Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- Maintenance cost and schedule control are the biggest challenges in fleet management.

- Maintenance costs will rise by 17% by 2029.

- 95% of companies have had a data quality issue that affected business outcomes.

In this article, we explore everything you need to know about equipment maintenance logs.

These documents are the foundation of successful maintenance operations, helping you cut costs, reduce downtime, and extend asset lifespans.

Yet, surprisingly, many teams fail to recognize their value.

And that’s good news for you.

By improving just this one aspect of your operations, you can outpace competitors without them even realizing why. What a powerful weapon, hiding in plain sight.

Let’s take a closer look at what maintenance logs are, what to include in them, and how to manage them effectively.

What Is an Equipment Maintenance Log?

An equipment maintenance log is a document that records all maintenance activities performed on a specific piece of machinery.

It typically includes two main components: essential asset information (like the name, model, serial number, and location) and a chronological history of every repair or service performed.

This tool is used in all industries that depend on reliable assets, from manufacturing to IT, to track upkeep and make better-informed decisions.

Tyler Smith, Product Manager at Volvo Construction Equipment, puts it this way:

Just as a doctor uses medical history to make accurate diagnoses, maintenance teams use equipment logs to identify inefficiencies, reduce downtime, and lower operational costs.

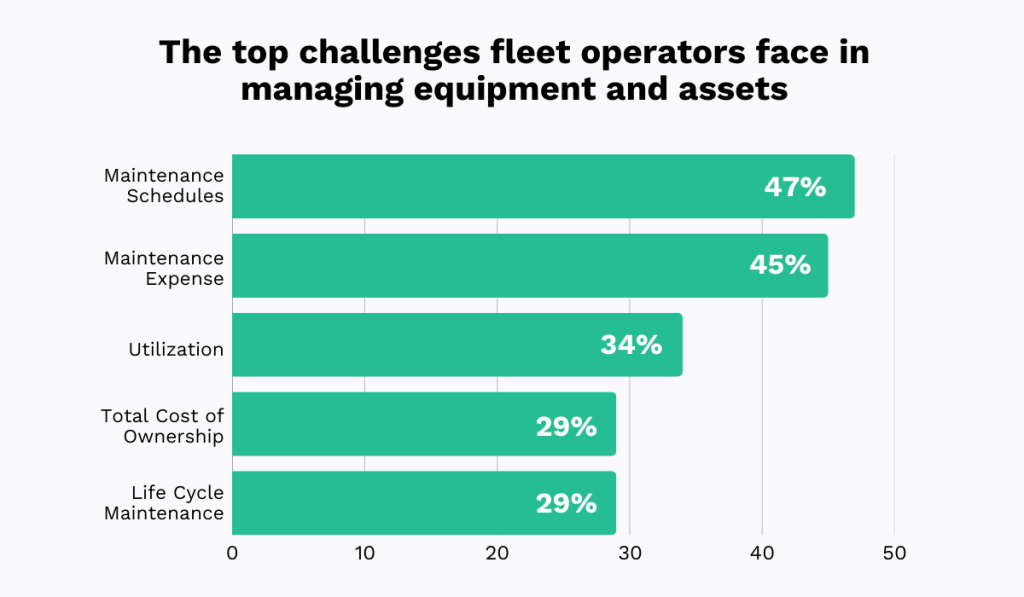

According to the 2025 Teletrac Navman survey, many challenges modern fleets face are directly tied to maintenance, particularly in managing schedules and controlling costs.

Fleets, just like any other asset-heavy sector, currently find themselves in a difficult situation: machinery is becoming more advanced, repairs are getting pricier, and teams are expected to do more with less.

That’s where an equipment maintenance log proves invaluable.

It provides the visibility and transparency needed to plan better, react faster, and ultimately take back control of maintenance operations.

Important Components of an Equipment Maintenance Log

Here’s what data to collect to unlock this kind of visibility and transparency for yourself.

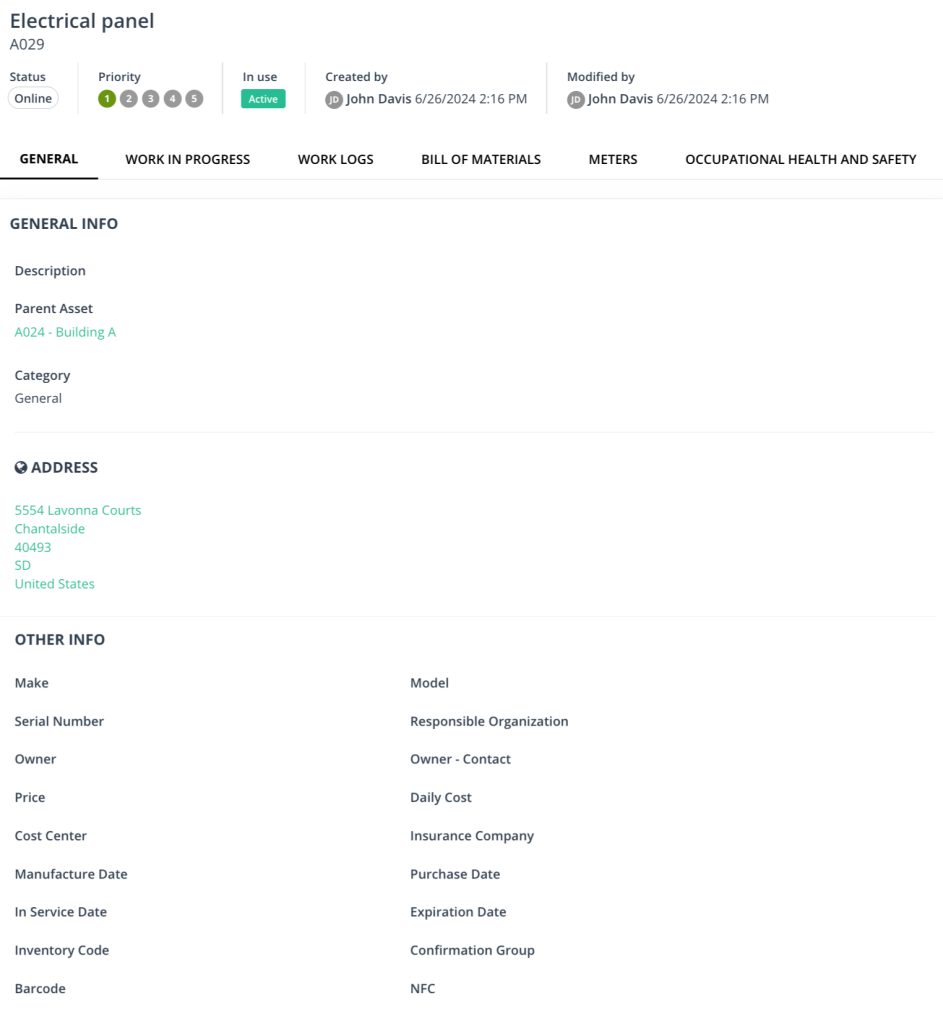

Equipment Details

This is the core information that uniquely identifies each piece of equipment.

It typically includes data like the equipment name, make, model number, serial number, manufacturer, purchase date, and location:

You may also include warranty details, insurance information, and any certificates to create a more complete picture of your assets.

While basic, this information is vital for accurately tracking maintenance history for each unit, particularly in facilities with multiple similar machines.

Without it, upkeep records can easily get mixed up and attributed to the wrong equipment, limiting visibility and leading to inefficiencies and unnecessary downtime.

Insurance and warranty claims can also get chaotic.

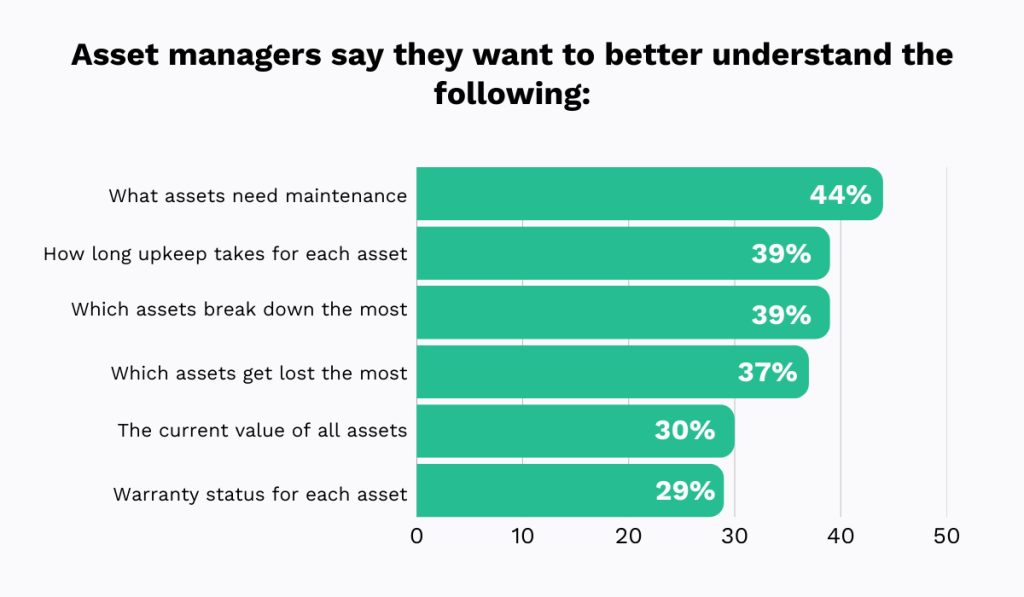

The 2025 Cheqroom survey backs this up, revealing that many asset managers admit they’re missing this kind of foundational data and want more of it.

It’s easy to see why.

Without a strong data foundation, it’s nearly impossible to reliably track warranties, costs, maintenance schedules, or total cost of ownership.

In short, rich equipment profiles are where all successful maintenance and asset management processes begin.

No maintenance log is complete without them.

Maintenance Schedules

It’s also important to diligently track all maintenance activities.

This is where many teams fall short; they only record what was done, when it was done, and perhaps add a vague description of the actions taken.

High-quality maintenance records should provide much more than that.

They should include detailed task descriptions, responsible personnel, supervisors, planned costs, spare parts, and due dates.

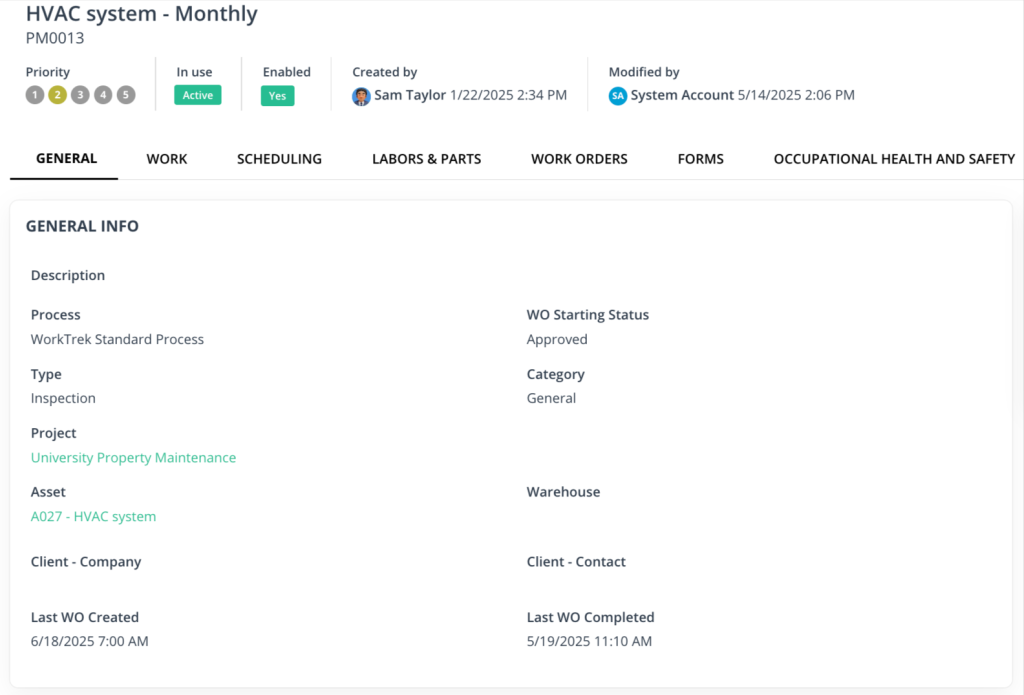

Task frequency or intervals, SOPs, and safety information should be included, too, particularly for recurring (preventive) tasks and critical assets:

This information serves two important purposes.

First, it ensures technicians have everything they need to perform their work efficiently and safely.

With a detailed log, they can easily confirm exactly how to complete a task and understand potential hazards or any special quirks of the equipment.

No more unnecessary calls or guesswork. No more preventable safety incidents and wasted time.

Second, it enables supervisors to more accurately plan future maintenance.

When every task is documented thoroughly, a maintenance history develops over time, complete with all the past issues, costs, and spare parts used.

This allows supervisors to monitor compliance with PM schedules, compare planned versus actual costs, and identify inefficiencies.

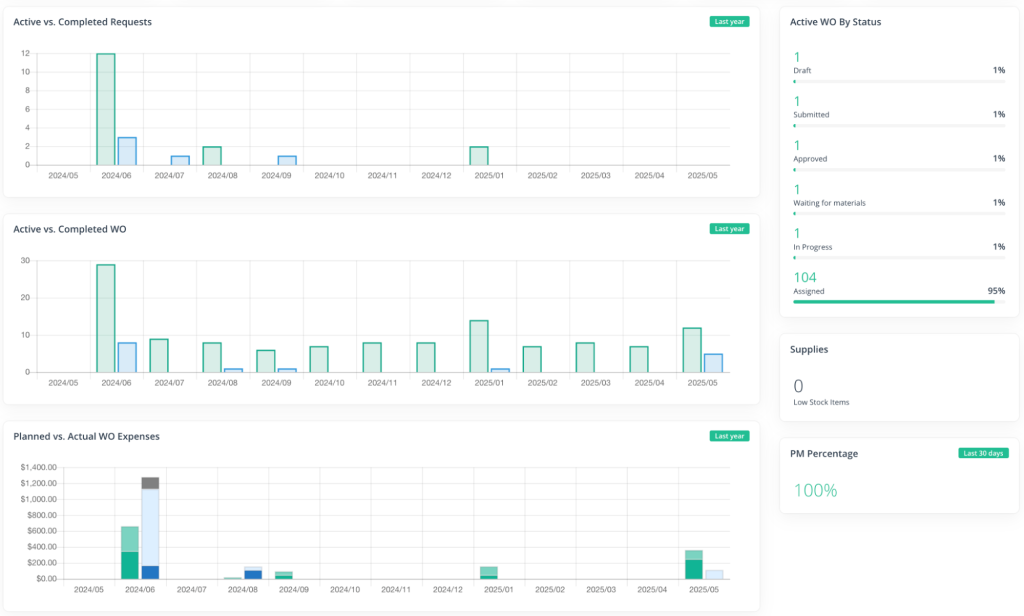

Users of digital maintenance management systems can also get these analyses automatically, like this:

That way, they can allocate resources more strategically and make timely adjustments to protect operational efficiency, equipment reliability, and, ultimately, the bottom line.

Usage Information

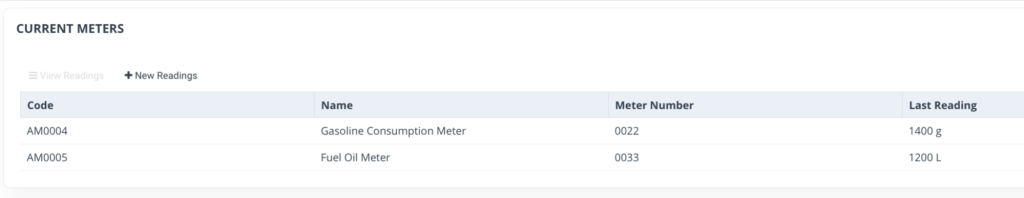

Usage Information records how, when, and by whom equipment is being used.

This includes operational data, environmental conditions, and workload metrics like the number of cycles, units produced, or load weight:

Any deviations from normal operation should also be documented here.

Tracking this information is important because it helps maintenance teams understand the real-world stresses on equipment.

This is a key component of condition-based maintenance, which adjusts schedules based on actual asset usage and, as the name implies, condition.

So, instead of relying on calendar-based intervals, which can lead to under- or over-maintenance, work is scheduled only when it is truly needed.

India Gibson, Launch Leader at Schneider Electric, a French corporation that specializes in digital automation and energy management, explains the benefits of such an approach:

“Rather than spending time and money and having downtime to do a reactive approach or check the box on a typical maintenance protocol, we can respond quicker to changes that require immediate attention.”

She adds that condition-based maintenance focuses efforts on areas that need them most, making maintenance activities both efficient and effective.

That’s why usage data is so valuable. It gives you a more complete picture of your assets’ needs, making your upkeep planning more precise and cost-effective.

Cost Tracking Data

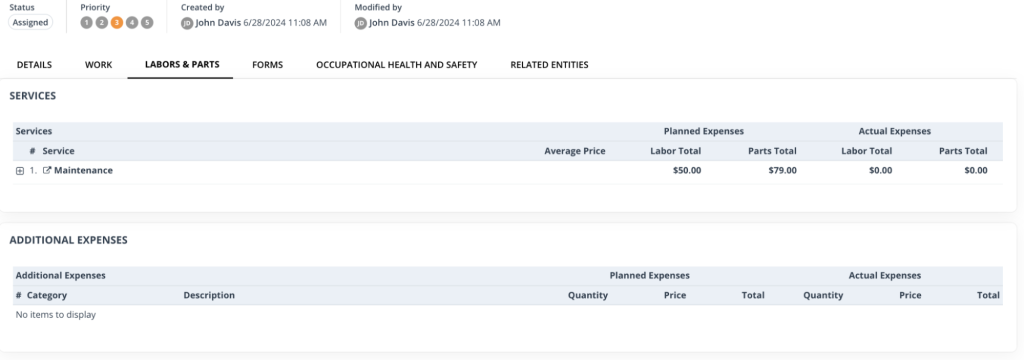

Your maintenance log should also include all expenses associated with a piece of equipment throughout its life.

This covers repairs, labor, spare parts, downtime costs, and potentially depreciation or miscellaneous costs, such as PPE used during maintenance:

The reason for tracking this kind of information is straightforward.

It enables more accurate cost forecasting and budget planning, helping you determine the total cost of ownership and whether it’s more cost-effective to repair or replace equipment.

In short, it supports more cost-effective maintenance management decisions.

And those are more important than ever.

The 2025 BCIS Facilities Management Forecast predicts that maintenance costs, as measured by the BCIS All-in Maintenance Cost Indices, will rise by 17% by Q4 2029.

Various factors drive this increase.

On one hand, there are labor shortages, rising wages, and broader economic uncertainty plaguing all sectors and industries.

On the other hand, safety regulations are tightening, and the fines for noncompliance are only increasing.

Managing maintenance under these conditions is becoming more challenging every day, leaving little room for error, particularly when it comes to spending.

The only way to stay ahead of these growing risks is to diligently track all costs and use this data to plan more strategically.

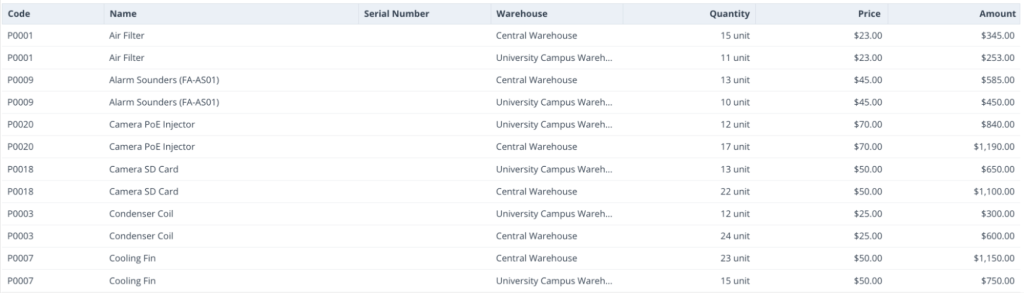

Spare Parts Usage

Lastly, ensure your maintenance log includes detailed information about parts replaced or consumed during maintenance.

Record the part name, number, quantity, cost, date of replacement, supplier, and, if applicable, installation instructions:

This creates a clear picture of your inventory usage, helping you optimize inventory management.

Instead of overordering and wasting money and space, or underordering and causing costly downtime, you’ll know exactly what to order, how much, and when.

That way, you ensure your team has the tools and materials they need without putting unnecessary pressure on the budget.

Jim Owens, President at Marrad, a sustainable materials management solutions provider, agrees that parts management is no easy feat.

Its biggest issue is, he notes, the lack of ownership, which often leads to a tangled web of competing priorities:

Logging parts usage solves this problem by providing everyone with cold, hard data on what is actually needed and its cost.

It can also show if a cheaper option ends up being more expensive due to more frequent replacements or serious malfunctions.

No more endless debates, guesswork, or finger-pointing among different departments.

All the evidence is right there, laid out clearly for everyone to see.

Equipment Maintenance Log Common Mistakes

Now, that’s a lot of data to manage. It’s only natural that some mistakes will be made along the way.

Here are some of the most common ones and how to fix them.

Failing to Document All Relevant Details

Often, technicians fail to record all relevant details, whether it’s parts replaced, task descriptions, or signatures, without realizing the impact of this mistake.

But in reality, incomplete data can be worse than no data at all.

It misrepresents the state of your operations, leading to misinformed decisions.

It causes you to miss cost-saving opportunities, overlook important tasks, and, ultimately, harm equipment reliability.

The 2024 Anomalo research shows how damaging poor data can actually be.

Nearly every company has experienced a data quality issue that directly affected business outcomes.

Many even admit they won’t make data-driven decisions if they don’t trust their data.

To solve this problem, you need to first understand what causes it.

Most of the time, the answer is the lack of a standardized data entry system.

There are simply too many different data points to track. Technicians can’t be expected to stay on top of it all without any guidance.

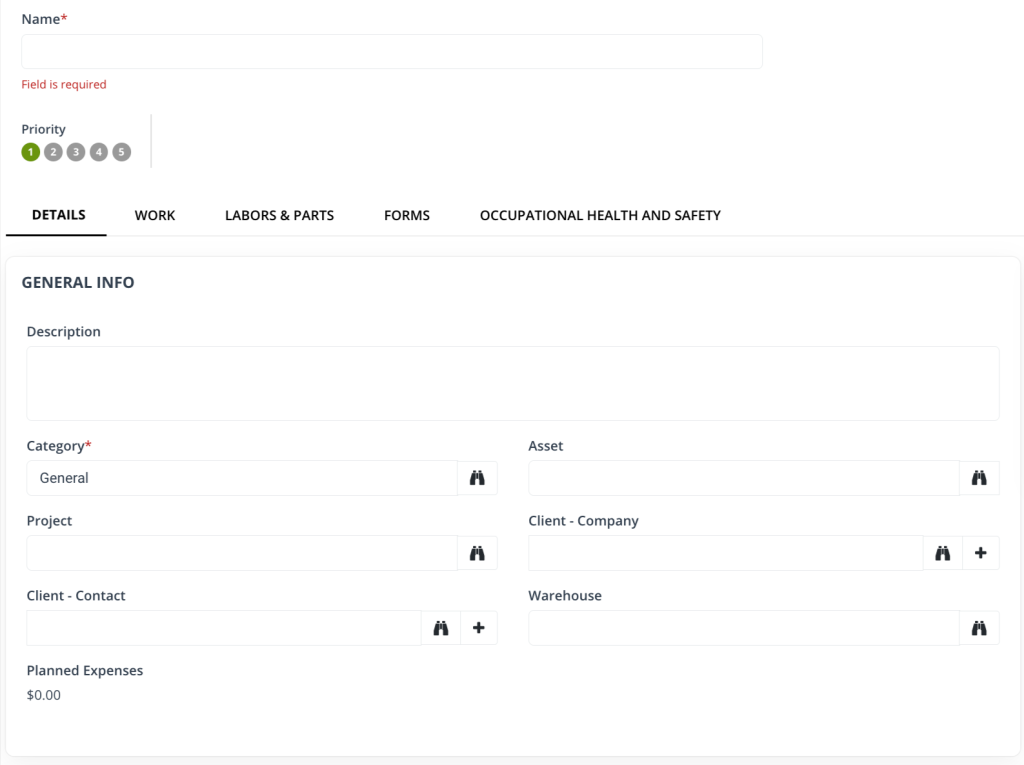

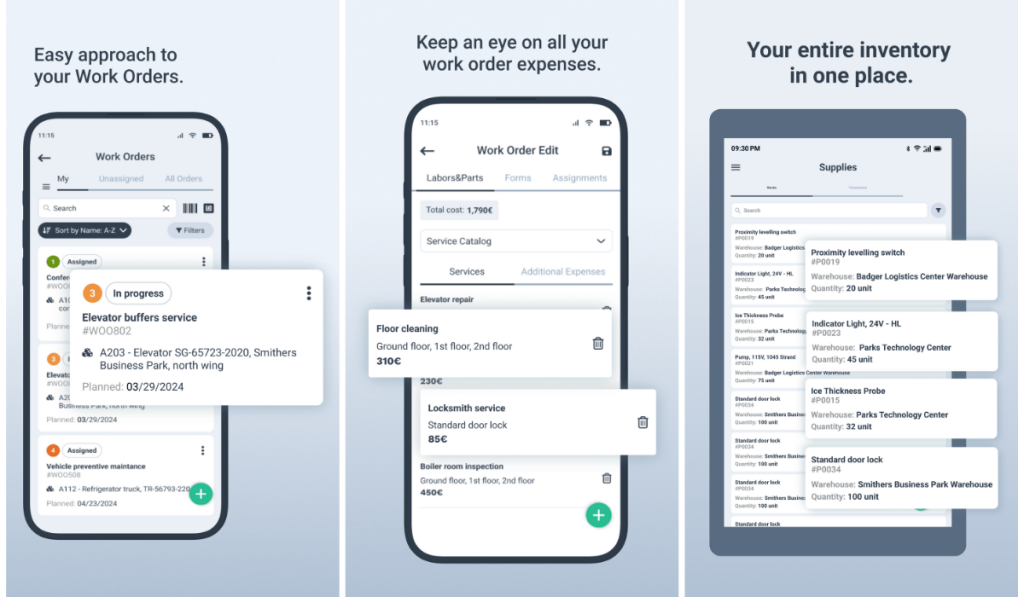

CMMS solutions like WorkTrek provide that guidance, offering pre-built templates for all the documents your team creates daily.

That includes work requests and orders, invoices, PM schedules, and more.

As you can see below, each template features customizable required fields that must be filled in before submission, making it impossible to submit incomplete forms.

This ensures your workers will capture every piece of critical information. No exceptions.

Over time, diligent record-keeping becomes routine, and incomplete logs become a thing of the past.

Not Recording Maintenance Immediately

Similarly, technicians don’t always record their work immediately.

The longer they wait, the greater the risk of misremembering or forgetting vital details, which, yet again, undermines the reliability of your maintenance log.

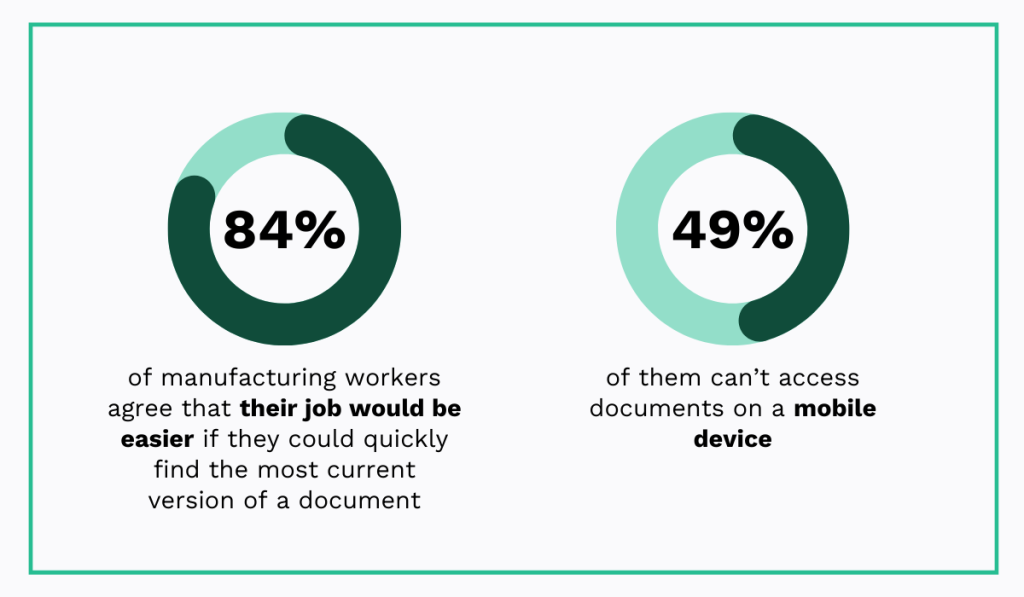

The 2021 EDH Technology study identifies both the possible cause and a solution to this very problem.

Most manufacturing professionals agree that their jobs would be easier if they could quickly and easily access the data they need.

Yet, nearly half report that they cannot access important documents via mobile devices.

This is a significant missed opportunity.

Mobile accessibility allows technicians to find, access, and update equipment logs in the field, instead of having to drive to and from the office just to complete and collect paperwork.

When recording information is that simple, technicians are far more likely to do it immediately.

With just a few taps on a phone, they can log work, sign documents, take photos, and close out the work order:

It’s a system that benefits everyone.

It simplifies the data-entry process for technicians, allows supervisors to track progress in real time, and ensures data is captured accurately and consistently.

Undervaluing the Importance of a Maintenance Log

Many record-keeping inefficiencies and mistakes stem from technicians not understanding the full value of accurate, complete maintenance logs.

It makes sense. With so many other tasks that seem more urgent, it’s easy for administrative work to feel like something to push to the bottom of the list.

As Aaron Zimmerman, a Partner at the construction defect law firm Berding & Weil, explains, frontline personnel often aren’t even thinking about the bigger picture issues, such as compliance:

“People who are documenting these issues, the people who are actually keeping the records – the plant engineers, maintenance personnel, even the janitors – they’re not thinking that six years from now we’re going to be in a lawsuit.”

And realistically, it isn’t their job to do so.

However, it is the leadership’s responsibility to educate staff on the strategic value of accurate maintenance logs.

You can do that by providing case studies and real-world examples where poor documentation led to financial loss or reputational damage.

If your organization has internal examples, share those.

Explain what happened and the costs to the organization and the individuals involved.

Ruth Edge, Records and Information Management Specialist at Intech Records and Information, a data management firm, offers some additional advice:

These real-life case studies will make the impact of good (and bad) record-keeping more tangible and easy to understand.

With that context, your team will be much more likely to comply with your maintenance log requirements and avoid cutting corners.

Conclusion

Once your entire team internalizes good maintenance log practices, you’ll finally have a strong foundation for smarter decision-making, greater agility, and more effective risk management.

This will take some time, effort, and the right tools, but you’ll get there.

And when you do, you’ll see that every bit of trouble was worth it.

Because, in the end, without transparency and accountability, you can’t have the control you need to take your maintenance operations to the next level.