Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeBreakdown maintenance is a strategy for managing equipment and machinery in various industries. It involves fixing or replacing parts when they unexpectedly fail or stop working.

Breakdown maintenance works specifically on nonoperational equipment, emphasizing its effectiveness when it is new and within its lifespan. Breakdown maintenance is also known as reactive maintenance, as it responds to issues after they occur rather than preventing them in advance.

Advantages and Drawbacks of Breakdown Maintenance

This maintenance strategy has both advantages and drawbacks. It can be cost-effective for non-critical equipment or when preventive maintenance is not feasible. Breakdown maintenance is often used for easily replaceable parts or when equipment failures don’t significantly impact operations.

Understanding the ins and outs of breakdown maintenance can help businesses make informed decisions about their maintenance strategies. This guide will explore the types of breakdown maintenance, its benefits, and when it’s most appropriate.

It will also discuss how modern software tools can improve the management of breakdown maintenance processes.

Source: WorkTrek

Understanding Breakdown Maintenance

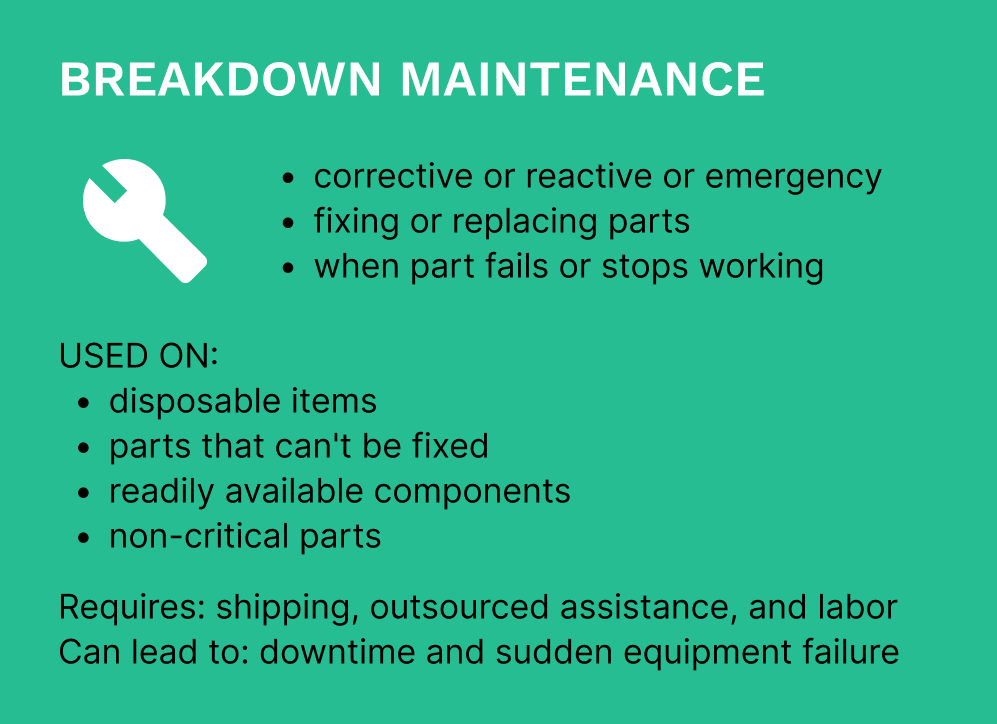

Breakdown maintenance is a type of corrective maintenance done when machines fail unexpectedly. It involves repairing or replacing parts to get operations running again. This method is used for disposable items, parts that can’t be fixed, or readily available components.

This is a reactive approach to equipment repairs. Emergency maintenance can increase maintenance costs due to the increased cost of expedited shipping, outsourced assistance, and labor.

This approach focuses on fixing issues after a breakdown, making it unsuitable for critical assets. It can also lead to costly downtime and sudden equipment failure.

Source: Rasmussen Mechanical Services

Definition and Scope

Breakdown maintenance is a type of corrective maintenance done when machines fail unexpectedly. It involves repairing or replacing parts to get operations running again. This method is used for disposable items, parts that can’t be fixed, or readily available components.

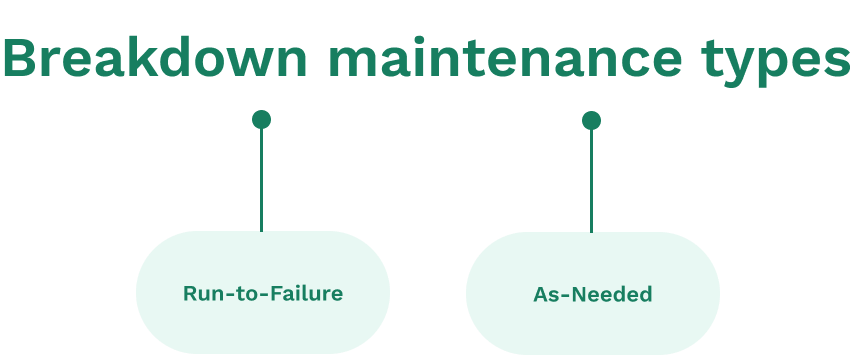

Two main types of breakdown maintenance are:

- Run-to-Failure: Equipment runs until it stops working, then gets fixed.

- As-Needed: Repairs happen when failures occur, or problems arise.

Companies often use breakdown maintenance for non-critical equipment. It can save money on regular upkeep for less important machines.

Source: WorkTrek

Importance in Industry

Breakdown maintenance plays a key role in many industries. It helps businesses deal with sudden equipment failures quickly. This approach can be useful when:

- Regular inspections are too costly

- Failures are hard to predict

Equipment is not critical to operations

Source: ifm

Source: ifm

Some benefits of unplanned breakdown maintenance include:

- Lower upfront maintenance costs

- Less time spent on routine checks

- Focus on running equipment until it fails

Unplanned Breakdown Maintenance

However, unplanned breakdown maintenance involving unexpected equipment failure can lead to significant drawbacks and operational disruptions.

But it also has risks. Unexpected breakdowns can lead to:

- Production delays

- Higher repair costs

- Safety risks

- Equipment breakdown

- Potentially increased maintenance cost

- Increased number of emergency repairs

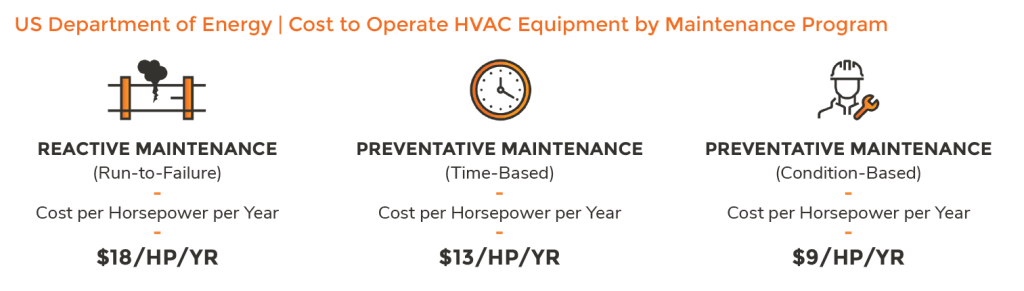

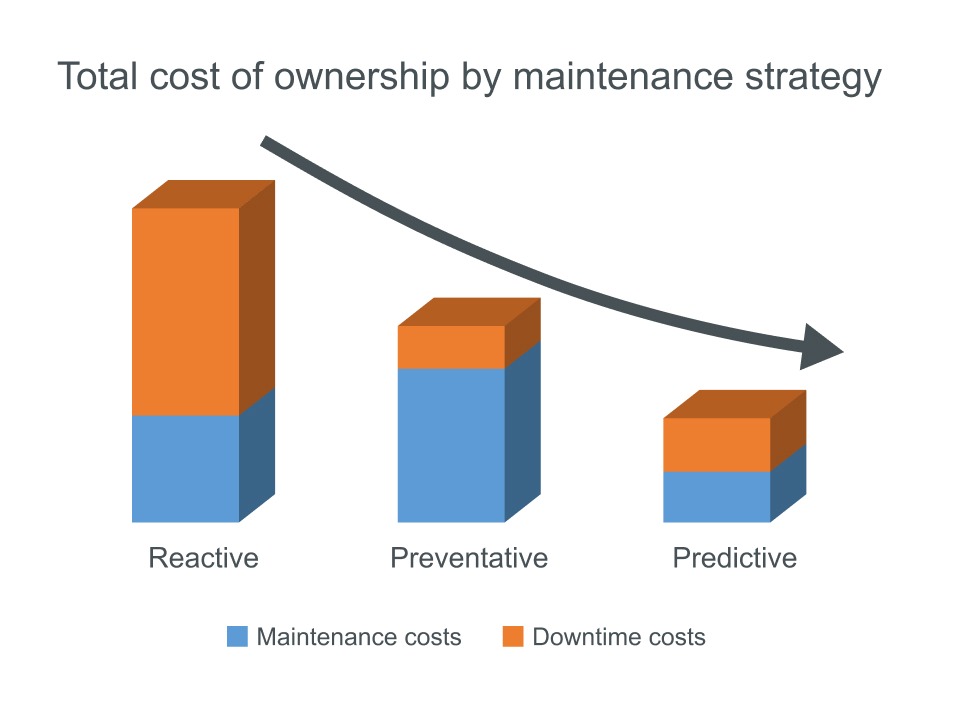

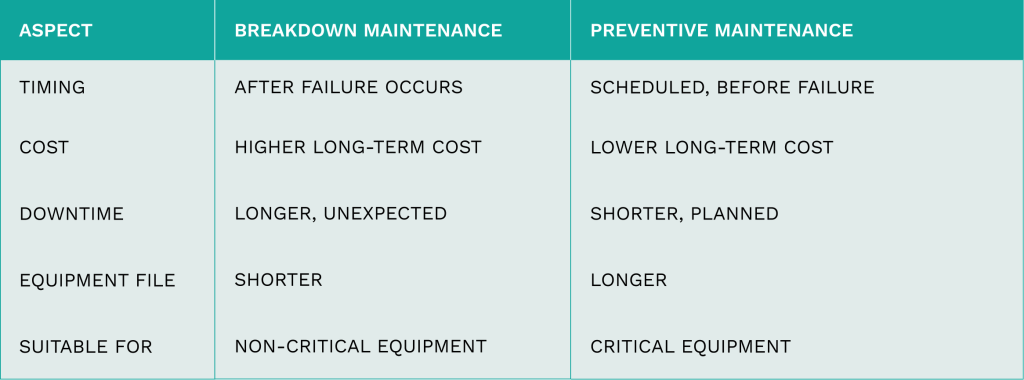

Comparison with Preventive Maintenance

Breakdown maintenance differs significantly from preventive maintenance. Here’s how they compare:

Source: WorkTrek

Preventive maintenance aims to prevent problems before they happen. It involves regular checks and upkeep, which can lead to less downtime and longer-lasting equipment.

Breakdown maintenance is more reactive. It waits for issues to occur before taking action. This can save time on routine tasks but may result in more significant problems later.

Choosing between these methods depends on the equipment’s importance and potential failure impacts.

Planning for Breakdown Maintenance

Getting ready for equipment failures is key. Planned breakdown maintenance is a systematic approach to managing equipment failures.

It allows non-critical equipment to run until a failure occurs while minimizing negative impacts on operations. This approach also reduces unnecessary preventive maintenance.

A solid plan helps fix issues fast and keep work going. Good planning covers quick responses, staff training, and having the right parts on hand.

Developing a Response Plan

A response plan clearly outlines the steps to take when machines break down and the type of maintenance needed. It should list who to call and what to do first.

The plan also needs to cover different failures and how to handle each.

Key parts of a good plan include:

• Contact info for repair teams

• Steps to assess the problem

• Rules for when to fix vs. when to replace

• Ways to keep other work going during repairs

Make sure the plan is easy to find and use. Keep copies in key spots around the work area.

Illustration: WorkTrek / Quote: Comparesoft

Training and Preparedness

Staff need to know how to spot issues early and what to do when things break. Regular training sessions help workers stay ready.

Training topics should cover:

• Basic troubleshooting steps

• Safety rules for broken equipment

• How to report problems quickly

• Using backup systems

Practice drills can test how well staff know the plans. These drills help find gaps in knowledge and improve response times.

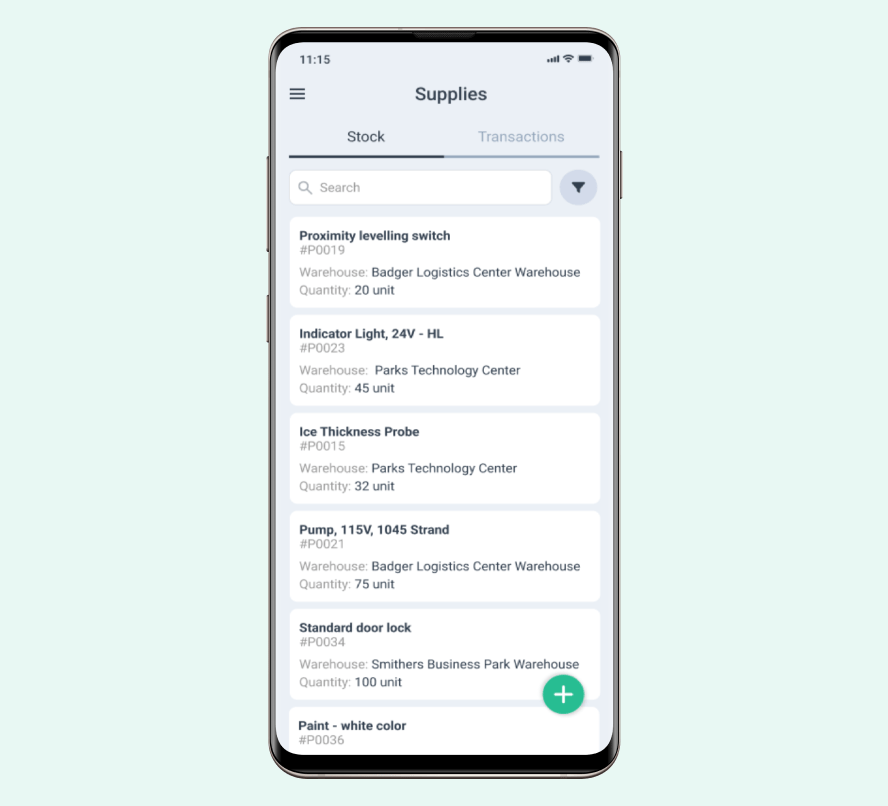

Inventory Management

Having the right parts on hand can cut repair times. A good inventory system tracks what parts are needed most often.

A Computerized Maintenance Management System (CMMS) system can also be important in managing parts inventory and providing low-quantity alerts.

Source: WorkTrek

Tips to Help Manage Inventory

• Keep a list of critical parts

• Set up auto-orders for items that run low

• Store parts where they’re easy to find

• Check stock levels often

For hard-to-get parts, have backup suppliers ready. This helps avoid long waits when rare parts are needed.

Execution of Breakdown Maintenance

Breakdown maintenance requires quick action and careful planning. The process involves assessing the problem, choosing repair methods, and keeping detailed records.

Initial Assessment

When equipment fails, technicians must act fast. They start by checking the machine to determine what’s wrong, which is key to fixing the issue quickly.

Techs use special tools to test different parts. They look for signs of wear, damage, or faulty components. Sometimes, they talk to machine operators for more information about what happened.

Safety is paramount during this check. Techs wear protective gear and follow strict rules to avoid accidents.

Repair Strategies

After finding the problem, techs decide how to fix it. They might replace broken parts or repair what’s there. The choice depends on time, cost, and the extent of the damage.

Breakdown maintenance often means working fast. Techs may use quick fixes to get machines running again. But they also plan for longer-term solutions.

Some standard repair methods include:

- Replacing worn-out parts

- Fixing electrical issues

- Adjusting mechanical components

- Cleaning and lubricating moving parts

- Checking and changing fluids

Documentation and Reporting

Keeping good records is crucial in breakdown maintenance. Techs write down what they did and why, which helps prevent future problems.

Reports include:

- What broke and why

- How long the repair took

- Parts and tools used

- Costs involved

Good records help managers make smart choices about equipment care. They can spot patterns and decide if machines need more regular upkeep.

Proper documentation also helps teams learn from each breakdown. A CMMS system like WorkTrek can centralize all of your documentation in a single, easy-to-access application.

This can lead to better maintenance plans in the future.

Source: WorkTrek

Tools and Equipment

Proper tools and equipment are crucial for effective breakdown maintenance. Having the right items on hand allows technicians to diagnose issues quickly and repair them efficiently.

Essential Tools for Repairs

A well-stocked toolkit is vital for breakdown maintenance. Basic hand tools like screwdrivers, wrenches, and pliers are must-haves. Specialized tools may be needed for specific equipment.

Power tools such as drills and impact drivers speed up repairs, and measuring instruments like multimeters help diagnose electrical problems.

Safety gear is also essential. This includes:

- Safety glasses

- Work gloves

- Steel-toed boots

- Hard hats (when needed)

Maintenance technicians should have easy access to spare parts for common repairs. Keeping an inventory of frequently used components reduces downtime.

Technological Aids

Modern technology enhances breakdown maintenance efforts. Handheld diagnostic devices can quickly identify issues in complex machinery.

Thermal cameras detect overheating components before they fail. Vibration analyzers spot potential problems in rotating equipment.

Computerized maintenance management system

Computerized maintenance management systems (CMMS) help track repair histories and schedule work. Mobile devices allow technicians to access manuals and documentation on-site.

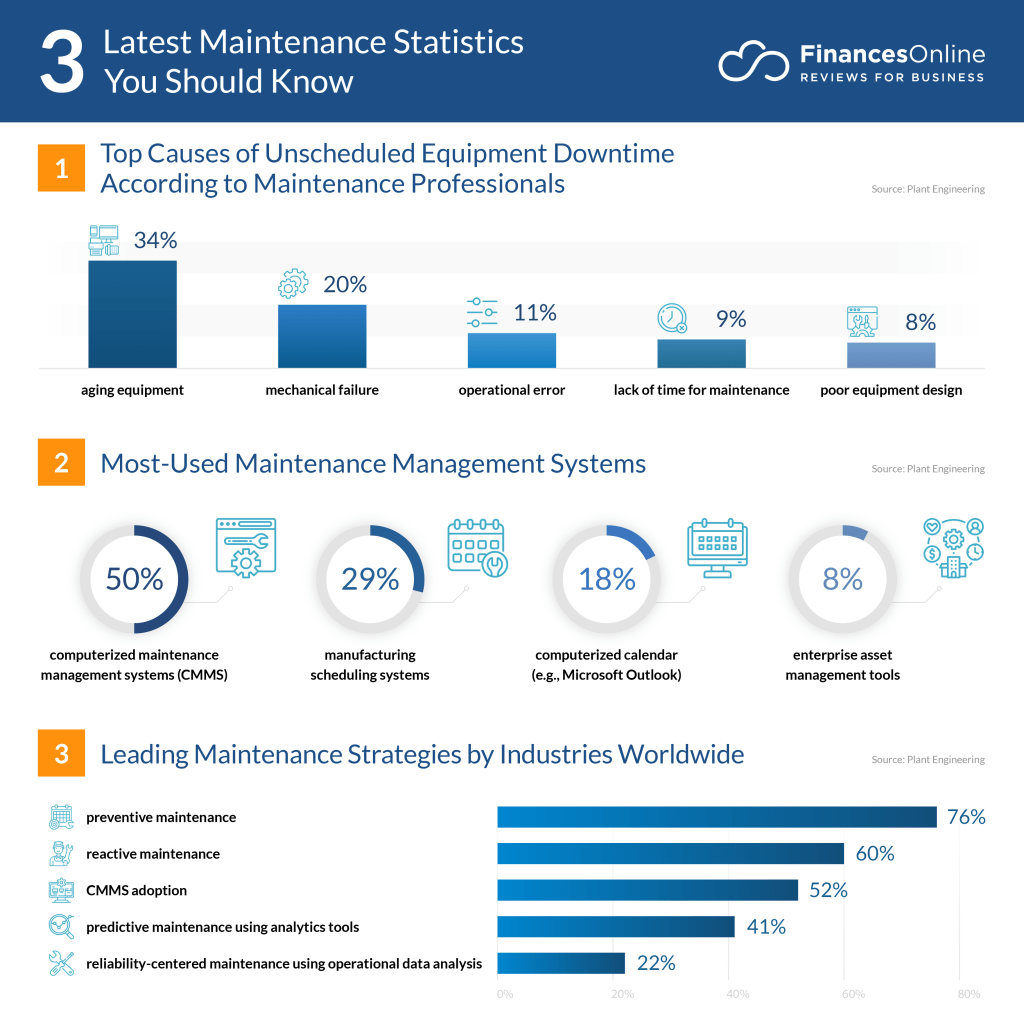

Source: FinancesOnline

Augmented Reality and Artificial Intelligence (AI)

Augmented reality (AR) tools are emerging in maintenance. These can overlay repair instructions onto equipment, guiding technicians through complex procedures.

Data analysis and AI software help identify patterns in breakdowns. This information can be used to prevent future failures and improve maintenance strategies.

Safety Considerations

Safety is crucial when performing breakdown maintenance. Considering safety risks is essential when implementing different maintenance strategies, as equipment failure can lead to severe safety concerns. Proper precautions protect workers and equipment from harm. Careful planning and procedures minimize risks.

Risk Assessment

Identifying potential hazards is the first step in breakdown maintenance safety. Evaluate equipment conditions and work areas for risks. Look for electrical dangers, moving parts, and chemical exposure.

Create a checklist of common hazards for each machine. Update it regularly as new risks emerge.

Train staff to spot and report dangers quickly. Use a risk matrix to prioritize threats. Focus on high-risk items first. Set up controls to reduce danger levels where possible.

Safety Protocols

Clear safety rules keep workers protected during repairs. Lockout/tagout procedures prevent accidental starts. Proper personal protective equipment (PPE) is required for all tasks.

Set up barriers around work areas. Use signs to warn others of ongoing maintenance. Follow confined space entry rules when needed.

Create step-by-step guides for everyday repair tasks. Include safety checks at each stage. Train staff regularly on these protocols.

Test safety equipment often. Replace damaged items right away. Keep first aid kits stocked and easily accessible.

Source: WorkTrek

Emergency Procedures

Fast action in emergencies can save lives. Post clear evacuation routes near all work areas and hold regular drills to practice these plans.

Train staff in basic first aid and CPR. Keep contact info for local emergency services handy. Install emergency stop buttons on all machines.

Set up a communication system for quick alerts. Use radios or alarms to spread warnings fast. Have a plan to account for all workers after evacuations.

Create an incident reporting system. Learn from close calls to prevent future accidents. Review and update emergency plans yearly.

Measuring Maintenance Effectiveness

Tracking the right metrics helps organizations assess and improve their maintenance practices. Key performance indicators provide insights into efficiency and reliability, and continuous improvement efforts use these metrics to drive ongoing enhancements.

Key Performance Indicators

Maintenance effectiveness is often measured as a ratio of planned, corrective, and breakdown activities. Preventive maintenance strategies are essential to avoid costly failures and unplanned downtime, especially for critical or high-value equipment. Planned maintenance should make up the most significant portion.

Common KPIs include:

- Overall Equipment Effectiveness (OEE)

- Mean Time Between Failures (MTBF)

- Mean Time To Repair (MTTR)

- Preventive Maintenance Compliance (PMC)

Tracking these metrics helps identify problem areas. For example, low MTBF may indicate equipment reliability issues, while high MTTR could point to inefficient repair processes.

Regular KPI reviews allow teams to spot trends. This data guides decisions on resource allocation and maintenance strategies. It’s important to choose KPIs that align with organizational goals.

Illustration: WorkTrek / Quote: Forbes

Continuous Improvement

Using KPI data, maintenance teams can drive ongoing enhancements. They should:

- Set clear improvement targets

- Analyze root causes of issues

- Implement changes

- Monitor results

Robust inspection standards help prevent breakdowns. Teams can develop these by studying past failures, and training programs keep staff up-to-date on best practices.

Regular audits ensure processes stay effective. Teams should adjust strategies based on changing equipment needs. New technologies like predictive maintenance can further boost efficiency.

Engaging frontline staff in improvement efforts is crucial. Their hands-on experience often reveals valuable insights, and celebrating successes helps maintain motivation for ongoing progress.

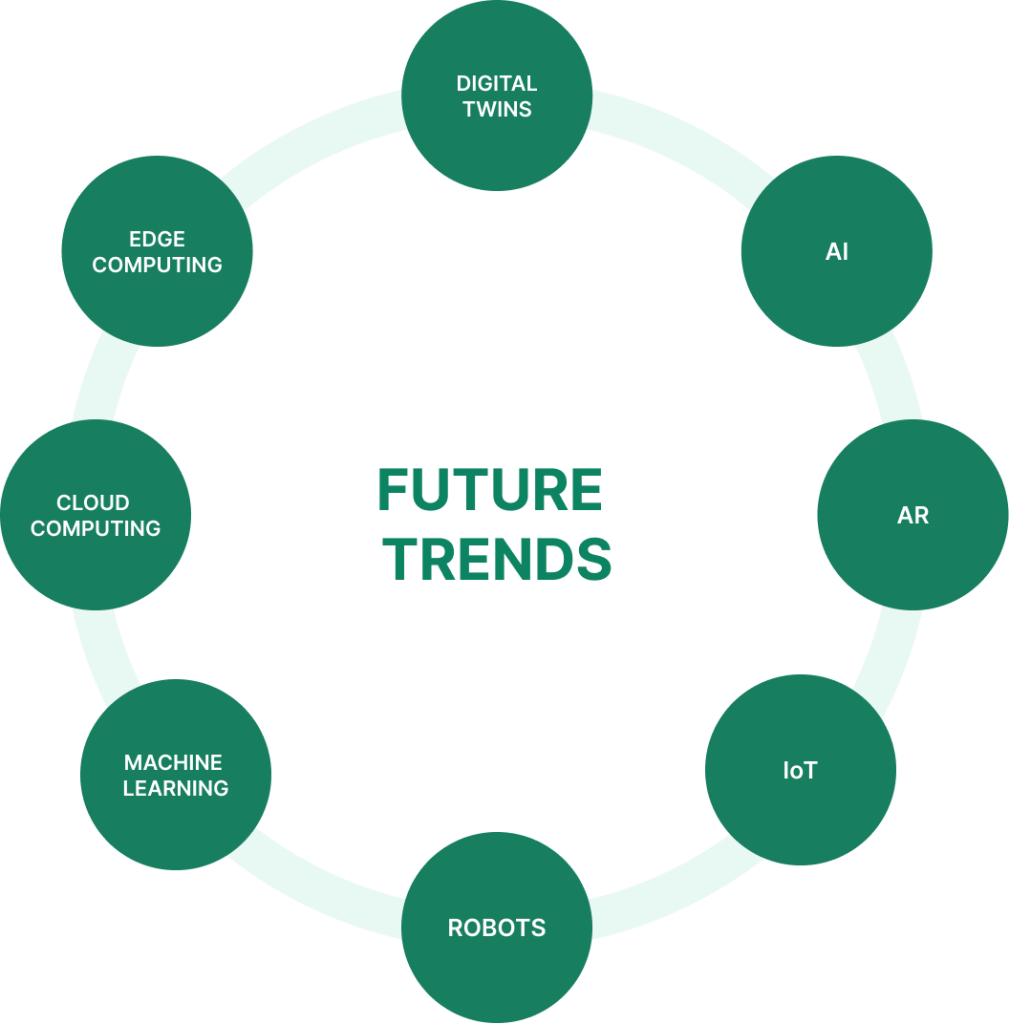

Future Trends in Maintenance

Maintenance is changing fast. New technology and smart systems are making it easier to fix things before they break, which saves companies time and money.

Predictive Maintenance Technologies

Predictive maintenance uses data to spot problems early. Machine sensors collect information about how they work, and computer programs analyze this data to guess when parts might fail.

Smart sensors can check things like:

- Vibration

- Temperature

- Noise levels

These tools help fix issues before they cause major problems. This reduces surprise breakdowns, reduces unnecessary maintenance, and is cost-effective.

AI and machine learning make predictions better over time. They learn from past data to make smarter guesses about future breakdowns.

Integration with Industry 4.0

Industry 4.0 brings the internet and smart tech to factories, and maintenance systems are a big part of this change.

Smart factories use connected devices to share information. This helps maintenance teams work better, as they can see how machines perform in real-time.

Some cool Industry 4.0 tools for maintenance:

- Digital twins (virtual copies of machines)

- Augmented reality for training and repairs

- Robots that can do simple maintenance tasks

- Internet of Things (IoT)

- Cloud Computing

- AI and Machine Learning

- Edge Computing

These tools make maintenance faster and more accurate. They also help workers learn new skills.

Source: WorkTrek