Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- A major energy company improved asset reliability through maintenance optimization.

- U.S. manufacturers spent more than $135 billion on equipment in 2021.

- Safety concerns are a common reason industrial workers leave their jobs.

- Product recalls can cost anywhere between $8 million and $50 million.

“We don’t need to invest in new maintenance technology; our old processes work just fine.”

“No, there’s no need for more proactive maintenance. Run-to-failure is enough for our operation.”

If you’ve ever tried to implement any improvements in your maintenance processes, chances are, you’ve heard statements like these.

They may have even come from you.

However, such a mindset is a costly mistake.

In maintenance, investing in advanced technologies, proactive strategies, and continuous training is always a good idea; it can pay off in so many different ways.

Read on to learn more about how optimizing maintenance operations can help your business.

Increased Asset Reliability

Optimized maintenance operations tend to place strong emphasis on proactive upkeep strategies, whether preventive, condition-based, or predictive maintenance.

While these vary in execution, they do share a common goal: addressing potential problems before they cause major disruption.

The result is more reliable assets, increased uptime, fewer production interruptions, and more consistent performance.

According to the 2025 Cheqroom survey, the vast majority of businesses agree that it’s critical for physical equipment to always be available and in working order.

After all, these assets are the backbone of daily operations and key to meeting customer expectations.

One survey respondent elaborates, highlighting the consequences of poor asset reliability:

“Production deadlines get postponed, which then dominoes down the line, affecting everything from production times to finishing times and even to the customer receiving it.”

It’s safe to say that, without reliable assets, there can be no successful business, especially in asset-heavy sectors such as manufacturing.

This is why organizations must continually look for opportunities to optimize their maintenance operations.

Often, improving just one workflow or task can lead to significant gains.

Take, for instance, Santos Ltd., a major Australian energy company, which achieved notable improvements in reliability through maintenance optimization.

Sigurdur Jonsson, former Vice President for PNG Operations at Santos, commented:

He explained that this success came from improving maintenance processes by critically reviewing and prioritizing work carried out at their facilities.

Rather than attempting to do everything at once, Santos focused on maintaining their most critical assets first, ensuring that the machines most essential to operations were always ready for work.

Santos is clear proof that reliability is never an accident.

It is the result of an intentional maintenance strategy, disciplined execution, and constant improvement.

Extended Asset Lifespan

Those who have mastered maintenance in their facilities understand that asset lifespan is influenced more by how equipment is operated and maintained.

Treat your machines right, and they’ll not only deliver higher uptime but also last longer.

Treat them poorly and inevitably, the opposite occurs.

Farouk Abrahams, Sales Director at Weba Chute Systems, a provider of customized bulk material chute transfer solutions, warns:

It’s important to emphasize that optimizing maintenance operations doesn’t necessarily mean performing more maintenance.

Overmaintaining can be just as harmful to assets as undermaintaining.

Instead, effective maintenance accounts for a machine’s actual condition, ensuring equipment is serviced at the right time: not too early or too late, and not too much or too little.

This is known as condition-based maintenance.

India Gibson, Launch Leader at Schneider Electric, a French multinational specializing in digital automation and energy management, explains how it works:

“We’re involving methods of monitoring the condition of the equipment based on different parts of the infrastructure. We’re understanding better how the gear is performing, and we’re supporting the maintenance intervals based on what needs to be enhanced or maintained.”

With this approach, organizations can reduce overmaintenance, which introduces unnecessary stress on equipment, and undermaintenance, which allows degradation to accelerate.

Ultimately, this significantly prolongs assets’ useful lives.

And this matters quite a bit. After all, capital assets are costly.

As reported by Machinery Partners, U.S. manufacturers spent more than $135 billion on equipment in 2021, accounting for more than 60% of annual capital expenditures.

Extending asset life delays replacement cycles and significantly reduces these expenditures.

It’s an effective way to extract maximum value from expensive equipment while freeing up capital to reinvest in growth, innovation, or debt reduction.

Reduced Safety Risks

Well-maintained equipment is safe equipment.

When assets are maintained regularly, efficiently, and strategically, the risk of accidents, injuries, and hazardous incidents caused by equipment or operational failures is significantly reduced.

A strong example of how maintenance optimization can enhance overall safety comes from Singleton Birch, the UK’s leading independent lime supplier.

After installing condition-monitoring sensors on their conveyor belt cleaners, the company greatly reduced the need for workers to physically access each asset.

As Singleton Birch Engineering Manager, Stuart Howden explained:

“Through the app, we can clearly see whether each blade is correctly tensioned against the conveyor belt and when it might be nearing the end of its life and will need replacing.”

While this naturally improved efficiency and reduced downtime, it also had a major impact on worker safety.

Howden noted:

He added that remote monitoring also keeps workers away from moving conveyors and reduces the need to enter enclosed, dusty environments, further improving safety conditions.

This example clearly shows that improving maintenance practices benefits not only equipment performance, but also the people responsible for keeping operations running.

And what’s good for technicians is good for the company.

Fewer accidents lead to healthier, more confident employees, which boosts morale, productivity, and ultimately, retention.

According to a 2024 Vector Solutions study, safety concerns are a common reason employees leave their jobs.

That’s hardly surprising. Few people are willing to stay in roles where their well-being is at risk.

By improving maintenance strategies, companies also improve the worker experience, reducing turnover and the likelihood of legal action, fines, and reputational damage.

It’s a win all around.

Improved Output Quality

Optimized maintenance ensures that machines, tools, and systems operate within their designed specifications, consistently producing high-quality output.

In other words, when equipment is reliable, the products it helps produce are reliable as well.

No scrap caused by incorrect dimensions, and no defects stemming from heat, vibration, or pressure variations.

Efficient maintenance detects and corrects wear before it affects production, thus minimizing waste, rework, and every manufacturer’s worst nightmare: recalls.

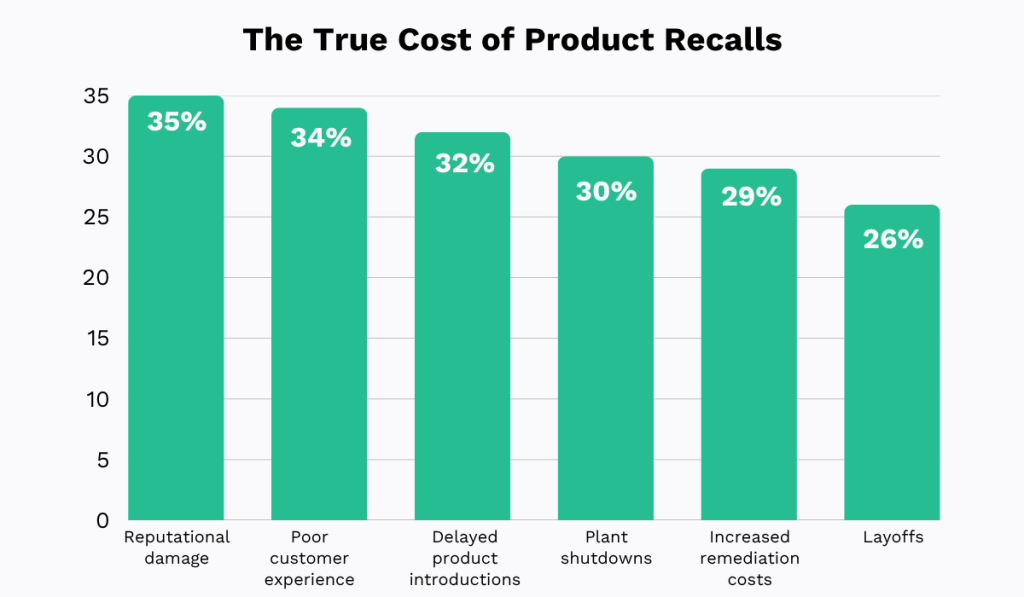

As shown by the 2024 ETQ and Hexagon survey, product recalls can have devastating consequences for businesses.

These incidents can cost manufacturing companies anywhere between $8 million and $50 million.

The damage, however, doesn’t stop there.

Recalls often lead to reputational harm, decreased customer trust, plant shutdowns, and long-term financial setbacks.

Even when quality issues don’t escalate to recalls, they can still seriously impact a business.

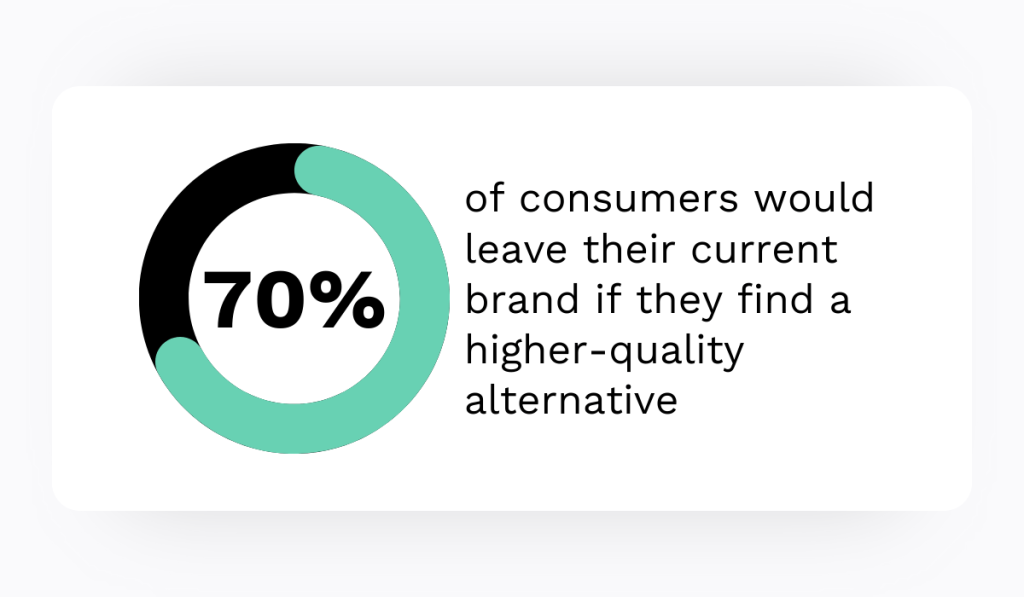

Customers care deeply about quality, and they won’t tolerate declining standards for long.

In fact, 2025 Forbes research shows that 70% of consumers are willing to switch brands if they find a higher-quality alternative.

Clearly, a lot hinges on output quality, from operational efficiency and brand reputation to client satisfaction and the ability to attract new customers.

By improving maintenance processes, manufacturers gain better control over production outcomes and set up their business for long-term success.

That’s right: maintenance isn’t just about fixing machines. It can also be a defining factor in a company’s future overall.

Lower Operating Costs

Along with these improvements come significant cost savings.

Optimizing maintenance reduces expenses in multiple ways:

- Longer asset lifespans mean fewer replacements

- Improved output quality reduces expensive rework and recalls

- Preventive maintenance lowers the need for costly emergency repairs

- Enhanced safety cuts costs associated with fines, legal issues, and workforce turnover

Ultimately, it’s about eliminating inefficiencies that quietly drain money through recurring mistakes, overlooked tasks, and poorly managed time and resources.

Robert Peffen, Director of Asset Performance Excellence at Implementation Engineers, an Implementation Execution (IX®) services firm, puts it perfectly:

At TRIUS, a Croatian property management company, they experienced this firsthand.

The company struggled with disorganized and poorly managed work orders, causing technicians to miss critical tasks and generating unnecessary expenses.

However, that all changed with the implementation of WorkTrek, a CMMS that gave them full control over WO workflows and helped save money in the process.

Tomislav Matković, TRIUS Maintenance Manager, commented:

“Using the WorkTrek mobile application, work orders are clearly arranged, and field workers know exactly what their responsibilities are, which has improved our service. It saved us time and money and resulted in much happier tenants.”

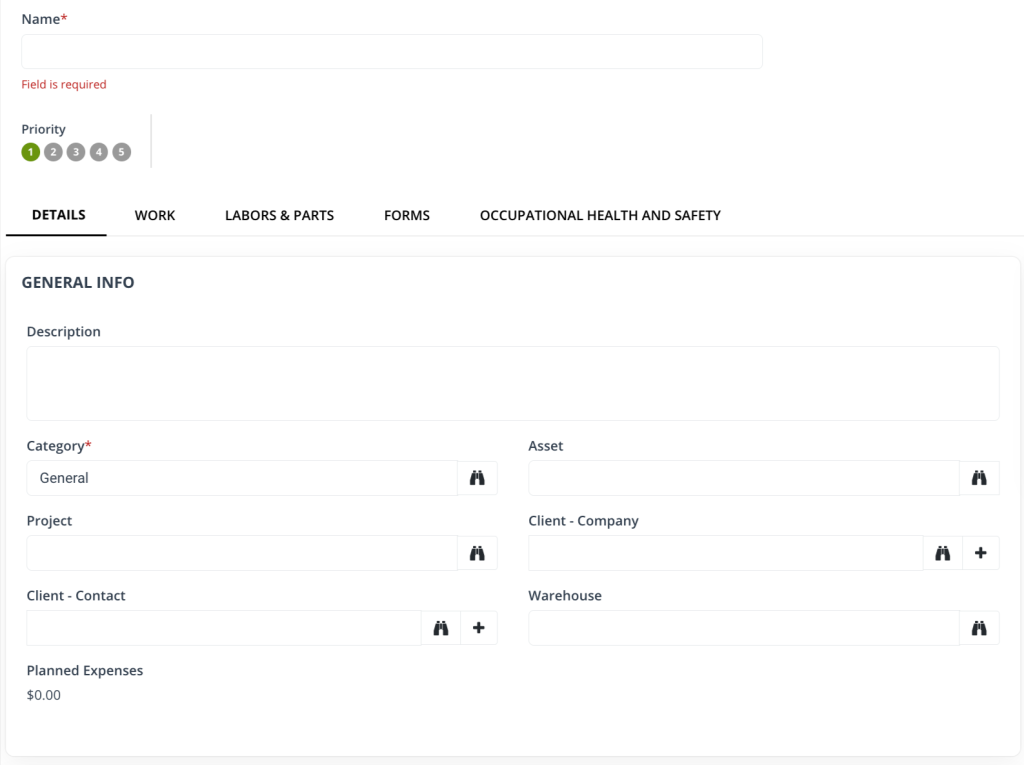

That’s because WorkTrek centralizes all work orders in one easily accessible platform.

For technicians, this means they can quickly see what tasks need to be done, where, by when, and how, right from their phones.

For supervisors, it means they can assign tasks to the right personnel, monitor progress, add notes, and collect feedback in just a few clicks.

WorkTrek also offers customizable templates, ensuring every work order captures all vital information, every single time:

All of this creates a more efficient, error-free process in which each asset gets timely and proper care.

No more forgotten tasks, no more wasting time searching for instructions and progress updates.

With WorkTrek, maintenance becomes more efficient, strategic, and ultimately more cost-effective.

Conclusion

Maintenance touches nearly every aspect of a business.

This means that, if done poorly, it can reduce product quality, compromise worker safety, shorten asset lifespan, and even hurt profitability and reputation.

That’s too high a price to pay for something preventable.

So, start treating maintenance like the strategic advantage it is today.

Invest in automation tools, monitor asset conditions, and schedule work accordingly.

Most importantly, educate your team on the value of efficient maintenance operations.

When everyone prioritizes proper maintenance and understands why it matters, strong and sustainable results follow naturally.