Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeIn the complex world of industrial operations, machine maintenance represents a critical intersection of human expertise and mechanical systems. This machine maintenance safety guide explores the fundamental aspects of safely maintaining machinery, offering deep insights into the procedures and protocols that protect personnel and equipment.

Ensuring the safety of maintenance crews is paramount to maintaining operational efficiency and protecting both personnel and equipment

Rather than viewing safety as a series of checkboxes to tick off, we’ll examine how each element contributes to creating a comprehensive safety ecosystem.

Machine Maintenance Safety Template

Below is a machine maintenance safety template that maintenance organizations can use:

The Foundation of Machine Safety

Machine safety is understanding that every piece of equipment harbors potential risks, regardless of complexity.

These risks become particularly pronounced during maintenance procedures when protective guards are removed, systems are disassembled, and the maintenance team must interact directly with machine components.

This direct interaction creates a unique set of challenges that require careful consideration and systematic approaches to ensure safety.

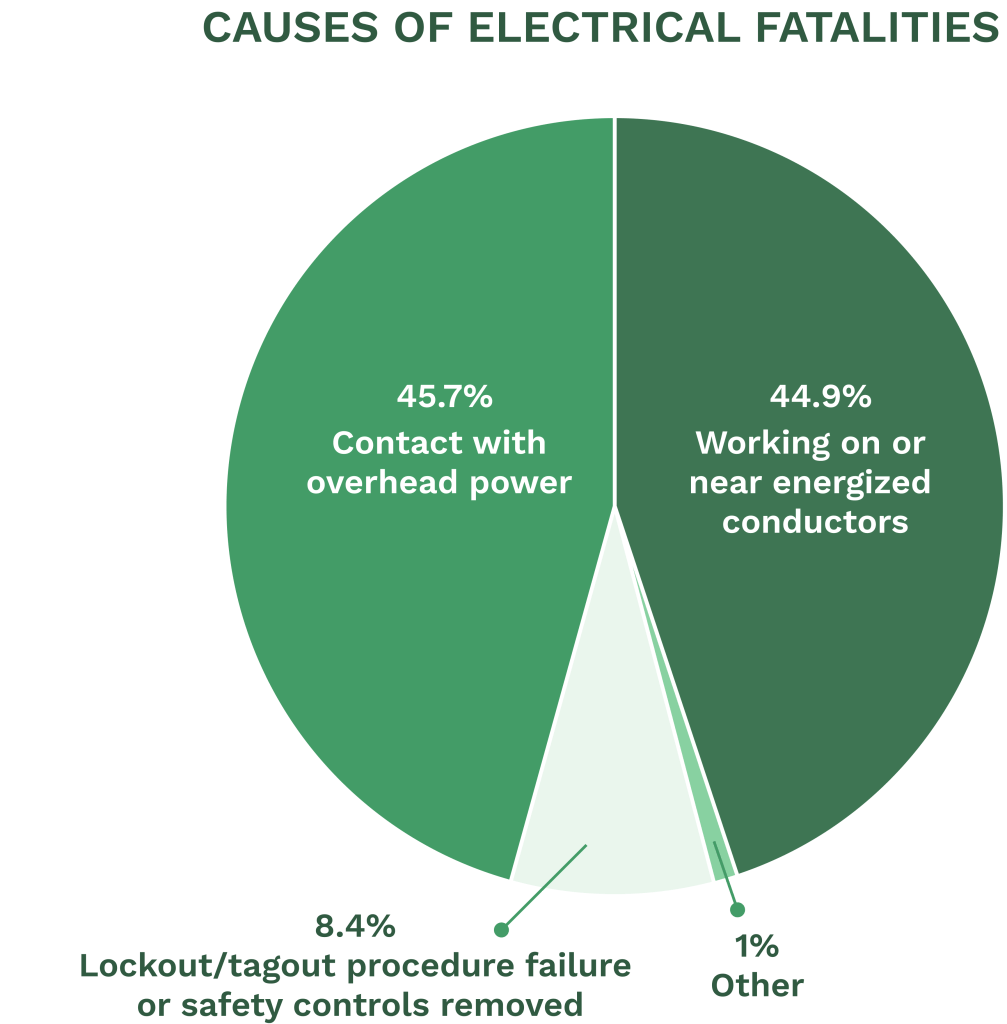

Implications of Unsafe Maintenance

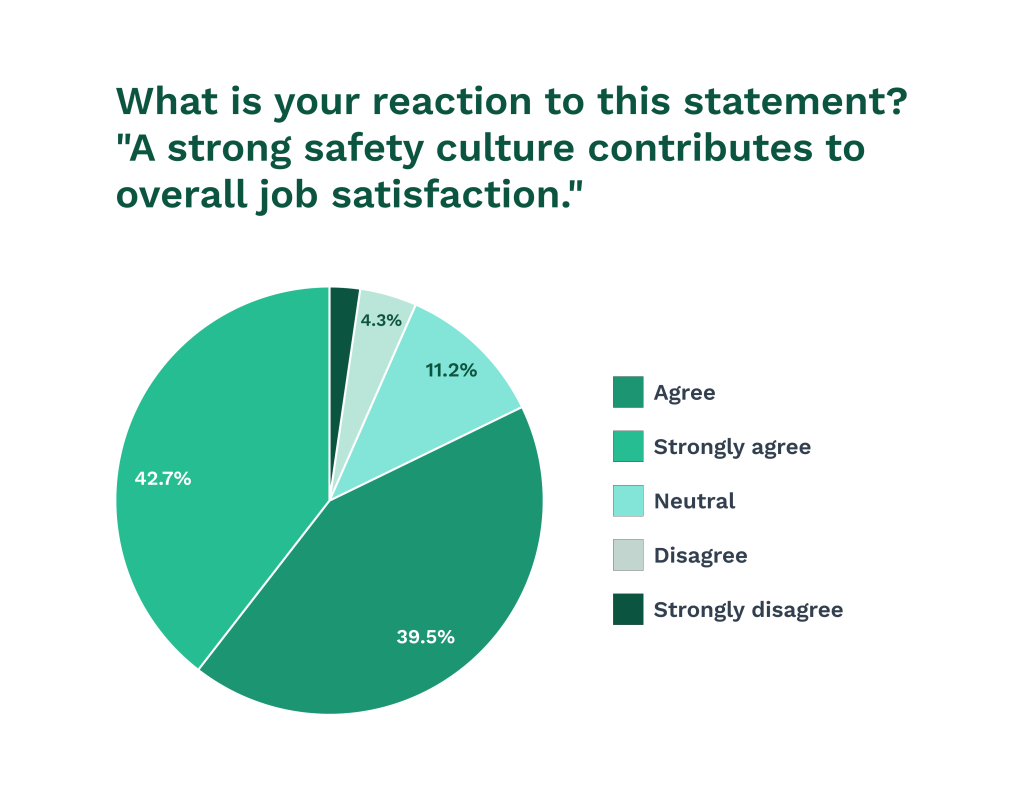

Unsafe maintenance practices have implications far beyond immediate physical harm. When safety protocols are compromised, the consequences ripple, affecting everything from worker morale to financial stability.

Consider a scenario where a maintenance technician rushes through a lock-out procedure on a hydraulic press. The immediate risk of injury is obvious, but the broader implications include the potential long-term psychological impact on coworkers, decreased trust in management, increased insurance costs, and possible regulatory scrutiny.

Definition of Maintenance Safety

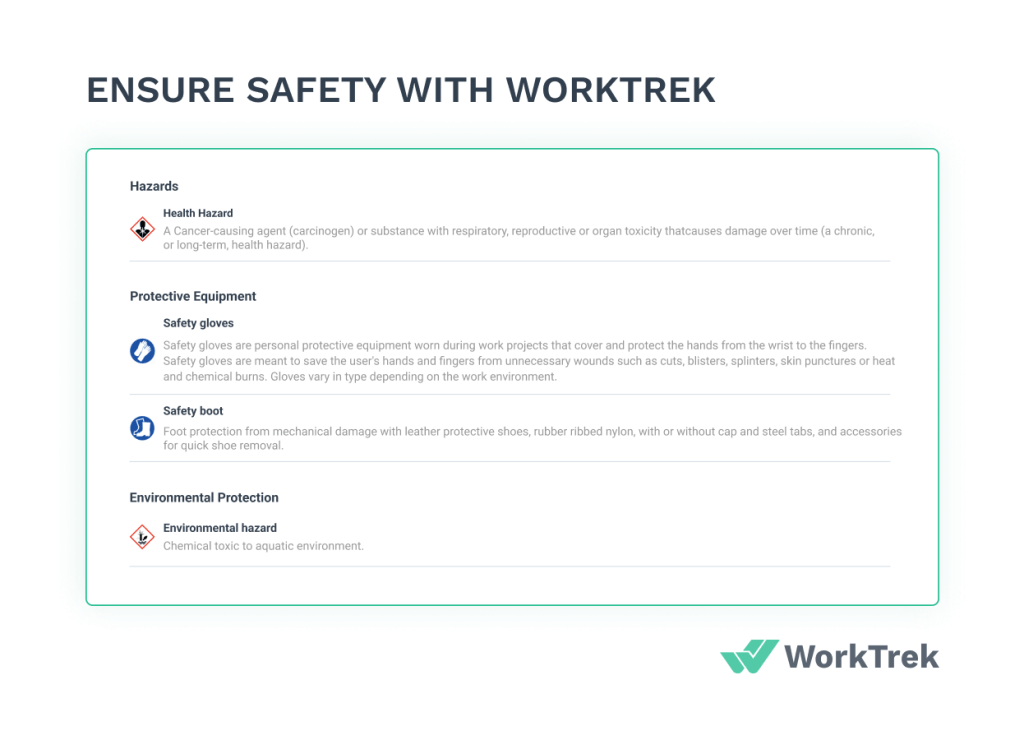

Maintenance safety refers to the practices and procedures to ensure the safety of maintenance workers, equipment, and the surrounding environment during maintenance activities.

It involves identifying and mitigating potential hazards, providing appropriate personal protective equipment (PPE), and following established safety protocols to prevent injuries and accidents.

Maintenance safety is a comprehensive approach encompassing everything from the initial risk assessment to verifying a safe working environment.

By prioritizing maintenance safety, organizations can protect their workforce, maintain operational efficiency, and minimize the risk of costly incidents.

The True Cost of Unsafe Maintenance

Before delving into specific procedures, it’s crucial to understand what’s at stake. Unsafe maintenance practices can lead to:

- Severe injuries or fatalities among maintenance personnel

- Costly equipment damage requiring extensive repairs

- Production downtime affecting business operations

- Legal liabilities and regulatory violations

- Decreased worker morale and increased turnover

- Environmental incidents and associated cleanup costs

- Reduced efficiency and morale among maintenance crews due to safety concerns

Understanding these potential consequences helps reinforce the importance of following proper safety protocols during every maintenance task.

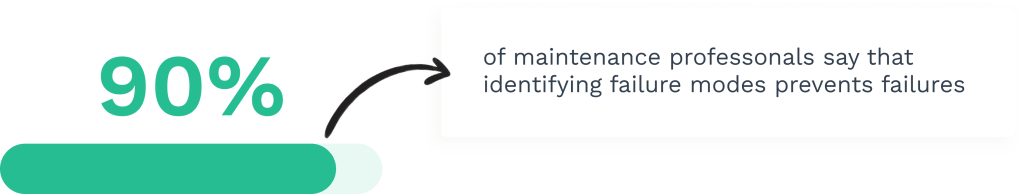

Pre-Maintenance Safety: A Critical Foundation for Preventive Maintenance

Thorough preparation is the cornerstone of safe maintenance. Before any tool touches a machine, maintenance crews, and personnel must engage in a comprehensive risk assessment process.

This assessment isn’t merely about identifying obvious hazards; it requires a deep understanding of how different systems interact and how various failure modes might manifest.

Consider a seemingly simple task like replacing a bearing in an industrial mixer. The risk assessment must account for not just the mechanical aspects of the task but also potential stored energy in the system, chemical residues, ergonomic challenges of accessing the bearing, and even environmental factors like temperature and humidity that might affect the maintenance process.

Risk assessment becomes crucial when dealing with complex systems with multiple energy sources. A modern manufacturing line, for instance, might incorporate electrical, hydraulic, pneumatic, and mechanical systems, each requiring specific consideration during maintenance procedures.

Developing a Maintenance Safety Plan

Developing a maintenance safety plan is crucial to ensure the safety of maintenance workers and the overall success of maintenance operations. The plan should include:

- Hazard Identification and Risk Assessment: Identify all potential hazards associated with maintenance activities. Then, a thorough risk assessment will be conducted to evaluate the severity and likelihood of each hazard and determine appropriate control measures.

- Development of Safety Protocols and Procedures: Establish clear safety protocols and procedures tailored to the specific risks involved in maintenance operations. These protocols should cover everything from personal protective equipment to emergency response actions.

- Training and Education for Maintenance Workers: Provide comprehensive training and education to maintenance workers on safety protocols, proper use of maintenance tools, and the risks involved in their tasks. Regular training sessions help reinforce safety practices and inform workers about new safety measures.

- Regular Safety Inspections and Audits: Conduct regular safety inspections and audits to ensure compliance with safety protocols and identify potential safety hazards. These inspections help maintain a safe working environment and promote workplace safety.

- Review and Revision of the Plan as Needed: Continuously review and revise the maintenance safety plan based on feedback, incident reports, and changes in regulations or equipment. Keeping the plan up-to-date ensures it remains effective in addressing current safety challenges.

By implementing a comprehensive maintenance safety plan, organizations can mitigate risks, protect maintenance workers, and ensure the smooth operation of maintenance activities.

Essential Pre-Maintenance Safety Procedures

Risk Assessment

Before any maintenance work begins, maintenance crews must conduct a thorough risk assessment. This involves:

- Identifying all potential hazards associated with the maintenance task

- Evaluating the severity and likelihood of each hazard

- Determining appropriate control measures

- Documenting findings and sharing them with all involved personnel

The risk assessment should consider mechanical, electrical, chemical, and ergonomic hazards and any environmental factors affecting worker safety.

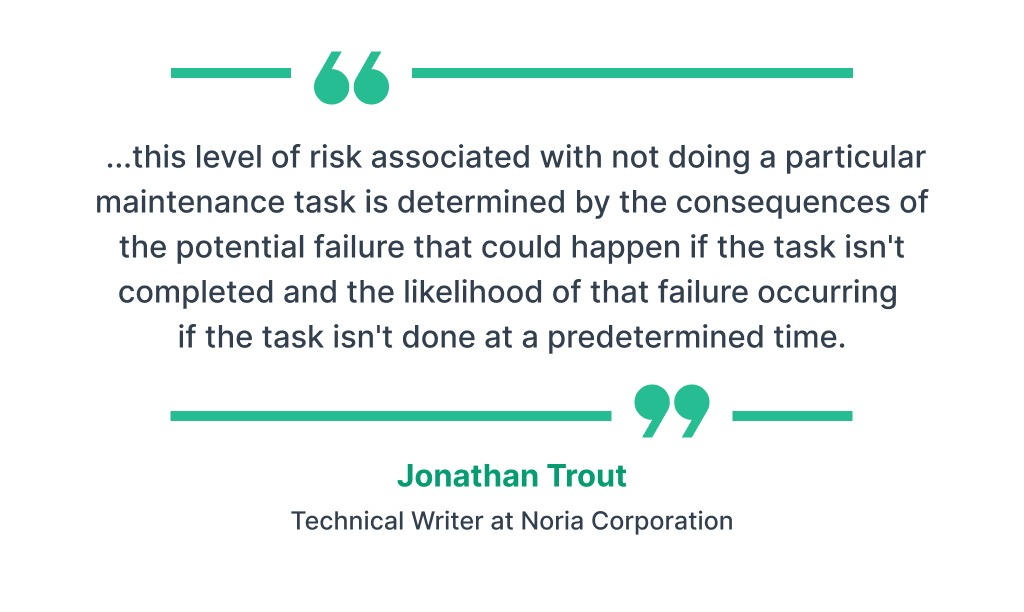

The Art and Science of Lock-Out/Tag-Out

Lock-Out/Tag-Out (LOTO) procedures represent one of the most critical aspects of maintenance safety, yet they’re often misunderstood or oversimplified. Maintenance crews must be thoroughly trained in LOTO procedures to ensure all energy sources are properly isolated before beginning any maintenance work.

LOTO isn’t just about turning off power and locking a switch; it’s a comprehensive process that requires a deep understanding of equipment operation and potential energy sources.

Understanding energy isolation begins with recognizing that energy can exist in many forms. In an industrial setting, these might include electrical current flowing through conductors, pressurized fluid in hydraulic lines, compressed air in pneumatic systems, stored mechanical energy in springs or elevated components, and thermal energy in heated surfaces.

Each type of energy requires specific isolation procedures and verification methods.

Perhaps the most critical step in the LOTO process is verifying the zero-energy state. This verification must be active rather than passive—simply observing that a switch is off or a valve is closed isn’t sufficient.

Maintenance personnel must attempt to operate the equipment and test for the presence of energy using appropriate instruments and methods.

LOTO is perhaps the most critical safety procedure in machine maintenance. It involves:

- Identifying all energy sources (electrical, mechanical, hydraulic, pneumatic, chemical, thermal)

- Notifying all affected employees about the maintenance activity

- Properly shutting down the equipment

- Disconnecting or blocking all energy sources

- Applying locks and tags to energy isolation devices

- Verifying zero energy state through testing

- Maintaining the lock-out condition until work is complete

Personal Protective Equipment: The Last Line of Defense

While Personal Protective Equipment (PPE) often receives significant attention in safety discussions, it’s essential to understand its place in the hierarchy of safety controls. Maintenance crews must be equipped with the appropriate PPE to protect themselves from potential hazards during maintenance tasks. PPE should be viewed as the last line of defense, not the primary means of protection.

This perspective doesn’t diminish its importance but emphasizes the need for proper selection, maintenance, and use of PPE in conjunction with other safety measures.

The selection of appropriate PPE requires careful consideration of the specific hazards present during maintenance tasks.

For instance, when working on electrical systems, it’s not enough to wear insulated gloves; the gloves’ voltage rating must match or exceed the potential voltage present in the system.

Similarly, eye protection must be selected based on specific hazards—impact protection, chemical splash protection, or protection from optical radiation in the case of welding operations.

Selection and Use of Appropriate PPE

Different maintenance tasks require different types of PPE. Maintenance crews must carefully select and use the appropriate PPE based on the hazards they may encounter during their tasks. Essential items typically include:

- Safety glasses or face shields for eye protection

- Hard hats for head protection in areas with overhead hazards

- Steel-toed boots to protect against falling objects

- Cut-resistant gloves appropriate for the task

- Hearing protection in high-noise areas

- Respiratory protection when working with hazardous materials

- Arc flash protective clothing when working with electrical systems

Equipment Maintenance Best Practices

Equipment maintenance is essential to ensure equipment reliability, efficiency, and safety. Here are some best practices for equipment maintenance:

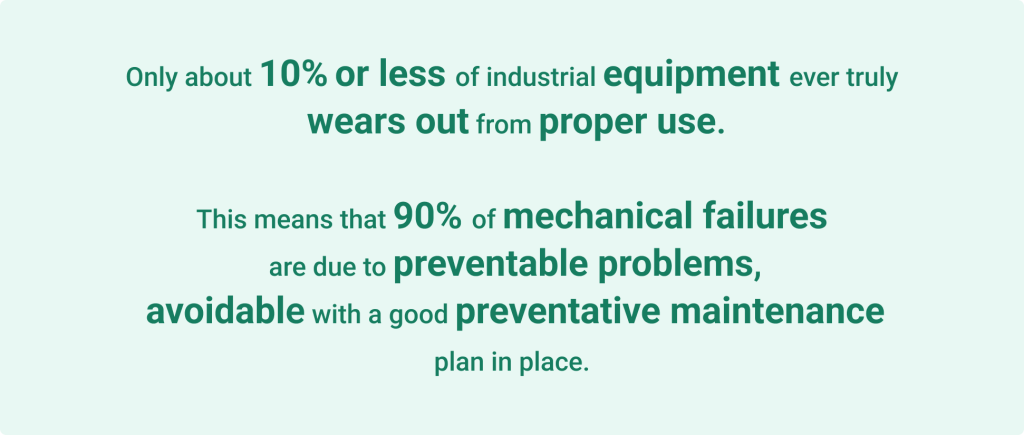

Performing Regular Preventive Maintenance

Regular preventive maintenance is essential to prevent equipment failures and reduce downtime. This includes:

- Scheduling Regular Maintenance Tasks: Develop a schedule that outlines regular maintenance tasks for each piece of equipment. Adhering to this schedule helps ensure that maintenance activities are performed consistently and on time.

- Performing Routine Inspections and Checks: Conduct routine inspections and checks to identify any signs of wear, damage, or potential hazards. Early detection of issues allows for timely repairs and prevents more significant problems.

- Replacing Worn-Out Parts and Components: Regularly replace worn-out parts and components to maintain equipment performance and safety. Using high-quality replacement parts ensures the longevity and reliability of the equipment.

- Lubricating and Cleaning Equipment: Proper lubrication and cleaning are vital for the smooth operation of equipment. Regularly lubricate moving parts and clean equipment to prevent the buildup of dirt and debris that can cause malfunctions.

- Updating Maintenance Records and Logs: Keep detailed records and logs of all maintenance activities, including inspections, repairs, and part replacements. Accurate documentation helps track the maintenance history and identify patterns that may indicate recurring issues.

Preventive maintenance can help identify potential hazards and prevent accidents, reducing the risk of injuries and equipment damage. By following these best practices, organizations can ensure their equipment remains in optimal condition, promoting workplace safety and operational efficiency.

The Human Factor in Maintenance Safety

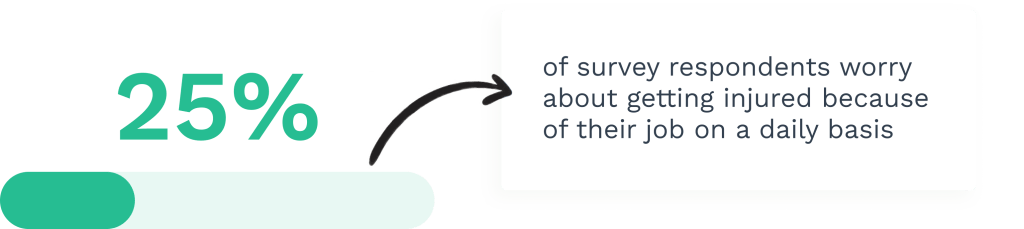

The role of human factors in maintenance safety cannot be overstated.

Maintenance crews must be aware of human factors such as fatigue and time pressure that can impact their safety and performance.

Even the most comprehensive procedures and highest-quality protective equipment can be rendered ineffective by human error, fatigue, or complacency.

Understanding these human factors requires exploring the psychological aspects of maintenance work.

Consider the impact of time pressure on maintenance operations. When production demands are high, and equipment downtime means lost revenue, maintenance personnel may feel pressure to cut corners or rush through procedures.

This pressure can manifest subtly, such as skipping steps in a lock-out procedure or forgoing a final safety check before restarting.

Fatigue presents another significant human factor challenge. Maintenance work often involves complex problem-solving, physical exertion, and the need to maintain high attention to detail.

When fatigue sets in, the risk of errors increases dramatically.

This relationship between fatigue and error risk necessitates careful consideration of work scheduling and rest periods.

Documentation and Communication: Building a Safety Culture

Adequate documentation and communication form the backbone of any successful maintenance safety program.

Maintenance crews must ensure that all safety procedures are appropriately documented and communicated to all relevant personnel.

However, these elements extend beyond simply maintaining written procedures or posting warning signs.

They involve creating a comprehensive system that ensures critical safety information is available, understood, and acted upon at all organizational levels.

Documentation in maintenance safety serves multiple purposes. It provides a reference for standard procedures, records maintenance activities and safety incidents, and serves as a training tool for new personnel.

However, the mere existence of documentation isn’t sufficient; living documentation must evolve based on experience and lessons learned.

Communication in maintenance safety must flow in multiple directions – up and down the organizational hierarchy and horizontally between departments and shifts.

This communication must be formal (through established reporting systems and regular meetings) and informal (through daily interactions and immediate feedback channels).

Emergency Preparedness and Response

Emergency preparedness in maintenance operations requires more than just having a first aid kit and knowing the location of emergency exits.

Maintenance crews must be trained in emergency response protocols and participate in regular drills to ensure they are prepared for emergencies.

It demands a comprehensive understanding of potential emergency scenarios and the development of specific response protocols for each.

Consider a scenario where a maintenance technician becomes trapped in a confined space during equipment repair.

Responding to this emergency requires immediate action from multiple parties – rescue personnel with appropriate training and equipment, medical responders, and personnel who can safely shut down any affected systems.

This scenario illustrates why emergency preparedness must include regular drills and updates to emergency procedures based on lessons learned.

Regulatory Compliance and Beyond

While regulatory compliance is integral to maintenance safety, truly effective safety programs go beyond mere compliance.

Maintenance crews must adhere to all regulatory requirements to ensure their own and their coworkers’ safety. Regulations should be viewed as minimum requirements rather than ultimate goals.

This perspective encourages the development of safety practices that address specific organizational needs and challenges while meeting or exceeding regulatory requirements.

Understanding and implementing regulatory requirements requires staying current with regulations and changes in industry standards.

This ongoing process involves regular procedure reviews, updating training programs, and maintaining proper documentation of compliance activities.

Conclusion

Machine maintenance safety represents a complex interplay of technical knowledge, human factors, and systematic approaches to risk management.

Maintenance crews’ ongoing commitment to safety practices is essential for maintaining a safe working environment. Maintaining a safe maintenance operation requires constant vigilance, ongoing training, and a commitment to continuous improvement.

The future of maintenance safety lies in integrating new technologies and methodologies while focusing on fundamental safety principles.

As equipment becomes more complex and automated, the challenges of maintaining it safely will evolve, requiring maintenance professionals to update their knowledge and skills continually.

Remember that safety in maintenance isn’t achieved through any procedure or piece of equipment. Still, through the careful integration of multiple systems and approaches, all work together to protect the most valuable asset in any organization – its people.