Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways

- Preventive maintenance prevents costly equipment failures through scheduled servicing and regular inspections

- Manufacturing companies benefit from reduced downtime, lower costs, and improved product quality

- Successful programs require proper planning, skilled technicians, and the right tools to overcome common challenges

If you run a manufacturing facility, you know that equipment breaks down at the worst possible times.

This can often result in production lines coming to a halt and costing companies thousands of dollars per hour.

What is the industry best practice to reduce downtime? The solution lies in implementing a preventive maintenance plan for your organization.

Preventive maintenance in manufacturing is a preventative maintenance approach to maintaining equipment and machinery by performing regular, scheduled servicing to prevent and reduce unexpected breakdowns.

Companies that implement preventive maintenance programs see fewer emergency repairs, better product quality, and significantly lower maintenance costs over time.

What is Preventive Maintenance in Manufacturing?

Like most industries, preventive maintenance in manufacturing involves scheduling of equipment maintenance to prevent failures before they occur.

How Preventive Maintenance Differs from Reactive and Predictive Approaches?

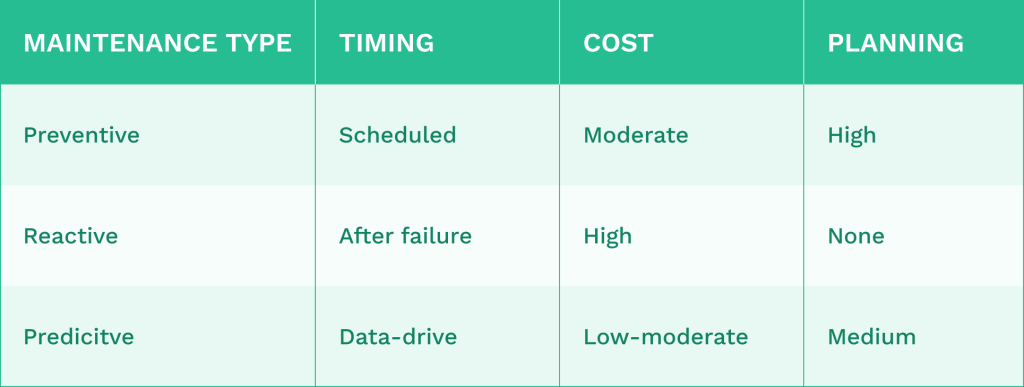

Preventive maintenance

Follows a scheduled approach based on time intervals or usage cycles. Manufacturers perform regular inspections, cleaning, and part replacements regardless of the current equipment condition.

Reactive maintenance

Only happens after the equipment breaks down. This approach leads to unexpected downtime and costly emergency repairs. Production stops completely until technicians fix the problem.

Predictive maintenance

Utilizes real-time data from sensors to predict when failures may occur. Temperature readings, vibration patterns, and other measurements help predict maintenance needs.

The key differences include:

Preventive maintenance programs often require more upfront planning than reactive methods. However, long-term, they provide better control over production schedules and maintenance costs.

Core Objectives of Preventive Maintenance

The primary goal of any manufacturing maintenance program is to prevent unexpected equipment failures. General goals include:

Reducing downtime

Stands as the most important objective. Scheduled maintenance happens during planned breaks rather than disrupting active production runs.

Extend equipment lifespan

If equipment lasts longer, it can save the organization money over time. Well-maintained machines last longer and provide better return on investment than neglected equipment.

Maintain product quality

Manufacturing quality products requires consistent machine performance. Equipment that receives regular care produces more reliable output with fewer defects.

Improve workplace safety

Protects workers from equipment-related accidents. Regular inspections catch potential hazards before they cause injuries.

Controlling maintenance costs

Becomes easier with planned spending. Preventive care costs less than emergency repairs and equipment replacement.

Key Benefits of Preventive Maintenance

According to the US Department of Energy, companies can save between 12% and 18% on maintenance costs by implementing preventive maintenance over reactive maintenance approaches. Additionally, each dollar spent on preventive maintenance saves an average of $5 in future costs.

These benefits include reduced equipment downtime, extended asset life, safer work environments, and increased productivity levels.

Reducing Equipment Downtime and Unplanned Disruptions

Preventive maintenance has repeatedly been shown to reduce costly equipment failures that stop production lines. When companies schedule regular inspections and repairs, they catch small problems before they become major breakdowns.

Manufacturers that use preventive maintenance experience up to 25% less unplanned downtime compared to those that use reactive maintenance approaches. This reduction translates directly into higher production output and revenue.

Common preventive tasks include:

- Oil changes and lubrication

- Belt and filter replacements

- Electrical connection checks

- Calibration adjustments

- Cleaning and debris removal

Extend Equipment Lifespan

It is no surprise that regular maintenance can significantly increase the lifespan of equipment. Well-maintained machines can operate effectively for years beyond their expected service life.

With preventive maintenance, you can keep all components in good working condition. This proactive approach prevents the cascading failures that occur when one worn part damages other system components.

The reliability of assets improves when maintenance teams follow consistent schedules for inspections and repairs

Reliable equipment produces consistent quality and meets production targets without interruption.

Factors that extend asset lifespan:

- Regular cleaning prevents corrosion

- Proper lubrication reduces friction wear

- Timely part replacement prevents system damage

- Calibration maintains accuracy over time

Companies typically see 15-20% longer asset lifespan with proper preventive maintenance programs. This extended life provides a better return on equipment investments.

Enhance Workplace Safety and Compliance

Preventive maintenance helps create safer work environments by identifying and addressing potential hazards before they lead to accidents. Regular equipment inspections reveal safety risks that could harm workers.

Well-maintained equipment reduces safety hazards by ensuring all safety systems function properly. Faulty equipment poses serious risks, including electrical hazards, mechanical failures, and chemical leaks.

Regulatory compliance becomes easier when companies maintain detailed maintenance records and follow prescribed safety checks.

Several industry regulations require regular equipment inspections and maintenance documentation.

Compliance requirements vary by industry but often include safety system testing, pressure vessel inspections, and electrical system checks.

Preventive maintenance programs help companies consistently meet these requirements.

Safety benefits include:

- Reduced workplace accidents

- Lower insurance premiums

- Fewer regulatory violations

- Better audit results

- Improved worker confidence

Boosting Productivity and Operational Efficiency

Preventive maintenance increases productivity by keeping equipment running at optimal performance levels. Well-maintained machines operate more efficiently, produce higher-quality products, and use less material.

Operational efficiency improves when equipment performs consistently without unexpected breakdowns. This reliability allows production teams to meet schedules and customer demands more effectively.

Maintenance costs decrease over time as preventive care prevents the need for expensive emergency repairs. The cost of scheduled maintenance is typically three to five times lower than emergency breakdown repairs.

Energy efficiency also improves with regular maintenance. Clean, well-lubricated equipment uses less power and generates less heat than poorly maintained machines.

Productivity improvements include:

- Higher production speeds

- Better product quality

- Reduced material waste

- Lower energy consumption

- Fewer production delays

Types of Preventive Maintenance in Manufacturing

Manufacturing facilities use four main types of preventive maintenance strategies. Each maintenance strategy offers different approaches to equipment care, from scheduled intervals to advanced technology solutions.

Time-Based Maintenance

Time-based maintenance follows fixed schedules, regardless of the equipment’s condition. Maintenance tasks are performed at regular intervals, such as weekly, monthly, or yearly.

This approach is particularly effective for critical equipment with predictable wear patterns. A factory might lubricate conveyor belts every 30 days or replace filters quarterly.

Common time-based tasks include:

- Weekly equipment inspections

- Monthly lubrication schedules

- Annual component replacements

- Seasonal cleaning procedures

The primary advantage is the simplicity of scheduling and planning. Maintenance teams know exactly when work needs to be completed.

However, this method can lead to unnecessary maintenance on equipment still in good condition. It may also miss problems that develop between scheduled intervals.

Usage-Based Maintenance

Usage-based maintenance links tasks to equipment operating hours or production cycles. This is similar to changing your car’s oil every 5,000 miles. Maintenance happens based on actual machine usage rather than calendar dates.

A CNC machine might need service after every 1,000 operating hours. Forklifts could require inspection after moving 500 pallets.

This method better matches maintenance needs to the equipment workload. Machines that are used heavily receive more frequent attention than idle equipment.

Usage triggers include:

- Operating hours

- Production cycles completed

- Parts processed

- Distance traveled

Manufacturing facilities that have variable production schedules benefit most from this approach. Equipment gets appropriate care based on actual wear and tear.

The challenge to usage-based maintenance is to track usage data across all machines accurately. Some equipment may require additional monitoring systems to be installed, like IoT devices, which are further described in the next section.

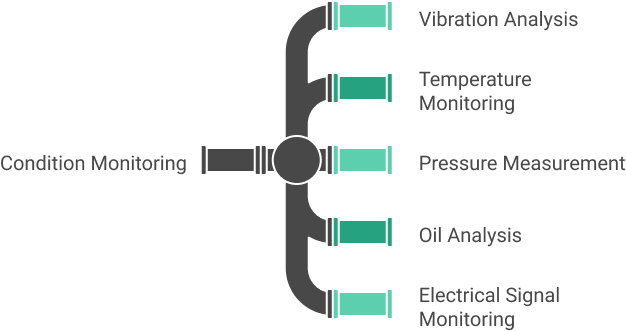

Condition-Based Maintenance

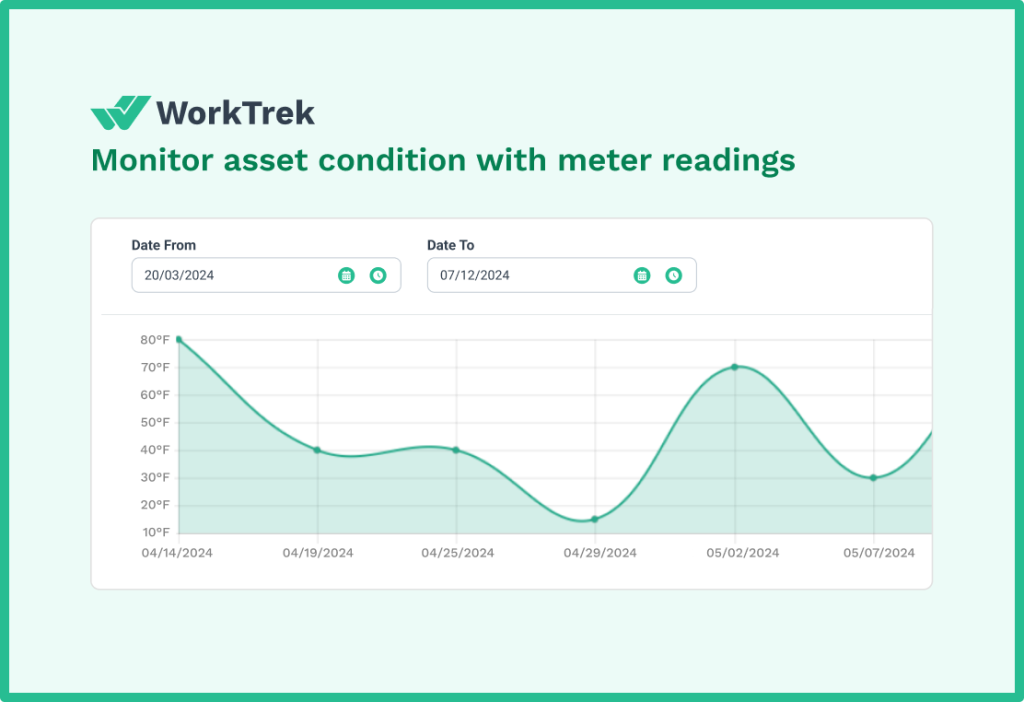

Condition monitoring uses real-time equipment data to determine maintenance needs. Sensors and diagnostic tools detect signs of wear or performance decline.

Vibration sensors on motors can identify bearing problems early. Temperature monitoring reveals overheating issues before equipment fails.

This approach prevents both unnecessary maintenance and unexpected breakdowns. Work only happens when equipment actually needs attention.

Common monitoring methods:

- Vibration analysis for rotating equipment

- Temperature monitoring for electrical systems

- Oil analysis for hydraulic machinery

- Ultrasonic testing for structural integrity

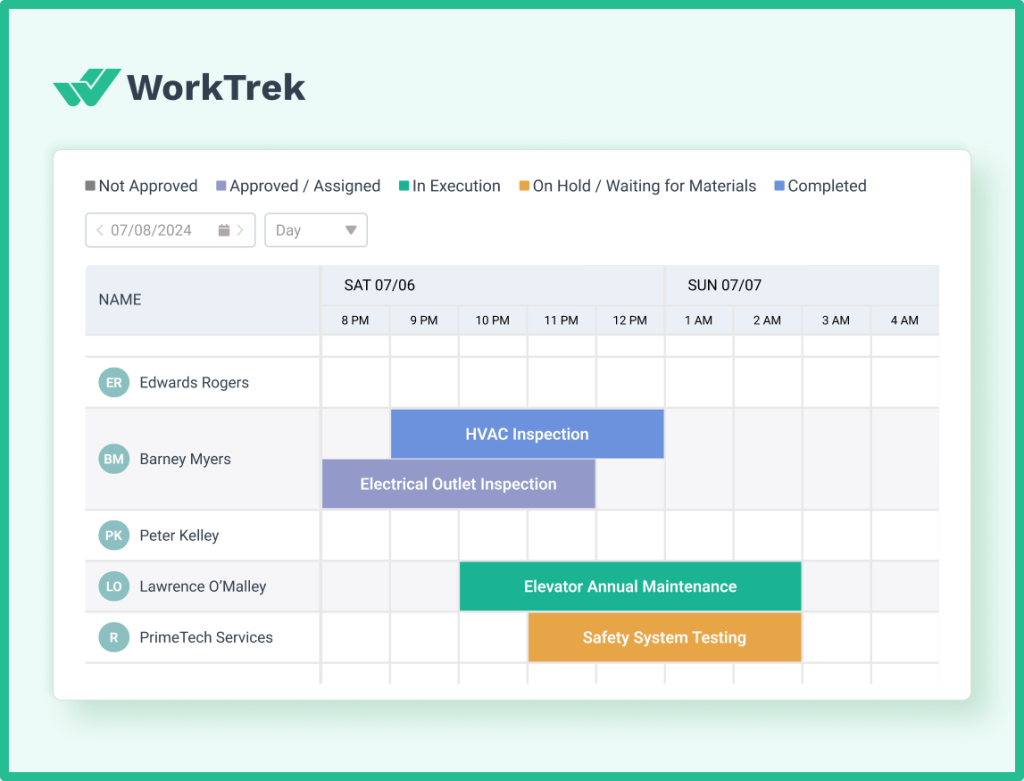

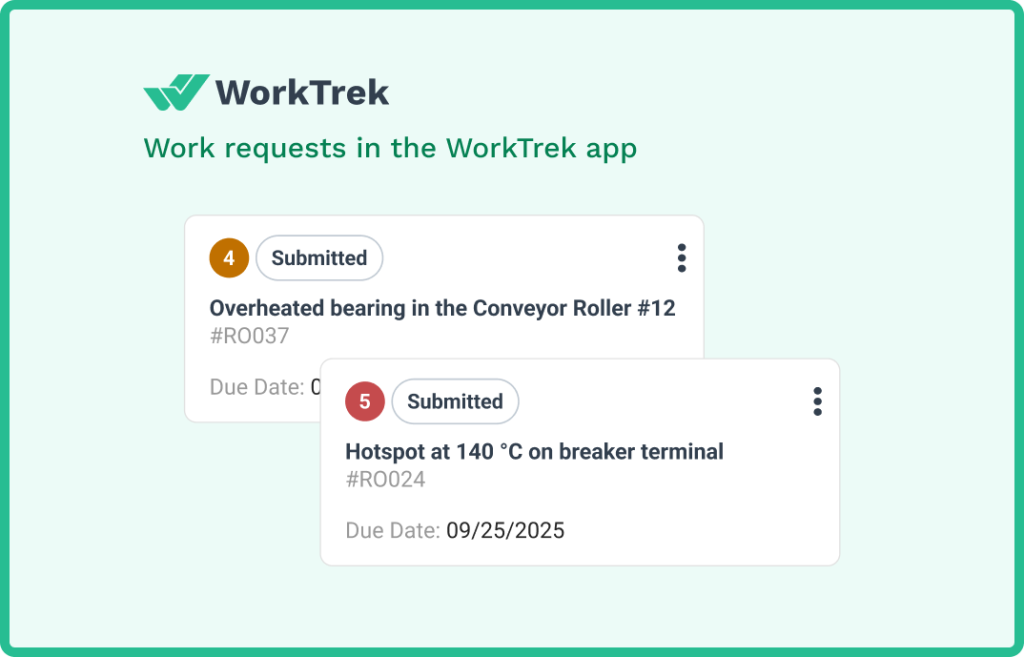

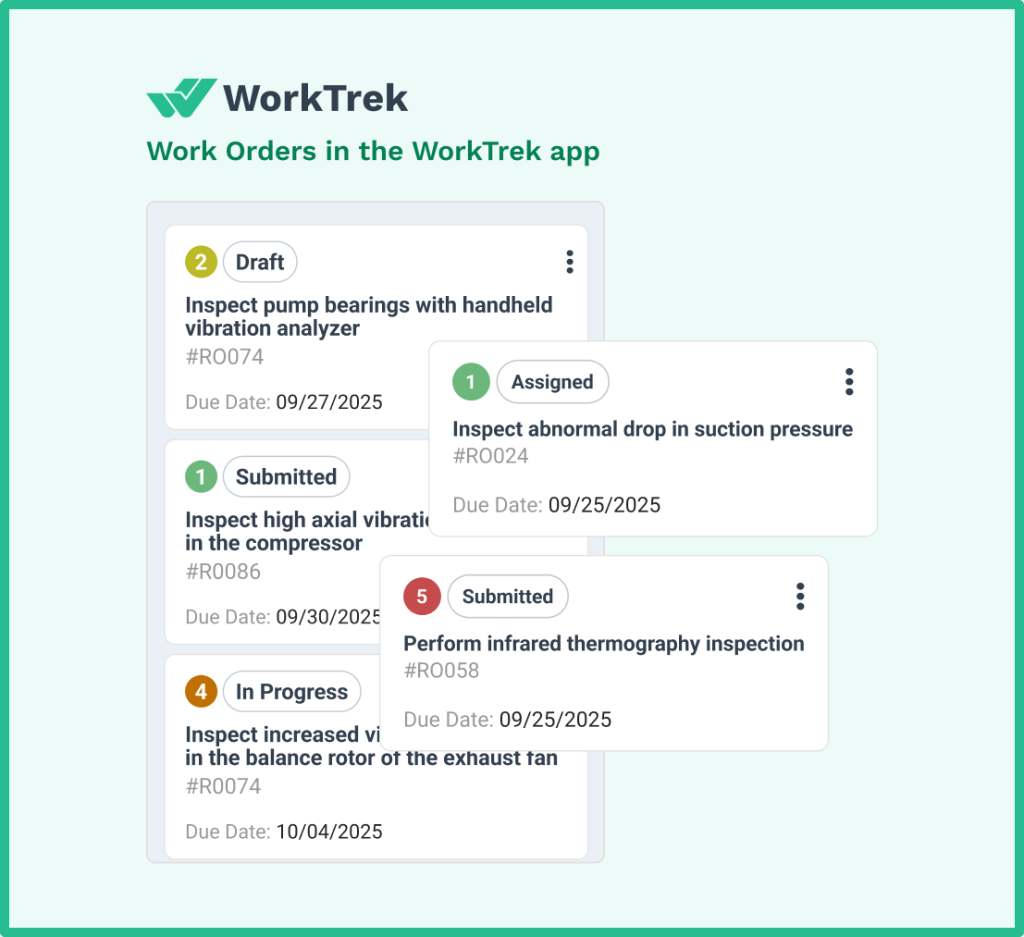

Maintenance teams receive alerts when readings exceed normal ranges. When paired with a CMMS system like WorkTrek, these readings can automatically generate work orders.

Additionally, maintenance managers can also manually create work orders and schedule repairs based on the data.

Investment in monitoring equipment and staff training is required upfront. However, the precision of this method often justifies these costs.

Predictive Maintenance in Manufacturing

Predictive maintenance combines condition monitoring with predictive analytics and machine learning to optimize maintenance.

Advanced algorithms analyze historical data to forecast future equipment needs.

Systems learn normal operating patterns for each machine. These systems then identify subtle changes that indicate developing problems weeks or months ahead.

For example, a packaging line might use predictive analytics to forecast bearing replacement dates. The system considers usage patterns, environmental conditions, and historical failure data to inform its decisions.

Key technologies include:

- Machine learning algorithms

- IoT sensors and connectivity

- Data analytics platforms

- Artificial intelligence systems

This represents the most advanced maintenance strategy available. It provides maximum equipment uptime while minimizing maintenance costs.

Implementation requires significant investment in technology and robust data management capabilities. Many manufacturers begin with critical equipment before expanding their systems across the board.

The prescriptive maintenance approach can even automatically generate work orders and schedule repairs. This level of automation reduces manual planning and improves response times.

Essential Preventive Maintenance Tasks and Schedules

Successful manufacturing operations depend on well-planned maintenance tasks that follow specific schedules and target the most critical equipment.

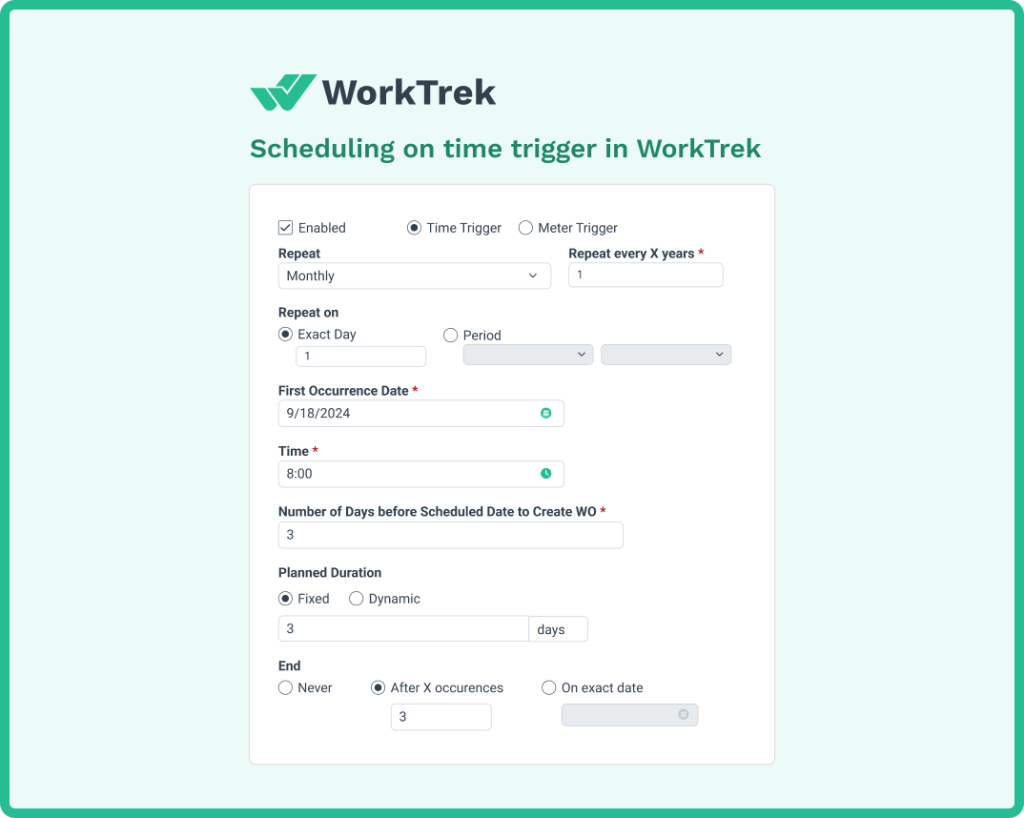

Preventive maintenance scheduling involves creating structured maintenance plans in which tasks are performed routinely at fixed intervals, rather than reacting to problems as they arise.

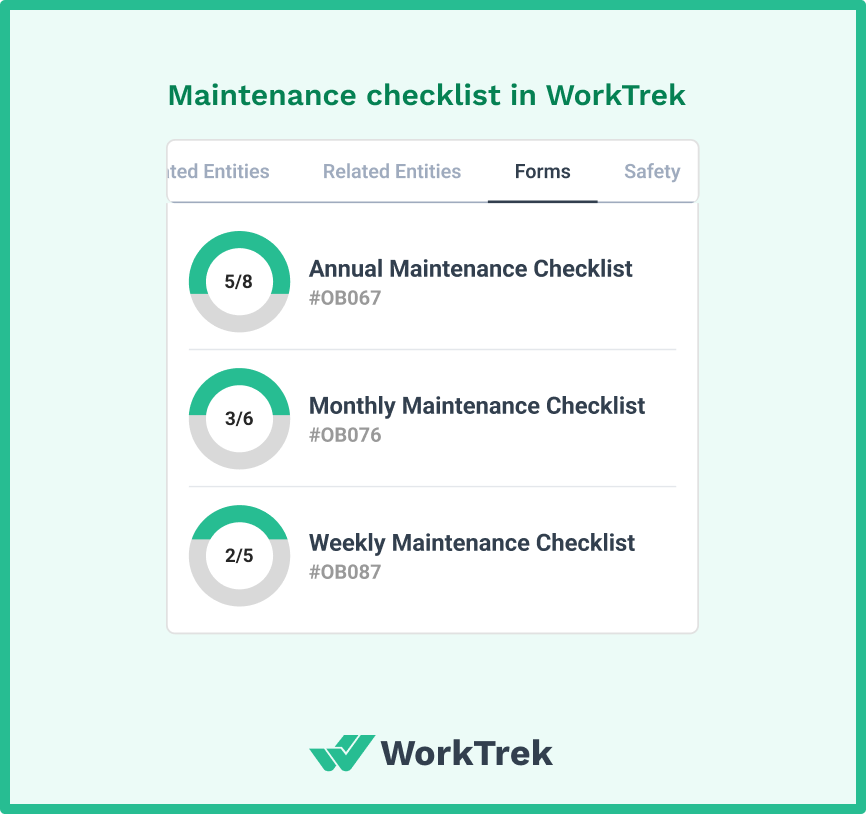

Creating Effective Maintenance Checklists

A preventive maintenance checklist is a list of tasks that need to be performed as part of the maintenance process. These checklists encompass inspections, lubrication schedules, parts replacement, and additional tasks.

The goal of maintenance checklists is to break down complex procedures into simple steps. Each task should specify the necessary tools, the required time, and any necessary safety precautions.

Key Elements of Manufacturing Checklists:

- Visual inspections for wear and tear

- Fluid level checks and replacements

- Belt tension adjustments

- Electrical connection testing

- Safety system verification

It is important to customize checklists for each piece of equipment. A conveyor system requires different maintenance tasks than a hydraulic press or packaging machine.

This can be easily done with a CMMS like WorkTrek. You can create customized checklists designed for specific systems.

Prioritizing Critical Equipment

Not all manufacturing equipment requires the same level of maintenance attention. Critical equipment identification focuses resources on assets that would cause significant disruptions if they fail.

Manufacturing teams should focus on analyzing which machines have the highest impact on production.

Equipment that stops entire production lines receives top priority in maintenance scheduling.

Equipment Priority Categories:

- High Priority: Production bottlenecks, safety-critical systems

- Medium Priority: Support equipment, backup systems

- Low Priority: Non-essential utilities, storage equipment

Past maintenance records reveal frequent failure points that need extra attention. Manufacturer recommendations also guide maintenance intervals for complex machinery.

Cost of failure helps determine priority levels. A $10,000 repair that stops production for days ranks higher than routine maintenance on auxiliary equipment.

Implementing Lubrication and Routine Inspections

Scheduled maintenance involves performing specific tasks at predefined intervals, such as cleaning, lubrication, or part replacements.

These routine tasks are designed to prevent minor issues from escalating into major failures.

Lubrication schedules vary depending on the type of equipment and its operating conditions. High-speed machinery requires more frequent lubrication than slower-moving equipment.

Common Lubrication Intervals:

- Daily: High-speed bearings, chain drives

- Weekly: Conveyor systems, packaging equipment

- Monthly: Motors, gearboxes, pumps

- Quarterly: Heavy machinery, hydraulic systems

Routine inspections catch problems before they cause breakdowns. Technicians check for unusual noises, vibrations, temperature changes, and visible wear patterns.

Temperature monitoring reveals bearing problems and electrical issues. Vibration analysis detects misalignment and worn components before they fail completely.

Documentation of inspection findings helps track the condition of equipment over time. This data supports decisions about repair timing and replacement planning.

Creating and Implementing a Preventive Maintenance Program

As explained in this blog, a successful preventive maintenance program requires structured planning, proper team training, and continuous performance monitoring.

Manufacturing companies should begin by establishing a clear maintenance schedule, training technicians who understand the equipment’s requirements, and implementing a data-driven approach to track effectiveness and make necessary improvements.

Developing a Structured Maintenance Plan

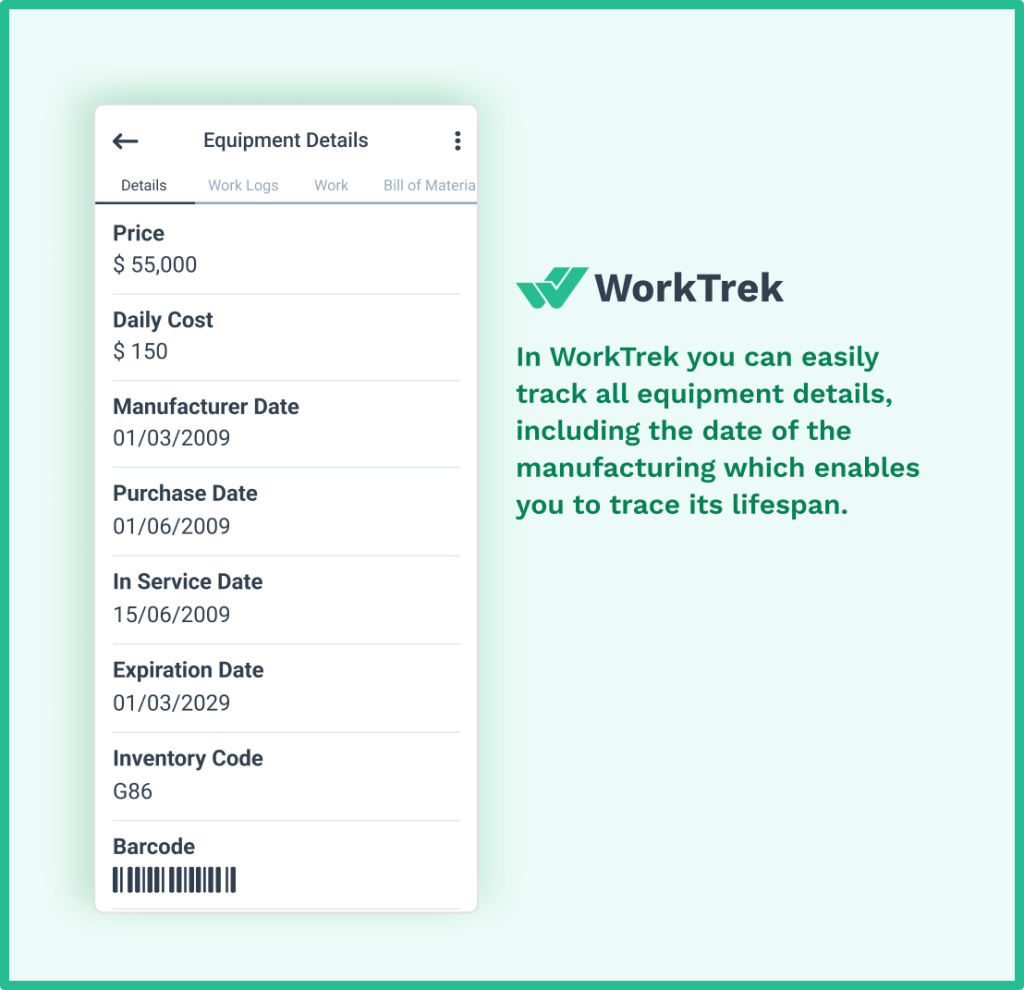

Manufacturing facilities should begin with a comprehensive asset inventory that includes the names, locations, model numbers, and maintenance histories of all equipment.

Critical asset prioritization enables teams to focus resources on equipment that has the greatest impact on safety, production, and downtime costs.

Companies should evaluate each asset using factors like safety impact, production importance, and failure frequency.

A scoring system from 1-5 helps rank equipment objectively.

Maintenance triggers come from three main sources:

- Time-based schedules (monthly, quarterly inspections)

- Usage-based metrics (operating hours, cycles completed)

- Manufacturer recommendations from equipment manuals

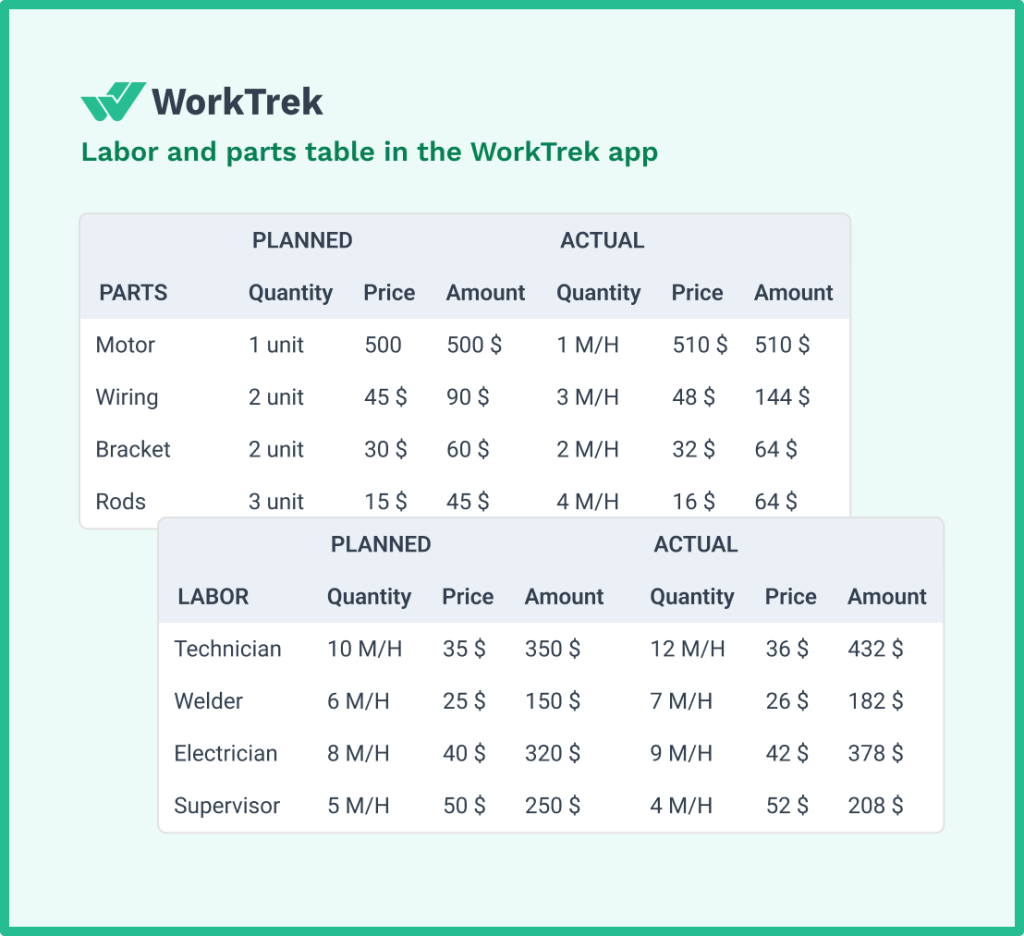

Teams need detailed task lists for each maintenance activity. These lists should specify required tools, parts, estimated completion time, and safety procedures.

A computerized maintenance management system like WorkTrek helps automate scheduling and work order generation.

CMMS software can increase PM completion rates by 70% compared to manual tracking methods.

Training Technicians and Managing Teams

Maintenance technicians require specialized training on equipment systems, safety procedures, and digital tools utilized in the preventive maintenance program.

Companies should provide hands-on training for each asset type and maintenance task.

Standardized operating procedures (SOPs) ensure consistent work quality across all team members. Digital checklists and step-by-step guides help technicians complete tasks accurately and consistently.

Teams perform better when they understand the importance of preventive maintenance. Training should cover how PM reduces downtime costs and prevents safety incidents.

Mobile maintenance software allows technicians to access procedures, report issues, and update work orders from anywhere in the facility. This improves communication between maintenance staff and operations teams.

Regular skills assessments help identify training gaps. Companies should schedule ongoing education sessions to keep technicians updated on new equipment and techniques.

Tracking and Optimizing Maintenance Performance

Maintenance management systems can provide you with completion rates, equipment downtime, and maintenance costs.

Key metrics include PM completion percentage, mean time between failures, and maintenance cost per asset.

Teams should track which maintenance activities prevent the most failures. This data helps optimize schedules and focus resources on high-impact tasks.

Equipment failure patterns reveal whether maintenance intervals are too frequent or not frequent enough.

CMMS can analyze historical data to suggest adjustments to the schedule.

Performance indicators to monitor include:

- Unplanned downtime reduction

- Equipment availability rates

- Maintenance cost trends

- Safety incident frequency

Regular program reviews help identify opportunities for improvement. Manufacturing teams should adjust maintenance schedules based on actual equipment performance rather than relying only on manufacturer recommendations.

Overcoming Challenges in Preventive Maintenance

Like any new initiative, implementing preventive maintenance presents challenges.

These include balancing maintenance costs with production demands, reducing equipment downtime during scheduled maintenance, and maintaining proper inventory levels for spare parts.

Balancing Maintenance Costs and Production Schedules

Rising maintenance costs pose a significant challenge as equipment becomes increasingly complex and aging assets require more intensive attention.

Labor expenses and part replacements can add up quickly without proper planning and an over-reliance on reactive maintenance.

Manufacturers can control costs by using automated maintenance scheduling tools.

CMMS platforms help track parts usage and reduce waste. These systems also prevent unnecessary maintenance by scheduling work based on the actual condition of the equipment, rather than fixed time intervals.

Production scheduling integration becomes critical for cost control. Teams should coordinate maintenance windows during planned downtime or periods of low demand.

This approach prevents costly equipment downtime that impacts production schedules and delivery commitments.

Performance-based maintenance offers better cost efficiency than time-based schedules. This method triggers maintenance based on runtime hours or cycle counts, rather than calendar dates. It aligns maintenance activities with actual equipment usage patterns.

Minimizing Equipment Downtime During Maintenance

Equipment downtime directly impacts production lines and can halt entire manufacturing operations. Shutting down machines for maintenance leads to lost output, wasted labor hours, and missed deadlines.

Modern technology significantly helps reduce these disruptions.

IoT sensors enable condition-based maintenance by continuously monitoring equipment in real-time. Teams can detect vibration changes, temperature spikes, and pressure drops that indicate potential equipment failures.

For mature organizations, predictive maintenance extends mean time between failures (MTBF) by identifying issues before they occur.

Scheduling maintenance during off-hours or slow production periods minimizes impact.

Real-time monitoring systems and predictive analytics help identify optimal maintenance windows. This timing strategy ensures that production lines continue to run during peak demand periods.

Managing Inventory and Spare Parts

Managing parts can be a challenge for most organizations.

Organizations that implement proper inventory management can ensure that critical spare parts are available when needed.

Poor inventory control leads to extended downtime when equipment failures occur unexpectedly. Also, overstocking ties up capital and warehouse space unnecessarily.

Just-in-time inventory strategies work well for predictable maintenance items. Teams can order routine parts, such as filters and belts, on a regular schedule.

However, critical components that prevent major equipment failures require higher stock levels.

Digital inventory systems, typically part of a CMMS, track part usage patterns and automatically reorder items. These systems reduce manual errors and prevent stockouts of essential components. They also identify slow-moving inventory that ties up resources.

Maintaining good supplier partnerships enhances parts availability and minimizes inventory investment. Vendors can maintain stock levels for critical components and deliver them quickly when needed. This approach reduces on-site storage requirements while ensuring parts availability.

Conclusion

Preventive maintenance is a strategic investment that transforms manufacturing operations from reactive to proactive.

Manufacturing facilities that implement structured maintenance programs can reduce unplanned downtime by up to 25%, extend equipment lifespan by 15-20%, and save between 12-18% on overall maintenance costs.

Success is not always easy and requires commitment to proper planning, skilled technician training, and leveraging modern tools like WorkTrek CMMS to track performance and optimize schedules. However, facilities that do implement preventive maintenance can improve operations.