach increases morale, productivity, and job satisfaction among team members. When they feel recognized and valued, these individuals exceed expectations, offer creative solutions, and enthusiastically engage in teamwork. More importantly, it helps keep the team focused on shared objectives.

Rewarding your maintenance team members

Acknowledging, rewarding, and recognizing your maintenance team members can help nurture a positive work environment.

Verbal commendations or public recognition can be equally meaningful. Continuous recognition for diligence and excellence cultivates an environment where high standards are pursued.

This approach can cultivate an environment where ongoing high standards are pursued by setting up continuous recognition for diligence and excellence.

Source: WorkTrek

Recognition and Rewards

To foster an enthusiastic maintenance team that excels, incorporate a robust system of acknowledgment and incentives.

While physical rewards like monetary bonuses or gift vouchers can serve as solid motivators, the potency of spoken praise or open commendation should not be overlooked. Often, these gestures carry more weight in boosting morale over time.

Establishing structured appreciation programs for standout employees demonstrates their value to the enterprise.

A particularly effective means of recognition involves inviting maintenance staff into decision-making spheres. This validates their expertise and instills an enhanced sense of responsibility toward their work.

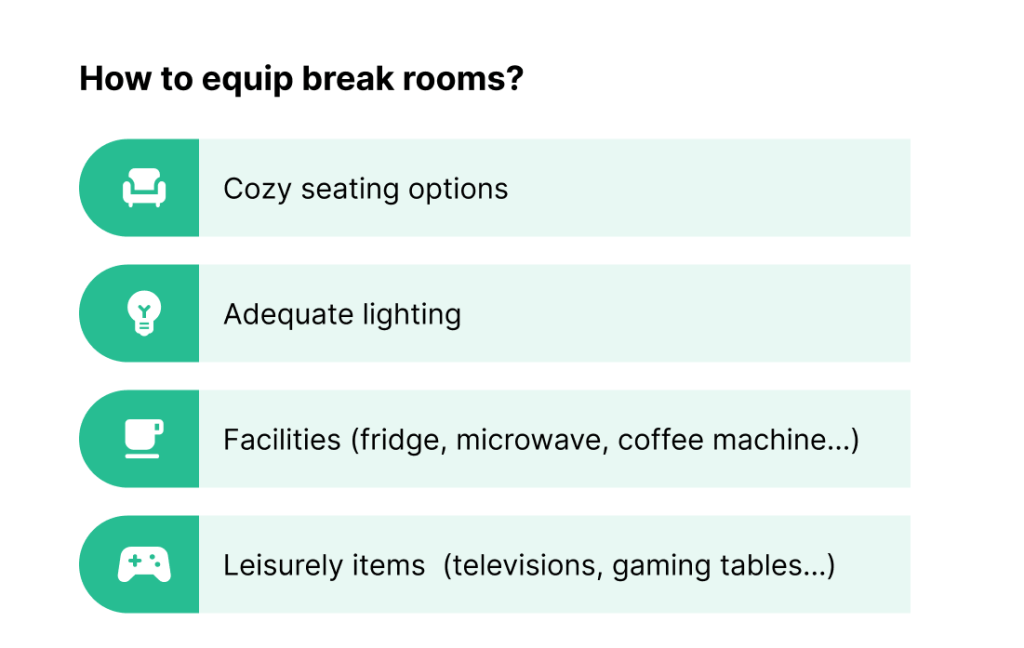

Break Rooms and Amenities

Often overlooked, comfortable break rooms are equally important in creating a supportive environment for your maintenance team.

A thoughtfully arranged break room provides a sanctuary where maintenance staff can unwind, rejuvenate, and partake in casual conversations that frequently lead to creative solutions.

To equip these spaces adequately, consider including:

- Cozy seating options

- Adequate lighting

- Facilities like a fridge, microwave oven, and coffee machine

- Leisurely items such as televisions or gaming tables to promote relaxation during downtime

Investing in these key areas shows your support for the comfort and happiness of your team members, which significantly enhances morale and job satisfaction. Remember that when a maintenance team’s welfare is prioritized, its members often reciprocate with heightened dedication to their roles—positively impacting overall facility management objectives.

Source: WorkTrek

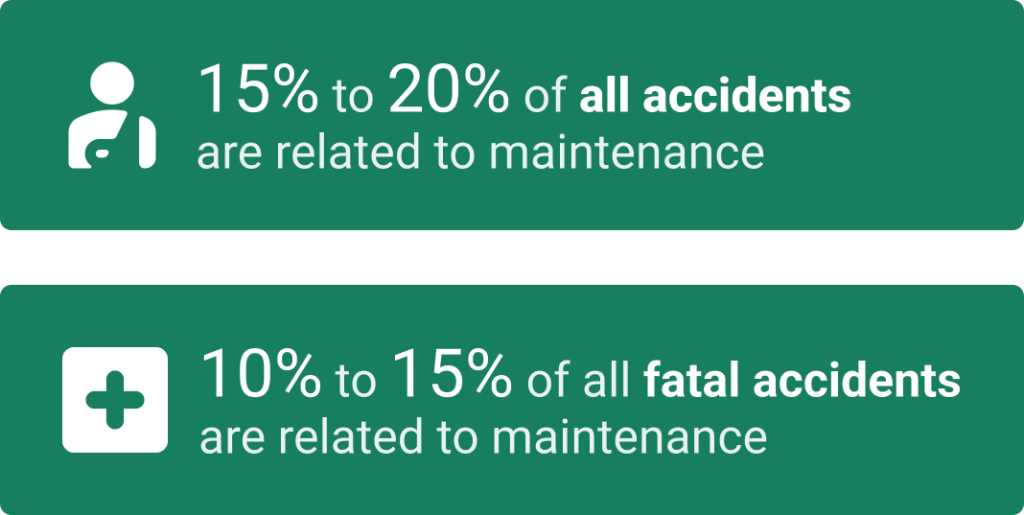

10. Ensure Safety Protocols are Followed

Safety should be the primary concern in any maintenance task. Establishing and adhering to solid safety protocols is essential for protecting team members, safeguarding assets, and preserving high operational efficiency.

These protocols require regular updates incorporating industry best practices and adjustments corresponding to changes within your operations.

Merely having safety guidelines is insufficient. Every team member should be regularly trained on safety protocols and procedures.

Another approach is to hold regular safety drills so all personnel involved in maintenance thoroughly understand what actions must be taken during emergencies. Such exercises help staff internalize procedures geared towards keeping them safe, enabling automatic responses when faced with stressful conditions.

Provide easy access to adequate PPE (Personal Protective Equipment) and conduct periodic audits pertaining to security measures at work.

By consistently emphasizing securing a hazard-free environment, you’ll not only shield workers from harm but also show dedication to their welfare—this can lead to substantially improved spirits among employees alongside enhanced job contentment.

Safety Training

Ensuring the safety and efficiency of maintenance operations hinges on continuous and comprehensive safety education.

Such training must encompass a broad spectrum, extending from general to specialized practices tailored to your facility’s distinctive machinery and processes.

It’s important for your program to continually keep the maintenance workforce abreast of evolving standards as well as industry best practices in various domains, including:

- Correct utilization of personal protective equipment (PPE)

- Management of hazardous substances

- Safety regarding electrical systems

- Protocols for emergencies

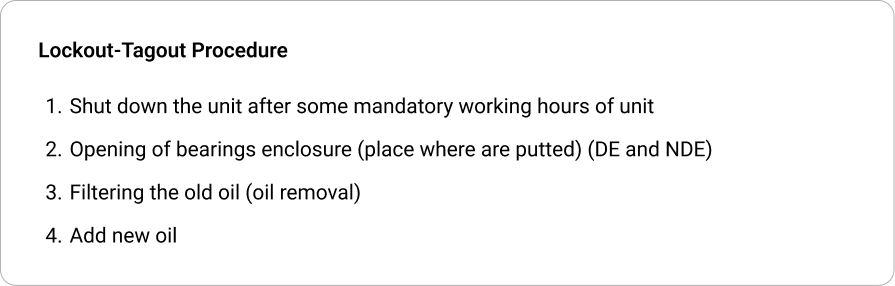

Lock-out and Tag-Out Procedures

Place heightened emphasis on critical safety measures such as lock-out tag-out procedures that prevent injuries when maintaining equipment.

Adopt diverse instructional approaches, such as classroom learning, practical exercises, and digital courses, that accommodate distinct educational preferences while promoting a thorough grasp of crucial information. Regularly scheduled refresher trainings play an indispensable role in keeping key concepts fresh and briefing staff on modified guidelines.

Committing to continual instruction about safe conduct meets legal obligations and cultivates an ethos where conscientiousness about security resonates through every dimension of your maintenance tasks.

Source: WorkTrek

Emergency Procedures

Establishing clear-cut emergency protocols is can mitigate hazards and ensure efficient, synchronized action in dire circumstances. These plans must encompass a variety of urgent scenarios, such as:

- Malfunctions in equipment

- Acts of nature causing widespread disruption

- Fire-related crises

- Health-related urgencies

- Security breaches

Such strategies ought to be customized for your establishment’s particular requirements. It’s important that every member of the maintenance team receives comprehensive training regarding these procedures and recognizes their specific responsibilities during assorted crisis events.

Safety Workshops

It’s vital to conduct regular safety workshops that focus on the established protocols and promote knowledge about spotting dangers and evaluating risks.

Workers should be adept at swiftly identifying and neutralizing immediate threats when an emergency arises—this could mean ceasing machinery operations or initiating evacuations from hazardous zones.

Developing readily available guides or checklists for emergencies can offer quick references that team members may turn to amidst stressful conditions.

Illustration: WorkTrek / Data: Bearing and Machine Ltd.

Summary

To conclude, developing and sustaining a superior maintenance team hinges on strategic planning, unwavering effort, and an ethos of continuous improvement.

By incorporating these essential top 10 best practices—from selecting competent technicians to defining precise roles, embracing technological advancements, emphasizing preventive maintenance strategies, and cultivating a positive work environment—you can substantially boost your maintenance operations’ productivity and competence.

Adopting these individual practices into a unified approach can help support your organizational objectives.

Maintenance crews have the potential to evolve into an exemplary model of effectiveness, resilience, and ingenuity within the maintenance industry.