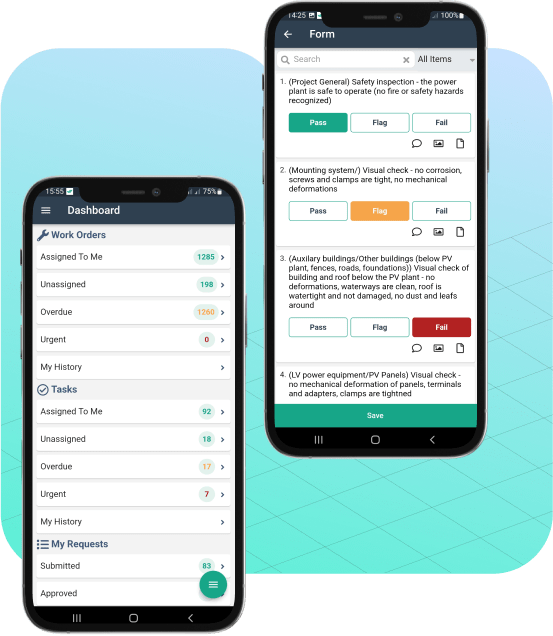

Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeIntroduction

In HVAC systems, CMMS is a software-based tool that helps organizations manage and streamline maintenance operations. It assists in organizing, scheduling, and tracking maintenance activities, including preventive maintenance, efficiently and systematically.

What is Preventive Maintenance?

Preventive maintenance is a proactive approach to maintenance that involves regularly scheduled inspections, upkeep, and repairs of equipment and systems before they fail or experience a significant malfunction. The primary goal of preventive maintenance is to prevent equipment breakdowns, minimize downtime, and extend the overall lifespan of assets. This approach helps ensure that machinery and systems operate at their optimal efficiency and reliability.

Key components of preventive maintenance include:

Scheduled Inspections

- Regularly scheduled inspections are conducted to identify potential issues, wear and tear, or signs of impending failure.

- Inspections may involve visual checks, measurements, and testing to assess the condition of equipment.

Cleaning and Lubrication

- Cleaning and lubricating moving parts prevent friction, reduce wear and tear, and contribute to smoother operation.

- Removing dirt, debris, and other contaminants helps maintain the efficiency of machinery.

Replacement of Wearable Parts

- Parts that are prone to wear, such as belts, filters, and seals, are replaced on a scheduled basis to prevent unexpected failures.

- Regular replacement of these parts helps maintain the reliability of the equipment.

Predictive Maintenance Tools

- In some cases, predictive maintenance tools, such as sensors and monitoring systems, are used to detect early signs of equipment failure.

- These tools can provide real-time data to help anticipate and address issues before they escalate.

What are HVAC Systems?

HVAC stands for Heating, Ventilation, and Air Conditioning. HVAC systems are designed to provide and regulate comfortable and healthy indoor environments in residential, commercial, or industrial buildings. These systems play a crucial role in maintaining temperature, humidity, and air quality within a specified range.

Here’s a brief overview of each component of HVAC:

Heating

- The heating component is responsible for raising the temperature of indoor spaces during colder seasons.

- Common heating systems include furnaces, boilers, heat pumps, and electric heaters.

Ventilation

- Ventilation involves the exchange of indoor and outdoor air to maintain air quality.

- Proper ventilation helps remove pollutants, control moisture, and replenish oxygen.

- Mechanical ventilation systems, such as fans and air exchangers, are often used to enhance airflow.

Air Conditioning

- Air conditioning is the process of cooling and dehumidifying indoor air during warmer seasons.

- Common air conditioning systems include central air conditioners, ductless mini-split systems, and window units.

Efficient HVAC systems contribute to energy conservation, cost savings, and improved comfort for occupants. Regular maintenance is essential to ensure the optimal performance and longevity of these systems. Advanced HVAC technologies may also include features such as smart thermostats, energy-efficient components, and integration with building automation systems.

Spring and Summer Maintenance Work on HVAC System

Spring is a great time to look closer at your air conditioning system before you start using it full-time in the next few weeks.

Here is a free checklist to follow when performing spring/summer preventive maintenance on your HVAC:

- Clean or replace filters as needed.

- Check the condenser and make sure the evaporator coil is free of debris.

- Check the drain pipe for blockage to ensure it is clear.

- Replace worn parts such as belts.

- Check for mold growth.

- Check thermostat controls, humidity, and timers.

- Check the fan motor, pulleys, bearings, and other moving parts and lubricate them if necessary.

- Replace batteries and check all electrical connections.

- Check the cabinets for leaks and check that the cabinet doors are closed tightly.

- Clean external fixtures.

Autumn and Winter Maintenance Work on HVAC System

Just as spring/summer HVAC preventive maintenance is critical to keeping your home cool, fall/winter preventive maintenance can also help keep your furnace running.

Here is a free checklist to follow when performing fall/winter preventive maintenance on your HVAC:

- Replace the heater filter. Ideally, this should be done every 3 months.

- Make sure the pilot assembly and other heating elements and heat exchangers are functioning properly.

- Check for air pressure and possible leaks in any components.

- Check all moving parts and lubricate them if necessary.

- Make sure there is no debris in the drain and that there is no standing water in the pot that could overflow.

- Check the heat pump.

- Check the thermostat and other controls.

- Check the wiring of all electrical connections.

- Check the exhaust system for possible problems.

- Check fans, blowers, ducts, and vents.

What is CMMS in HVAC Systems?

In the context of HVAC systems, CMMS stands for Computerized Maintenance Management System. CMMS is a software solution designed to streamline and enhance the management of maintenance-related tasks for various assets, including heating, ventilation, and air conditioning (HVAC) systems. Here’s how CMMS is relevant to HVAC systems:

Asset Management: CMMS helps in maintaining a comprehensive database of HVAC assets, including details about each component, installation date, and maintenance history.

Work Order Management: It facilitates the creation, assignment, and tracking of work orders related to HVAC maintenance tasks. This includes both routine preventive maintenance and corrective maintenance.

Preventive Maintenance Scheduling: CMMS enables the scheduling of routine preventive maintenance tasks for HVAC equipment, such as inspections, filter replacements, and system cleanings. This proactive approach helps prevent unexpected breakdowns.

Inventory Management: The system can manage the inventory of HVAC-related spare parts and supplies. It helps in tracking stock levels, reordering when necessary, and optimizing inventory costs.

Preventive Maintenance in HVAC Systems

Preventive maintenance in HVAC (Heating, Ventilation, and Air Conditioning) systems involves routine and planned activities aimed at keeping the system in good working condition. The primary goal is to prevent potential issues, maximize efficiency, and extend the lifespan of the equipment. Here are some key aspects of preventive maintenance in HVAC systems:

Scheduled Inspections

- Regular inspections are conducted to identify and address potential issues before they become major problems.

- Inspections may include checking for leaks, inspecting components for wear and tear, and verifying the overall system performance.

Cleaning and Lubrication

- Dirt and debris can accumulate in various HVAC components, such as coils, filters, and fans, reducing efficiency.

- Cleaning and lubricating moving parts help prevent friction, enhance performance, and reduce energy consumption.

Checking Refrigerant Levels

- For air conditioning and refrigeration systems, checking and maintaining proper refrigerant levels is essential for optimal performance.

- Low refrigerant levels can lead to reduced efficiency and potential damage to the compressor.

Why is HVAC Preventive Maintenance Important?

HVAC preventive maintenance is crucial for several reasons, and its importance extends to various aspects of building management and operation. Here are key reasons why preventive maintenance in HVAC systems is important:

Prevention of Breakdowns: Regular maintenance helps identify and address potential issues before they escalate into major problems. This reduces the likelihood of unexpected breakdowns and system failures, minimizing downtime.

Extended Equipment Lifespan: Proper maintenance contributes to the longevity of HVAC equipment. Regular inspections, cleaning, and lubrication can prevent premature wear and tear, ensuring that the system operates efficiently over an extended period.

Energy Efficiency: Well-maintained HVAC systems operate more efficiently, consuming less energy to provide the same level of heating or cooling. This leads to energy savings and lower utility costs over time.

Improved Indoor Air Quality: HVAC preventive maintenance includes tasks such as cleaning or replacing air filters and inspecting ventilation systems. This helps maintain good indoor air quality by reducing the circulation of pollutants and allergens.

Cost Savings: Preventive maintenance can result in significant cost savings in the long run. By addressing issues proactively, organizations can avoid expensive emergency repairs, reduce downtime, and extend the overall lifespan of HVAC equipment.

Conclusion

In summary, CMMS for HVAC systems is a digital tool that brings efficiency and organization to the management of maintenance tasks. It promotes a proactive and systematic approach to HVAC maintenance, contributing to improved equipment reliability, energy efficiency, and overall cost-effectiveness.