Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

- A poor onboarding experience often makes employees leave the company.

- 43% of companies currently face challenges in recruiting maintenance staff.

- OSHA recently increased its penalties for violations.

- Maintenance costs are expected to increase by 17% by Q4 2029.

Maintenance logs are hardly a new concept.

For as long as maintenance work has existed, technicians have tracked the tasks performed, the associated costs, the responsible personnel, and more.

Yet despite their long history, many still fail to recognize the full extent of their operational impact and therefore neglect to keep them properly.

In this article, we go over the six most important benefits of maintenance logs to help you avoid that very mistake and ensure you don’t miss out on valuable cost savings and efficiency gains.

Let’s begin.

Helps Optimize Your Preventive Maintenance Program

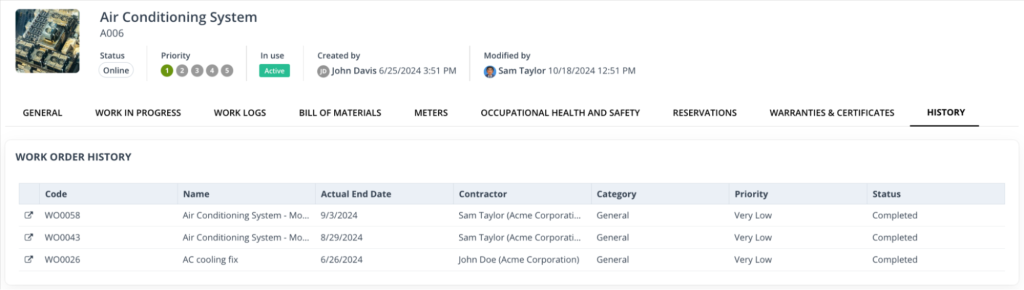

A maintenance log tracks a wealth of valuable information, such as service dates, equipment condition, parts replaced or lubricated, technician notes on wear, and more.

Over time, this creates a data history for every asset, as shown below:

That history enables maintenance teams to schedule service based on real usage trends and asset condition, instead of relying on guesswork and risking under- or over-maintenance.

Ultimately, with such an efficient PM program, technicians catch issues before they escalate, reducing unplanned downtime and unnecessary repair costs while extending asset lifespan.

Keith Schafer, now retired from TC Energy, an energy infrastructure company that develops and operates natural gas pipelines, knows this better than most.

He implemented preventive maintenance throughout his career and has seen its effectiveness firsthand.

In the 1980s, his company used engine analyzers (oscilloscopes) connected to engine flywheels.

These devices revealed vibration and pressure traces for a single engine revolution, showing what was happening inside the cylinders.

They had no digital storage at the time, but Schafer understood the value of data long before it was easy to collect.

That’s why he documented everything with Polaroid photographs, building reference catalogs that showed normal signatures for each engine.

This is how they caught issues in the making, he explains:

Over the decades, the technology and processes improved, and so did the results.

Preventive schedules became more precise, ensuring equipment runs smoothly for longer.

Schafer recalls:

“When they pulled [the engines], they were clean as a whistle. No carbon buildup. No excessive wear. They just ran forever.”

That’s the power of a well-run preventive maintenance program: more savings, less unplanned downtime, longer asset lifespans.

And it all starts with the data you find in your maintenance log.

Improves Root Cause Analysis

The data in your maintenance log not only supports more strategic PM scheduling but also helps pinpoint the source of repeating failures.

When you consistently capture what was repaired, how it was done, and what the outcome was, you dramatically improve your ability to identify patterns and trace issues back to their origin.

Modern digital logs add even more context by allowing you to include photographs (shown below) and integrate data from condition-monitoring tools.

This information can then be analyzed and presented in an easy-to-understand format using built-in reporting features, making root cause analysis more data-driven than ever before.

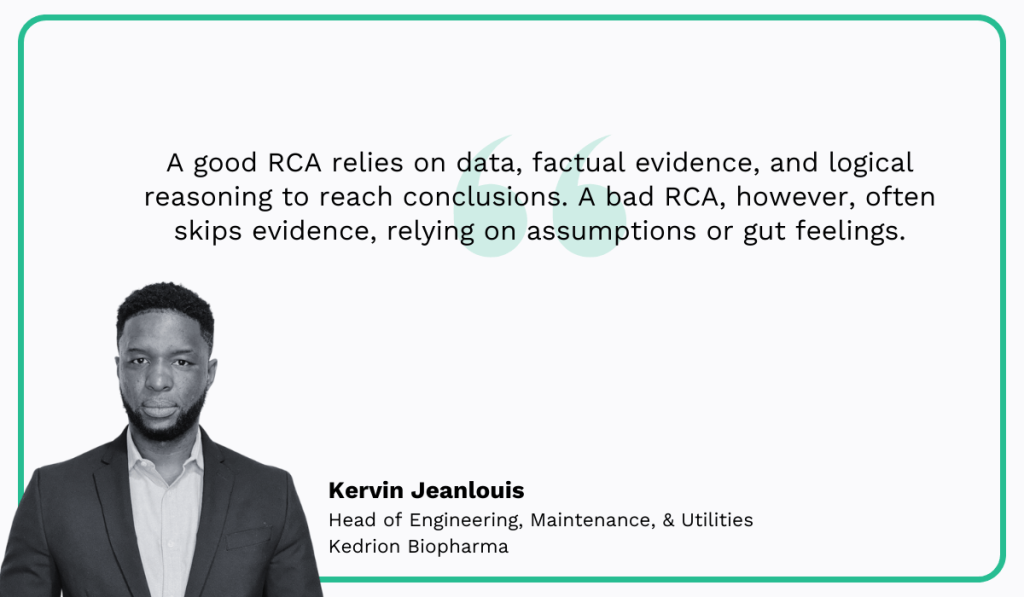

According to Kervin Jeanlouis, Head of Engineering, Maintenance, and Utilities at the global biopharmaceutical company Kedrion Biopharma, that’s exactly what root cause analysis should be:

You might have a sense that something is off, but a maintenance log gives you proof.

Maybe failures always happen under specific conditions, during a certain shift, or with one particular component.

Whatever the cause, the trends become impossible to overlook.

Pete Bradley, Head of International Technical Training and Association Affairs at Hella Gutmann Solutions, a failure diagnosis systems manufacturer, explains why that matters:

In short, data-driven root cause analysis leads to better repair decisions.

Ultimately, this eliminates repeat issues, saving money on unnecessary repairs and ensuring smoother operations.

Supports Efficient Employee Onboarding

With a detailed, easily accessible maintenance log, technician onboarding becomes a breeze.

It enables new team members to quickly review asset or repair history and better understand common equipment problems, quirks, best practices, hazards, and more.

Chris Simon, EVP of Operations for Atlanta-based apartment manager The RADCO Cos., notes:

Your maintenance log is that support.

Instead of new employees having to ask questions, make guesses, or rely on verbal instructions, they have documentation that trains them automatically.

It’s a win for everyone: veteran employees aren’t constantly interrupted with questions, and new technicians get up to speed faster.

However, the benefits of efficient onboarding go far beyond this.

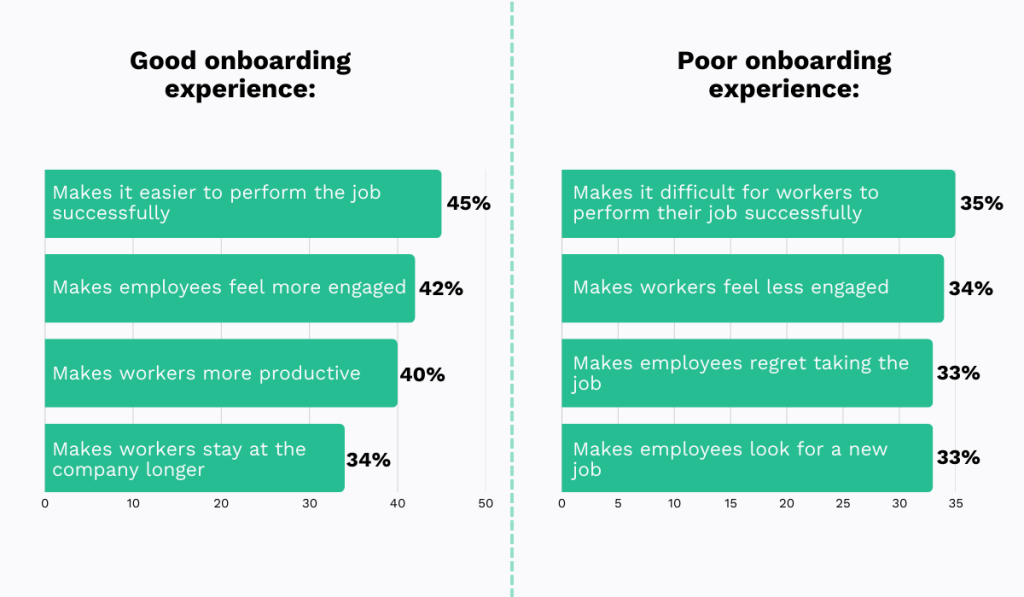

According to the 2024 Enboarders survey, a strong onboarding experience makes employees more productive, more successful, and even more loyal.

Conversely, poor onboarding can cause employees to regret taking the job and immediately start looking for another one.

In other words, onboarding has a major impact on employee retention, which, given today’s maintenance labor shortages, matters more than ever.

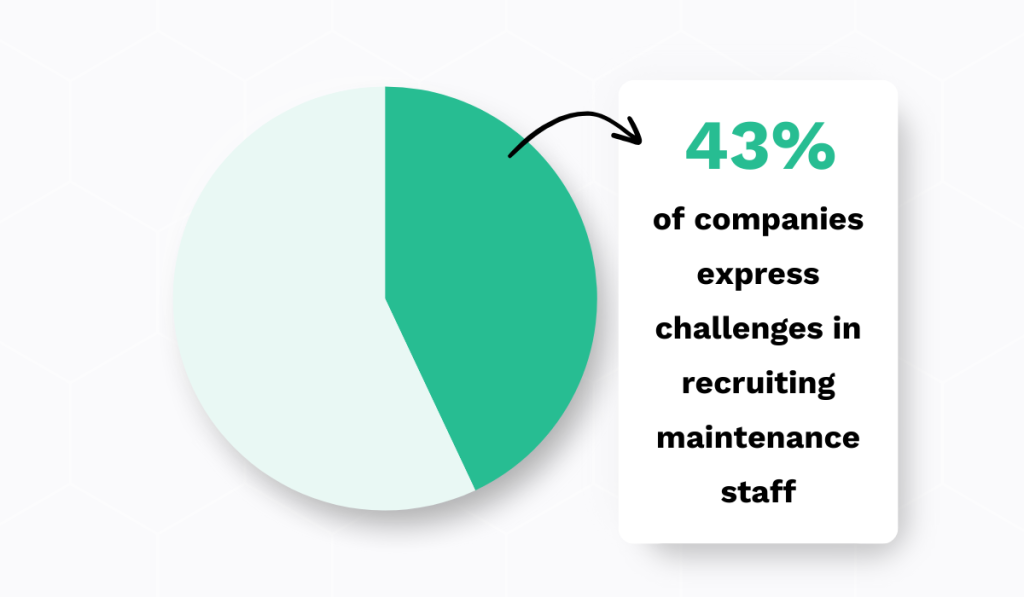

A recent ABB survey found that 43% of companies currently face challenges in recruiting maintenance staff.

A well-maintained maintenance log can be a surprisingly effective tool in combating this issue.

It helps new hires learn quickly, become more independent, and build confidence.

And when your team feels capable and valued, they’re far more likely to stay with the company.

Ensures Safer Operations

Maintenance logs are the foundation of a strong safety culture among technicians.

They typically contain information that helps workers perform their jobs safely and avoid accidents.

This includes safety procedures, instructions, reminders about field hazards, and more.

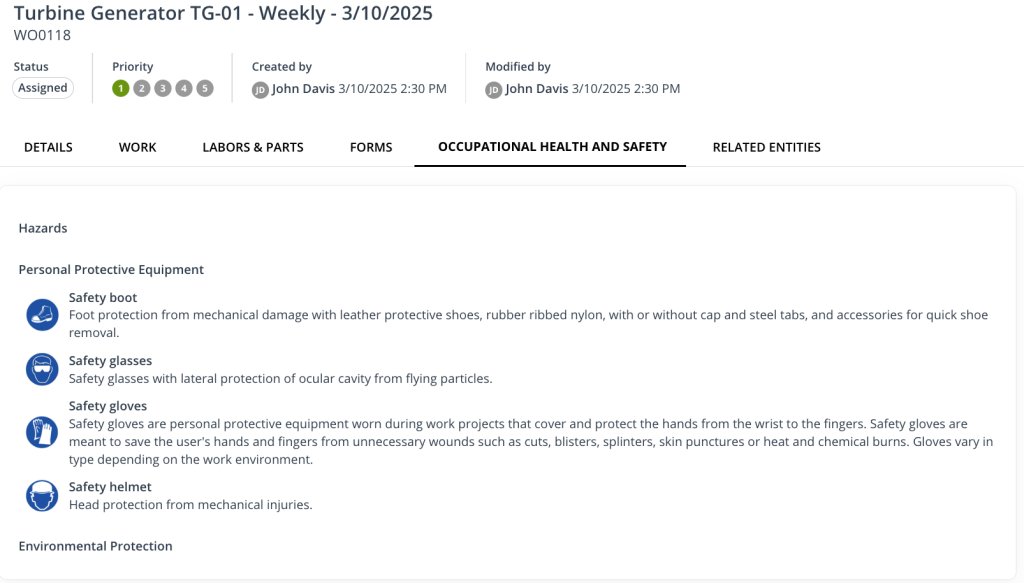

Digitized maintenance management systems like WorkTrek take safety to the next level.

WorkTrek enables you to upload safety rules, LOTO procedures, instructions, checklists, and PPE reminders into a centralized system and attach them to specific assets or work orders.

So, when a worker is assigned a task, they can immediately access a work order on their phone, complete with all the necessary information, including spare parts and costs, to relevant health and safety guidelines.

There’s no need to dig through scattered paperwork anymore.

Everything is in one easily accessible location, which significantly improves adherence to safety protocols.

After all, when instructions are easy to find, it’s easier to follow them.

This naturally translates into fewer safety incidents, reduced injuries, and a happier, more loyal workforce.

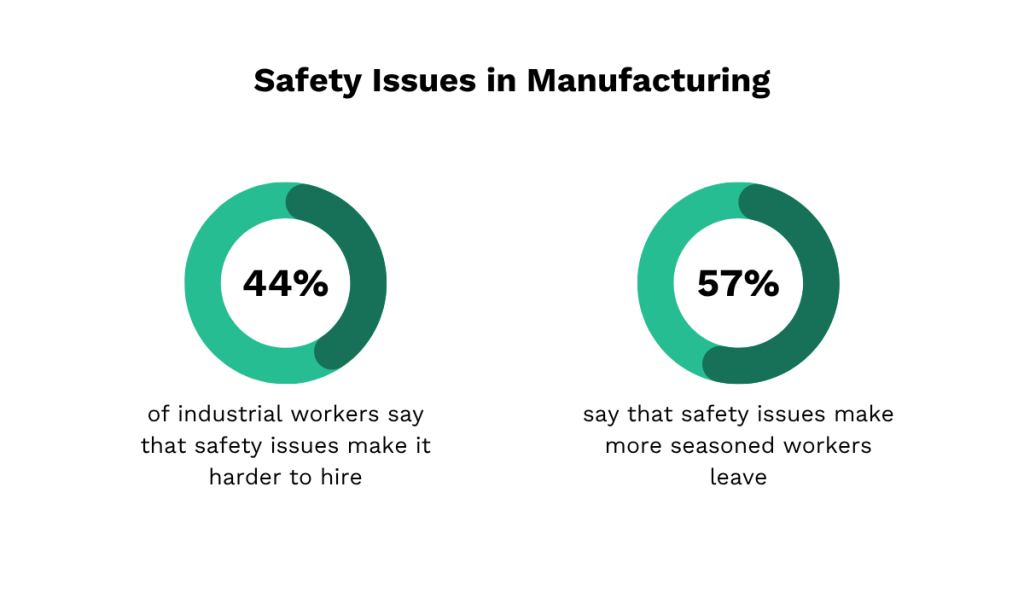

One Vector Solutions survey confirms this, showing that safety concerns often make hiring difficult and cause experienced workers to leave.

It makes sense. If workers don’t feel safe at their workplace, why would they stay?

Moreover, a strong safety culture protects companies just as much as it protects employees.

Safety incidents can easily lead to lawsuits, reputational damage, and hefty fines from regulatory bodies.

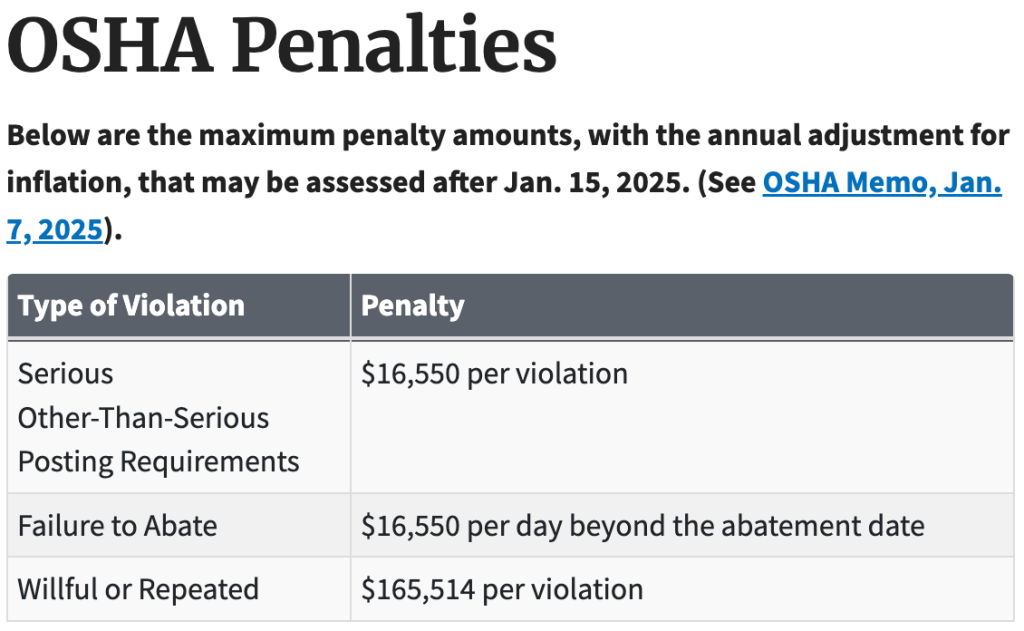

For example, OSHA just recently increased its maximum penalties from $16,131 per violation in 2024 to $16,550 per violation in 2025.

That’s a steep price to pay, especially for something that can often be prevented by making employees better informed about relevant protocols and possible threats.

This is exactly what a maintenance log does.

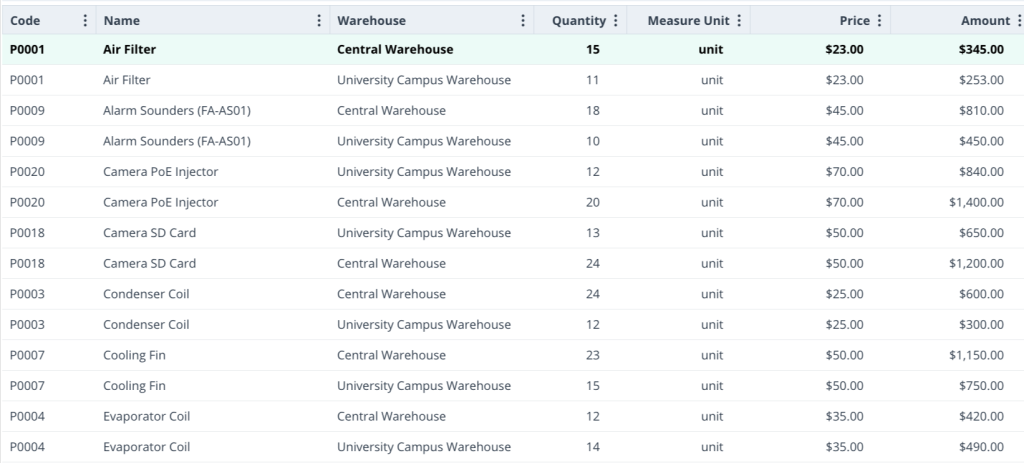

Improves Inventory Management

Maintenance logs, especially when integrated into a digital maintenance management system, give you more control over your inventory.

They provide real-time insights into stock levels and detailed information about each part, including location, make, model, price, and user manuals.

Some systems even allow you to track parts by serial number, giving you their complete history, from initial warehousing to installation and eventual disassembly.

This kind of data ensures you know exactly how each part is used, which, in turn, supports more effective inventory management.

Put simply, it helps you maintain the right stock levels without overspending on unnecessary items.

Take Alstom SA, the French multinational manufacturer of rail transport systems, as an example.

After merging with Bombardier Transportation in 2021, their global operations significantly expanded.

Naturally, their inventory grew as well.

Therefore, to manage this growth, they decided to digitize their maintenance records to unlock better inventory planning and more accurate availability tracking.

According to Alexandre Domingues, Chief Digital Services Officer at Alstom, the results were amazing:

Such a system is especially valuable when inventory is spread across multiple locations.

Instead of managing each location separately, digital logs enable easy communication between sites, allowing parts to be shared as needed.

That’s exactly what Alstom did, resulting in significant cost savings and reduced waste.

Because, in the end, you can’t truly control what you can’t see.

Enhances Budget Planning

Historical repair data recorded in your maintenance log allows you to predict future maintenance expenses and plan capital expenditures more accurately.

By understanding how much it costs to maintain each asset and how frequently certain repairs occur, you can make maintenance costs more predictable and reduce unexpected expenses.

Today, this might be more necessary than ever, given the growing pressures experienced by the maintenance sector.

Dr. David Crosthwaite, Chief Economist at Building Cost Information Service (BCIS), explains:

Indeed, safety regulations are tightening, fines are increasing, and maintenance costs continue to rise.

For example, the 2025 BCIS Facilities Management Forecast predicts that maintenance costs, as measured by the BCIS All-in Maintenance Cost Indices, will increase by 17% by Q4 2029.

This is, in part, driven by equipment becoming more advanced and therefore more expensive to maintain.

Industrial environments, in particular, now rely on numerous sensors that monitor asset conditions in real time and AI-driven systems that analyze this data.

Implementing and maintaining these technologies comes at a high cost.

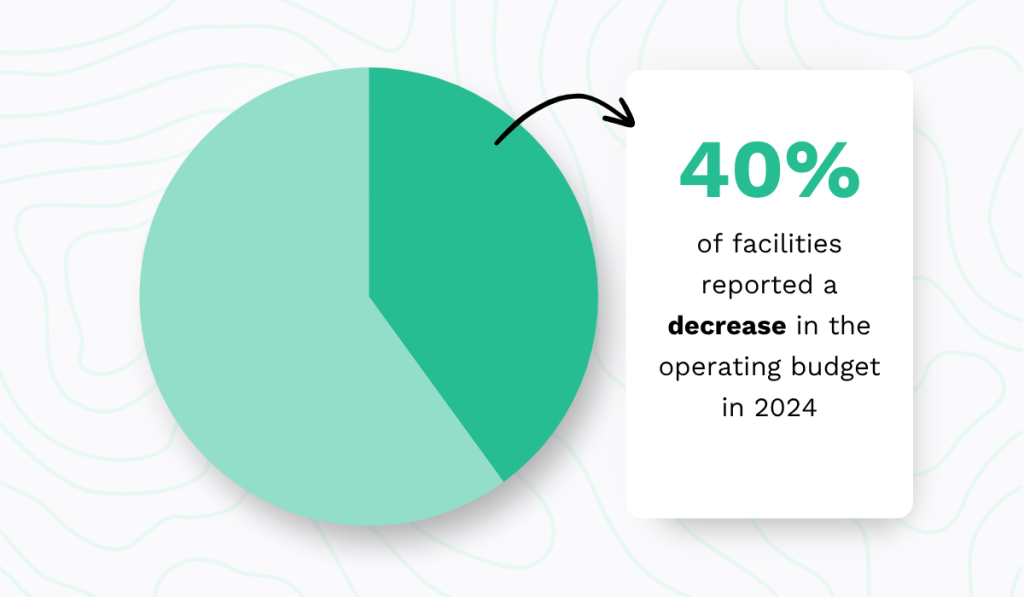

To make matters worse, maintenance budgets are not keeping pace.

In fact, they are shrinking in many cases.

According to the 2025 SFG20 report, almost half of organizations have reduced their facilities management budgets compared to the previous year.

Across industries, companies are cutting operational costs, and maintenance is no exception.

Maintenance managers face the challenge to do more with less, and strategic, data-driven budget planning is the most effective path forward.

When you diligently maintain your records, you gain better insight into anticipating costs, plan effectively, and keep operations running smoothly.

Conclusion

Your maintenance log is a truly valuable asset.

In it, you’ll find everything you need to make better decisions, plan strategically, and unlock significant benefits across your maintenance operations.

So, keep your records organized, accurate, complete, and up-to-date.

Instill a culture of diligent document management within your team, and use digital tools for easy access and consistency.

When you invest in your maintenance data, it delivers long-term ROI, ultimately saving you money, extending asset life, and boosting efficiency across the board.