Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways:

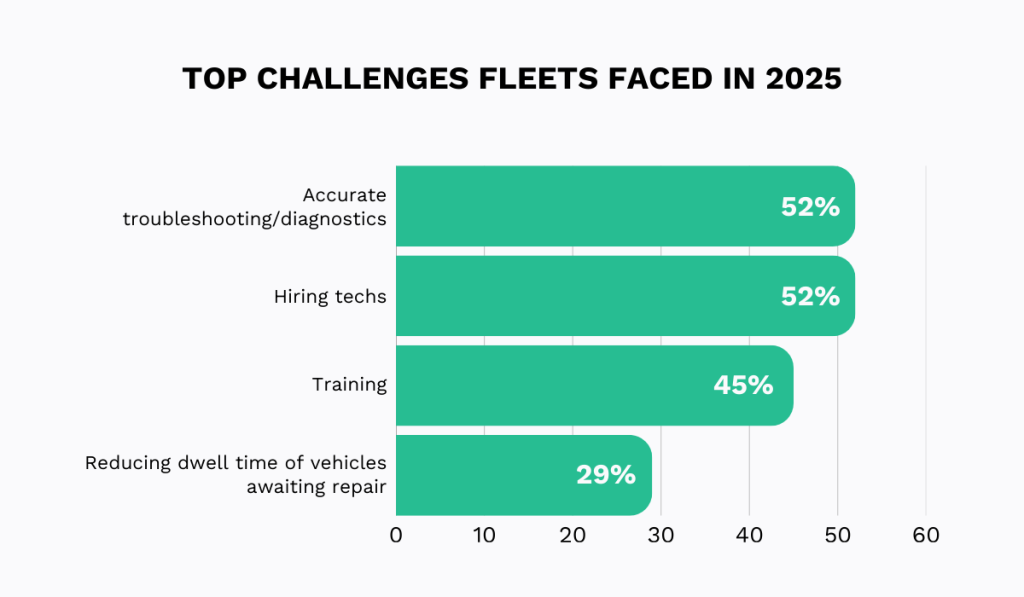

- Accurate troubleshooting was the biggest challenge for fleets in 2025.

- Noncompliance in maintenance leads to fines, reputational damage, and operational shutdowns.

- 40% of organizations have reduced their facilities management budgets in 2025.

Your historical maintenance data has the potential to transform your operations beyond recognition.

It can help reduce costs, boost technician productivity, and improve overall equipment reliability.

You just need to know what to look for and how to act on it.

This article shows you exactly that, outlining six ways to leverage maintenance history records to unlock new levels of efficiency.

Identifying Recurring Equipment Issues

Maintenance history records make it easier to spot patterns that might otherwise go unnoticed, helping you address recurring asset issues.

This makes them especially valuable today, when modern companies struggle with accurate troubleshooting and diagnostics, along with hiring technicians with the right skill sets.

Maintenance records help solve both of these problems at once.

By capturing detailed maintenance data, you can move beyond temporary fixes and focus on permanent solutions, thereby reducing repeat failures, downtime, and costly, unnecessary labor.

Put simply, maintenance history records make your work more effective, allowing you to do more with less.

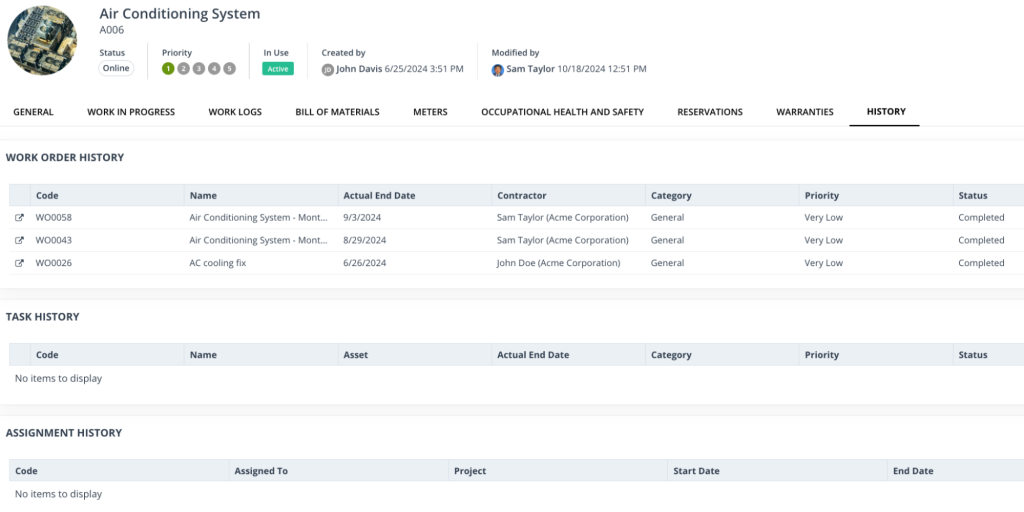

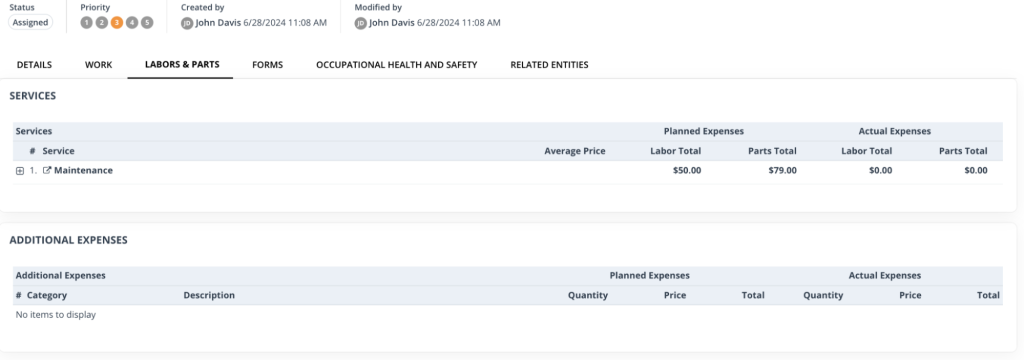

For example, reviewing past work orders (as shown below) can reveal whether the same component or system fails repeatedly.

This is often a sign of a systemic issue rather than random failure, indicating that previous repairs may have addressed symptoms instead of root causes.

With the right record-keeping system, you can analyze data even more deeply, including run hours, responsible personnel, and operating conditions for each individual machine.

This enables patterns such as failures occurring after a specific number of operating hours or seasonal breakdowns.

You could also compare multiple assets to get amore complete picture, identifying which machines consume the most labor or parts and which components fail disproportionately often.

This supports more strategic decisions around upgrades, replacements, and long-term maintenance planning.

In the end, without maintenance records, all these issues remain largely invisible, becoming silent killers of reliability, efficiency, and profitability.

That’s what makes recurring problems so dangerous: they don’t announce themselves until the damage is already done.

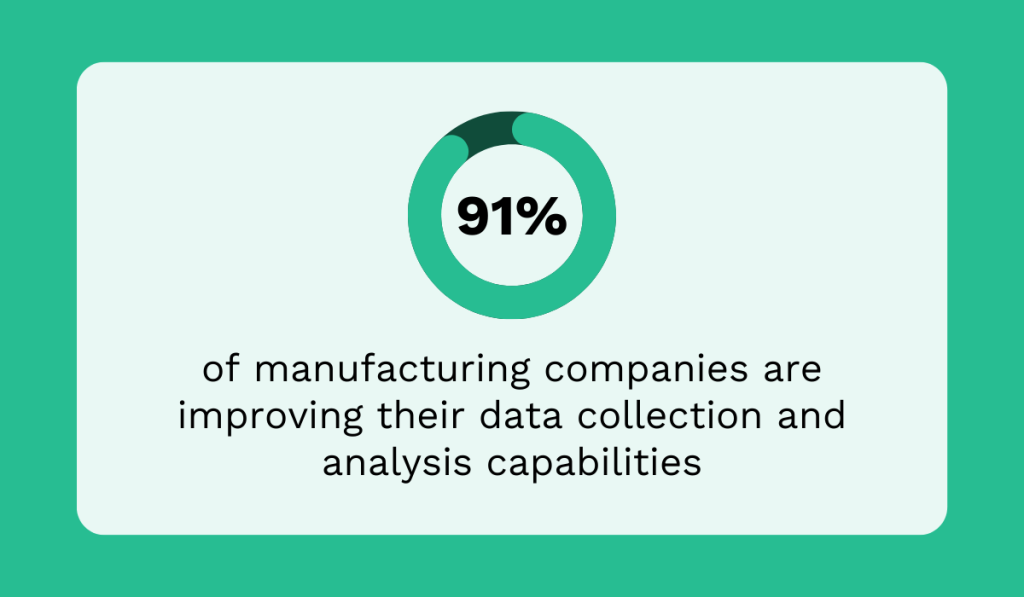

It’s no surprise, then, that most manufacturing companies are now investing heavily in better data collection and analysis.

Visibility is the first step toward control, and reliable data is the key to maintaining stable, efficient, and resilient operations.

Improving Preventive Maintenance Scheduling

You can also use your maintenance history to fine-tune your preventive maintenance (PM) program.

Instead of relying on often generic, manufacturer-recommended PM intervals, historical data shows how long components last in your operating environment and when failures typically occur.

This allows you to optimize maintenance schedules so assets receive the care they need, exactly when they need it.

The result: fewer major failures and less unplanned downtime.

A great example comes from the Lake Mainit hydropower plant in the Philippines.

By analyzing historical maintenance data, the plant’s maintenance service provider identified a variation in the actuation time of the main inlet valve on Unit 1.

This early warning enabled them to intervene in time, replace the valve, and prevent a full plant shutdown.

Angelo A. Panganiban, Plant Manager at the Lake Mainit hydropower plant, commented:

This example clearly shows why historical maintenance data matters.

It reflects how equipment actually behaves under real operating conditions, not how it was expected to behave on paper, allowing you to tailor your PM program to real-world needs.

This is even more true when maintenance data is managed in a digital maintenance management system, such as a CMMS.

These tools automatically track and analyze data, schedule maintenance tasks, and notify technicians at the right time for more accurate and reliable PM execution.

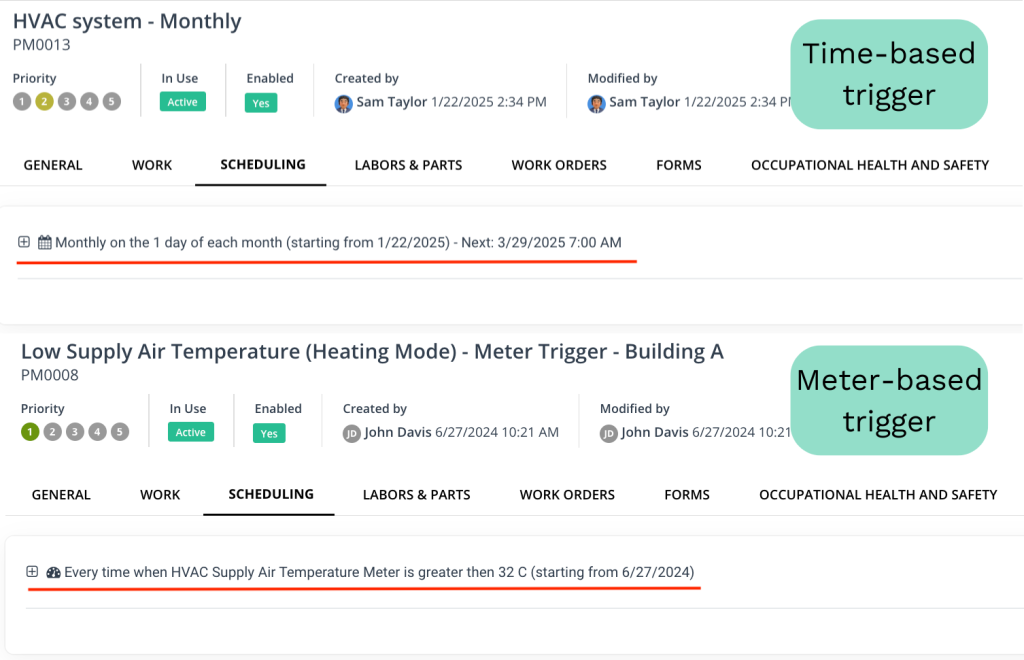

Take our CMMS, WorkTrek, as an example.

It lets you create recurring tasks based on criteria that best suit your assets, whether fixed time intervals or condition-based triggers like operating hours, temperature, mileage, pressure, and more.

You can also define priority levels, assign responsible technicians, set due dates, attach SOPs, plan task duration, and establish end rules for each recurring job.

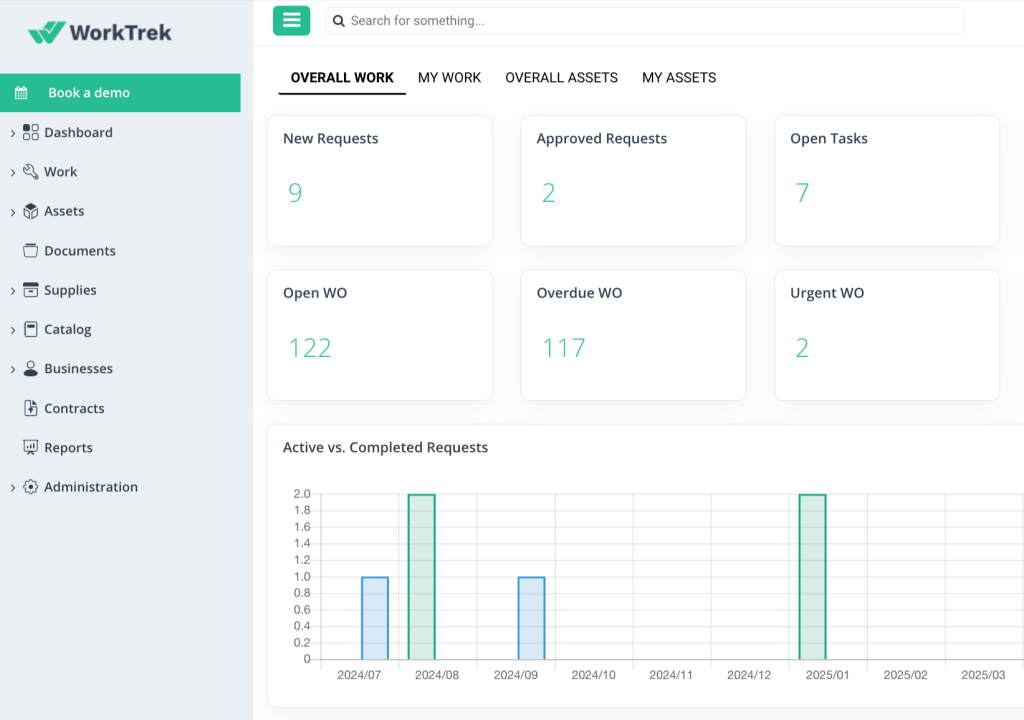

When a task is due, technicians receive automated reminders, while supervisors can monitor progress and compliance through an intuitive dashboard, like the one you see below:

The result is a precise, data-driven preventive maintenance program that teams actually follow.

No more guesswork, no more forgotten tasks, and no more operational disruption.

Strengthening Compliance

Your maintenance history records are your first line of defense against noncompliance with safety, health, and regulatory requirements, as well as the consequences that follow.

These can range from costly fines that only seem to increase year after year to irreparable reputational damage and even operational shutdowns.

You can learn more about these risks in the video below.

Highly regulated industries, such as aviation, should prioritize proper record-keeping the most.

Max Lutje Wooldrik, Founder & CEO of AeroVerify, an aviation document security platform, warns airlines against relying on outdated, paper-based systems.

According to him, such systems can’t keep pace with growing industry complexity and regulatory scrutiny, nor do they deliver the accuracy and security modern aviation operations need.

However, with well-organized, digitized historical data, companies stand a fighting chance, Wooldrik explains:

This is because historical records provide documented, traceable evidence that required maintenance activities were carried out correctly.

They clearly show what maintenance was performed, when it was completed, who performed it, and which standards were followed, with any deviations properly documented and approved.

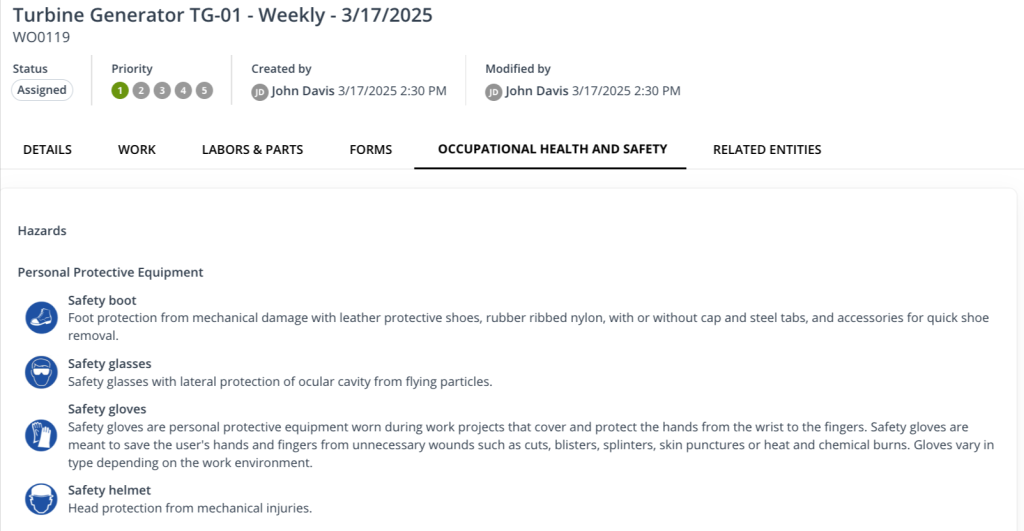

In addition, these records can demonstrate that appropriate PPE was used and that safety rules and lockout/tagout procedures were followed:

When all of this information is stored in a single, easily searchable system, audits become straightforward and are no longer a major source of stress or chaos.

Better Budget Planning

With historical maintenance data, you don’t have to rely on estimates or assumptions to forecast future costs and plan budgets.

Given the current state of the maintenance industry, there’s very little room left for subjective judgment anyway.

The 2025 BCIS Facilities Management Forecast predicts that maintenance costs, as measured by the BCIS All-in Maintenance Cost Indices, will rise by 17% by Q4 2029.

MRO parts are becoming more expensive, new technologies are entering the market, equipment is increasingly complex to maintain, and skilled workers are hard (and costly) to find.

Maintenance budgets need to account for all of this while still being sufficient to keep operations running smoothly and reliably.

That would seem to suggest that budgets, along with costs, must be increasing, right?

Wrong.

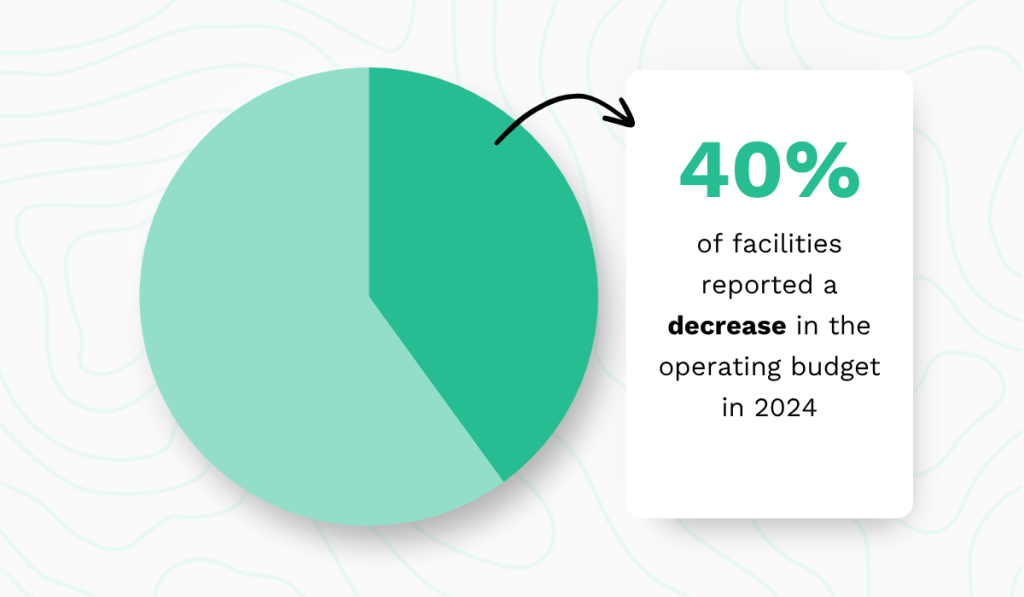

According to a 2025 report by SFG20, 40% of organizations have reduced their facilities management budgets compared to the previous year.

As a result, maintenance teams find themselves in a difficult position.

They’re expected to maintain the same level of efficiency, or even improve it, with fewer resources.

This is where maintenance history records become vital.

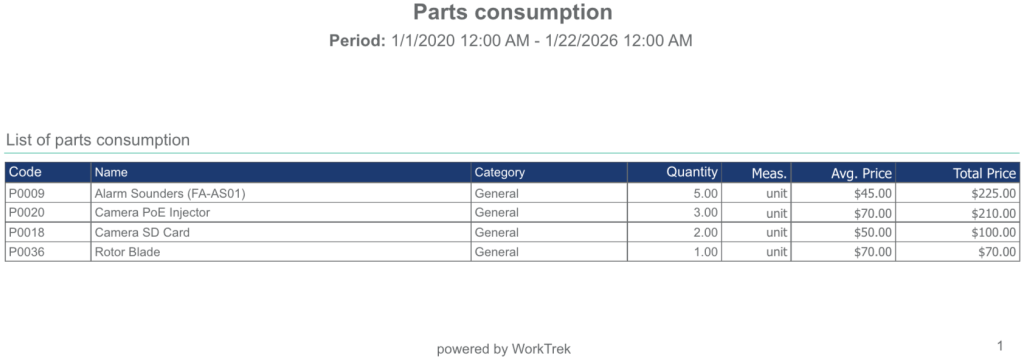

They provide clear visibility into past spending on labor, parts, contractor services, emergency repairs, and other cost categories:

By analyzing this data, you can more accurately predict annual maintenance costs by asset or system, create more realistic budgets, and improve long-term financial planning.

Similarly, these records allow you to compare planned versus unplanned costs, revealing how much is spent on preventive versus reactive maintenance.

This makes it easier to demonstrate to leadership that reactive work is more expensive and disruptive, helping justify investment in more effective maintenance strategies.

All in all, maintenance records are critical for forecasting future expenses more accurately and allocating resources where they deliver the most value.

In fact, with compelling data to support the case, they may even help secure bigger budgets.

Easier Parts Inventory Forecasting

Maintenance history records help with more accurate and efficient parts inventory forecasting by revealing which parts are actually used, how often, and under what conditions.

This information is more important than many realize, as accurate spare parts forecasting can make or break operations.

Jim Owens, President at Marrad, a technology-enabled supply chain solutions company that focuses on sustainable materials management, agrees:

Overestimating your needs ties up money and space in inventory that may never be used and could become obsolete.

Underestimating, on the other hand, risks last-minute emergency purchases and costly production stoppages.

Neither scenario benefits your operations.

However, by analyzing historical maintenance data, you can identify which spare parts are used most often, which fail repeatedly, and which components are common across multiple assets:

This allows you to classify parts based on criticality and consumption rate, ensuring stock levels reflect actual needs rather than assumptions.

You can order more high-risk items that often cause downtime, thereby reducing production interruptions and the cost of rush orders.

Similarly, you can identify rarely used parts to reallocate or dispose of, freeing up storage space and capital.

As a result, you benefit from a balanced inventory strategy that keeps critical parts available while minimizing unnecessary costs.

Ensuring Accountability

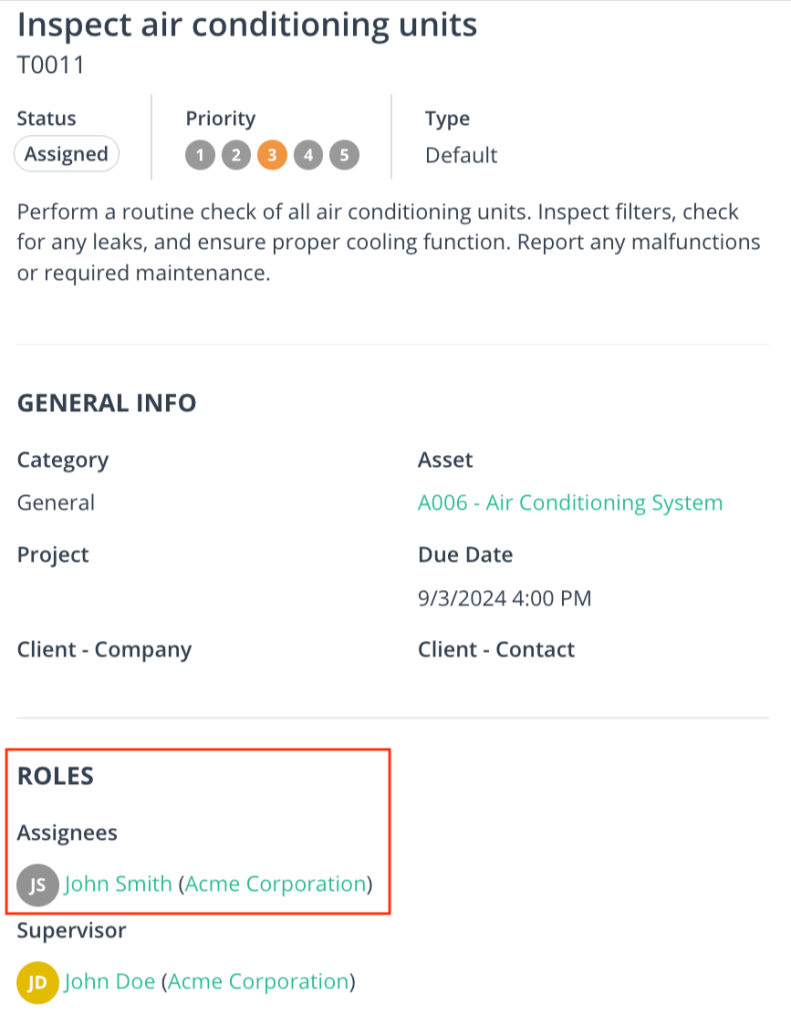

Maintenance history records are a great tool for accountability because they create a clear, traceable record of who did what, when, and how.

This allows you to track responsibility, verify work quality, and improve overall reliability.

When something goes wrong, instead of endless finger-pointing and guesswork, you can quickly pinpoint where the process broke down.

For example, if a tool goes missing, the records show who last used it and where.

If a task wasn’t completed, the records indicate who was assigned and when it was due:

Every action is attributable to a specific individual.

This not only helps supervisors monitor schedule compliance but also promotes personal responsibility among workers and reduces the likelihood of errors or skipped tasks.

Keith Fagan, Director Global Learning and Talent Development at Ritchie Bros, a marketplace for used equipment, trucks, and industrial assets, explains:

After all, maintenance records expose weak links, inefficiencies, or mistakes, and no one wants to be the person slowing things down.

At the same time, they spotlight top performers, giving your team clear examples of excellence to aim for.

In the end, such transparency and clear roles create an environment where employees not only take responsibility but actually want to do better, sometimes even competing with each other in a healthy way.

That’s how you end up with highly motivated, productive, and engaged team members.

Conclusion

Hopefully, this article has opened your eyes to the power of historical maintenance data.

When used effectively, it can unlock a wide range of benefits, boosting both productivity and profitability.

However, all of this depends on having accurate, up-to-date, and complete data.

So, before jumping into any kind of analysis, take the time to thoroughly audit your records and ensure you have a strong foundation for making meaningful operational improvements.