Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- Inadequate lubrication accounts for 35-40% of all equipment failures, making it the leading cause of equipment breakdowns.

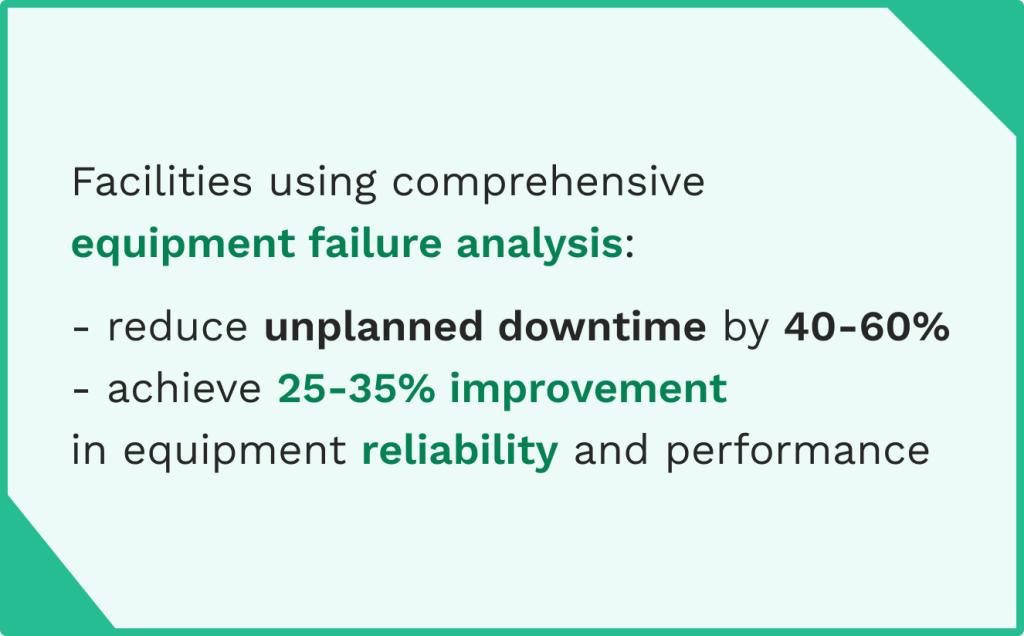

- Manufacturing facilities implementing systematic failure analysis achieve 40-60% reductions in unplanned downtime.

- Proper operator training can prevent up to 12% of equipment failures caused by improper operation and human error.

Maintenance managers don’t like it when equipment fails. When consequences extend far beyond immediate repair costs.

Production stops, maintenance teams scramble to identify impending issues, and every minute of unplanned downtime translates into lost revenue.

According to a 2024 Siemens study, the annual cost of downtime at a large automotive plant has reached $695 million.

Understanding the common causes of equipment failure is essential for organizations aiming to reduce costly downtime and prevent expensive, unplanned outages.

Research shows that 85-90% of equipment breakdowns can be traced to just eight common root causes.

Understanding equipment failure enables maintenance teams to implement proactive management strategies that minimize downtime and improve operational efficiency.

One approach is to use root cause analysis (RCA) techniques, such as the “5 Whys” or Fishbone diagrams, which are effective tools for identifying the underlying causes of equipment failures.

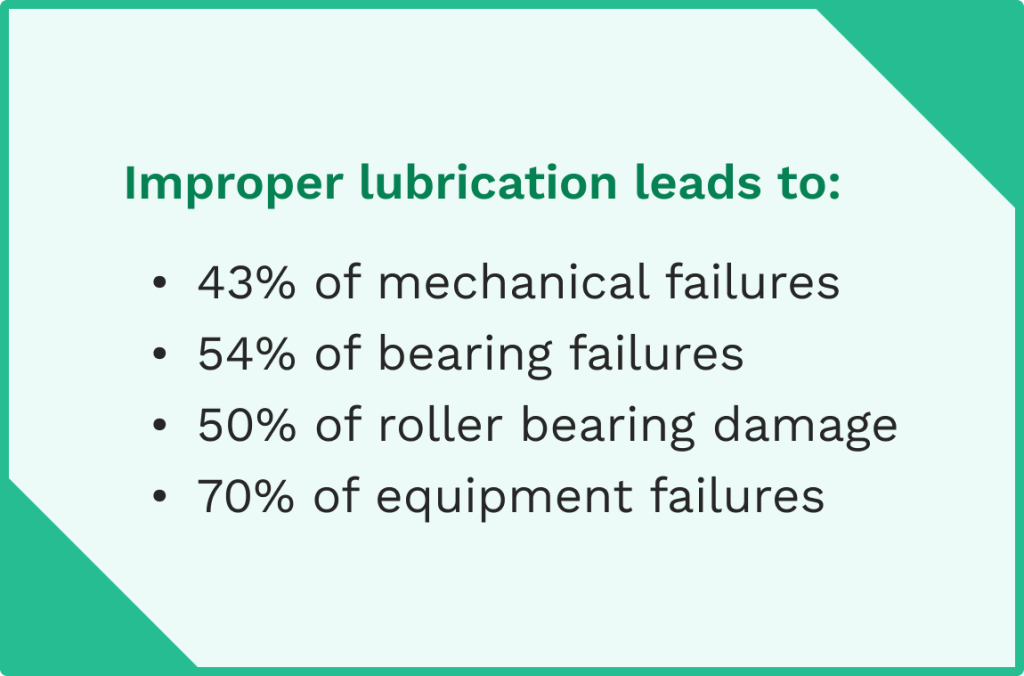

1. Inadequate Lubrication

Inadequate lubrication is likely the single most common cause of equipment failure. It is responsible for 35-40% of all equipment breakdowns.

This includes insufficient lubricant quantity, wrong lubricant type, contaminated lubricants, and over-lubrication.

When equipment bearings don’t receive proper lubrication, metal-to-metal contact generates extreme heat and friction. This can lead to premature wear and total equipment failure.

Research shows that lubrication-related failures typically provide a 2-8 week warning period through vibration analysis and temperature monitoring.

Reduce Lubrication Problems

How do you reduce this type of failure?

By implementing a comprehensive lubrication management programs that specify the correct lubricant for each asset, establishes regular lubrication schedules, and uses oil analysis to monitor condition.

What really can reduce this type of failure is by implementing a computerized maintenance management system that can help ensure consistent application of proper lubrication practices across all critical equipment.

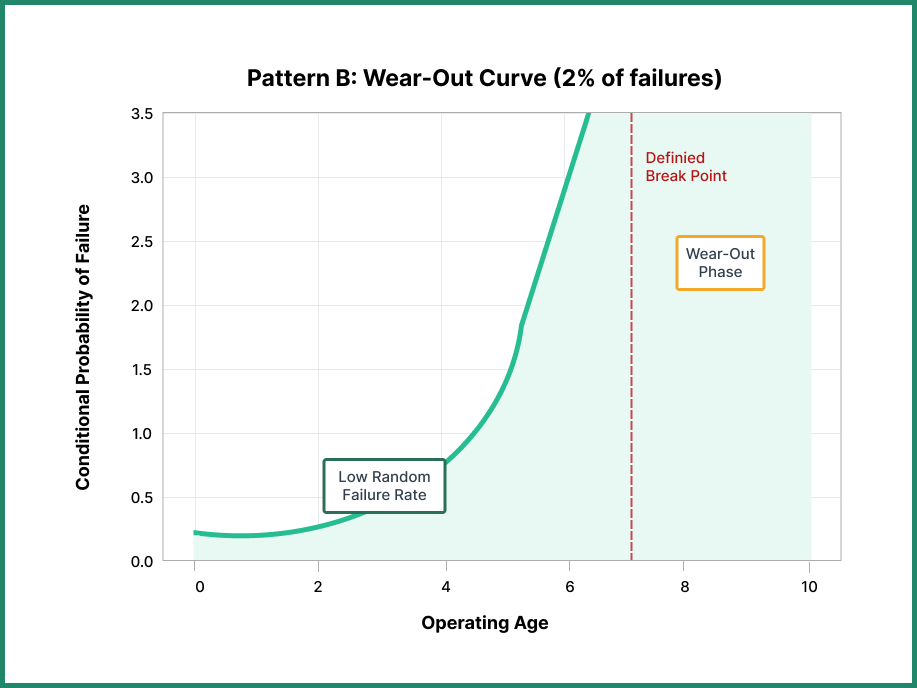

2. Normal Wear and Aging Equipment

Perfect maintenance cannot avoid the inevitable normal wear and tear on equipment.

This natural deterioration accounts for 18-25% of equipment failures and is one of the most predictable causes maintenance managers face.

Aging equipment is a challenge since degradation becomes harder to predict over time.

The Plant Engineering Maintenance Study found that aging equipment is a leading contributor to equipment downtime, accounting for 40% of unplanned downtime in plants.

Assets that run continuously require more frequent repairs, resulting in higher maintenance costs and greater production interruptions.

Financial Impact of Aging Equipment

The financial impact extends well beyond direct repair costs.

Equipment operators often accept performance loss as normal, even when it’s clearly measurable. Additionally, procuring replacement parts becomes harder as manufacturers reduce production of older components.

Managing wear-related failures requires condition monitoring programs that track equipment performance trends, component life curves based on historical data, and proactive replacement planning.

For aging equipment approaching end-of-life, organizations must decide whether to continue maintenance or invest in replacement assets offering better reliability.

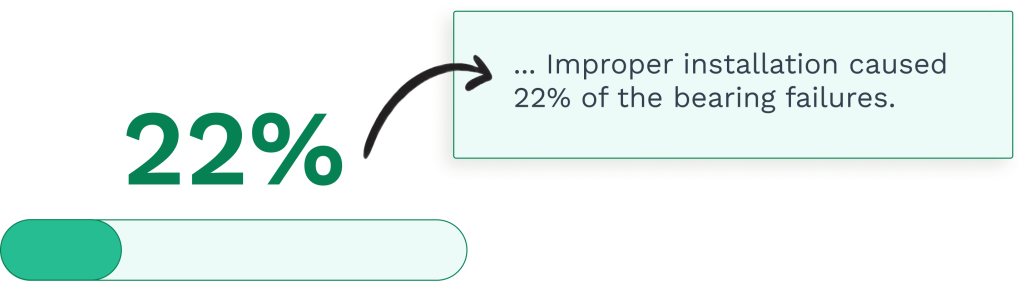

3. Improper Installation and Assembly

Improper installation accounts for anywhere from 12 to 18% of equipment failures. This makes it the third-most-common root cause.

Installation errors include misalignment between components, incorrect torque specifications, and improper fit between mating parts.

These problems often manifest within 1-6 months of installation and not necessarily on day one.

Manufacturing maintenance experts note that installation problems frequently occur during major overhauls, component replacements, and the introduction of new assets.

Preventing installation-related failures requires detailed installation procedures specifying exact requirements for alignment, torque, and fit tolerances.

Quality control inspections immediately following installation help catch errors before equipment enters service. For complex installations, precision measurement tools and laser alignment systems ensure accuracy beyond manual methods, delivering significant returns by preventing costly breakdowns.

4. Contamination of Equipment Components

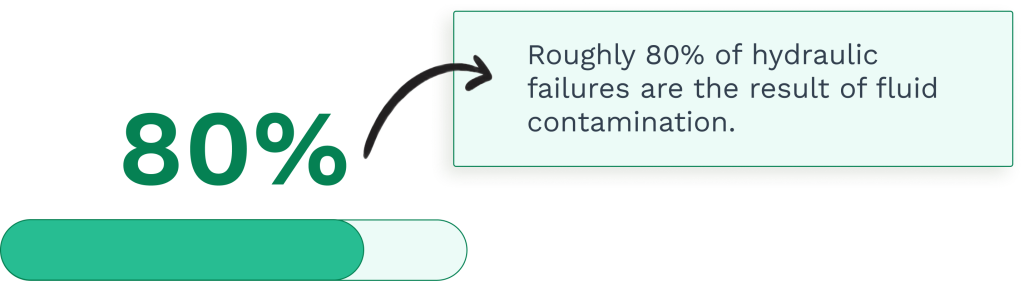

Contamination represents a particularly insidious cause of equipment failures. Industry data shows that it can be responsible for 8-15% of equipment breakdowns.

Foreign material, including dirt, water, chemicals, and process materials, can enter systems through multiple pathways and cause widespread damage before detection occurs.

The impact varies significantly by equipment type and operating environment.

In hydraulic systems, even microscopic particles can damage precision components. This can lead to leaks, reduced efficiency, and eventual system failure. In bearing assemblies, contaminated lubricants act like grinding paste, accelerating wear rates and dramatically shortening component life. In electrical equipment, moisture can cause short circuits, corrosion, and insulation breakdown, leading to dangerous failures.

How long does contamination take to show up?

Contamination-related problems can emerge within 1-4 weeks once foreign material enters a system.

This compressed timeline demands consistent monitoring from maintenance teams to prevent minor contamination from escalating into major equipment breakdowns.

Unlike wear-based failures that develop gradually over months, contamination creates urgent situations requiring quick response.

Various Manufacturing Environments

Manufacturing environments present countless opportunities for contamination through process material leaks, environmental dust entering through worn seals, condensation forming in enclosed spaces, and cleaning chemicals inadvertently contacting sensitive components.

Each contamination pathway requires specific prevention strategies that are tailored to the equipment and operating conditions.

Contamination control requires proper sealing systems, breather filters on reservoirs, and protective covers for exposed components.

Regular oil analysis helps detect contamination early, while visual inspections identify potential entry points before problems develop.

For critical equipment in harsh environments, implementing proper maintenance schedules with frequent contamination checks becomes essential for preventing costly downtime.

5. Operator Error and Improper Operation

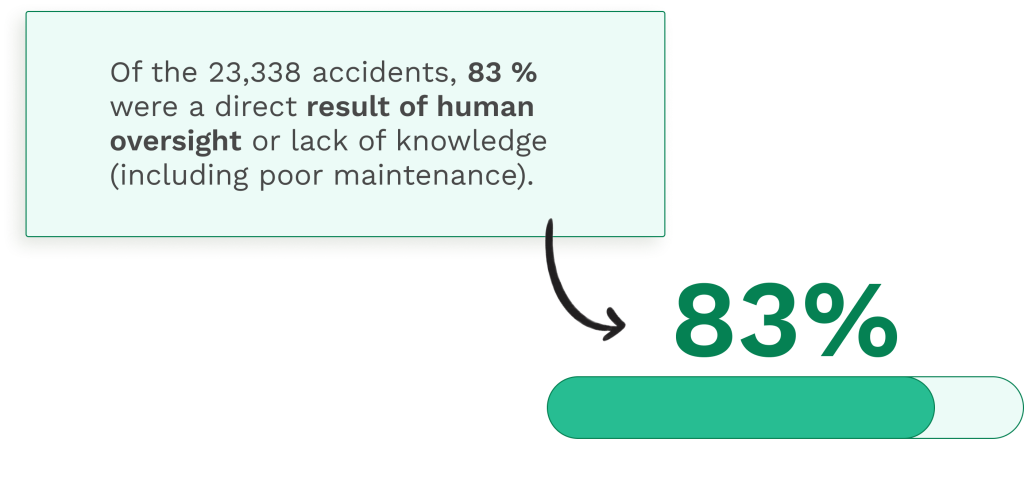

Operator error accounts for 6-12% of equipment breakdowns. The State of Industrial Maintenance 2024 report shows 12% of respondents anticipated operator error as a leading cause of unplanned downtime.

Operator-related issues range from incorrect startups to improper loading and failure to follow standard operating procedures. These mistakes usually stem from systemic issues, including a lack of standardized work procedures, inadequate operator training, and poor human-machine interface design.

Operator failures often mimic mechanical faults during troubleshooting, potentially masking the real issue of a lack of operational discipline. Running equipment beyond rated capacity, ignoring warning signs, or failing to perform basic operator care tasks can all lead to premature failure.

Prevention requires adequate operator training that covers proper operation, basic troubleshooting, and the recognition of abnormal conditions.

Safety Procedures

Safety procedures should be an integral part of operator training and proper equipment handling to minimize errors and ensure safe operation.

Standard operating procedures should be readily accessible and regularly updated.

Cross-training workers across multiple machines builds redundancy and deepens equipment understanding, supporting a culture of equipment reliability and proactive maintenance.

Management must strictly enforce policies that prevent untrained employees from operating machinery.

6. Improper Usage and Overloading

Improper usage occurs when equipment is misapplied or subjected to conditions outside design specifications.

This includes operating beyond rated capacity, using assets for unintended applications, and running machinery in unsuitable environmental conditions. Heavy equipment, such as cranes and excavators, is particularly susceptible to overload damage and requires specialized maintenance to prevent failures.

The consequences are severe.

Overloaded motors overheat and burn out. Conveyors beyond design specifications experience excessive vibration and premature bearing failure.

Hydraulic systems pushed past pressure ratings develop catastrophic failures. Each instance accumulates stress that accelerates machine failure.

Manufacturing operations sometimes maximize output by pushing equipment beyond limits. This short-term thinking ignores the long-term costs of higher repair costs, reduced equipment lifespan, and safety implications.

Prevention Steps

Prevention requires clear communication about equipment limitations and management support for proper operation. Equipment operators need to understand the designed capabilities and limitations. Standard operating procedures should explicitly state capacity limits and warning signs of overstressed equipment.

For critical assets, implementing automatic controls, such as load monitoring and pressure relief valves, provides mechanical safeguards against improper use.

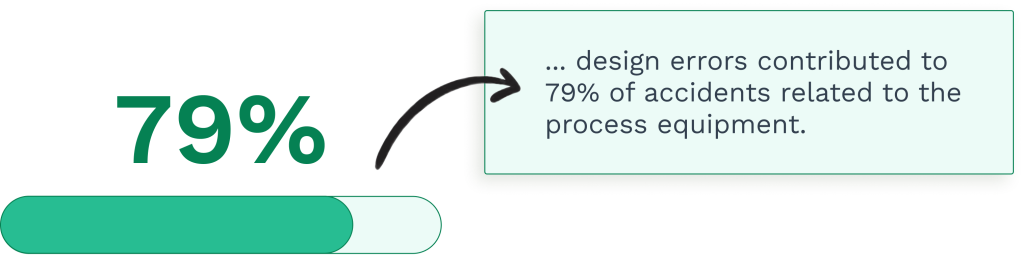

7. Design Deficiencies

Design deficiencies can account for 4-8% of failures. These inherent equipment problems include inadequate material selection, insufficient cooling capacity, structural weaknesses, and components that wear faster than anticipated.

Design-related failures typically surface 6-24 months after installation, distinguishing them from installation errors that appear quickly.

Manufacturing facilities identify these deficiencies through pattern recognition—when the same component repeatedly fails on identical machines despite proper maintenance.

Address Design Deficiency Issues

Addressing design deficiencies requires engineering modifications, such as upgrading materials, adding cooling capacity, reinforcing weak elements, or redesigning components.

While these represent significant investments, they’re often the only permanent solution to chronic failure modes. For assets with known design deficiencies, organizations must choose between implementing modifications, accepting higher maintenance costs, or planning early replacement.

8. Lack of Proper Maintenance

Like most mechanical equipment, a lack of proper maintenance often becomes both a root cause and amplifier of other failure modes.

When maintenance tasks are skipped or performed inadequately, equipment can fail prematurely.

This can drive up maintenance costs and create costly downtime. Ongoing maintenance and structured equipment maintenance programs are essential to prevent these issues and ensure long-term asset reliability.

Causes of Inadequate Maintenance

Many organizations struggle with proper maintenance due to budget constraints, staffing limitations, poor planning systems, or competing priorities.

Facilities that defer routine maintenance tasks often face dramatically higher repair costs when equipment eventually fails. Emergency repairs typically cost 3-5 times as much as planned maintenance.

Efficient planning methods, such as tracking equipment with asset tags and inventory control, support optimal performance and help minimize downtime. Including other maintenance tasks beyond basic repairs, such as inspections and documentation, ensures comprehensive maintenance coverage.

Results of Excessive Maintenance

Excessive maintenance also deserves attention.

Over-maintenance, or too much maintenance, can accelerate wear, waste parts, and divert attention from critical areas.

Over-maintenance can accelerate an asset’s depreciation by constantly disassembling and reconfiguring equipment components, increasing operational costs and disrupting system stability.

The key is to create a balance, with schedules based on equipment condition, manufacturer recommendations, and historical data rather than arbitrary intervals. Maintenance technicians play a key role in monitoring and balancing maintenance activities to avoid both under- and over-maintenance.

Modern preventive maintenance programs increasingly rely on data and condition monitoring to optimize timing. Condition-based maintenance (CBM) optimizes maintenance efforts by performing tasks only when necessary, reducing inefficiencies and preventing unnecessary interventions.

9. Environmental Factors

Environmental factors are often overlooked contributors to equipment failure. But they do have a profound impact on asset health and the longevity of critical assets.

Poor storage conditions, exposure to pests, high humidity, and extreme temperatures can all accelerate wear and lead to premature breakdowns. Inadequate facilities or improper environmental controls can compromise even the most robust equipment, increasing the risk of unplanned downtime and costly repairs.

To prevent equipment failure caused by environmental stress, organizations should incorporate regular environmental audits into their proactive maintenance strategy.

These audits help maintenance teams identify and address vulnerabilities in storage, handling, and operating environments. Ongoing monitoring of temperature, humidity, and other environmental conditions ensures that critical assets remain protected and perform reliably.

By integrating environmental management into proactive maintenance, companies can safeguard their equipment, extend asset life, and reduce the risk of unexpected failures.

How CMMS Software Helps Prevent Equipment Failure

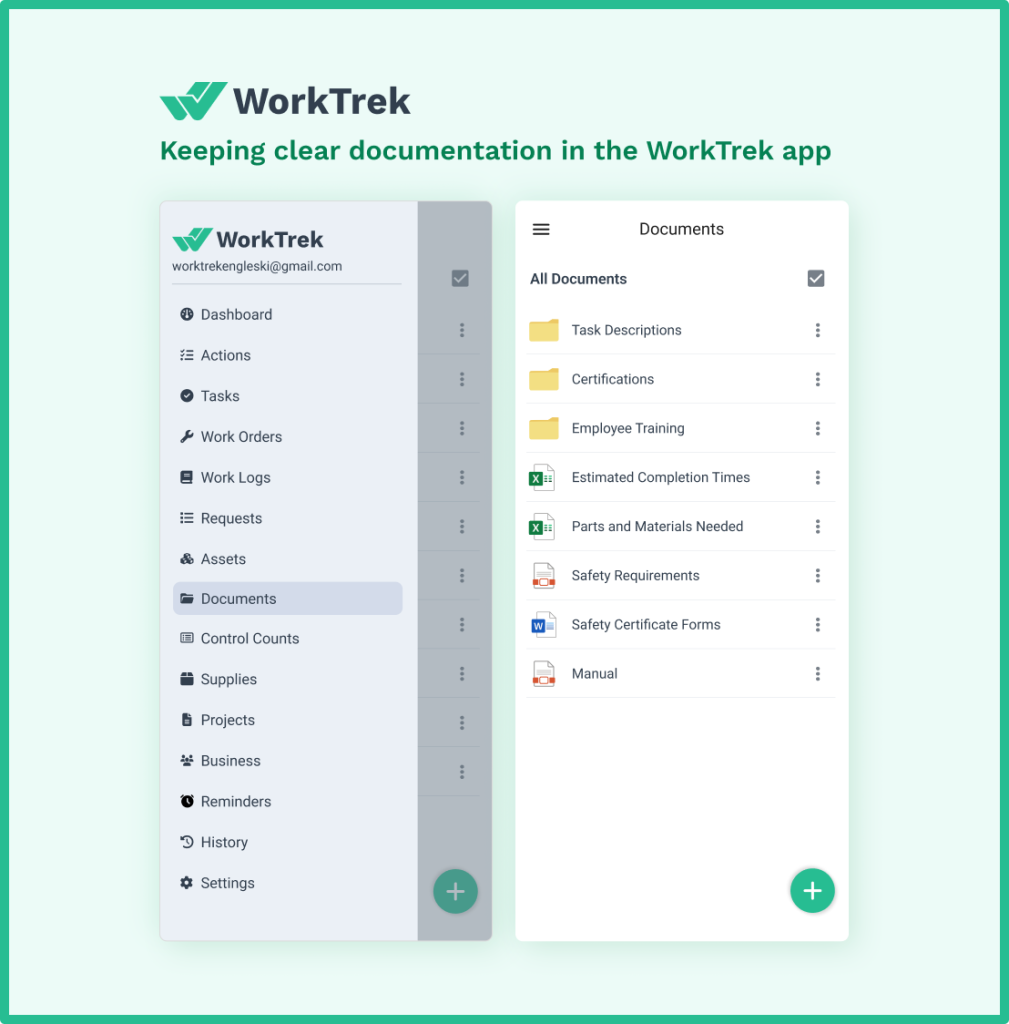

A computerized maintenance management system like WorKTrek serves as the foundation for preventing equipment failure through systematic maintenance management. Modern CMMS solutions like WorkTrek directly combat each of the eight common root causes through specific capabilities.

For lubrication management, CMMS schedules can track lubrication tasks, store lubricant specifications for each asset, and generate oil analysis work orders. This ensures inadequate lubrication, the leading cause of equipment failure, receives consistent attention.

For aging equipment, CMMS provides comprehensive asset tracking that monitors equipment age, usage hours, and performance trends. Historical data reveals patterns indicating when preventive maintenance should transition to planned replacement.

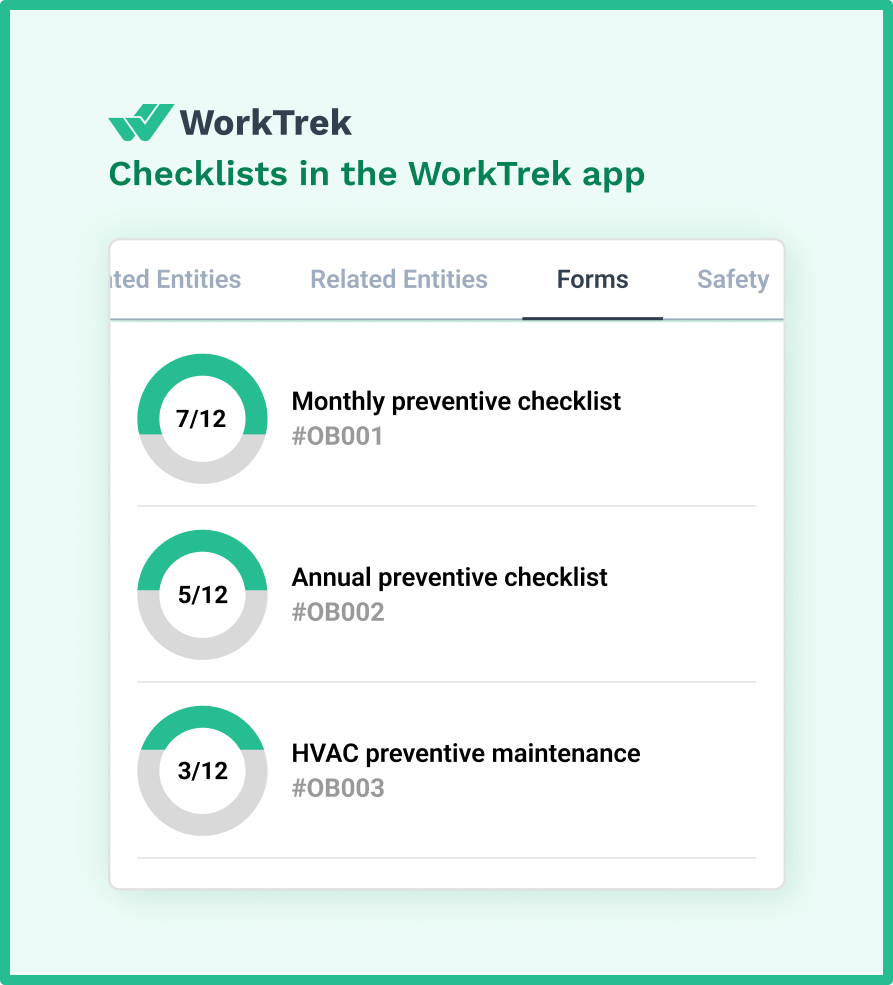

Installation quality improves through CMMS-managed procedures and checklists.

CMMS allows teams to attach detailed installation instructions, torque specifications, and alignment procedures to work orders. Quality control steps can be built into workflows to ensure technicians follow proper procedures.

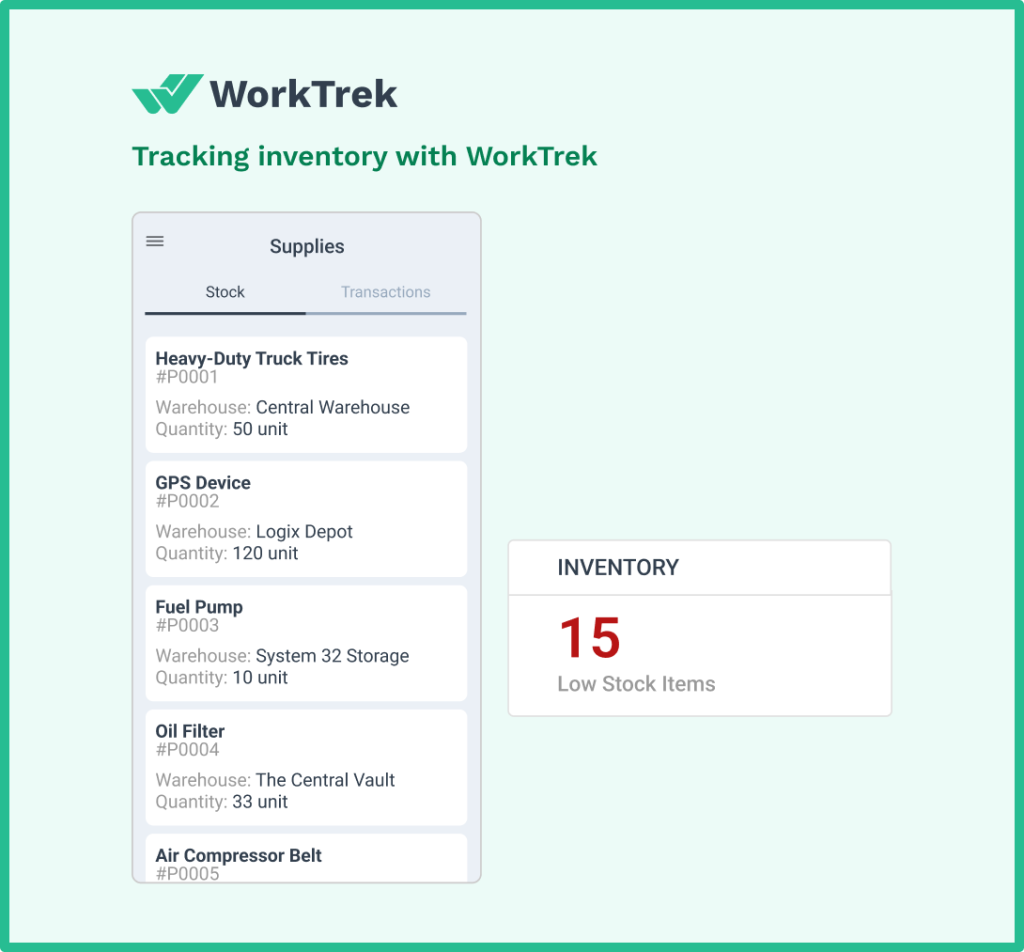

The system’s inventory management ensures spare parts and materials are available, reducing the temptation to skip or delay maintenance. Real-time inventory tracking prevents both stockouts of critical components and excessive carrying costs.

With reporting and analytics provide insights into maintenance performance, failure trends, and cost analysis that help teams continuously improve. For structured evaluation, consult this maintenance audit checklist to optimize your auditing process.

By identifying which assets consume the most resources and which failure modes occur most frequently, organizations can optimize their maintenance strategies for maximum impact.

Conclusion

The eight causes we’ve explored, from inadequate lubrication to lack of proper maintenance, account for 85-90% of equipment breakdowns that plague manufacturing operations and drive costly downtime.

The key insight is that equipment failures rarely happen randomly. They follow predictable patterns, provide warning signs, and respond to systematic prevention strategies.

Whether it’s implementing comprehensive lubrication programs to address the 35-40% of failures caused by inadequate lubrication, or establishing robust operator training to prevent the 6-12% of failures stemming from improper operation, targeted interventions deliver measurable results. Inadequate operator training can directly lead to machinery failure and increased downtime, making it essential to invest in proper training and clear SOPs to reduce the risk of equipment breakdowns.

Modern maintenance professionals have powerful tools at their disposal.

Computerized maintenance management systems provide the organizational infrastructure to prevent equipment failure through scheduled maintenance tasks, comprehensive documentation, and data-driven insights.

Condition-monitoring technologies such as vibration and oil analysis detect impending issues before equipment fails. Together, these tools enable the proactive maintenance strategy that keeps critical equipment running and costs under control.

Start by evaluating your current maintenance practices against the eight root causes outlined in this article.

Identify which factors contribute most significantly to your equipment failures. Are lubrication problems causing premature bearing failures? Is aging equipment approaching end-of-life without replacement planning? Are operators receiving adequate training to prevent improper operation?

Develop targeted prevention strategies that address your most significant failure modes.

For many organizations, this starts with implementing a CMMS to establish the foundation for systematic maintenance management. From there, layer on condition monitoring, operator training programs, and precision maintenance practices as resources and capabilities grow.

Leverage technology platforms like WorkTrek to ensure consistent execution of your maintenance programs. The investment in proper tools pays dividends through improved equipment reliability, reduced maintenance costs, and greater operational efficiency across your manufacturing operations.

Remember that preventing equipment failure is an ongoing journey, not a destination.

Equipment and operating conditions change, new failure modes emerge, and maintenance strategies must evolve accordingly. Organizations that embrace continuous improvement in their maintenance processes consistently outperform those that remain stuck in reactive maintenance patterns.