Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

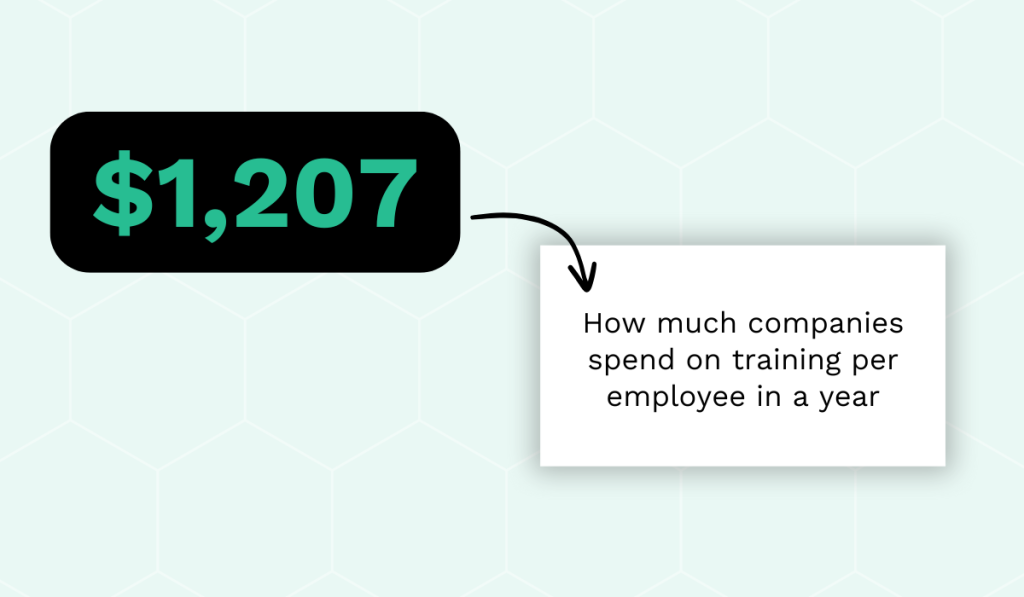

- Companies spend an average of $1,207 per employee on training in a year.

- Proper training makes workers feel more confident and less likely to leave the company.

- The U.S. Air Force adopted VR-based training for aircraft upkeep, thereby boosting employee retention.

A perfect storm is brewing in the maintenance industry right now.

An aging workforce is nearing retirement, taking decades of expertise with it.

At the same time, a younger generation is entering the field untrained, yet tasked with maintaining some of the most complex and expensive equipment ever.

The only solution?

Efficient, strategically planned training.

By developing a smart maintenance training plan, you can equip your team with the skills they need while making the best use of your time and resources.

Below, we outline six straightforward steps to make that happen.

1. Define Your Training Needs

First, identify the skills your maintenance team needs to meet your organization’s objectives.

This is the foundation of an effective training plan, says Emily Chipman, Principal Consultant and Executive Coach at Rusman Consulting Solutions, LLC:

And Chipman is right.

Without a clear understanding of what training is meant to achieve, you risk wasting money and time on irrelevant or ineffective programs.

After all, workplace training is a significant investment.

For instance, Training Magazine’s 2022 research shows that companies spent an average of $1,207 per employee on training that year.

For organizations with entire teams of technicians, these costs can add up quickly.

So, make sure the investment counts.

Start by analyzing your performance data to pinpoint problem areas.

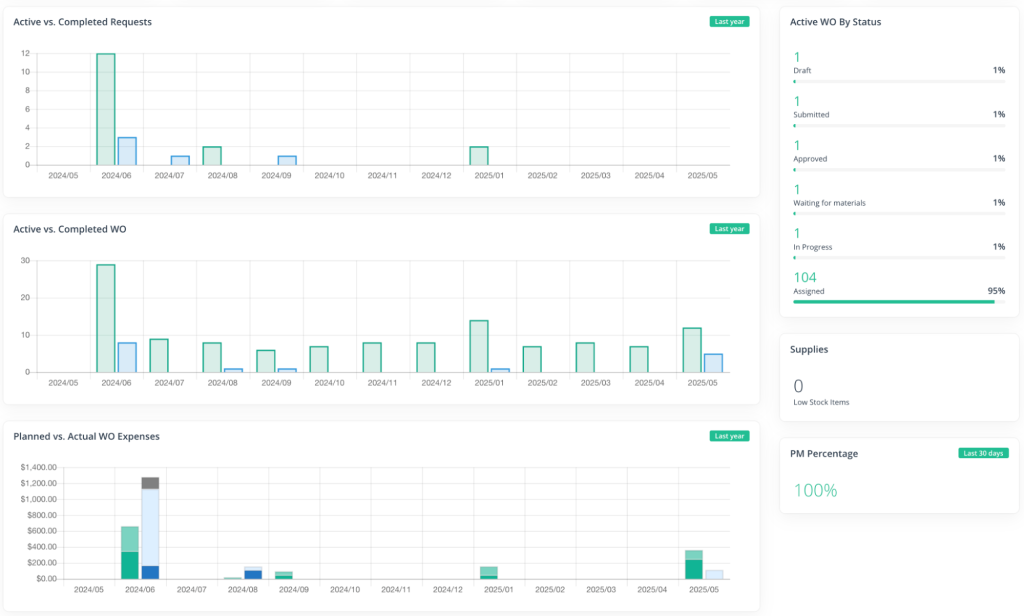

If you use a CMMS or similar maintenance management system, you already have access to dashboards and reports that make this easy.

Look at your downtime reports, work order completion rates, and other relevant KPIs.

Your upkeep managers can also provide insight into where improvements are needed, whether it’s excessive downtime, overspending on spare parts, or a shortage of specific technical skills.

Once you’ve identified the key issues, determine the corresponding skills required to address them.

For example:

- If excessive downtime is an issue, train technicians on preventive maintenance.

- If new advanced machinery is being introduced, provide training tailored to that equipment.

- If sustainability is a priority, focus on teaching practices that support efficiency and environmental goals.

By aligning training with actual performance needs, you ensure that both time and resources are spent effectively, helping your team acquire the skills that truly move the organization forward.

2. Assess the Current Skills of Your Maintenance Team

Before selecting specific training methods, it’s important to evaluate the knowledge and expertise your team already has.

Understanding each technician’s current skill level enables you to design a program that builds on their strengths while addressing gaps.

Ashley Donohoo, Sales and Marketing Director at Multi-Skill Training Services, Inc., a maintenance training vendor, agrees:

In other words, a one-size-fits-all approach rarely works.

If you’re providing technicians with training on skills they already have, that don’t apply, or are too advanced, you’re not just wasting time and money, but also risking disengagement.

Frustrated learners tune out fast, and that can hurt the success of any future training efforts.

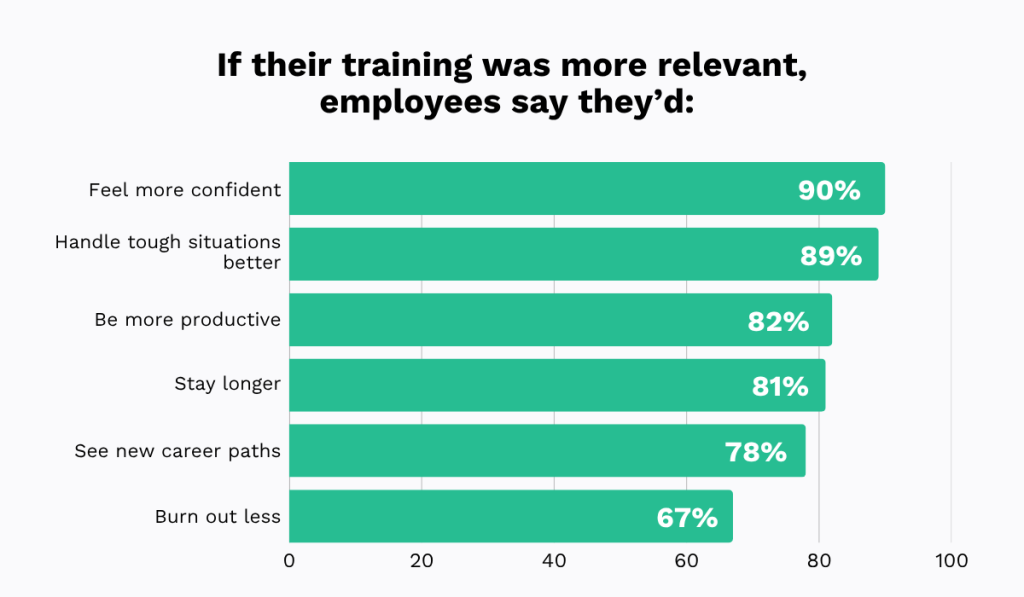

On the other hand, when you analyze their existing skills, you ensure the training is truly relevant, which can significantly boost their overall performance.

According to an Axonify survey, employees say that if their training were more relevant, they’d feel more confident, handle tough situations better, and even stay with the company longer.

Start by understanding where your team members currently stand.

Conduct skills assessments using written tests, practical evaluations, or interviews, and create individual training profiles for each technician.

This will help you compare current competencies to the skills required to meet organizational goals.

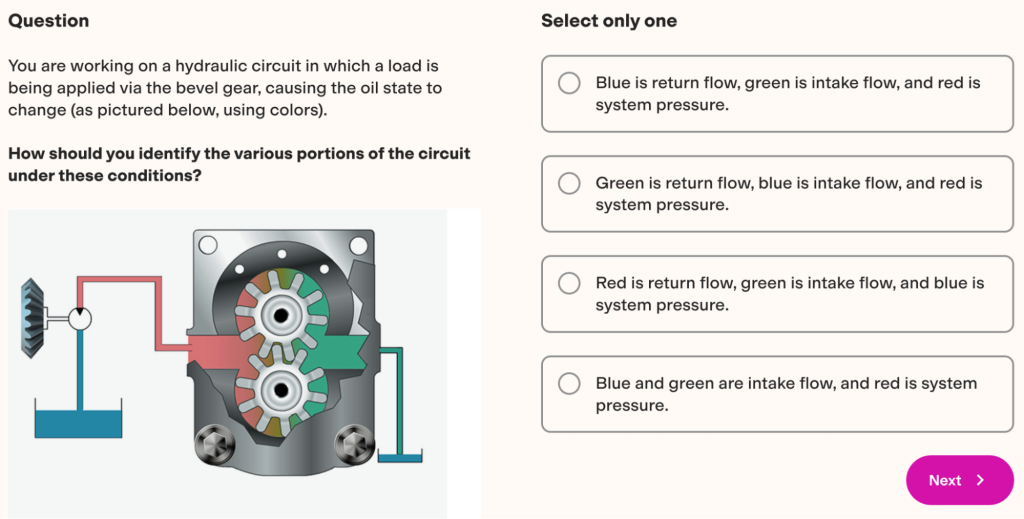

Here, you can use skill-testing platforms that offer pre-built, role-based assessments, such as the one shown below.

However, always evaluate these tools carefully to ensure they’re relevant and credible.

Look into who the subject matter experts are behind the tests, and prioritize those designed specifically for maintenance or your particular industry, rather than broad, generic options.

3. Select Training Methods

Different skills and learning styles require different training approaches.

By selecting the right training method, you can significantly improve knowledge retention and ensure hands-on competence.

AJ Ruperto, Manager of Video Acquisition at KPA, a provider of safety management and workforce compliance software and services, explains:

While Ruperto specifically refers to safety training here, the same applies to maintenance training.

He adds that the most successful programs blend theoretical instruction with practical experience, helping workers understand both the “what” and the “why”.

In other words, theory builds foundational knowledge, while hands-on training ensures that technicians can confidently apply what they’ve learned in real-world scenarios.

This is key for transforming knowledge from short-term memory into real, on-the-job skills.

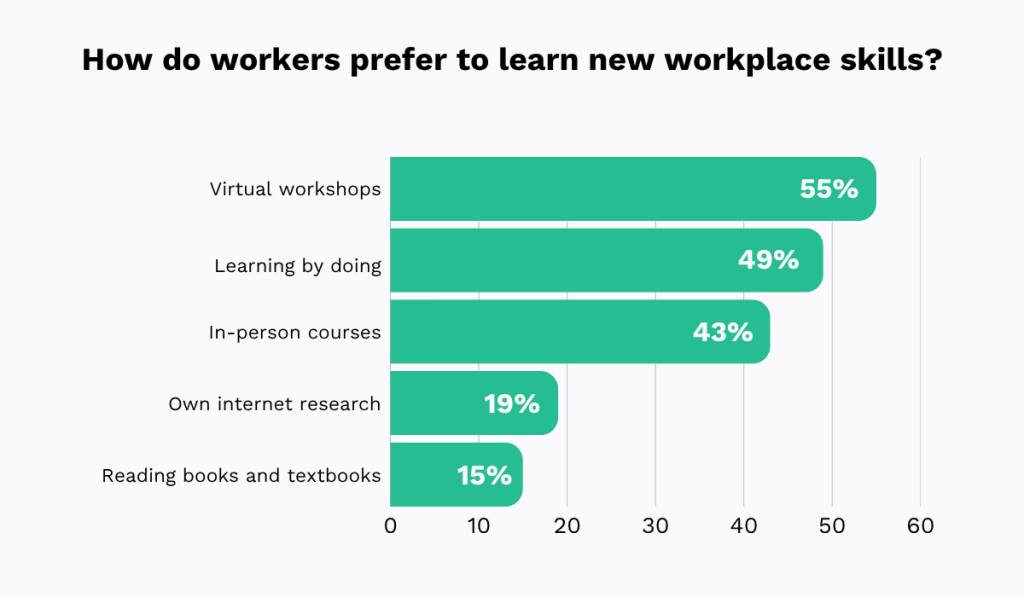

Ruperto’s insights also align with findings from a KPMG study, which revealed that trainees themselves prefer a mix of learning methods.

One increasingly popular method you might want to try out is virtual reality (VR) or augmented reality (AR).

These technologies offer the best of both worlds: immersive, hands-on learning experiences without the risk of real-world mistakes.

For example, the U.S. Air Force recently adopted VR-based training for aircraft maintenance.

In these programs, VR delivers interactive content, like images and videos, through headsets, computer monitors, or projected in immersive classrooms.

This allows trainees to explore, interact with, and manipulate objects in a fully realized 360-degree virtual environment.

John Sowder, their Chief of Maintenance Training Instruction, praises the impact of this technology:

“Until now, when we bring someone in who has received most of their training through PowerPoint slide presentations, trainees typically have only retained around 10% of the lesson knowledge, whereas with VR, it has been shown that retention levels are at least 35% or more.”

The takeaway is clear: how you train matters just as much as what you train.

By catering to different learning styles and embracing blended and immersive learning methods, you can boost retention, build confidence, and ultimately see real returns on your investment.

4. Ensure Skills are Used on the Floor Post-Training

If technicians don’t apply what they learn, their skills fade quickly. That’s why it’s vital to confirm their abilities on the shop floor after training.

Ashley Donohoo from Multi-Skill Training Services puts it this way:

Her philosophy is simple: if you don’t use it, you’ll lose it. No hands-on practice, no real results.

However, scheduling this type of hands-on work without interfering with regular maintenance or other day-to-day tasks can be tricky.

There’s always too little free time and available workers, and too much to be done.

In fact, the Intertek Alchemy survey identifies finding time for training as the biggest challenge in workplace learning.

Of course, you want your workers to retain knowledge, but not at the cost of operational efficiency.

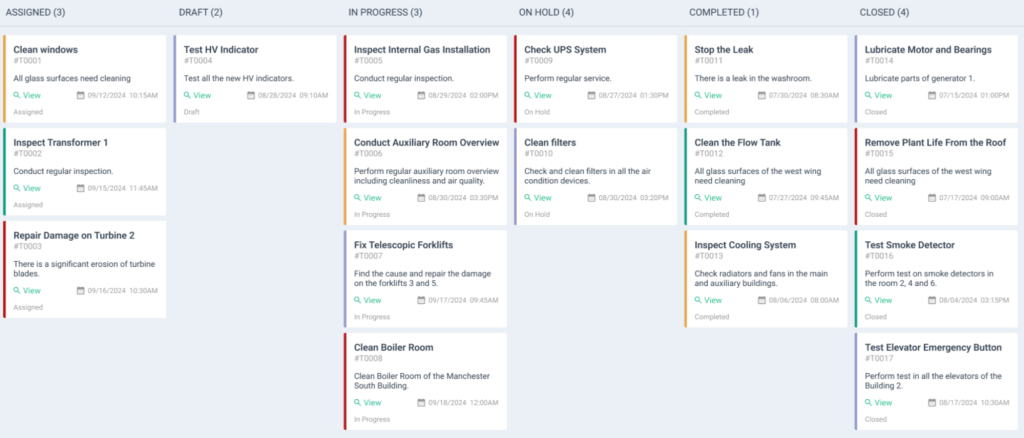

This is where a CMMS solution like WorkTrek can help.

It provides a clear overview of past and current work, available workers, planned downtime, and more, making it easier to schedule hands-on training without interrupting critical tasks.

You can identify free time slots, assign technicians, and even designate supervisors to review completed work orders, leaving feedback to reinforce good practices or correct mistakes.

WorkTrek also lets you attach job aids to work orders, like checklists, SOPs, LOTO procedures, and more.

That way, technicians always have quick access to best practices when needed.

In short, with a system like this, you gain full visibility into operations, making it easier to practice new skills in real-life situations while maintaining productivity.

5. Build a Growth Plan for Each Technician

A personalized growth plan aligns individual development with company goals.

It motivates your technicians, boosts their confidence and job satisfaction, and makes them excited to engage with the training you offer.

It may even help reduce turnover.

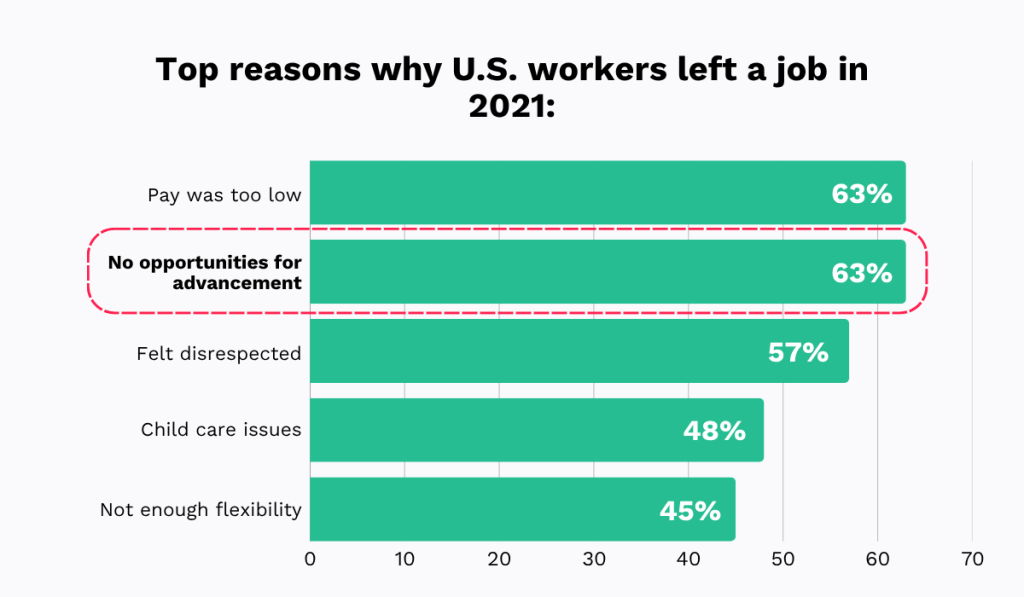

Research from the Pew Research Center shows that in 2021, 63% of employees left their jobs due to a lack of advancement opportunities.

If workers feel there’s no room to grow at your company, they will look elsewhere.

But by showing a clear, achievable career path, you give them a compelling reason to stay and grow with you.

This is especially important for today’s maintenance industry, where labor shortages are a real challenge.

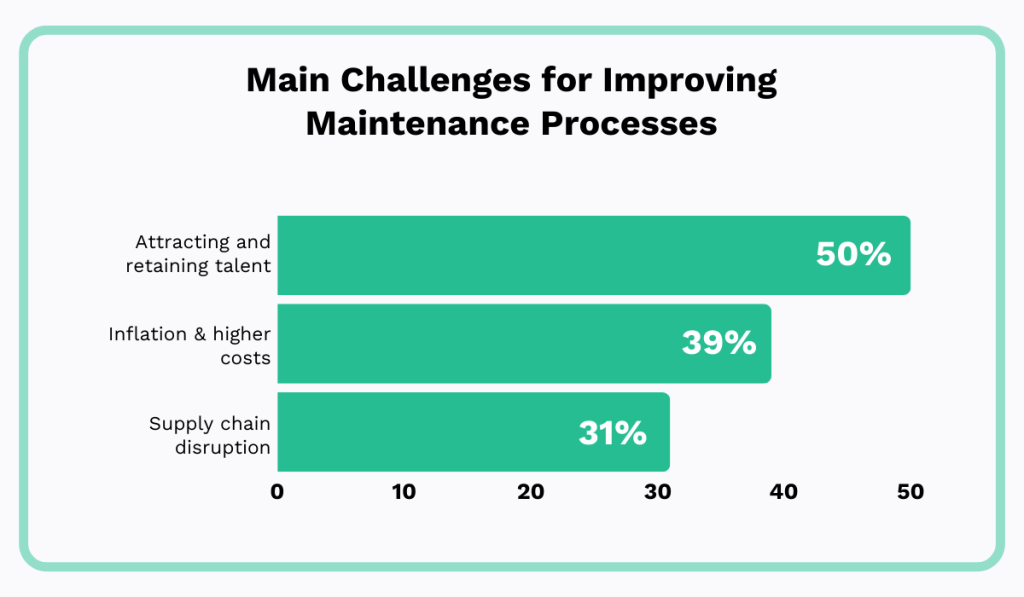

In fact, the 2024 survey by the Institution of Mechanical Engineers shows that attracting and retaining talent is currently the main challenge for maintenance teams.

Many skilled workers are nearing retirement, while fewer young workers are entering the field, creating a growing gap that’s difficult to fill.

The most effective solution is to invest in your existing workforce.

Start by creating a list of the different career paths technicians can take in your company, with clear job descriptions for each.

Here are some examples of career paths:

Technical Path:

- Entry-Level/Lube Tech

- C-Level Technician

- B-Level Technician

- A-Level/Master Technician

Leadership Path:

- Lead Tech

- Shop Foreman

- Service Manager

- General Manager

When employees can see a clear ladder, they are more likely to stay and progress.

Just remember: each step on the path should include specific expectations or milestones, such as required skills, certifications, or productivity benchmarks.

This ensures employees know exactly what is needed to advance, increasing their participation and engagement with the training you provide.

6. Develop a System for Evaluating Training Effectiveness

Lastly, it’s vital to have a way to prove ROI and ensure that training genuinely improves your workers’ performance.

Otherwise, it’s just a cost, not an investment.

Sarah Skinner, Global Head of Organizational Development and HR Business Partnering at Tait Communications, a company designing communication solutions, explains:

If you fail to demonstrate that ROI, securing leadership buy-in for future training investments becomes much more difficult.

Even if it doesn’t go that far, you still want your workers to actually learn something, and continued tracking of training effectiveness is the only way to ensure this.

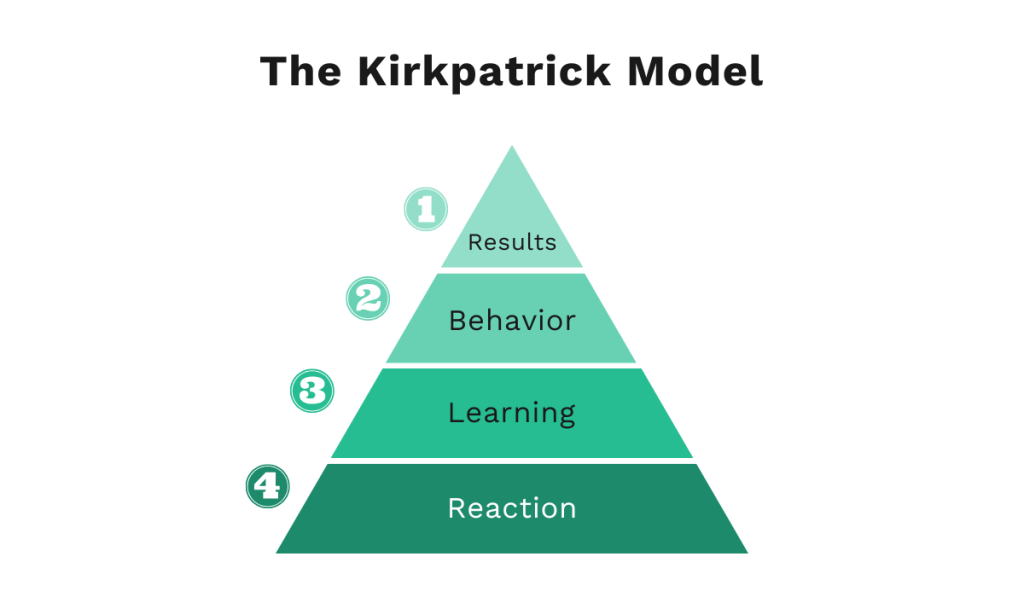

One widely used evaluation method is the Kirkpatrick Model, which assesses training effectiveness across four levels: reaction, learning, behavior, and results.

Let’s break it down briefly.

Reaction measures whether learners found the training relevant, engaging, and useful.

It’s typically gauged through a survey, often called a smile sheet, in which learners rate their experience and provide feedback.

Next, learning evaluates whether learners have acquired the knowledge or skills targeted by the training program.

This can be measured in the same way you assessed their skills at the beginning, giving you a clear “before and after” picture.

Behavior is crucial for understanding the true impact of training.

This level measures whether learners are applying what they’ve learned on the job.

Assessment takes place over time and combines data analysis with interviews or supervisor feedback, usually 30–60 days post-training.

Finally, results focus on whether the training has achieved the intended outcomes.

Here, you can use your CMMS or other maintenance software with reporting features to examine historical data on key performance indicators:

For example, are work order completions faster? Is preventive maintenance compliance higher?

These metrics reflect real behavior changes in technicians after successful training.

By following this straightforward yet thorough framework, you ensure that training isn’t just a feel-good activity, but a measurable investment that drives real performance improvements.

Conclusion

As you can see, an effective maintenance training plan is far more than just handing out manuals, sharing instructional videos, and administering a few tests at the end.

It requires careful planning and thoughtful analysis, taking into account each technician’s unique needs and abilities.

Yes, developing such a plan takes time and effort.

Yes, it relies on gathering and interpreting substantial data.

But in the end, that investment pays off: safer operations, fewer mistakes, smoother workflows, and a team that can handle whatever comes next.

So, don’t dismiss maintenance training as a routine task.

Treat it as the game-changer it truly can be, and commit to doing it right.