Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- Unplanned downtime from conveyor failures can cost manufacturers up to $250,000 per hour.

- IoT-enabled predictive maintenance systems can reduce unplanned downtime by up to 32%.

- Companies using CMMS for conveyor maintenance report 65% better visibility into maintenance operations and reduced unexpected breakdowns.

When your conveyor system goes down, everything stops. Production halts, deadlines get missed, and costs spiral out of control.

Yet despite the critical role conveyor systems play in material handling processes, many facilities still treat conveyor maintenance as an afterthought rather than a strategic priority.

That’s a costly mistake.

According to the National Institute of Standards and Technology, unplanned downtime can cost manufacturers upwards of $250,000 per hour. For operations running 24/7, even a single conveyor belt failure can eat into profits faster than most realize.

The good news is that most conveyor-related accidents and costly breakdowns are preventable with the right maintenance approach.

In this article, we’ll walk you through six essential best practices for successful conveyor maintenance that will help you minimize downtime and extend equipment life.

Best Practice 1: Implement Regular Visual Inspections

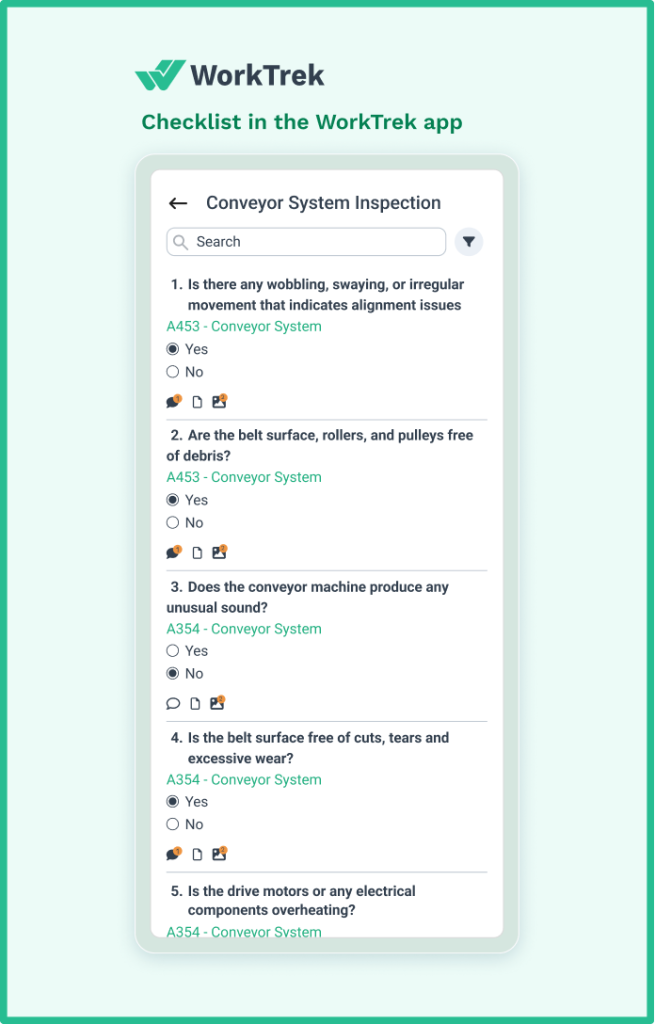

Start with visual inspection, which is the foundation of effective conveyor belt maintenance. It’s simple, cost-effective, and catches problems before they escalate into expensive failures.

During routine inspections, maintenance teams should check belt and conveyor systems for visible signs of damage, including cuts, cracks, fraying, or excessive wear. These daily visual checks take just a few minutes but can prevent hours or even days of unexpected downtime.

What should you be looking for during regular maintenance tasks? Focus on these critical areas:

- Belt misalignment

- Belt slippage

- Unusual wear patterns that indicate improper belt tension

- Misaligned belts

Belt tracking issues are particularly common

When belts drift off-center, they create uneven wear and can eventually lead to belt splices failing or the entire belt coming off the system. Catching belt alignment problems early through visual inspection prevents these more serious failures.

Material buildup is another critical aspect to monitor

Excessive material buildup or accumulated debris on the belt, pulleys, and rollers reduces efficiency and can interfere with proper belt tracking. Regular cleaning during inspections prevents these buildups from becoming problematic.

Electrical components also require attention

Check for loose connections, frayed wiring, or any signs of overheating in motors and control panels. These issues may not be immediately obvious, but can cause sudden failures during normal conveyor operation.

Listen for unusual noise during inspections

Strange sounds often indicate worn components, misalignment, or insufficient lubrication. A well-maintained conveyor system should operate relatively quietly, so any grinding, squealing, or rattling should be investigated.

Document inspection findings

Creating a maintenance log helps track patterns over time and provides valuable data for optimizing maintenance schedules.

According to Aberdeen Research, over 70% of companies aren’t fully aware of when their equipment is due for maintenance, upgrade, or replacement.

Regular visual inspections create that awareness and establish a baseline for normal conveyor operation, making it easier to spot deviations.

The frequency of visual inspections depends on your operation. High-speed conveyors handling heavy loads may require daily checks, while lighter-duty systems might be fine with weekly inspections. The key is consistency.

Best Practice 2: Maintain Proper Belt Tension and Alignment

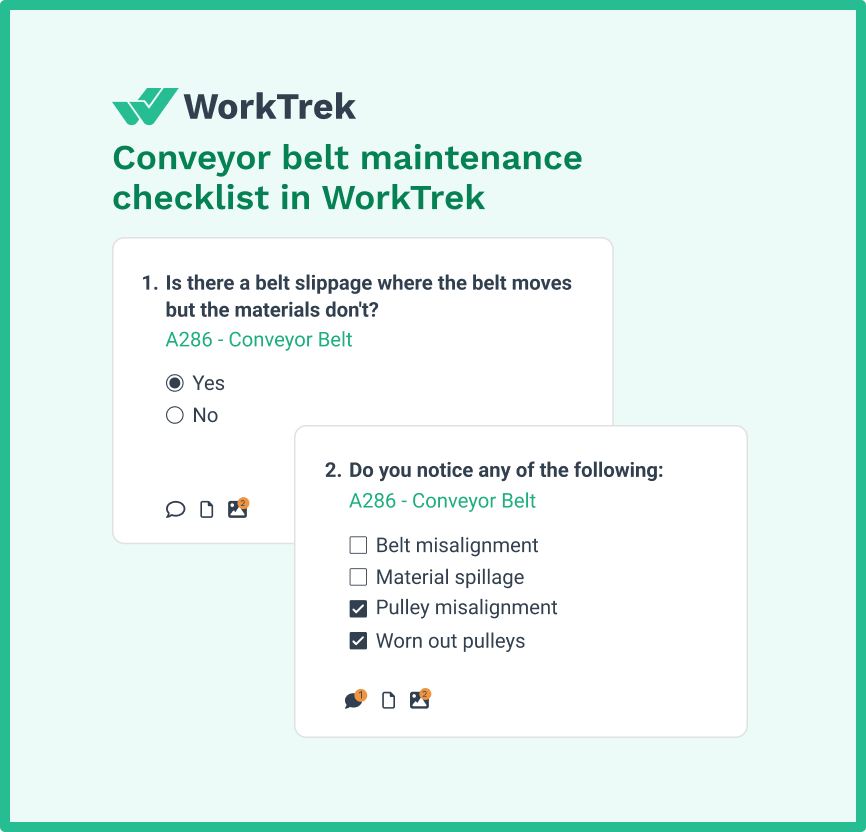

Proper belt tension and belt alignment are fundamental to conveyor system maintenance. When either is off, even slightly, it creates a cascade of problems that reduce efficiency and accelerate wear.

Belt tension directly affects how your conveyor belt systems perform

Too much tension puts excessive stress on the belt, causing premature wear and potentially damaging bearings and motor components. Too little tension leads to belt slippage, preventing materials from moving smoothly and causing the belt to wander off track.

The signs of improper tension are usually visible

If you notice belt slippage where the belt moves but the materials don’t, that’s a clear indicator of insufficient tension. On the other hand, if you see excessive wear on belt edges, stretched belts, or hear unusual noise from strain on the drive system, you’re probably dealing with over-tensioning.

Check belt tension regularly as part of your preventive maintenance program

Most manufacturers provide specific tension requirements in their documentation, typically specified as deflection over a set distance or measured with a tension meter. Following these specifications ensures optimal performance without causing unnecessary wear and tear.

Belt alignment is equally critical for smooth operation

Properly aligned belts run straight down the center of the conveyor frame, making even contact with pulleys and rollers. When belt misalignment occurs, the belt drifts to one side, causing uneven wear that significantly shortens belt life.

Misaligned belts also create operational headaches beyond just wear

Material spillage increases as products fall off the sides of a wandering belt. This creates cleanup issues, potential safety hazards from slippery floors, and wasted product. In food processing or pharmaceutical applications, material spillage can also create contamination risks.

Several factors contribute to belt tracking issues

Pulley alignment problems are common culprits—if pulleys aren’t perpendicular to the belt’s direction of travel, they’ll push the belt off-center. Worn pulleys with uneven surfaces or material buildup can also cause tracking problems.

The conveyor frame itself needs to be level and square

If the frame has shifted or wasn’t installed correctly, even perfect belt tension and pulley alignment won’t prevent tracking issues. Check that all frame components are properly secured and aligned during maintenance procedures.

Tension adjustment should be part of your regular maintenance plan

Many conveyor systems include take-up units that allow for easy tension adjustment. These can be gravity-powered, screw-driven, or hydraulic. Understanding your system’s tension adjustment method helps your maintenance team make corrections quickly and accurately.

When adjusting tension, make changes gradually

Small adjustments followed by a test run let you fine-tune tension without overshooting the target. Document the settings that work best for your specific application—this knowledge saves time during future adjustments.

For belt alignment corrections, start by checking pulley alignment

Use a straight edge or laser alignment tool to ensure pulleys are properly positioned. If pulleys are aligned but tracking is still off, small adjustments to the steering pulley or snub pulley can often correct the problem.

Remember that proper tension and alignment work together. You can’t properly align a belt that’s incorrectly tensioned, and perfect tension won’t help if the belt is running off-center. Address both as part of your comprehensive maintenance activities.

Best Practice 3: Establish a Proactive Maintenance Strategy

Reactive maintenance, when you only fix things when they break, is the most expensive maintenance approach you can take. A proactive maintenance strategy flips this script, addressing potential issues before they cause costly downtime.

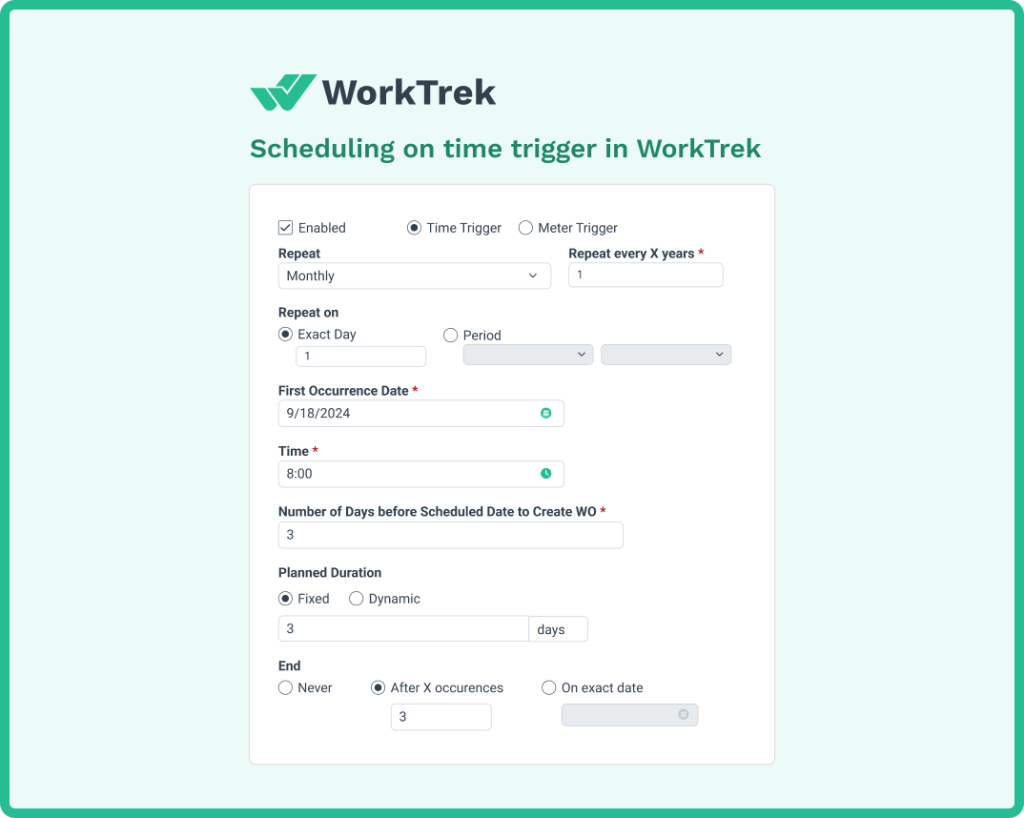

Preventive maintenance involves regularly scheduled maintenance tasks based on time intervals or usage metrics.

This might include monthly lubrication, quarterly belt inspections, or annual motor servicing. These routine inspections and maintenance procedures catch wear before it leads to failure.

But modern best practices for conveyor systems go beyond simple preventive maintenance. Leading facilities are adopting predictive approaches that use data to forecast when maintenance is actually needed.

According to Deloitte’s 2024 Future of Manufacturing report, predictive maintenance using IoT-enabled sensors can reduce unplanned downtime by up to 30%.

These smart sensors monitor critical parameters such as vibration, temperature, and belt speed in real time, detecting anomalies before they cause failures.

Consider the difference in cost. Lafayette Engineering reports that routine conveyor maintenance typically costs $7,500 to $20,000 annually, depending on system size.

Emergency repairs and downtime? That can run $10,000 to $100,000+ per incident—and that doesn’t account for lost orders or damaged customer relationships.

A comprehensive proactive maintenance strategy includes several components.

Develop a maintenance plan

Start with a detailed maintenance plan that documents every maintenance task required for your conveyor components. This should specify what needs to be done, how often, and by whom.

Your maintenance plan should cover all critical conveyor components, including belts, pulleys, rollers, bearings, motors, and electrical components.

Each component has its own maintenance requirements and lifecycle, so your plan needs to address them individually.

Schedule Maintenance During Planned Downtime

Whenever possible, schedule maintenance during planned downtime. For operations that run around the clock, coordination with production schedules is required to minimize impact. Some facilities schedule maintenance during shift changes or weekends to avoid disrupting peak production times.

Keep critical parts on hand

Stock critical spare parts to minimize repair time when issues do occur. Effective spare parts management and knowing which components fail most frequently in your operation helps you maintain an appropriate inventory without tying up excessive capital in parts that rarely need replacement.

Analyze component lifecycle

Consider component lifecycles when planning replacements. Rather than waiting for a bearing to fail, replace it when it reaches 80% of its expected lifespan. This prevents unexpected breakdowns while maximizing component use.

Train the maintenance team

Training is essential for a successful proactive maintenance strategy. Your maintenance team needs to understand proper maintenance procedures, safety protocols, and how to identify early warning signs of problems. Well-trained technicians catch issues during routine inspections that less experienced workers might miss.

Document everything

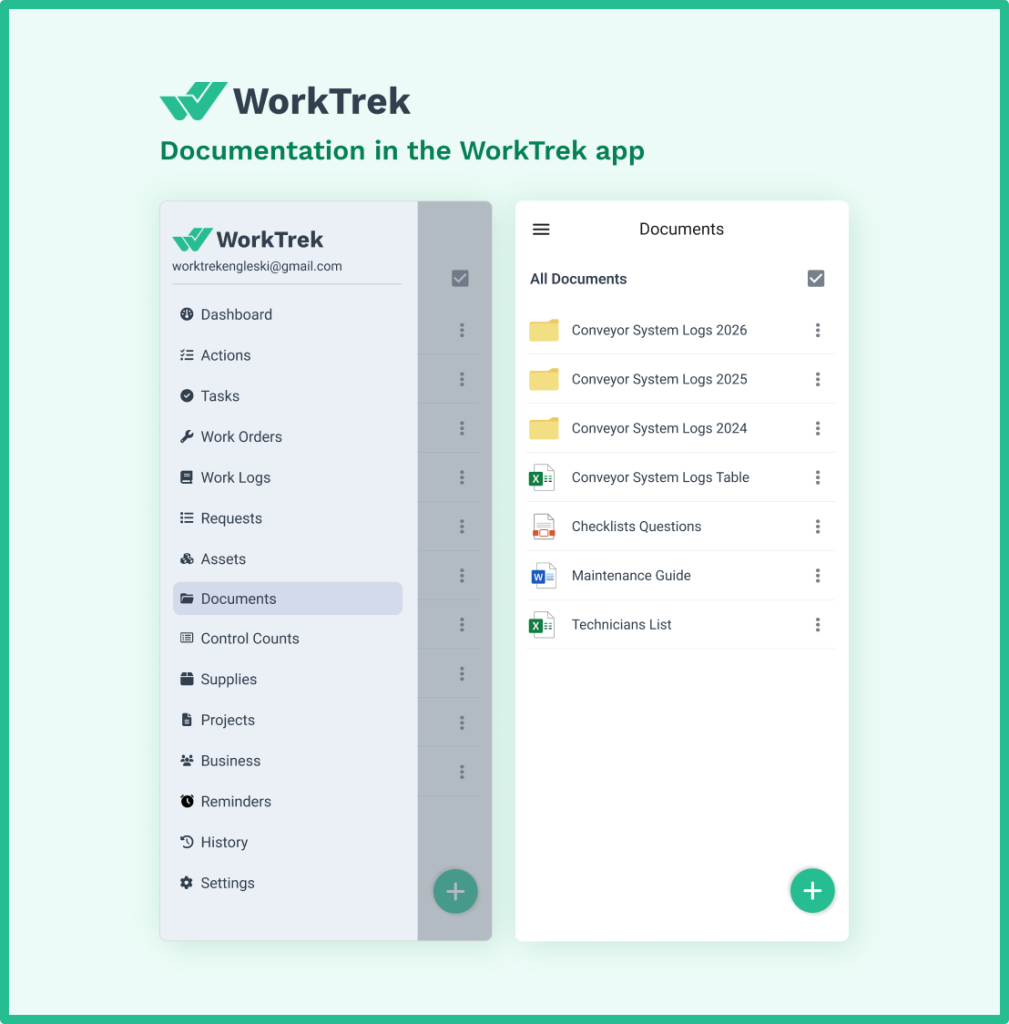

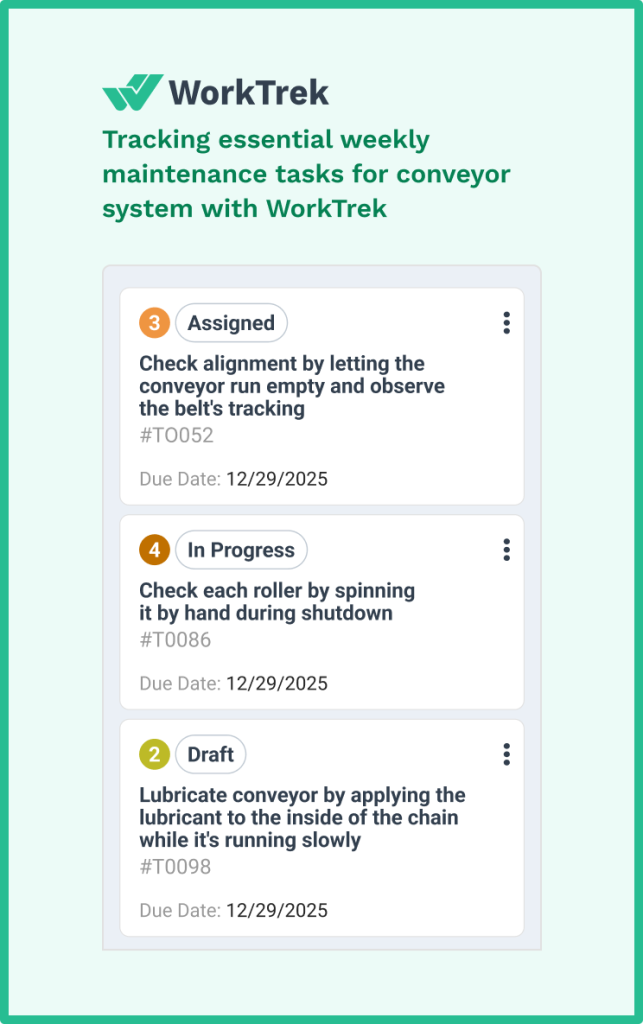

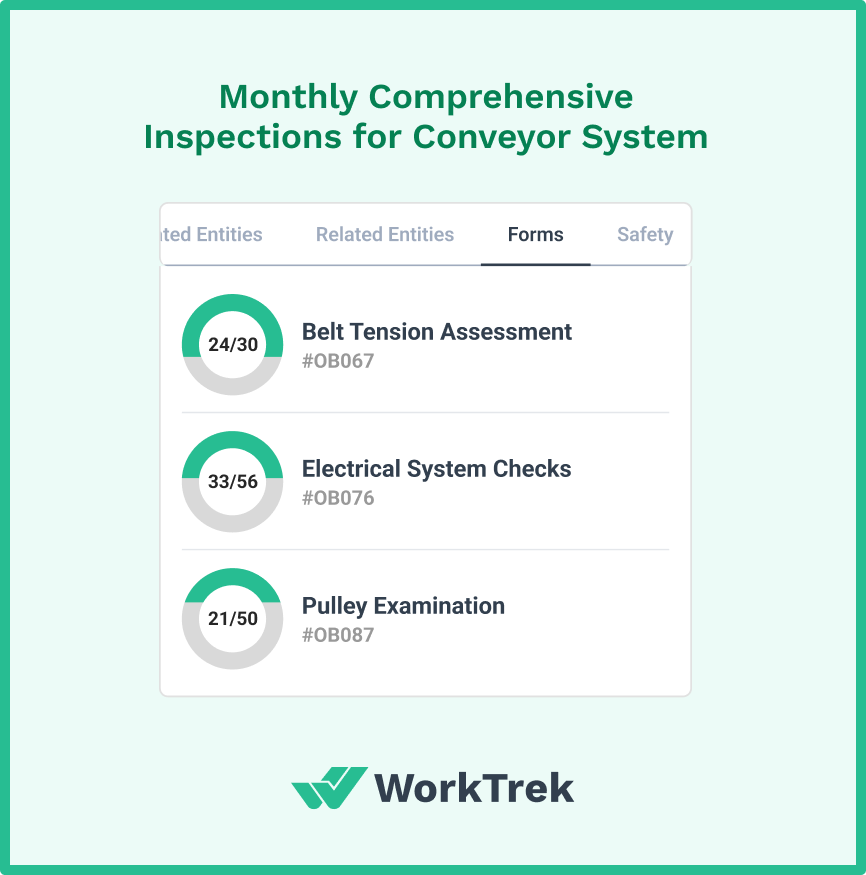

Documentation plays a crucial role in proactive maintenance. Maintain detailed maintenance logs that track every inspection, repair, and component replacement. If you use a CMMS like WorkTrek, this process can be significantly simplified. For more guidance, check out these 10 tips for an effective maintenance plan.

Modern maintenance teams increasingly rely on technology to support their proactive strategies. A Computerized Maintenance Management System (CMMS) like WorkTrek can automate scheduling, track maintenance history, manage spare parts inventory, and generate reports that demonstrate the value of your maintenance program.

Best Practice 4: Prioritize Proper Lubrication and Cleaning

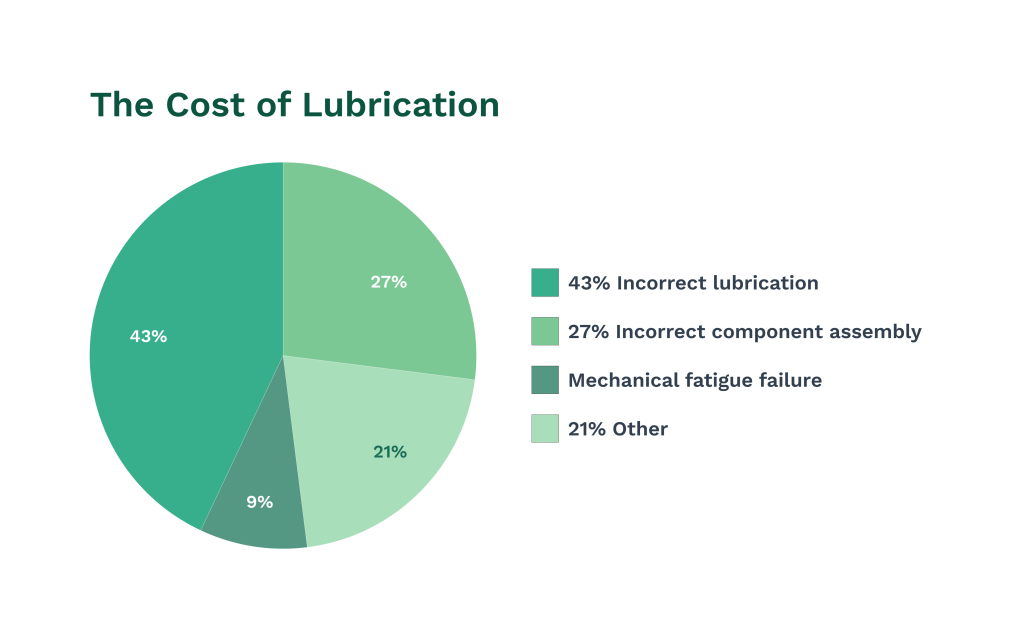

Proper lubrication and thorough cleaning might seem like basic maintenance tasks, but they are critical for conveyor belt systems.

Neglecting either leads to premature component failure and costly repairs.

Lubrication reduces friction between moving parts, minimizing wear and preventing overheating. Without proper lubrication, bearings seize, motors strain, and components fail long before their expected lifespan.

Use the right schedule

Bearings typically need regular greasing, with the frequency depending on operating conditions. In this scenario, monthly lubrication is common for continuously running systems. Motors and gearboxes have specific oil requirements detailed in manufacturer documentation.

Use the correct lubricant

Using appropriate lubricants is essential. The wrong lubricant can cause as many problems as no lubrication at all. In food processing applications, food-grade lubricants are mandatory. High-temperature environments require lubricants rated for those conditions. Consult manufacturer guidelines or work with a lubrication specialist to ensure you’re using the right products.

Over-lubrication can be just as problematic as under-lubrication. Excess grease attracts dirt and debris, creating an abrasive paste that accelerates wear. It can also cause seals to fail and contaminate products in food or pharmaceutical applications. Follow manufacturer specifications for lubrication quantities.

Cleaning equipment

Cleaning complements lubrication in maintaining optimal performance. Material buildup on belts, pulleys, and rollers interferes with smooth operation and can lead to belt tracking issues, increased wear, and even safety hazards.

The type of cleaning required depends on what your conveyor handles. Systems moving dry, non-sticky materials might only need periodic brushing or compressed air cleaning. Conveyors handling wet, sticky, or oily products require more aggressive cleaning methods.

Regular cleaning prevents excessive buildup of material, which becomes increasingly complex to remove over time. A quick daily cleaning takes minutes, while eliminating hardened buildup can take hours and potentially damage components in the process.

Focus on material accumulation

Pay particular attention to areas where material tends to accumulate. Return rollers under the belt often collect material that falls through. Pulleys can build up material in grooves or on surfaces. Belt scrapers and cleaning systems need regular inspection and cleaning to function effectively.

Cleaning also provides an opportunity for inspection. When you clean a component, you get a close look at its condition. This helps identify wear, damage, or other issues that might not be visible under a layer of material buildup.

Regulatory requirements

In some industries, sanitation is a regulatory requirement rather than just a best practice. Food processing facilities must follow strict cleaning protocols to prevent contamination. Pharmaceutical operations have similar requirements. Understanding and following industry-specific cleaning standards is essential for compliance and product safety.

Best Practice 5: Train Your Maintenance Team and Operators

Even the most sophisticated conveyor belt system won’t run smoothly without skilled people maintaining and operating it. Employee training is one of the most overlooked yet impactful best practices for conveyor maintenance.

Your maintenance team forms the front line of defense against conveyor failures. Their ability to spot early warning signs, perform routine maintenance correctly, and troubleshoot problems effectively determines how well your maintenance program performs.

Comprehensive training should cover both the technical and safety aspects of conveyor maintenance. Technicians need to understand how conveyor systems work, what regular operation looks like, and how to identify deviations that signal developing problems.

Take advantage of manufacturer training

Many manufacturers offer training programs specific to their equipment. Taking advantage of these opportunities ensures your team understands the particular requirements and quirks of your conveyor systems.

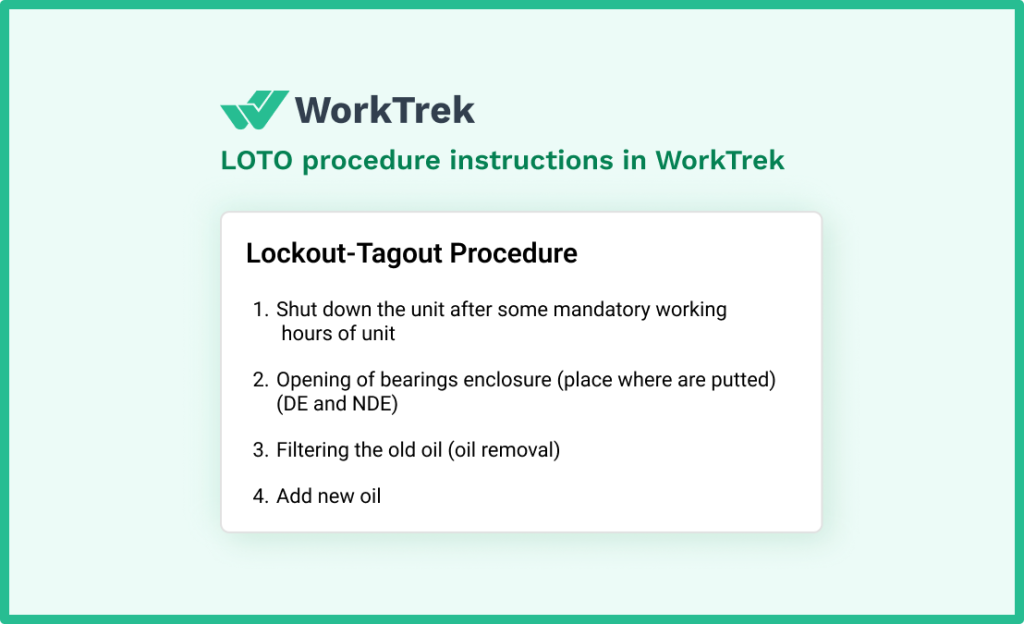

Safety Training

Safety training is equally critical. Conveyor systems have numerous pinch points, rotating components, and electrical hazards that can cause serious injuries if proper safety protocols aren’t followed. Lockout/tagout procedures, proper use of personal protective equipment, and awareness of common safety hazards should be regularly reinforced.

According to Martin Engineering, a wise mining leader once said: “If we’re not running, we’re training.” This mindset recognizes that investing in team development during downtime pays dividends in operational success.

Cross Training

Cross-training provides additional benefits. When multiple team members can perform critical maintenance tasks, you’re not dependent on a single person. This includes coverage during vacations, illnesses, or departures while also giving team members broader skills and career development opportunities.

Staggered expertise

Consider establishing different levels of training expertise. Entry-level training covers basic safety and simple maintenance tasks. Intermediate training might include more complex repairs and diagnostics. Advanced training could focus on specialized systems or predictive maintenance technologies.

Mentoring

Mentoring programs pair experienced technicians with newer team members. This hands-on learning complements formal training and helps transfer knowledge about your specific systems, operating conditions, and maintenance challenges that may not be covered in generic training programs.

Best Practice 6: Monitor and Track Maintenance Data

What gets measured gets managed. Monitoring and tracking maintenance data transforms maintenance from guesswork into a data-driven operation that continuously improves.

Maintenance Logs

Maintenance logs provide the foundation for data-driven maintenance. These records document every inspection, repair, component replacement, and maintenance task performed on your conveyor belt systems. Over time, this data reveals patterns and insights that optimize maintenance effectiveness.

Track Costs

Tracking costs provides valuable insights into maintenance efficiency. When you know that a particular conveyor section requires significantly more maintenance than others, you can investigate why. Perhaps that section handles heavier loads, operates at higher speeds, or has environmental factors that accelerate wear.

Comparing maintenance costs against downtime costs demonstrates the value of preventive maintenance. When you can show that a $15,000 annual preventive maintenance program prevents $100,000 in emergency repairs and downtime, justifying that expense to management becomes much easier.

Optimize Schedules

Data also helps optimize maintenance schedules. If you’ve been changing belts every six months based on manufacturer recommendations, but your data shows they consistently last nine months in your application, you can extend the interval and save money. Conversely, if components are failing before their scheduled replacement, you can shorten intervals to prevent unexpected breakdowns.

Implement IoT

Modern maintenance practices increasingly rely on real-time monitoring through sensors and IoT technology. According to Markets and Markets, more than 26,000 conveyor systems were equipped with IoT-enabled diagnostics in 2024, reducing unplanned downtimes by up to 32%.

These smart sensors continuously monitor conditions like vibration, temperature, belt speed, and load. When parameters drift outside normal ranges, the system alerts maintenance teams before a failure occurs. This predictive approach catches problems early when they’re easier and less expensive to fix.

Vibration analysis identifies imbalances, misalignment, loose components, and bearing wear. The vibration signature of a properly functioning conveyor differs distinctly from that of one with developing problems. Monitoring these patterns enables early intervention.

Belt monitoring systems can detect rips, tears, or splice failures before they cause belt failure. Some advanced systems use imaging or embedded sensors to monitor belt condition continuously, providing early warning of damage that visual inspections might miss.

Implement a CMMS

A Computerized Maintenance Management System (CMMS) like WorkTrek brings all this data together in one platform. Rather than tracking information in spreadsheets, paper logs, or tribal knowledge, a CMMS centralizes maintenance data and makes it accessible and actionable.

According to UpKeep’s 2024 State of Maintenance Report, 65% of companies now use a CMMS to manage maintenance activities and optimize costs. Users report better visibility into completed work, reduced unplanned downtime, and improved team communication.

Data analytics capabilities help identify trends that might not be obvious from individual maintenance events. Maybe belt failures cluster in summer months when temperatures are higher, or perhaps failures increase during production peaks when conveyor systems run longer hours.

Benchmark

Benchmarking your maintenance performance against industry standards provides context. Are you experiencing more failures than similar operations? Do your maintenance costs align with industry averages? This comparative data highlights areas for improvement.

The key to successful data monitoring is making it actionable. Collecting data is pointless if no one analyzes it or acts on the insights it provides. Regular review of maintenance metrics should be built into your management processes, with clear accountability for addressing identified issues.

Conclusion

Successful conveyor maintenance isn’t complicated, but it does require commitment and consistency.

The six best practices we’ve covered: regular visual inspections, maintaining proper belt tension and alignment, implementing a proactive maintenance strategy, prioritizing lubrication and cleaning, training your team, and monitoring maintenance data, work together to create a comprehensive maintenance program.

Each practice reinforces the others. Visual inspections catch problems that proper tension and alignment would prevent. Proactive scheduling ensures lubrication and cleaning happen consistently. Training helps technicians spot issues during inspections. Data monitoring shows whether your practices are effective and where improvements are needed.

Modern tools make these best practices easier to implement and sustain. A CMMS like WorkTrek automates scheduling, tracks data, manages inventory, and provides the visibility needed to improve continuously. It transforms maintenance from a reactive, administrative burden into a strategic, data-driven operation that directly contributes to your facility’s success.

The question isn’t whether you can afford to implement these best practices. It’s whether you can afford not to.

Source: WorkTrek

Source: WorkTrek