Get a Free WorkTrek Demo

Let's show you how WorkTrek can help you optimize your maintenance operation.

Try for freeKey Takeaways

- Predictive maintenance reduces overall maintenance costs by 18-25% compared to traditional approaches while delivering 8-12% savings over preventive maintenance alone

- Organizations experience 30-50% reduction in unplanned downtime, preventing losses that average $260,000 per hour across industries

- 95% of organizations implementing predictive maintenance report positive returns, with 27% achieving full payback within 12 months

- Modern CMMS platforms like WorkTrek enable predictive maintenance workflows through IoT sensor integration, automated work orders, and advanced analytics

A number of industry studies show that predictive maintenance delivers 18-25% maintenance cost reductions and up to 40% savings over reactive maintenance strategies.

According to McKinsey research, leading organizations achieve 10:1 to 30:1 ROI ratios within 12-18 months of implementation on top of reducing costly downtime.

The study also demonstrates that companies embracing predictive maintenance can achieve 30-50% downtime reduction. All this while extending equipment lifespan by 20-40%.

The move from reactive to predictive maintenance is one of the most impactful operational transformations available to modern organizations.

Fundamentals of Predictive Maintenance

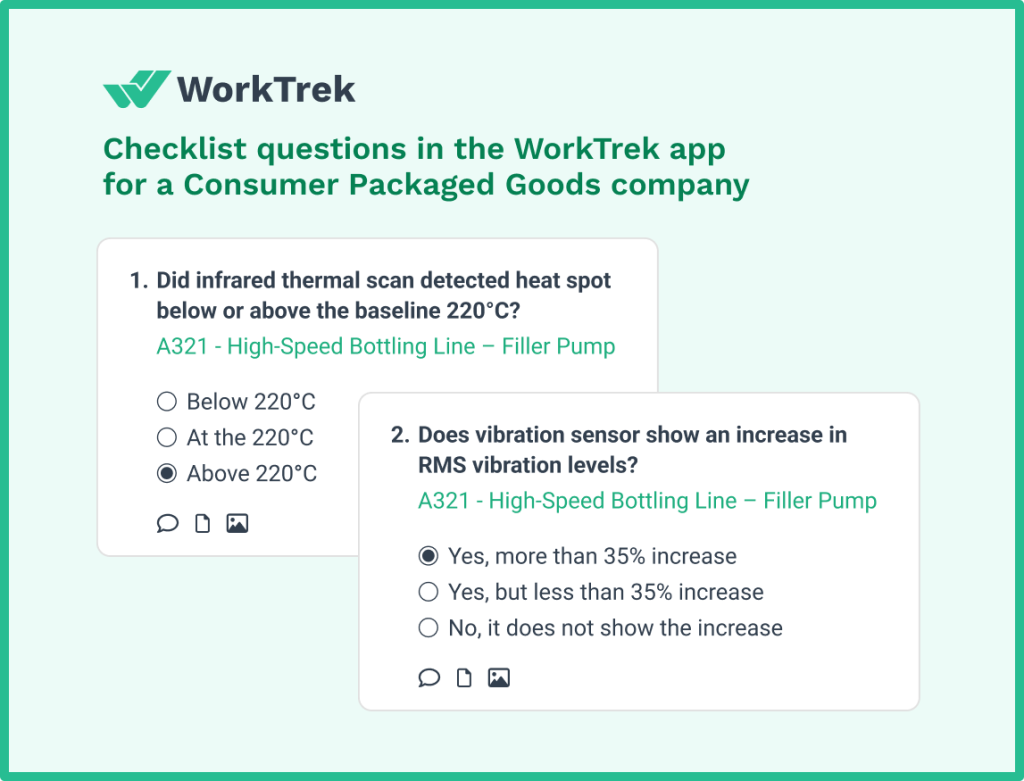

Predictive maintenance uses a combination of condition monitoring data, machine learning algorithms, advanced analytics, and Artificial Intelligence (AI) to forecast equipment failures.

While most traditional maintenance relies on scheduled intervals or equipment breakdowns, predictive maintenance analyzes vast troves of data in real-time to predict equipment failure. Maintenance tasks are then targeted to equipment that requires service, vs reactive or schedule-based maintenance.

A typical modern predictive maintenance system combines multiple data sources to predict failure.

These data generally come from vibration sensors, thermal imaging, oil analysis, and continuous monitoring sensors.

These devices can identify patterns in equipment behavior that precede failures. This allows maintenance teams to perform timely repairs during planned downtime that can reduce costly emergencies.

All of this data is then fed into machine learning algorithms that can be trained to detect anomalies.

These advanced analytics platforms can now process vast amounts of machine data from IoT sensors, SCADA systems, and equipment controllers to identify patterns that human technicians might miss.

Cost Savings of Predictive Maintenance

Reduced Unplanned Downtime

Costly unplanned downtime is the single largest opportunity for predictive maintenance cost savings.

Aberdeen Group research reveals that unplanned equipment failures cost organizations an average of $260,000 per hour, with large industrial operations facing potential losses of $532,000 per hour when critical production lines shut down unexpectedly.

The financial impact of downtime goes well beyond production losses.

Unnecessary downtime can trigger cascading costs, including idle workforce expenses, expedited shipping for emergency repairs, premium pricing for urgent parts procurement, and potential penalties for missed delivery commitments.

Manufacturing facilities typically lose 323 production hours annually due to unplanned outages, resulting in a total economic impact of $172 million per plant.

Early Detection to the Rescue

Predictive maintenance addresses these challenges through early detection of equipment anomalies.

This predictive approach enables maintenance technicians to schedule repairs during planned maintenance windows.

With constant monitoring of equipment conditions, maintenance teams can get advanced warning of potential failures.

On average, predictive maintenance can typically offer 5-7 days’ notice for critical components and 2-4 weeks for gradually degrading systems.

This advance notice enables teams to plan repairs during scheduled downtime, order parts at standard pricing, and coordinate with production schedules to minimize disruptions.

Optimize Maintenance Cost

With traditional maintenance methods, equipment is only fixed or replaced after failure.

Predictive maintenance eliminates this by providing data-driven insights into actual equipment condition.

IBM research indicates that 30% of preventive maintenance tasks are unnecessary. This can lead to higher maintenance expenditures.

Predictive maintenance eliminates this waste by forecasting equipment failures based on actual condition rather than fixed schedules. On average, this delivers 8-12% cost savings over preventive maintenance approaches.

Maintenance organizations can reduce repair costs if they intervene before a critical failure occurs.

It is no surprise that emergency repairs typically cost 3-5 times more. This is because during emergency maintenance, teams have to pay premium parts pricing, overtime labor costs, and additional shipping fees.

Another benefit is that predictive maintenance enables repairs during regular business hours, thereby reducing overtime labor costs.

Predictive maintenance can also help manage spare parts costs and inventories.

It does that by helping organizations optimize resource allocation by forecasting parts demand based on equipment condition trends.

This approach can reduce inventory carrying costs while ensuring critical components remain available when needed.

Extend Equipment Lifespan

Organizations can extend equipment lifespan through predictive maintenance, which delivers significant capital cost savings by maximizing return on asset investments.

Traditional maintenance approaches can often contribute to premature equipment wear through improper timing.

Over-maintenance can introduce unnecessary stress and component wear, while under-maintenance can degrade equipment lifespan.

Critical assets, in particular, benefit from predictive maintenance strategies.

A steel manufacturing facility achieved $1.5 million in first-year savings while preventing a $3 million transformer loss through the implementation of predictive analytics. The system successfully identified gradual degradation patterns.

This empowered the maintenance teams to implement proactive intervention before a critical failure occurred.

When it comes to asset reliability improvements, compound over time. This is because predictive systems learn from historical performance data and end up with improved suggestions.

Machine learning algorithms become more accurate at predicting optimal maintenance intervals, leading to progressively better asset performance and longer operational life.

Vibration analysis, thermal monitoring, and oil analysis provide comprehensive insights into the health of equipment.

This enables maintenance teams to address minor issues before they cause serious damage.

Industry Examples

Manufacturing operations achieve remarkable returns

Manufacturing equipment is the sweet spot for predictive maintenance. This is mainly due to the high costs of production line shutdowns and the critical nature of continuous operations.

Industrial operations implementing predictive strategies report some of the most impressive cost savings and operational improvements.

Packaged Goods

A consumer packaged goods company achieved $5 million in annual maintenance cost savings through the comprehensive deployment of sensors and predictive analytics.

The system correlated high-speed camera data with vibration sensor readings to detect packaging equipment issues before they caused product quality problems.

Automotive Manufacturing

When the line goes down, automotive manufacturing facilities face particularly high downtime costs. Some production lines can generate as much as $22,000 per minute in value.

Notably, predictive maintenance has enabled these operations to reduce unplanned stoppages by 45-60% while improving overall equipment effectiveness scores.

Food Processing Operations

Another industry that benefits from predictive maintenance is food processing operations. They mainly benefit from the ability of predictive maintenance to prevent contamination risks and improve quality.

Food processing operations benefit from the ability of predictive maintenance to prevent contamination risks and quality issues.

Equipment failures in these environments can require extensive cleaning and sterilization procedures. This can multiply downtime costs.

Predictive systems help maintain consistent production while ensuring compliance with food safety regulations.

Oil and Gas Industry

The petrochemical sector can also greatly benefit from implementing predictive maintenance strategies.

One facility prevented $600,000 in potential losses through early detection of compressor misalignment.

The vibration sensors identified vibration patterns indicating bearing wear, enabling planned maintenance before catastrophic failure occurred.

Power Generation and Utilities

Power generation facilities operate under extreme reliability requirements. A single equipment failure can affect the entire power grid.

Predictive maintenance is the key to maintaining operational excellence while managing aging infrastructure.

Along the same lines as power generation companies, utility companies face unique challenges. These facilities have geographically distributed assets and limited maintenance windows.

Predictive maintenance helps optimize maintenance scheduling by detecting faults early and optimizing calendar-based schedules.

Wind energy operations have adopted predictive maintenance to mitigate the high costs associated with accessing remote turbine locations.

Siemens reports 25% maintenance cost reduction through IoT sensor deployment that enables condition-based maintenance scheduling, reducing unnecessary service visits while preventing costly component failures.

Oil and Gas

Oil and gas operations normally operate in harsh environments where equipment failures can have environmental and safety implications.

Offshore platforms particularly benefit from predictive strategies. Maintenance organizations can minimize the need for expensive helicopter transportation and reduce personnel safety risks.

Transportation & Logistics

Fleet management operations can achieve significant cost savings through predictive maintenance of vehicles and support equipment.

Organizations report 45% increases in vehicle uptime and 30% reduction in maintenance costs through condition monitoring and predictive analytics.

Aviation

Aviation maintenance represents one of the most advanced applications of predictive maintenance, where safety requirements demand exceptional reliability.

GE Aviation reports a 15% reduction in engine failures through the use of quantum sensors and advanced analytics. This delivers substantial cost savings while improving safety margins.

Rail Operations

Rail operations have rapidly adopted predictive maintenance strategies. According to recent studies, 42% of rail facilities reached advanced predictive maintenance maturity by 2017.

The industry benefits from predictive maintenance’s ability to prevent track and rolling stock failures. This could significantly reduce service disruptions or safety incidents.

Maritime & Shipping Operations

Maritime operations utilize predictive maintenance to optimize vessel performance and reduce port downtime.

Predictive systems can monitor engine performance, propulsion systems, and auxiliary equipment to schedule maintenance during planned port calls.

This approach greatly reduces emergency dry-dock visits.

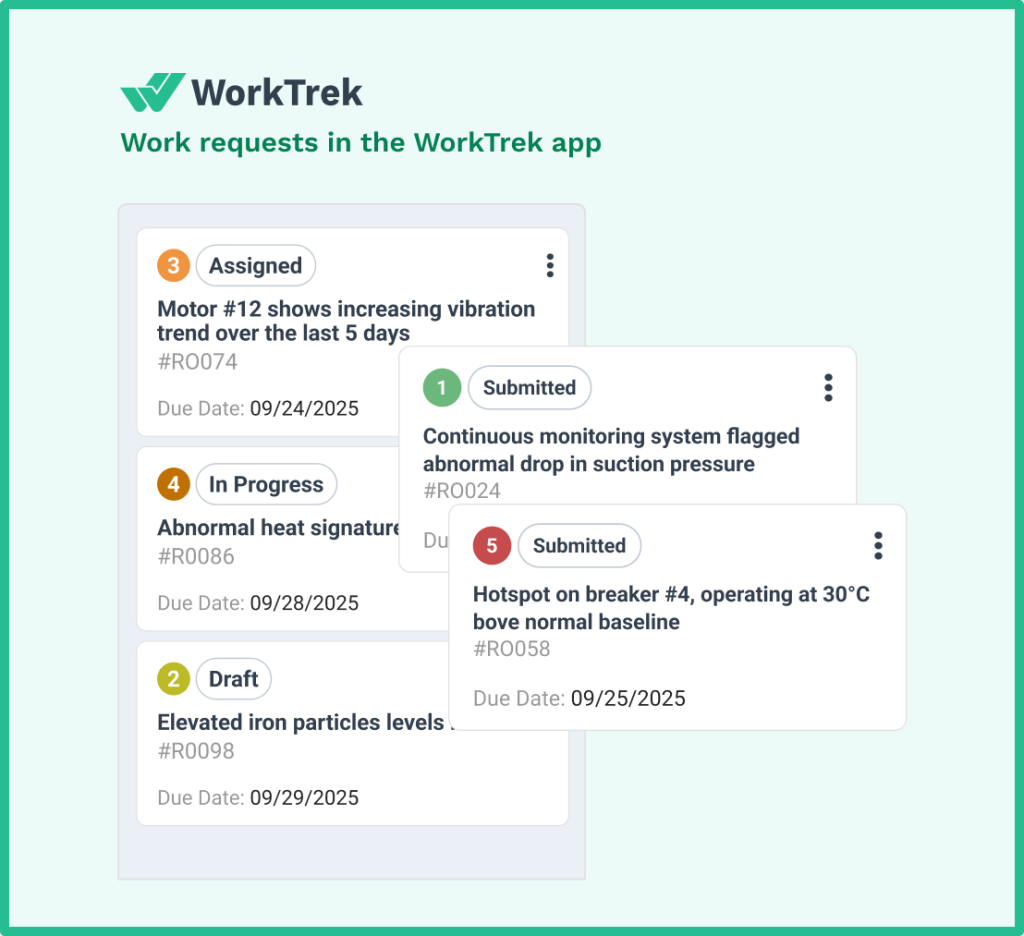

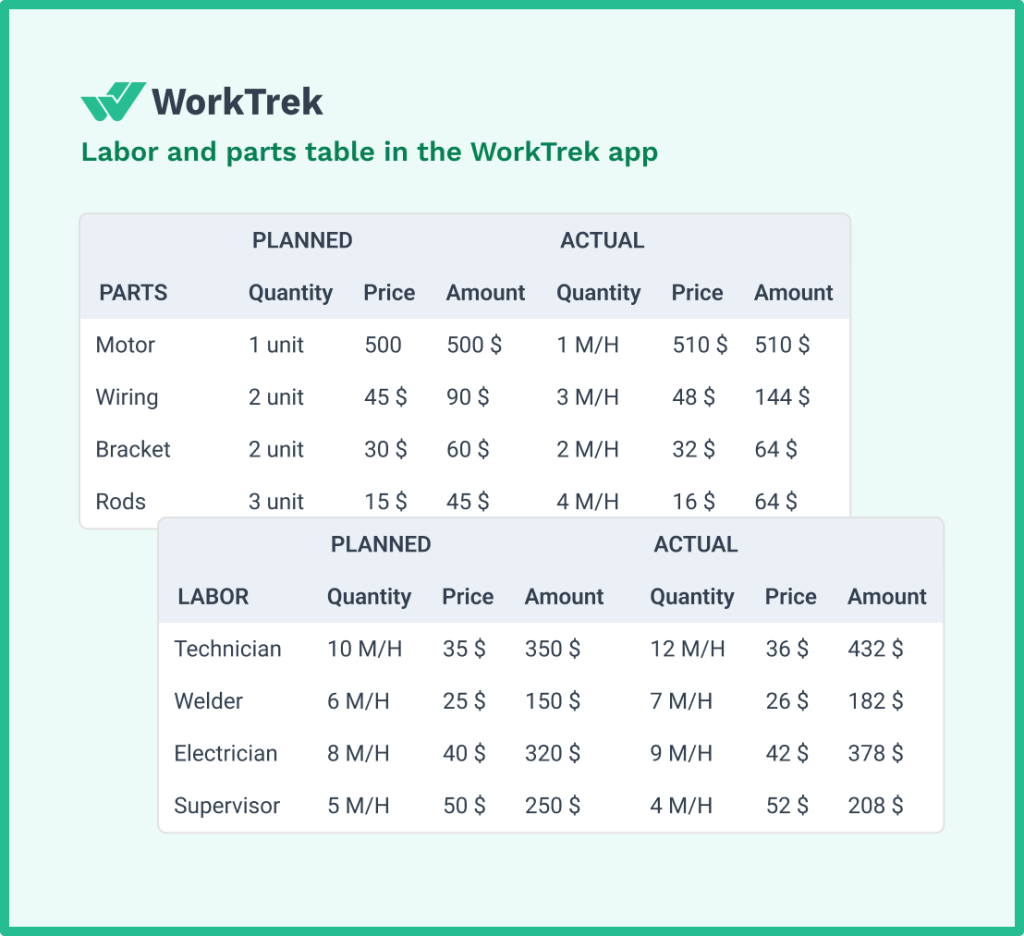

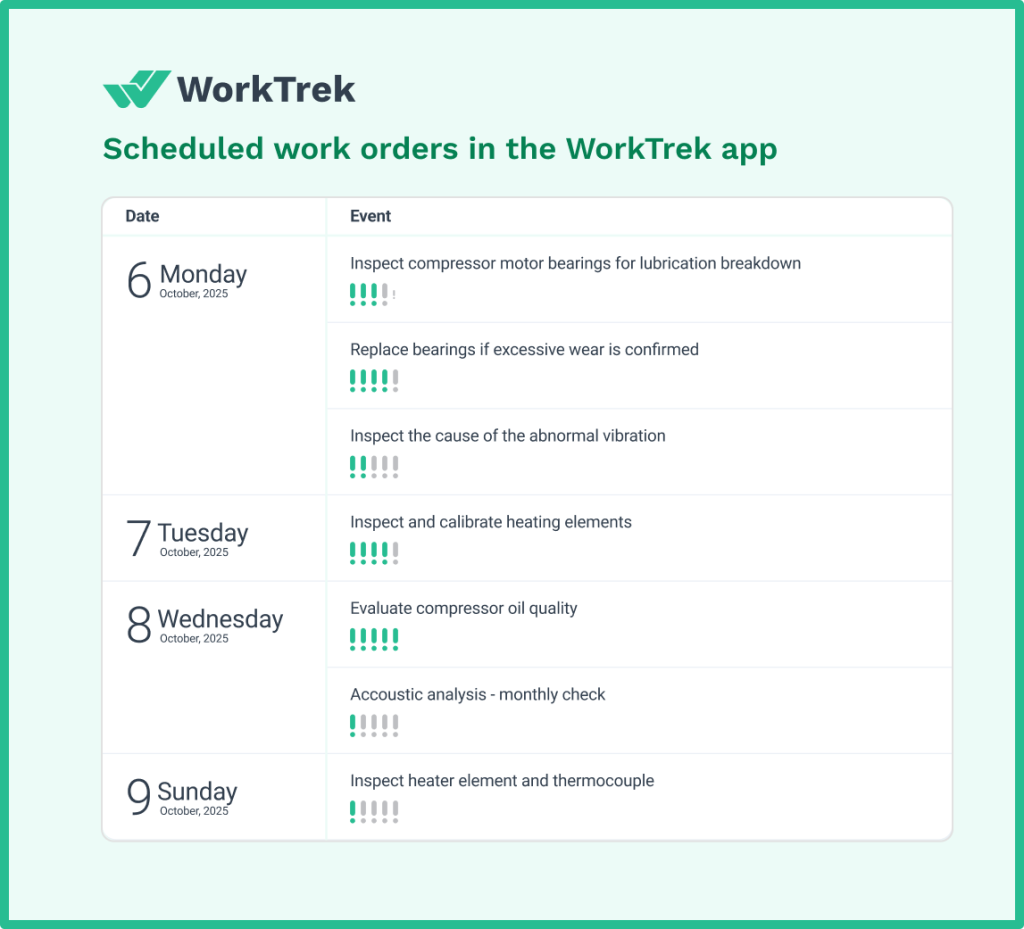

How CMMS enables predictive maintenance cost savings

Computerized Maintenance Management Systems, like WorkTrek, are the foundation for successful predictive maintenance programs.

These systems provide the data infrastructure, workflow automation, and analytics capabilities necessary to maximize cost savings.

Modern CMMS platforms have evolved beyond simple work order management to become complete predictive maintenance enablement systems.

Advanced CMMS solutions easily integrate with IoT sensors, condition monitoring equipment, and industrial automation systems to create comprehensive equipment health information.

This level of integration automates work order generation when there is data that indicates equipment operating outside predefined parameters.

This ensures that maintenance teams receive immediate alerts about potential issues.

Research indicates that 53% of facilities currently utilize CMMS for maintenance monitoring, with 80% reporting improvements in equipment lifespan.

The correlation between CMMS adoption and the success of predictive maintenance is clear: organizations with CMMS platforms regularly achieve higher ROI and faster implementation of predictive maintenance strategies.

How to Maximize Cost Savings

Selecting the right strategic assets is the first step in the process.

Organizations should prioritize critical assets where failures cause immediate production losses, safety risks, or environmental impacts.

These high-impact assets typically deliver the fastest ROI and most substantial cost savings.

To get accurate failure data, you need equipment with sufficient historical data.

Assets with documented maintenance history, known failure modes, and regular performance data offer the best opportunities for pattern recognition and failure prediction.

When installing new equipment, it can take between 6 and 12 months of operational data before predictive models achieve optimal accuracy.

Vibration monitoring, thermal analysis, oil condition monitoring, and electrical signature analysis are core monitoring technologies that provide comprehensive visibility into equipment health.

Technology Integration and Data Quality

Edge computing capabilities enable the real-time processing of condition monitoring data. This reduces latency and improves response times for critical alerts.

Local processing reduces bandwidth requirements and improves system reliability in industrial environments with limited connectivity.

Data standardization and integration across multiple systems ensure predictive maintenance platforms receive consistent, high-quality information.

Organizations should review and address data silos and establish protocols for sharing information between maintenance management systems, process control systems, and business applications.

Machine learning algorithms require sufficient training data to achieve optimal prediction accuracy. Organizations should expect a lag in data collection before predictive models deliver reliable results.

Change management and workforce development

Don’t skip on training your team. Maintenance team training ensures technicians understand how to interpret predictive maintenance alerts and take necessary action.

Successful implementation requires skills development in data interpretation, diagnostic techniques, and predictive technologies.

Part of training should include an emphasis on cultural change. Some organizations are slow to switch from reactive to predictive maintenance due to a lack of acceptance by the maintenance teams. It is always hard to switch from what you already know.

This change requires a significant organizational transformation that requires executive support and clear communication of benefits.

Additionally, maintenance workflows must evolve to incorporate predictive insights while maintaining focus on safety and reliability.

Continuous improvement processes enable organizations to optimize predictive maintenance programs over time.

Regular review of prediction accuracy, cost savings achievement, and operational optimization opportunities ensures maximum return on predictive maintenance investments.

Predictive Maintenance KPI

How do you measure success in any predictive maintenance program?

Start with Key performance indicators that measure maintenance cost reduction, unplanned downtime elimination, equipment availability improvement, and asset lifespan extension.

Maintenance organizations should establish baseline measurements before implementation to accurately assess improvement.

Financial impact tracking requires comprehensive cost accounting that captures both direct maintenance savings and indirect benefits such as improved operational efficiency, reduced inventory costs, and enhanced competitive advantage.

Many organizations underestimate total benefits by focusing only on maintenance cost reductions.

One popular strategy is benchmarking against industry standards, which helps organizations assess their predictive maintenance performance relative to best-in-class facilities.

Overall equipment effectiveness (OEE) metrics provide standardized comparison points across industries and operational contexts.

Advanced analytics platforms empower organizations with sophisticated ROI analysis. This is done by correlating maintenance activities with production performance, quality metrics, and financial outcomes.

These insights support data-driven decision-making about future predictive maintenance investments and expansion opportunities.

Conclusion

As outlined in this article, the benefits of predictive maintenance are undeniable to most industries and maintenance organizations.

Predictive maintenance drives substantial cost savings through dramatic downtime reduction. Additionally, it can optimize maintenance timing and extend equipment lifespan.

Studies show that leading organizations are achieving 18-25% maintenance cost reductions and 10:1 to 30:1 ROI ratios.

Modern CMMS platforms like WorkTrek serve as the never center for predictive maintenance success, providing the data integration, workflow automation, and analytics capabilities necessary to maximize cost savings.

Studies show that organizations implementing comprehensive predictive maintenance programs report a 30-50% reduction in downtime and significant improvements in operational efficiency within 12-18 months of deployment.