Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- 58% of facilities spend less than half their time on scheduled maintenance despite using preventive maintenance programs, indicating massive optimization potential

- Mean time to repair has increased from 49 to 81 minutes due to skills gaps and supply chain delays, making process optimization critical

- Organizations using CMMS-enabled optimization achieve up to 40% cost reduction and 75% equipment downtime reduction

- 91% of businesses report reduced repair time after implementing optimized preventive and predictive maintenance strategies

Your preventive maintenance program might be running, but is it truly performing?

This question haunts maintenance managers across industries, and for good reason.

According to The 2025 State of Industrial Maintenance, even though 87% of facilities claim to use preventive maintenance, 58% spend less than half their maintenance time on scheduled work.

The rest? They’re stuck in reactive firefighting mode.

This major disconnect between intention and execution reveals a harsh truth: having a preventive maintenance program isn’t enough.

Without the right optimization, your maintenance processes can become inefficient, your costs spiral out of control, and equipment failures continue disrupting operations.

That’s why learning how to optimize your preventive maintenance process has become essential for survival in today’s competitive landscape. It’s the difference between maintenance teams that struggle and those that thrive.bnj

Understanding Your Current Maintenance Process Performance

Before you can optimize maintenance, you need to understand where things stand.

Many organizations operate with limited visibility into their actual maintenance performance, making improvement nearly impossible.

The Reality Check Most Teams Need

Research shows that only 51% of maintenance activities in most industries are actually preventive. This is despite widespread adoption of preventive maintenance strategies.

This means that half of your maintenance team’s valuable time is spent on emergency repairs and unplanned downtime.

The impact is staggering.

According to Siemens’ 2024 report, unplanned downtime across the world’s top 500 companies costs $1.4 trillion annually. In the automotive sector alone, downtime costs exceed $2.3 million per hour—a twofold increase since 2019.

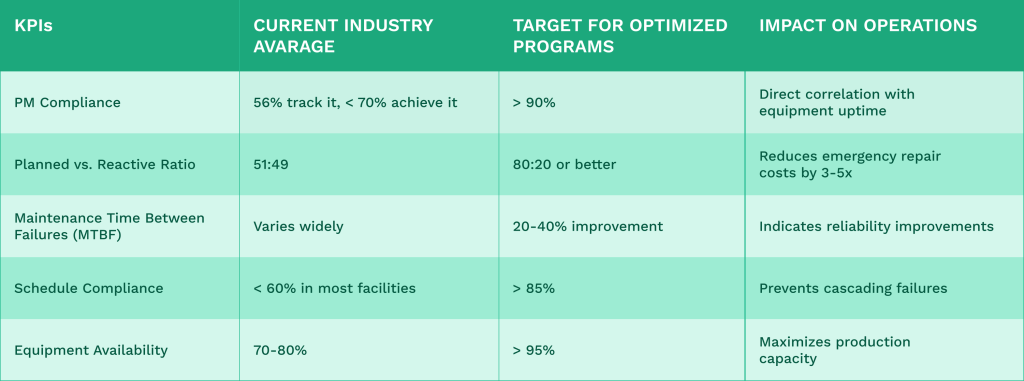

Key Performance Indicators That Matter

To optimize your preventive maintenance process effectively, track these critical metrics:

WorkTrek’s analytics platform automatically tracks these KPIs, transforming raw performance data into actionable insights that drive continuous improvement.

Identifying Process Bottlenecks

Your maintenance process likely suffers from common bottlenecks that prevent effective preventive maintenance:

- Poor scheduling practices: Maintenance tasks often compete with production demands

- Incomplete data: Missing or incomplete equipment history makes optimization impossible

- Resource constraints: 45% of maintenance leaders cite lack of resources as their primary obstacle

- Skills gaps: Amazingly, only 29% of facility owners believe their technicians are adequately prepared

- Manual processes: Using paper-based systems can create delays and data inaccuracies

Understanding Preventive Maintenance Optimization

Preventive maintenance optimization transforms basic maintenance schedules into data-driven programs that target real equipment problems.

This approach can reduce costs while improving equipment reliability through smarter maintenance decisions.

What Is Preventive Maintenance Optimization?

Preventive maintenance optimization is a structured approach designed to improve maintenance programs.

It does that by analyzing existing maintenance tasks to find which ones actually prevent equipment failures.

The process utilizes historical data and equipment performance records. Additionally, maintenance teams review past breakdowns to identify patterns.

Using this data, teams can then adjust maintenance schedules based on actual equipment needs rather than generic recommendations.

PMO uses data analytics to tune maintenance schedules. Real-time sensor readings and performance indicators guide decision-making.

This creates maintenance programs that target specific failure modes.

The optimization process examines each maintenance task’s value.

Tasks that don’t prevent failures get removed or modified. Resources shift to activities that actually improve equipment reliability.

Key Differences from Traditional Maintenance Programs

Traditional preventive maintenance follows fixed schedules regardless of equipment condition.

Machines are serviced every 30, 60, or 90 days, depending on manufacturer recommendations or industry standards.

Optimized maintenance programs, on the other hand, adapt to the actual performance of the equipment. The goal is to track failure patterns and adjust frequencies accordingly.

Some equipment might need more frequent attention, while others need less.

Traditional Approach:

- Fixed time intervals

- Generic manufacturer schedules

- Same tasks for similar equipment

- Limited data analysis

Optimized Approach:

- Variable intervals based on data

- Equipment-specific schedules

- Customized task lists

- Continuous data monitoring

Traditional programs can often waste resources on unnecessary tasks. Optimized programs eliminate low-value activities and focus maintenance efforts on preventing actual failure modes.

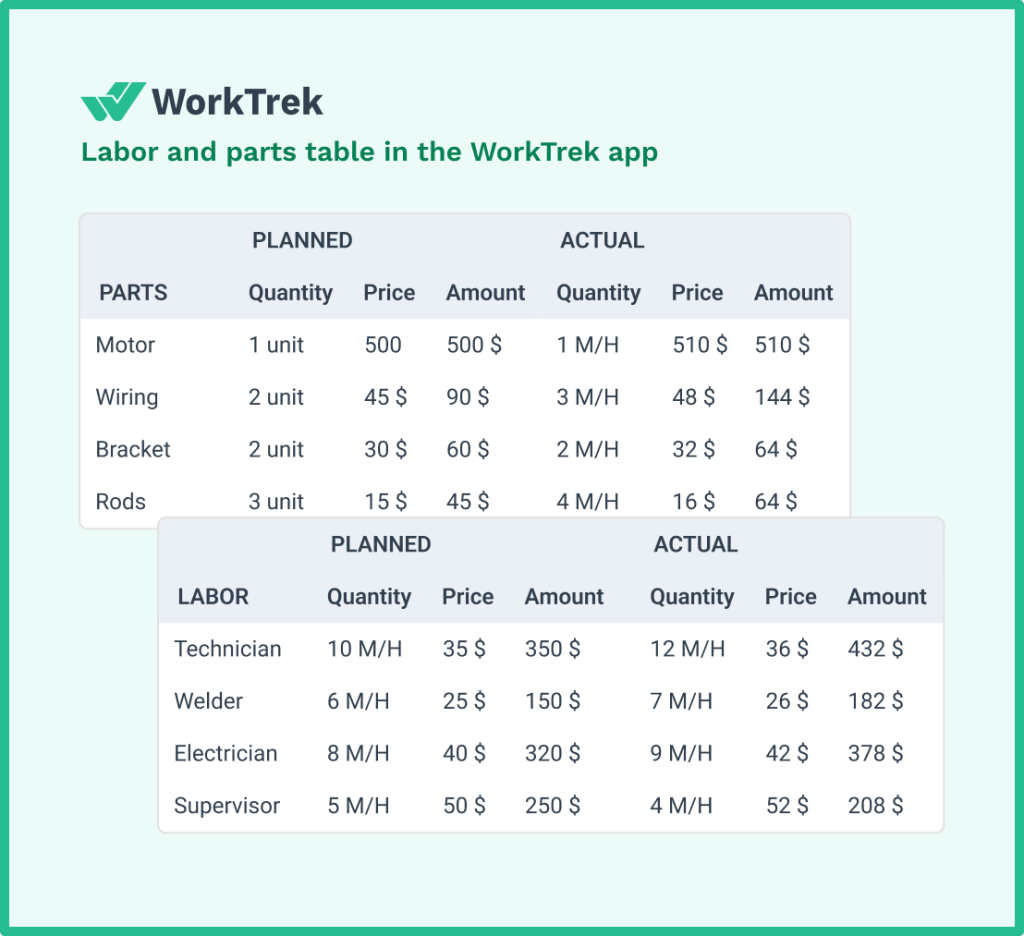

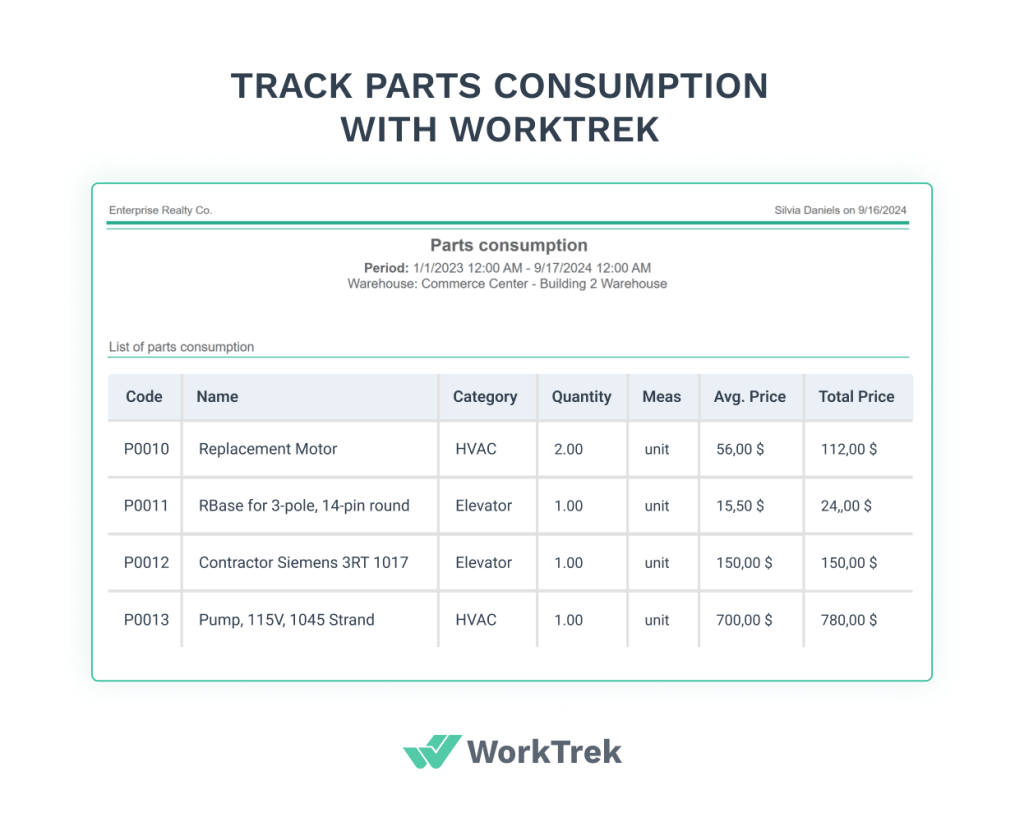

Data drives all optimization decisions. Maintenance management systems, such as a WorkTrek CMMS, track task effectiveness and equipment performance.

This creates feedback loops that will improve the program over time.

Benefits of Optimizing Preventive Maintenance

Industry studies show that optimized maintenance programs reduce total maintenance costs by 15-25% on average. They reduce and often eliminate unnecessary tasks while increasing focus on critical activities. This improves resource allocation and technician productivity.

Equipment reliability increases when maintenance targets actual failure modes.

By using optimized programs, you can reduce unplanned downtime and equipment breakdowns. This can make your production schedules more predictable.

Cost Benefits:

- Lower labor hours per asset

- Reduced spare parts inventory

- Less emergency repair work

- Improved technician efficiency

Operational Benefits:

- Higher equipment availability

- Better production planning

- Fewer safety incidents

- Extended asset life

You can greatly improve asset management through better data collection and analysis. Maintenance teams gain insights into equipment condition trends.

This approach supports better replacement and upgrade decisions for all assets.

The optimization process creates standardized maintenance procedures. Technicians follow consistent methods that produce reliable results. Training becomes more effective when procedures target specific outcomes.

Quality improvements occur when maintenance processes are focused on preventing actual problems rather than following generic checklists.

Building a Solid Foundation for Optimization

A successful preventive maintenance program requires more than good intentions. It requires planning, the right tools, and a commitment to execute.

Below is a clear 3 step process that you can follow:

Step 1: Conduct a Comprehensive Asset Inventory

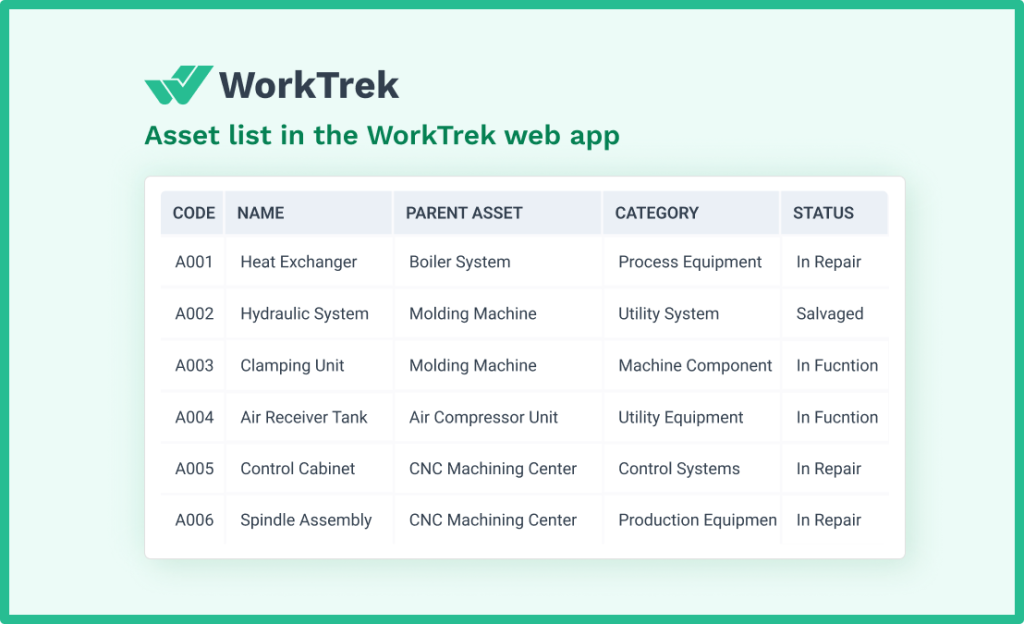

You can’t optimize what you don’t track. Start by cataloging all critical assets and their maintenance requirements:

- Document equipment specifications and operating hours

- Record manufacturer recommendations for each asset

- Identify critical equipment that impacts production

- Map out specific failure modes for high-value assets

- Establish baseline performance data for comparison

WorkTrek’s asset management features centralize this information, making it accessible to maintenance teams when and where they need it.

Step 2: Analyze Your Historical Data

Your maintenance history holds valuable insights waiting to be discovered.

Studies indicate that 77% of manufacturers mainly rely on OEMs and suppliers for maintenance information. However, your own historical data often provides more relevant insights.

Examine your records to identify:

- Recurring failure patterns that suggest systemic issues

- Assets consuming disproportionate maintenance resources

- PM tasks that don’t prevent failures

- Seasonal variations affecting equipment performance

- Opportunities to shift from time-based to condition-based maintenance

Step 3: Prioritize Critical Assets

Not all equipment deserves equal attention. Focus your optimization efforts where they’ll deliver maximum impact.

Critical assets typically share these characteristics:

- Single point of failure in production

- High replacement or repair costs

- Long lead times for replacement parts

- Significant safety implications

- Direct impact on product quality

Creating a criticality matrix helps visualize priorities and ensures maintenance resources flow to the most important equipment first.

Implementing Effective Preventive Maintenance Procedures

With your foundation in place, it’s time to transform your maintenance processes for peak efficiency.

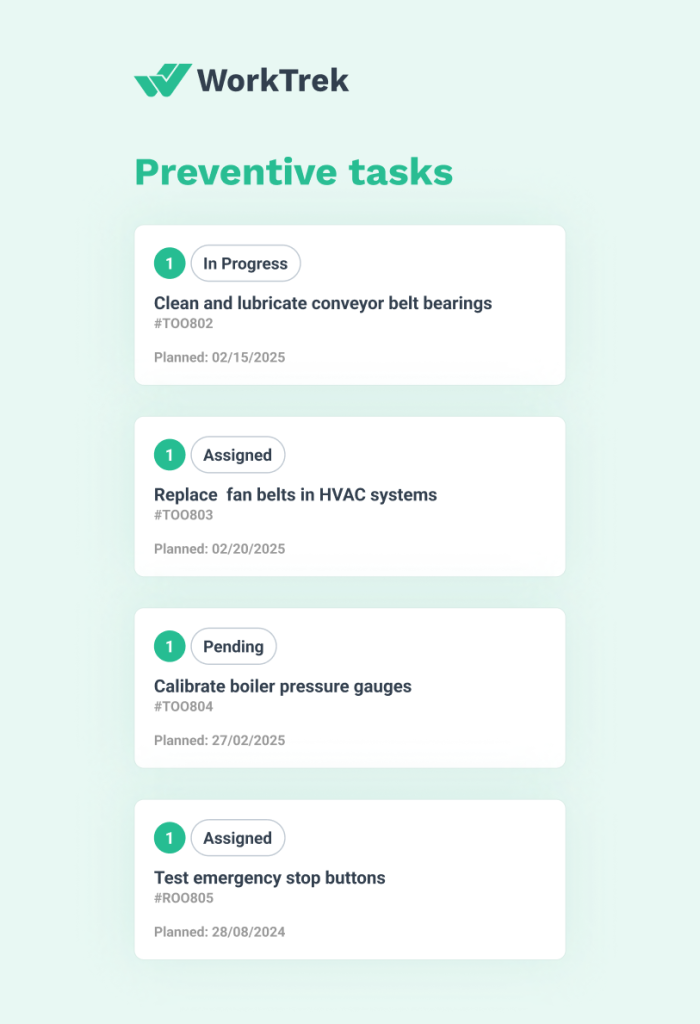

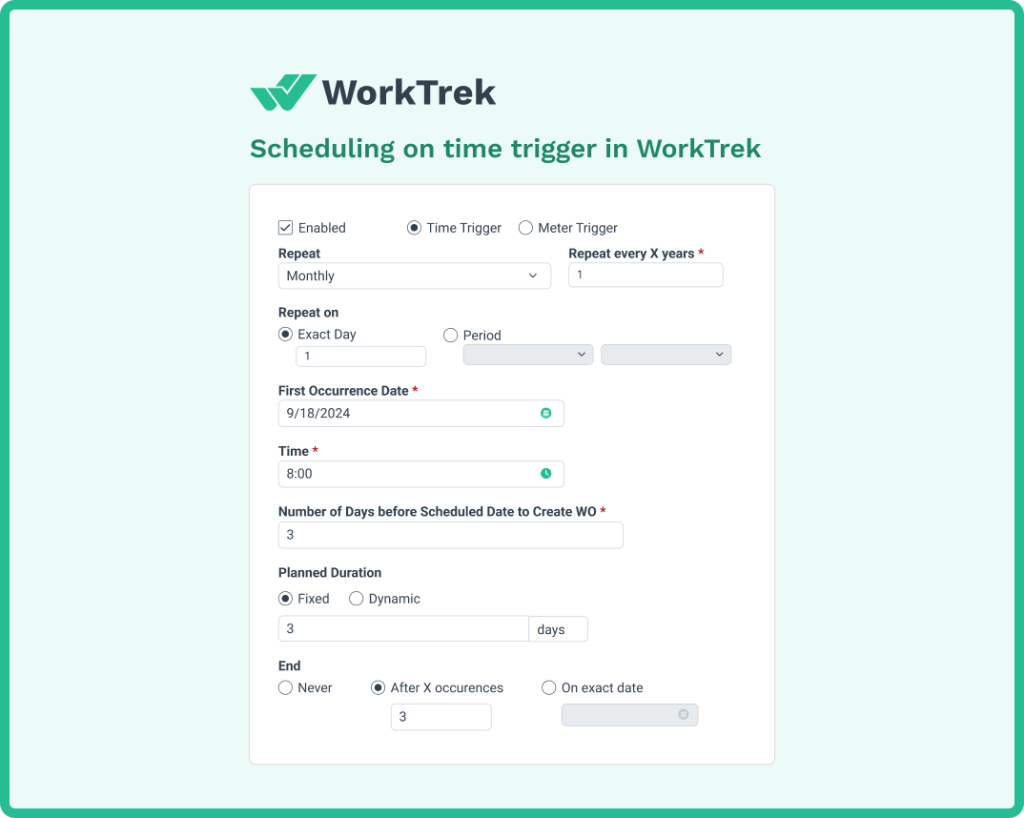

Optimize Your Preventive Maintenance Schedule

Generic maintenance schedules waste resources and miss failure points.

The better approach is to target your maintenance schedule to the actual equipment need based on:

Schedule PM tasks based on operating hours or production cycles rather than calendar dates. This approach ensures maintenance happens when equipment actually needs it.

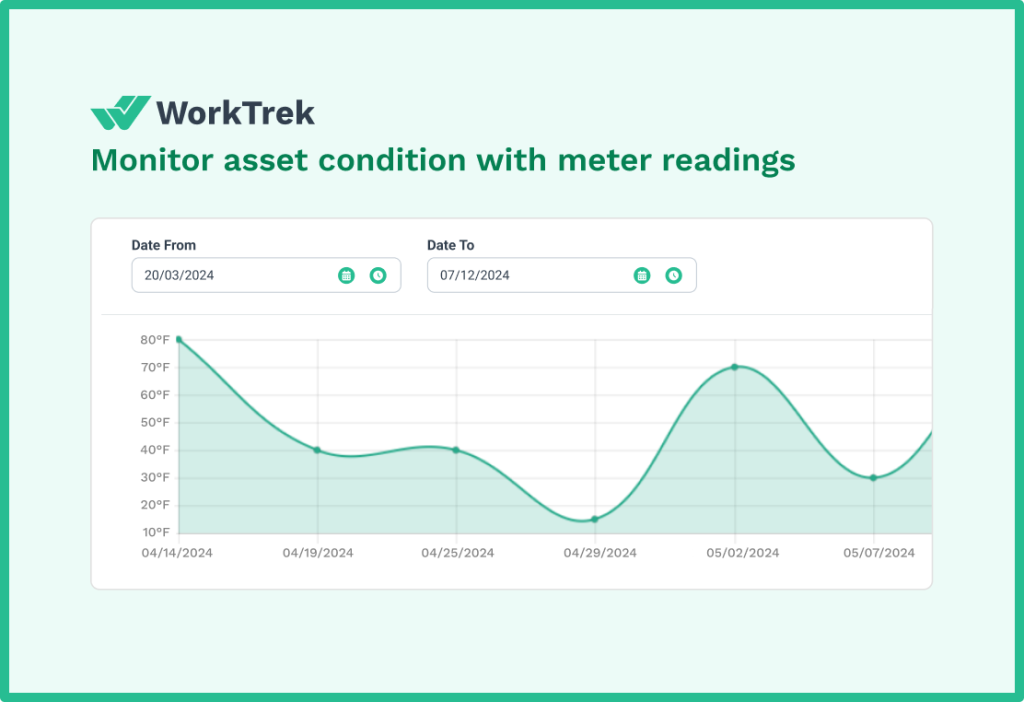

Monitor equipment health indicators to trigger maintenance only when necessary. Research shows this can reduce maintenance costs by 25% while improving equipment availability.

Risk-Based Intervals:

Adjust frequencies based on failure consequences. Critical equipment may need more frequent inspections while non-critical assets can extend intervals.

WorkTrek’s preventive maintenance software enables dynamic scheduling that automatically adjusts based on meter readings, conditions, or custom triggers you define.

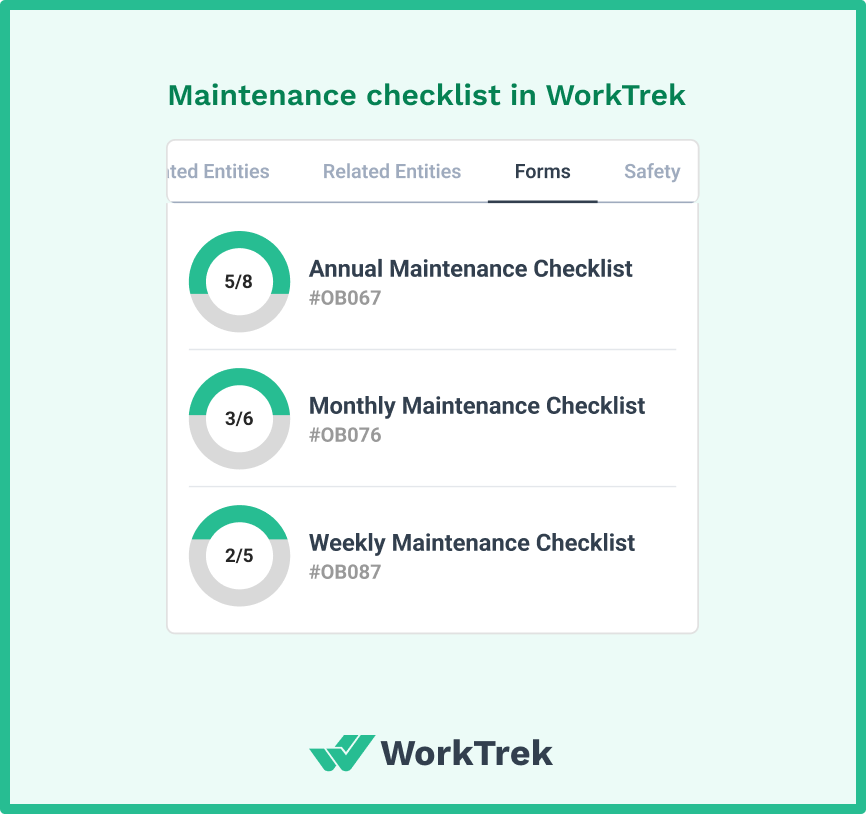

Standardize Your Preventive Maintenance Tasks

Consistency usually drives efficiency.

Standardized procedures ensure that every technician performs maintenance consistently, reducing human error and improving outcomes.

Essential elements of standardized PM procedures include:

- Step-by-step task instructions with visual aids

- Required tools and replacement parts lists

- Safety protocols and lockout/tagout procedures

- Inspection criteria with pass/fail thresholds

- Time estimates for planning and scheduling

Digital checklists and mobile access ensure technicians follow procedures correctly while capturing valuable data for analysis.

Balance Preventive and Predictive Maintenance

While preventive maintenance forms the backbone of your program, combining it with predictive maintenance delivers superior results.

Industry data shows that 40% of manufacturing companies now use both strategies together.

Predictive techniques complement your PM program by:

- Validating maintenance intervals with real-time data

- Detecting issues that routine inspections might miss

- Providing early warning signs of developing problems

- Enabling more precise maintenance timing

Start with simple condition-monitoring techniques, such as vibration analysis or oil sampling, then expand as your team gains experience and confidence.

Leveraging Technology to Optimize Maintenance

Modern maintenance optimization is virtually impossible without technology support. The right tools transform maintenance operations from reactive chaos to proactive control.

The CMMS Advantage

A computerized maintenance management system serves as your optimization command center. Research indicates that 52% of industrial plants now use CMMS platforms, with adoption accelerating rapidly.

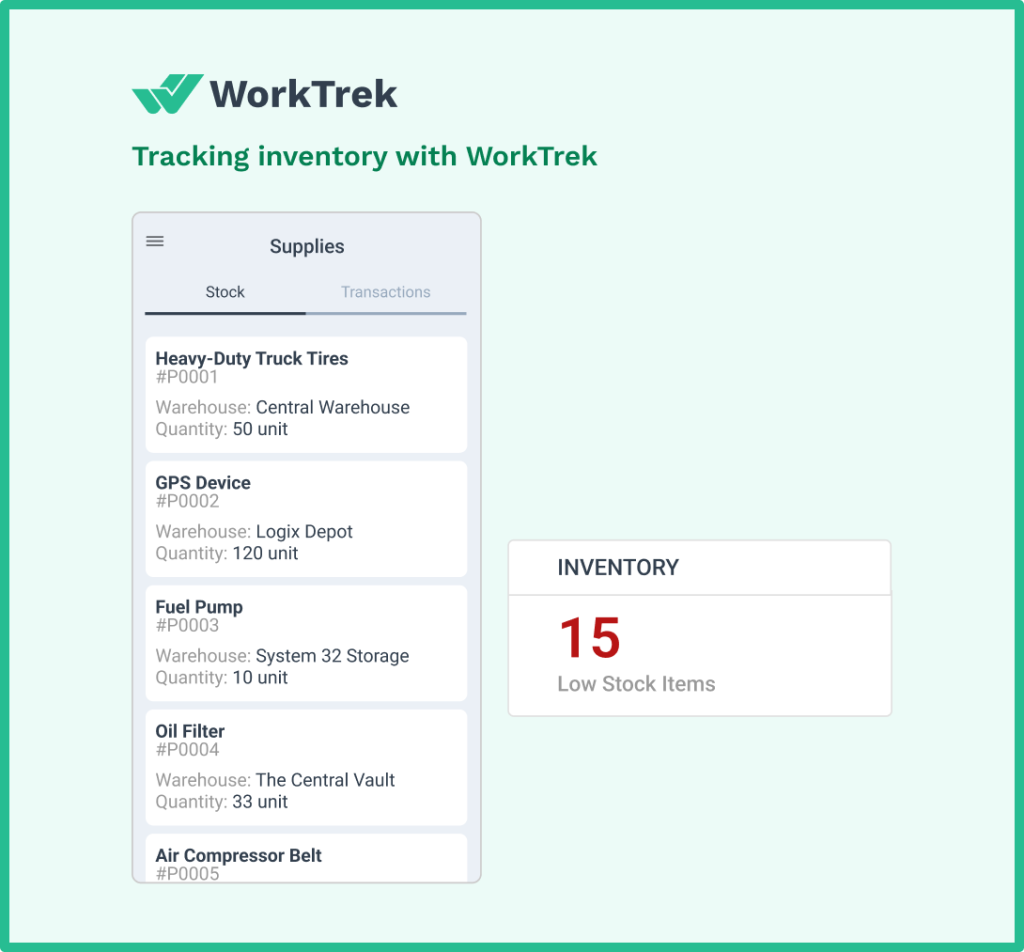

WorkTrek’s CMMS solution provides the foundation for optimization through:

- Automated scheduling: Eliminates missed PM tasks and ensures consistent execution

- Mobile accessibility: Enables real-time updates from the field

- Inventory management: Ensures parts availability without overstocking

- Work order tracking: Provides visibility into maintenance activities

- Performance analytics: Identifies optimization opportunities

The data is overwhelming: Organizations implementing CMMS-enabled maintenance see up to 40% cost reduction and 75% decrease in equipment downtime.

Data Analysis and Machine Learning

Your maintenance data becomes more valuable when analyzed properly. Machine learning models can identify patterns humans miss, predicting failures before they occur.

According to recent studies, 39% of maintenance leaders see knowledge capture as AI’s most valuable contribution to maintenance, followed by reducing unexpected equipment failure at 36%.

These technologies enable:

- Dynamic adjustment of PM intervals based on actual conditions

- Identification of early warning signs invisible to human inspection

- Optimization of spare parts inventory

- Root cause analysis of recurring failures

IoT and Real-Time Monitoring

Internet of Things sensors (IoT) provide continuous equipment monitoring, transforming maintenance from periodic checks to constant vigilance.

IDC projections estimate industrial IoT will generate $800 billion in economic value by 2024.

Real-time monitoring enables:

- Immediate alerts when parameters exceed thresholds

- Automatic work order generation for developing issues

- Performance trending to optimize maintenance timing

- Remote diagnosis reduces travel time for technicians

Overcoming Common Implementation Challenges

Even the best optimization plans face obstacles from both internal and external stakeholders. Here’s how to overcome the most common challenges.

Challenge 1: Resistance from Maintenance Personnel

Change is hard, especially for experienced maintenance technicians comfortable with existing procedures.

Solution: Involve your maintenance team early in the optimization process. Studies show that 23% of companies cite employee buy-in as a significant challenge.

You can address this by:

- Demonstrating how optimization makes their jobs easier

- Providing comprehensive technical training

- Celebrating early wins to build momentum

- Creating feedback loops for continuous improvement

Challenge 2: Budget Constraints

Research indicates that 29% of maintenance managers cite budget limitations as a major obstacle.

Solution: Start small and scale gradually:

- Focus initial efforts on critical assets with the highest ROI potential

- Use existing data to justify investment with projected savings

- Implement low-cost improvements or small pilots to first to demonstrate value

- Consider cloud-based solutions with lower upfront costs

WorkTrek’s flexible pricing enables organizations to start small and expand as they see results.

Challenge 3: Data Quality Issues

Poor or missing historical data undermines optimization efforts.

Solution: Don’t let perfect be the enemy of good:

- Start collecting data systematically, moving forward

- Use estimates based on industry benchmarks where data is missing

- Implement data validation processes to ensure accuracy

- Gradually build your data set through consistent recording

Challenge 4: Balancing Production and Maintenance

Production pressure often forces teams to skip scheduled maintenance, creating a vicious cycle of reactive repairs.

Solution: Make maintenance non-negotiable:

- Educate stakeholders on the actual cost of deferred maintenance, including replacement costs

- Schedule maintenance during natural production breaks

- Demonstrate how PM prevents costly production downtime

- Track and report the impact of skipped maintenance

Measuring Success: Tracking Your Optimization Progress

You can’t manage what you don’t measure. Track these metrics to gauge your optimization success:

Equipment Performance Metrics

Equipment Uptime:

Target 95% or higher for critical assets. Studies show optimized programs can increase uptime by 10-20%.

Overall Equipment Effectiveness (OEE):

Combines availability, performance, and quality into a single metric. World-class OEE exceeds 85%.

Failure Rate Reduction:

Track the decrease in unexpected breakdowns. Successful programs achieve 70-75% reduction in failures.

Cost-Related Metrics

Maintenance Cost Reduction:

Optimized programs typically achieve 12-18% savings compared to reactive maintenance. Each dollar spent on preventive maintenance saves an average of $5 in emergency repairs.

Labor Hours Efficiency:

Monitor the shift from reactive to planned work. Target 80% of labor hours on scheduled maintenance.

Inventory Optimization:

Boston Consulting Group research shows a 15% improvement in spare parts management through optimization.

Process Efficiency Metrics

PM Compliance Rate:

Should exceed 90% for optimized programs. This directly correlates with reduced equipment failures.

Measures adherence to planned maintenance windows. Target 85% or higher.

Mean Time to Repair:

Industry data shows MTTR has increased from 49 to 81 minutes on average. Optimization should reverse this trend.

WorkTrek’s reporting capabilities automatically track these metrics, providing real-time visibility into your optimization progress.

Advanced Optimization Strategies

Once you’ve mastered the basics, these advanced techniques can elevate your preventive maintenance program to world-class levels.

Reliability-Centered Maintenance (RCM)

RCM systematically evaluates each failure mode to determine the most effective maintenance strategy. This approach ensures every PM task directly addresses a specific risk.

The RCM process involves:

- Identifying functions and performance standards

- Determining functional failures

- Identifying failure modes and root causes

- Assessing failure consequences

- Selecting appropriate maintenance strategies

- Implementing and refining based on results

Total Productive Maintenance (TPM)

TPM engages operators in basic maintenance tasks, multiplying your maintenance capacity without adding headcount. Operators performing routine inspections and minor maintenance can:

- Detect problems through daily equipment familiarity

- Prevent issues through consistent basic care

- Free skilled technicians for complex repairs

- Foster ownership of equipment condition

Integration with Enterprise Systems

Connect your maintenance processes with broader business systems for holistic optimization:

- ERP integration for seamless parts ordering

- Production scheduling coordination to minimize conflicts

- Quality systems to correlate maintenance with product defects

- Financial systems for real-time cost tracking

Creating a Culture of Continuous Improvement

Optimization isn’t a one-time project. It requires continuous effort and commitment from the organization. —it’s an ongoing journey requiring organizational commitment.

Foster a Proactive Mindset

Shift your organization from reactive firefighting to proactive prevention:

- Celebrate prevented failures, not just quick repairs

- Make “good maintenance is invisible” your mantra

- Reward teams for high PM compliance

- Share success stories across the organization

Invest in Your Maintenance Teams

Your people are your greatest asset.

Research shows that 48% of companies struggle to hire and retain maintenance staff.

Support your teams through:

- Regular technical training on new technologies

- Cross-training to build versatility

- Career development paths for advancement

- Recognition programs for excellence

Embrace Data-Driven Decision Making

Let data guide your optimization efforts:

- Base decisions on metrics, not opinions

- Test improvements with pilot programs

- Measure results and adjust accordingly

- Share performance data transparently

The Future of Preventive Maintenance Optimization

The maintenance landscape continues evolving rapidly. Stay ahead by preparing for these emerging trends:

Artificial Intelligence and Machine Learning

AI transforms maintenance by analyzing vast datasets to automatically optimize processes.

Market Projections indicate the predictive maintenance market will reach $32.30 billion by 2030, growing at 27.4% CAGR.

Augmented Reality Support

IDC projects $4.1 billion will be invested in AR/VR for industrial maintenance by 2024, enabling:

- Remote expert assistance

- Interactive maintenance procedures

- Accelerated training for new technicians

- Visual documentation of completed work

Sustainability Integration

Environmental considerations increasingly influence maintenance strategies:

- Energy-efficient equipment operation

- Waste reduction through optimized parts usage

- Extended equipment lifespan reduces replacement needs

- Predictive maintenance prevents environmental incidents

Conclusion

The gap between organizations with optimized preventive maintenance processes and those stuck in a reactive mode continues to widen.

With Fortune Global 500 companies losing 11% of yearly turnover to unplanned downtime, the cost of inaction has never been higher.

But here’s the good news: optimization doesn’t require revolutionary change. Start with these immediate actions:

- Assess your current state: Calculate your planned vs. reactive maintenance ratio

- Pick your battles: Focus on your most critical assets first

- Standardize procedures: Create consistent PM tasks and schedules

- Embrace technology: Implement a CMMS platform like WorkTrek to automate and track

- Measure and adjust: Use data to refine your approach continuously

Remember, 91% of businesses report reduced repair time after implementing optimized maintenance strategies. Your facility can achieve similar results.

The tools exist. The strategies are proven. The potential savings are massive.

The only question is: When will you start optimizing?

Your equipment is waiting. Your bottom line is waiting. Your competitive advantage is waiting.

Take the first step toward optimization today.