Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- Preventive maintenance delivers an average 545% ROI, with every dollar invested saving up to $5 in future costs

- Organizations implementing preventive maintenance programs reduce equipment failures by 70-75% and unplanned downtime by 30-50%

- Equipment lifespan extends by 20-40% with proper preventive maintenance, delaying costly repairs

- Manufacturing companies lose $1.4 trillion annually to unplanned downtime—preventive maintenance is the proven solution

Are you still relying on reactive maintenance, waiting for equipment to break before fixing it?

If so, you’re not alone.

Research shows that 21% of facilities still operate primarily in reactive mode, treating equipment failures as inevitable rather than preventable.

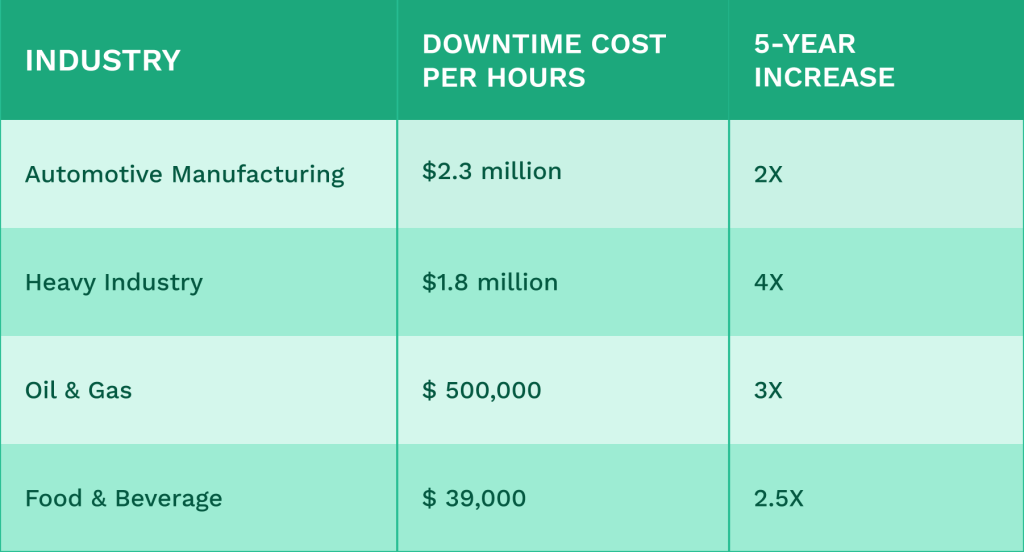

But here’s what that approach really costs: According to Siemens, unplanned downtime at the world’s top 500 companies costs $1.4 trillion annually. In the automotive sector alone, downtime now costs over $2.3 million per hour. This is a twofold increase since 2019.

The solution is clear: implement preventive maintenance. Yet many organizations hesitate, viewing it as an added expense rather than the investment it truly is.

These eight compelling reasons to implement a preventive maintenance program will show you why proactive maintenance isn’t just smart, but essential for your organization.

1. Reduce Equipment Failures and Unplanned Downtime

The immediate and most impactful benefit of implementing a preventive maintenance program is the reduction in equipment failures and unexpected downtime.

The Downtime Crisis

Unplanned downtime can potentially devastate operations across all industries. It often leads to costly emergency repairs, which can hit the bottom line.

Fortune Global 500 companies lose 11% of their yearly turnover to unexpected equipment failures. This is a staggering financial hemorrhage that’s entirely preventable.

The impact varies by industry but remains consistently devastating:

The Preventive Solution

A successful preventive maintenance program attacks this problem head-on. Organizations implementing comprehensive preventive maintenance achieve a 70-75% reduction in breakdowns. This means that you can eliminate three out of every four potential failures.

However, this approach is not only about preventing catastrophic failures. With regular maintenance, you can catch small issues before they become major problems:

- Loose belts get tightened or inspections show wear before they snap

- Worn bearings get replaced before they seize

- Filters get changed before the equipment overheats

- Leaks get fixed before they cause damage

WorkTrek’s preventive maintenance software automates these routine tasks, ensuring nothing is missed and equipment stays operational.

2. Achieve Remarkable ROI and Cost Savings

Perhaps the most compelling reason to implement preventive maintenance service is the extraordinary financial return it can deliver.

The 545% Return Reality

Jones Lang LaSalle’s comprehensive study revealed that preventive maintenance delivers an average 545% return on investment. This is an almost unheard-of return in the business world.

How does this translate to real dollars?

Research consistently demonstrates that every dollar invested in preventive maintenance saves up to five dollars in future costs. Another study shows that for every $1 spent on preventive maintenance, companies save $4-5 in future repair costs.

The savings come from multiple sources:

- Reduced repair costs: Planned maintenance costs 3-5x less than emergency repairs

- Lower labor costs: Eptura’s research shows preventive maintenance work orders take half the time of reactive ones

- Decreased parts expenses: Avoiding emergency procurement and expedited shipping

- Energy savings: Well-maintained equipment uses 10-20% less energy

Beyond Direct Savings

The financial benefits of preventive maintenance extend beyond obvious cost reductions:

Production Protection:

Preventing a single hour of downtime in automotive manufacturing can save $2.3 million. With one prevented failure per month, it can equal $27.6 million in annual savings.

Overtime Reduction:

Emergency repairs often require overtime labor at 1.5-2x normal rates. Preventive maintenance eliminates most of this premium labor cost.

Improve Customer Satisfaction

Preventive maintenance procedures can boost customer satisfaction by ensuring the quality and reliability of services or products.

Insurance Benefits:

Many insurers offer premium reductions for facilities with documented preventive maintenance programs, recognizing the reduced risk profile.

WorkTrek’s maintenance management system automatically tracks all these savings, providing real-time ROI calculations that justify your preventive maintenance investment.

3. Extend Equipment Lifespan Dramatically

Equipment replacement represents one of the largest capital expenditures for most organizations. Implementing a preventive maintenance strategy dramatically extends equipment lifespan, delaying these costly replacements.

The Longevity Equation

McKinsey research found that proper preventive maintenance extends equipment life by 20-40%.

For perspective, that means a chiller expected to last 15 years with reactive maintenance could operate effectively for 20+ years with preventive care, which can reduce maintenance costs.

Consider the financial impact:

- $350,000 chiller lasting 5 extra years = $70,000/year in deferred replacement costs

- $50,000 production equipment extended by 3 years = $16,667/year saved

- $25,000 HVAC system lasting 4 additional years = $6,250/year avoided

Studies indicate that without preventive maintenance, equipment typically loses 20% of its expected life.

The Compound Effect

Extending equipment lifespan delivers compound benefits:

- Technology advancement: Delaying replacement allows you to purchase more advanced equipment later

- Budget flexibility: Spreading capital expenses over more extended periods improves cash flow

- Sustainability: Keeping equipment operational longer reduces environmental impact

- Knowledge retention: Maintenance teams develop deep expertise with long-lasting equipment

4. Create a Safer Work Environment

Workplace safety is a business necessity. Preventive maintenance plays a crucial role in preventing accidents and ensuring regulatory compliance.

Safety by the Numbers

Organizations with structured preventive maintenance programs experience 25% fewer safety incidents.

This reduction stems from:

- Equipment operating within design parameters

- Early detection of safety hazards

- Proper lubrication prevents mechanical failures

- Regular testing of safety systems

Preventing Catastrophic Failures

Equipment failures don’t just stop production; they can pose a massive safety risk to your team.

- Hydraulic system failures can cause crushing injuries

- Electrical failures risk fires and electrocution

- Mechanical breakdowns can eject parts at high velocity

- Pressure vessel failures can cause explosions

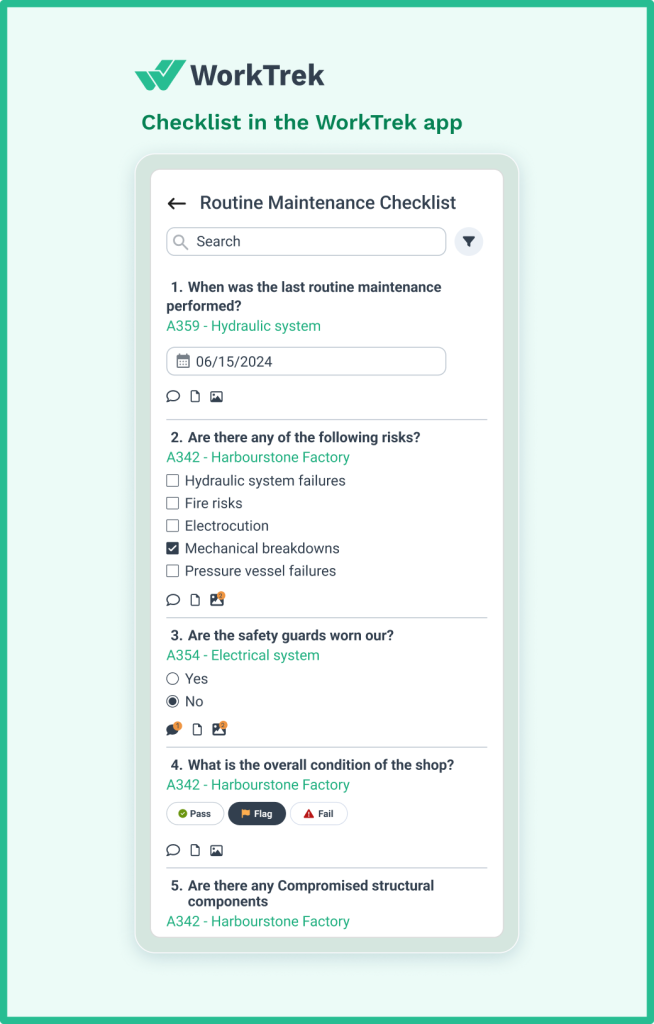

Routine preventive maintenance identifies and addresses these risks before they materialize. Regular inspections catch:

- Frayed electrical cables before they arc

- Worn safety guards before they fail

- Degraded emergency stops before they’re needed

- Compromised structural components before collapse

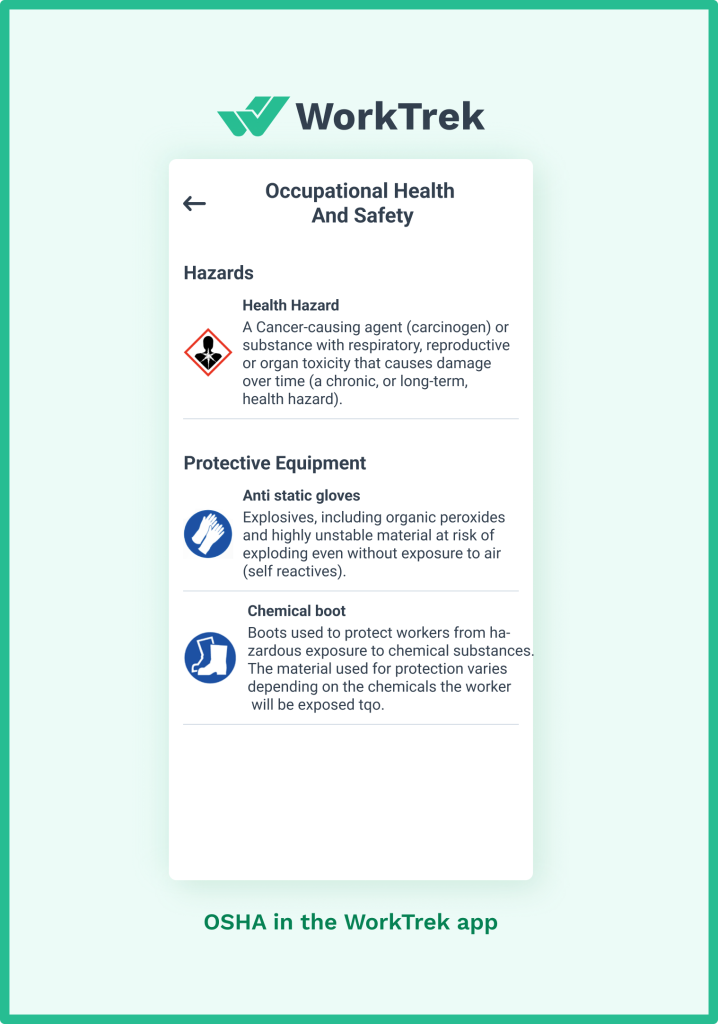

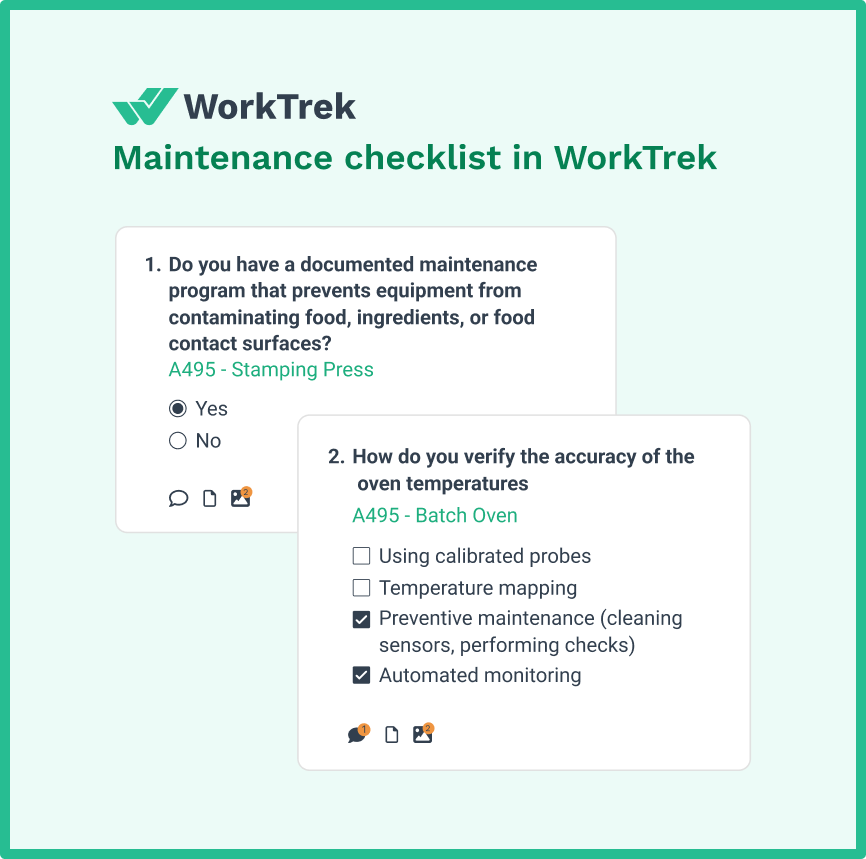

WorkTrek’s maintenance checklists include safety inspection points, ensuring maintenance technicians never overlook critical safety components.

5. Boost Operational Efficiency and Productivity

A well-executed preventive maintenance can be a productivity multiplier if implemented correctly.

The Efficiency Gains

This improved availability translates directly to increased productivity:

- More production hours available

- Consistent output quality

- Predictable scheduling capability

- Reduced work-in-process inventory

Standardization Benefits

Preventive maintenance programs drive operational efficiency through standardization:

Standard Operating Procedures:

Every maintenance task follows documented procedures, ensuring consistency regardless of who performs the work.

Predictable Scheduling:

With a fixed schedule for preventive maintenance activities, production can plan around maintenance windows rather than scrambling during breakdowns.

Performance Optimization:

Regular maintenance keeps equipment operating at peak performance. Studies indicate that preventive maintenance improves overall equipment effectiveness (OEE) by up to 90%.

The Ripple Effect

Improved efficiency extends beyond the maintenance department:

- Production hits its goals and achieves consistent output targets

- Quality improves with properly calibrated equipment

- Customer satisfaction increases with reliable delivery

- Employee morale improves without crisis management

6. Optimize Resource Utilization

Preventive maintenance can transform how organizations use their maintenance resources. This is for both humans and equipment.

Labor Optimization

Eptura’s data reveals that preventive maintenance tasks take roughly half the time of reactive work. This dramatic efficiency improvement means:

- Maintenance teams accomplish twice as much with the same headcount

- Skilled technicians focus on value-adding activities rather than firefighting

- Training becomes more effective with predictable work patterns

- Work-life balance improves without constant emergency calls

Parts and Inventory Management

Preventive maintenance revolutionizes spare parts management:

Predictable Consumption:

Knowing when parts will be needed eliminates the need for emergency procurement. Boston Consulting Group research shows this improves spare parts efficiency by 15%.

Reduced Inventory Costs:

No need to stock parts “just in case” when you know exactly when they’ll be needed. You can optimize spare parts management by using a CMMS system like WorkTrek.

Bulk Purchasing Power:

Planning enables bulk orders at better prices versus emergency single-item purchases.

WorkTrek’s inventory management features integrate with your preventive maintenance schedule, automatically generating purchase orders when parts are needed.

Technology Utilization

A computerized maintenance management system maximizes technology investments:

- 35% improvement in maintenance scheduling efficiency with CMMS integration

- 40% reduction in inspection time with automated routines

- 50% faster inspections using mobile devices

7. Ensure Compliance and Reduce Legal Risks

In today’s regulatory environment, compliance is critical to all maintenance organizations. Preventive maintenance programs provide the documentation and consistency required for regulatory compliance.

Regulatory Requirements

Many industries face strict maintenance regulations:

- FDA requirements for pharmaceutical and food production

- OSHA safety standards for all industries

- EPA environmental regulations

- Industry-specific standards (ISO, API, ASME)

Non-compliance results in:

- Regulatory fines and penalties

- Forced shutdowns

- Legal liability for accidents

- Loss of certifications and licenses

Documentation Excellence

Preventive maintenance provides the paper trail regulators demand:

- Scheduled maintenance records proving proper care

- Inspection reports documenting safety checks

- Repair histories showing proactive management

- Training records demonstrating competency

Research indicates that 82% of maintenance managers see improved compliance with safety standards through preventive maintenance programs.

Risk Mitigation

Beyond compliance, preventive maintenance reduces legal exposure:

- Fewer accidents mean fewer lawsuits

- Documentation provides legal defense

- Insurance companies recognize reduced risk with lower premiums

- Due diligence demonstration in case of incidents

8. Gain Competitive Advantage Through Reliability

In today’s competitive marketplace, equipment reliability can drive increased profitability.

The Customer Satisfaction Connection

Equipment reliability directly impacts customer experience:

- On-time delivery: No production delays from equipment failures

- Consistent quality: Properly maintained equipment produces consistent output

- Service reliability: No service interruptions from facility equipment failures

- Price stability: Lower maintenance costs enable competitive pricing

Organizations with effective preventive maintenance programs achieve 60-80% better equipment reliability than those using reactive maintenance.

Market Positioning Benefits

Reliable operations create competitive advantages:

Capacity Confidence:

Bid on all-sized contracts knowing you can deliver without equipment-related delays.

Premium Pricing:

Customers pay more for reliable suppliers who won’t cause them problems.

Partnership Opportunities:

Other businesses prefer partners with stable, reliable operations that can deliver what they promise.

Growth Capability:

Scale operations confidently, knowing maintenance and your equipment won’t become a bottleneck.

The Innovation Dividend

When maintenance teams aren’t constantly fighting fires, they can focus on improvement:

- Implementing new technologies like predictive maintenance

- Optimizing processes for better efficiency

- Training on advanced techniques

- Contributing to continuous improvement initiatives

Overcoming Implementation Barriers

Despite these compelling benefits, some organizations remain reluctant to implement preventive maintenance due to perceived barriers.

Addressing Upfront Costs

Yes, implementing a preventive maintenance program requires initial investment.

However, ROI typically appears within 8-16 months, with mature programs delivering 300-500% annual returns.

Start small:

- Focus on critical assets first

- Use early wins to fund expansion

- Leverage technology like WorkTrek’s scalable platform that grows with your needs

Managing the Transition

Moving from reactive to preventive maintenance requires change management:

- Involve maintenance teams in planning

- Provide comprehensive training

- Celebrate early successes

- Share metrics showing improvement

Only 20-30% of organizations follow comprehensive preventive maintenance schedules, indicating a massive opportunity for competitive advantage.

Technology Adoption

Modern preventive maintenance software makes implementation easier than ever:

- Cloud-based systems require minimal IT infrastructure

- Mobile apps enable immediate adoption

- Automated scheduling reduces administrative burden

- Built-in analytics prove value quickly

Conclusion

Begin with these immediate steps:

- Calculate your current costs: Add up emergency repairs, downtime, and overtime from the last year

- Select pilot equipment: Choose 2-3 critical assets for initial implementation

- Deploy technology: Implement a CMMS like WorkTrek for visibility and control

- Create your first preventive maintenance schedule: Start with manufacturer recommendations

- Track your results: Monitor the reduction in failures and emergency repairs

Remember, every day without preventive maintenance costs money.

Equipment that could be maintained for $100 today might fail tomorrow, requiring $500 in emergency repairs plus thousands in downtime costs.

But it’s not too late. The tools, knowledge, and support exist to transform your maintenance operations from reactive chaos to proactive control.

Take the first step today. Because in maintenance, as in medicine, prevention is always better and cheaper.